If you rely on a 2 post lift to work on your vehicle, you know how frustrating it is when it doesn’t operate smoothly. Whether your lift won’t raise, lowers too slowly, or makes strange noises, these problems can stop your work and even put your safety at risk.

But don’t worry—most 2 post lift issues come down to a few common causes like hydraulic glitches, electrical faults, or mechanical wear. In this guide, you’ll discover simple, clear troubleshooting steps to get your lift back in shape quickly. Keep reading to learn how to spot the problem early, fix it effectively, and avoid costly repairs down the road.

Your next lift session will thank you!

Credit: www.fleetequipmentmag.com

Hydraulic Problems

Hydraulic problems are common issues in 2 post lifts. They affect the lift’s ability to raise and lower vehicles smoothly. These problems can cause delays and safety hazards in your workshop. Understanding the causes helps fix the lift quickly and safely.

Hydraulics rely on fluid pressure to move the lift arms. Any disruption in this system slows down or stops the lift. Regular checks on hydraulic parts prevent major breakdowns and costly repairs.

Slow Lowering Causes

Slow lowering happens when hydraulic fluid moves too slowly through the system. It can be due to clogged release valves or low fluid levels. Air trapped in the system also reduces fluid flow. Dirt or debris blocking the cylinder orifice causes the same problem. Check these parts first to restore normal speed.

Stalling Issues

Stalling means the lift stops moving during operation. Hydraulic stalling often results from fluid contamination or worn seals. Electrical faults or mechanical problems can also cause stalling. Inspect the hydraulic fluid and seals for damage. Test electrical connections and mechanical parts to find the stall source.

Oil Leaks

Oil leaks signal a failing hydraulic system. Leaks often come from damaged cylinders or seals. The power unit may also leak if seals wear out. Leaking oil reduces pressure and can cause lift failure. Look for wet spots under the lift and inspect hoses and fittings. Replace faulty parts to stop leaks and maintain safety.

Electrical Problems

Electrical problems are common issues in 2 post lifts. They can stop the lift from working properly or cause safety risks. Many faults come from power supply issues, control button failures, or sparks during operation. Identifying these electrical problems early helps keep the lift safe and functional. Regular checks reduce downtime and costly repairs.

Power Loss

Power loss means the lift does not turn on or respond. Check the main power source first. Look for tripped breakers or blown fuses. Inspect the wiring for loose connections or damage. Sometimes, a faulty power cord or plug causes the issue. Reset the breaker or replace fuses if needed. Test the power outlet with another device to confirm it works.

Control Button Faults

Control buttons can fail or stick, stopping the lift from moving. Dirt and dust often block the button contacts. Clean the buttons gently with a dry cloth. Test each button for proper function. Replace buttons that do not respond or feel loose. Faulty buttons may cause the lift to stop mid-operation or not start at all.

Sparks And Electrical Noise

Sparks or crackling sounds show an electrical fault inside the lift. These noises often come from loose wires or bad connections. Turn off the power before inspecting. Tighten any loose terminals and check for worn insulation. Sparks near motors or switches need immediate attention. Ignoring them can cause serious damage or fire risk.

Mechanical Problems

Mechanical problems in a 2 post lift can cause delays and safety risks. These issues often stem from worn parts, poor lubrication, or misalignment. Identifying mechanical faults early helps keep the lift running smoothly and safely.

Regular checks and basic troubleshooting can resolve many common mechanical issues. This section covers unusual noises, jammed arms and pistons, and uneven lifting.

Unusual Noises

Clanking or grinding sounds usually mean worn or damaged components. Lack of lubrication often causes these noises. Check the lift’s moving parts for rust, dirt, or wear. Tighten loose bolts and apply proper grease to reduce noise and friction.

Jammed Arms And Pistons

Arms or pistons may jam due to dirt buildup or damaged seals. Lack of lubrication also causes parts to stick. Inspect the arms and pistons for visible damage. Clean and lubricate the joints regularly to ensure smooth movement and prevent jams.

Uneven Lifting

When one side lifts slower or higher, imbalance is often the cause. Hydraulic issues or cable problems may also create uneven lifting. Check cables for frays or slack and inspect hydraulic fluid levels. Adjust or repair parts as needed to restore level lifting.

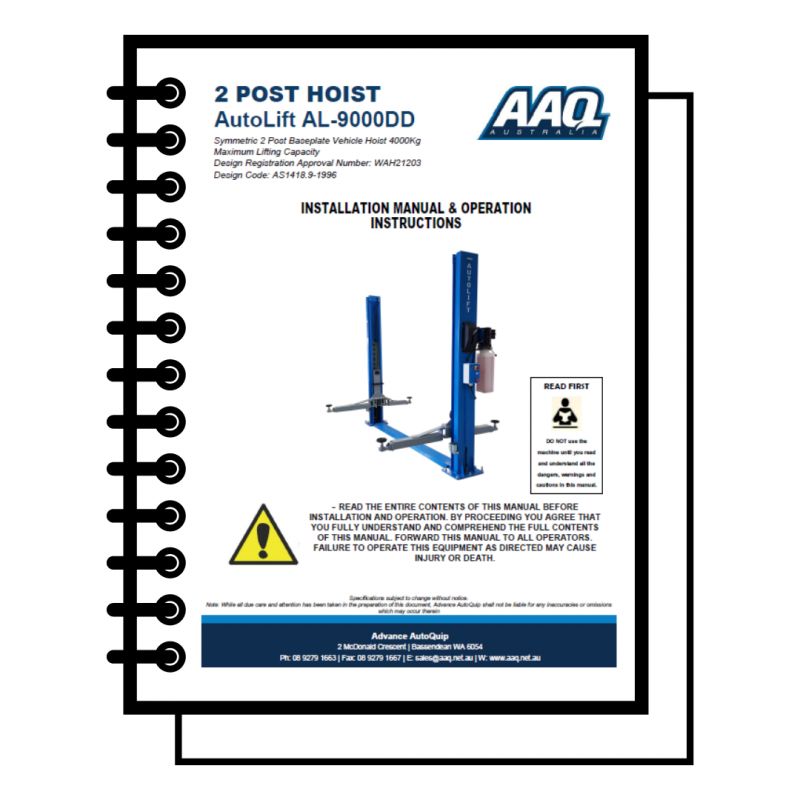

Credit: aaq.net.au

Safety And Stability

Ensuring safety and stability is vital when using a 2 post lift. It prevents accidents and protects both the vehicle and the operator. Problems with safety locks, vehicle slipping, or setup errors can cause serious hazards. Understanding these common issues helps maintain a secure working environment.

Safety Locks Malfunction

Safety locks hold the vehicle in place during lifting. If they fail to engage, the vehicle may fall suddenly. Common causes include worn parts, dirt buildup, or misalignment. Regular inspection and cleaning help keep locks working properly. Never rely on hydraulic pressure alone to hold the vehicle.

Vehicle Sliding Or Falling

Vehicle slipping happens when it is not centered on the lift arms. Incorrect lift point placement causes instability. The vehicle may slide or fall, risking injury and damage. Always position the vehicle according to the manufacturer’s guidelines. Use test lifts to confirm stability before raising the vehicle fully.

Improper Setup Risks

Using the wrong arm type or placing pads incorrectly creates instability. Symmetric arms used as asymmetric or vice versa can cause uneven lifting. Pads placed on body seams or weak spots may damage the vehicle. Follow setup instructions carefully to avoid dangerous lift conditions. Proper setup ensures a steady and safe lift every time.

Maintenance And Setup

Proper maintenance and correct setup are vital for the safe and smooth operation of a 2 post lift. Neglecting these areas can lead to frequent breakdowns and safety hazards. Regular checks help prevent costly repairs and ensure the lift works efficiently. Understanding key maintenance tasks and setup challenges allows you to address issues early.

Lubrication Needs

Lubrication keeps moving parts working smoothly. Without it, friction increases and parts wear out quickly. Regularly apply grease to all pivot points and locking mechanisms. Use manufacturer-recommended lubricants to avoid damage. Check lubrication levels during routine inspections. Lack of lubrication often causes noise and slow movement.

Air Contamination Effects

Air contamination in the hydraulic system causes poor lift performance. It leads to spongy or slow lowering of the vehicle. To remove air, bleed the hydraulic lines as needed. Keep hydraulic fluid clean and topped up. Contaminated fluid reduces lift power and can damage seals. Regular fluid changes prevent air and dirt buildup.

Installation Issues

Incorrect installation causes many lift problems. Ensure the lift is anchored on a level, solid concrete floor. Check all bolts and fasteners are tight and secure. Incorrect arm placement or uneven installation leads to vehicle instability. Follow the manufacturer’s setup guide precisely. Professional installation reduces safety risks and improves lift reliability.

Quick Fixes And Prevention

Quick fixes and prevention keep a 2 post lift working safely and smoothly. Regular checks stop small problems from turning big. Simple steps help avoid costly repairs and dangerous failures. Following easy routines extends the life of your lift and protects your vehicle.

Checking Hydraulic Fluid

Hydraulic fluid powers the lift’s movement. Low fluid causes slow lowering or stalling. Check fluid levels often and top up if needed. Use the manufacturer’s recommended fluid type. Look for leaks around cylinders and hoses. Clean fluid prevents air bubbles that block smooth lifting.

Inspecting Safety Locks

Safety locks hold the lift in place during use. Inspect locks for wear or damage regularly. Listen for clicking sounds to confirm locks engage fully. Clean and adjust locks if they stick or fail to engage. Never use the lift if safety locks do not work properly.

Lubricating Moving Parts

Moving parts need lubrication to reduce friction and wear. Apply grease to hinges, arms, and pins as recommended. Avoid over-lubricating to prevent dirt buildup. Smooth movement lowers noise and prevents jams. Lubrication keeps mechanical parts working longer and safer.

Maintaining Cleanliness

Dirt and debris cause mechanical problems and safety risks. Keep the lift clean by wiping down surfaces regularly. Remove oil spills and metal shavings around the base. Clean parts ensure proper functioning and easier inspection. A tidy workspace supports safe and efficient lifting.

Credit: www.youtube.com

Frequently Asked Questions

What Are The Common Problems With A 2 Post Lift?

Common problems with a 2 post lift include hydraulic failures, electrical faults, mechanical wear, safety lock issues, and improper vehicle loading causing instability. Regular maintenance, fluid checks, lubrication, and correct setup prevent these issues and ensure safe operation.

Why Is My 2 Post Lift Not Coming Down?

Your 2 post lift may not come down due to low hydraulic fluid, clogged release valve, air in the system, or faulty safety locks. Check fluid levels, inspect for leaks, ensure safety locks disengage, and verify proper electrical power and controls.

Regular maintenance prevents these issues.

Why Is My 2 Post Lift Stuck In Up Position?

Your 2-post lift may be stuck up due to low hydraulic fluid, air in the system, or clogged release valves. Check safety locks and electrical connections. Lubricate moving parts and inspect for mechanical jams or worn components. Proper maintenance prevents these issues.

Why Is My Lift Not Going Up Or Down?

Your lift may not move due to hydraulic fluid leaks, low fluid levels, air contamination, electrical faults, or mechanical jams. Check fluid, power supply, safety locks, and lubrication to fix the issue. Proper maintenance and correct vehicle placement ensure smooth lift operation.

What Causes A 2 Post Lift To Lower Slowly Or Not At All?

Slow lowering often results from clogged release valves, low hydraulic fluid, or air trapped in the system. Checking and cleaning these parts usually fixes the problem.

Conclusion

Troubleshooting a two-post lift becomes easier with regular checks. Keep hydraulic fluid clean and at the right level. Inspect electrical parts for loose wires or damage often. Lubricate moving parts to prevent noise and sticking. Always follow safety steps when lifting vehicles.

Proper setup avoids instability and accidents. Routine maintenance extends your lift’s life and performance. Small problems caught early save time and money. Stay safe, work smart, and maintain your lift well.