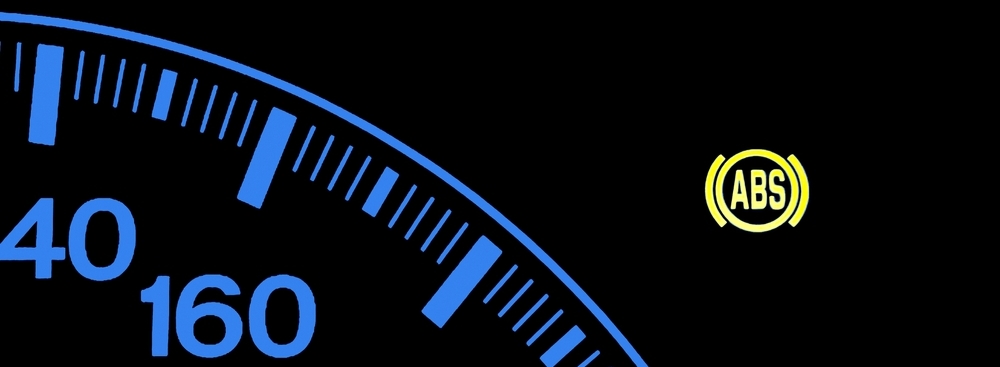

Is your ABS brake light glowing on your dashboard? That flashing warning can be confusing and even a little scary.

You rely on your brakes every day to keep you safe, so when your Anti-lock Braking System (ABS) acts up, you want answers fast. The good news is, many ABS problems come from simple issues like dirty sensors or damaged wiring—things you can often troubleshoot yourself.

In this guide, you’ll learn how to spot common ABS brake troubles, understand what’s causing them, and find out what steps you can take to fix the problem or know when to call a professional. Keep reading to take control of your brake system and keep your drives safe and smooth.

Credit: plymouth-auto.com

Common Abs Issues

Anti-lock Braking System (ABS) is vital for safe driving. It stops the wheels from locking during hard braking. Despite its importance, ABS can develop faults. Recognizing common issues helps in quick troubleshooting. Understanding these problems saves time and money.

Sensor Contamination

ABS sensors detect wheel speed to control braking. Dirt, metal shavings, or road debris can cover sensors. Contaminated sensors send wrong signals to the ABS computer. This causes the system to malfunction or shut down. Cleaning sensors regularly helps avoid this problem.

Wiring Damage

Wiring connects sensors to the ABS module. Wires can get cut, corroded, or loose. Damaged wiring causes poor or no signal transmission. This leads to ABS errors and warning lights. Inspecting wiring for wear and tear is essential for smooth ABS function.

Faulty Abs Module

The ABS module controls the entire braking system. Over time, it can fail due to electrical or mechanical issues. A faulty module might not process sensor data correctly. This results in braking problems or no ABS operation. Replacing the module is often necessary to fix this.

Warning Light Triggers

The ABS warning light alerts drivers to system issues. It turns on when sensors, wiring, or the module have faults. Ignoring the warning light risks brake failure during emergencies. Using a diagnostic tool helps identify the exact cause quickly.

Credit: www.mobil.com

Diagnosing Abs Problems

Diagnosing ABS problems requires careful attention and the right tools. The ABS system uses sensors and electronics to keep your wheels from locking during braking. When it fails, it can affect vehicle safety and control. Understanding the steps to diagnose ABS issues helps identify the root cause quickly. This section covers key methods to check and troubleshoot ABS troubles.

Using Diagnostic Tools

Start by connecting a diagnostic scanner to the vehicle’s OBD-II port. This tool reads the ABS system and checks for errors. It provides real-time data and alerts about system faults. Diagnostic tools save time and show if the problem is electrical or mechanical. They are essential for accurate troubleshooting of ABS issues.

Reading Fault Codes

After scanning, the tool displays fault codes stored in the ABS module. Each code points to a specific problem area. Learn the meaning of codes from the vehicle’s manual or online resources. Fault codes guide you to which sensor or component needs attention. Clearing codes after repairs helps confirm if the issue is fixed.

Inspecting Sensors And Wiring

Wheel speed sensors are common trouble spots in ABS systems. Dirt, metal shavings, or damage can cause sensor failure. Check sensors for dirt or corrosion and clean them gently. Inspect wiring for cuts, corrosion, or loose connections. Worn wiring causes intermittent faults or no signal to the ABS module.

Interpreting Warning Signs

The ABS warning light on the dashboard signals system trouble. Other signs include unusual brake pedal feel or locked wheels during braking. Listen for strange noises when braking. Pay attention to inconsistent brake performance. Noticing these signs early helps avoid more serious brake problems.

Quick Abs Fixes

Quick ABS fixes can save time and money. Many ABS issues come from simple problems. Checking and fixing these can restore your brake system fast. Understanding basic ABS troubleshooting helps keep your vehicle safe on the road.

Cleaning Sensors

ABS sensors detect wheel speed. Dirt and debris block signals. Use a soft brush or cloth to clean sensor surfaces. Avoid harsh chemicals that damage sensors. Clean sensors improve signal accuracy and brake performance.

Repairing Wiring

Damaged wires cause ABS errors. Inspect wiring harness for cuts or breaks. Use electrical tape or connectors to fix minor damage. Replace wires if damage is severe. Proper wiring ensures stable communication between sensors and control unit.

Replacing Faulty Sensors

Faulty sensors trigger ABS warning lights. Remove the old sensor carefully. Match the replacement sensor to your vehicle model. Install the new sensor and secure it firmly. Replacing sensors fixes common ABS malfunctions quickly.

Resetting The Abs System

Resetting clears error codes after repairs. Use an OBD-II scanner to reset the ABS system. Turn off and restart the vehicle to check the ABS light. Resetting helps the system relearn sensor data and confirms repairs.

Safety Tips For Diy Repairs

Working on ABS brakes yourself can save money and teach valuable skills. Safety must be your top priority during any DIY ABS brake repair. Mistakes can lead to serious accidents or damage. Preparing well and understanding your limits ensures safe and effective repairs.

When To Seek Professional Help

ABS systems are complex and affect vehicle safety. Professional mechanics have special tools and knowledge. Call a pro if the ABS warning light stays on after your repair. Strange noises or brake failures also need expert attention. Avoid risks with electrical parts and brake fluids.

Avoiding Common Mistakes

Do not ignore the vehicle’s manual and warning labels. Avoid rushing the process or skipping safety checks. Never use damaged or worn-out tools. Do not touch brake fluid with bare hands. Keep the work area clean and well-lit. Check all connections twice before reassembling.

Tools Needed For Abs Repair

Proper tools improve repair safety and success. You need a diagnostic scan tool to read ABS codes. Basic hand tools include screwdrivers, wrenches, and pliers. A brake bleeder kit helps remove air from the system. Wear gloves and safety glasses to protect yourself.

Preventive Maintenance

Preventive maintenance plays a key role in avoiding ABS brake problems. Regular care keeps the system working properly. It also extends the life of brake parts and sensors. Simple checks and cleaning can stop many common issues. Following basic steps reduces the risk of costly repairs and ensures safety on the road.

Regular Sensor Checks

ABS sensors detect wheel speed and send data to the brake system. Dirt or damage to sensors may cause false readings. Check sensors often for dirt, corrosion, or cracks. Clean sensors gently using a soft cloth. Replace sensors if they show signs of wear or damage. Regular checks help keep the ABS system accurate and reliable.

Protecting Wiring From Damage

Wiring connects ABS sensors to the control module. Damaged wires can cause signal loss or errors. Inspect wiring for cuts, frays, or loose connections. Avoid sharp bends or pinching of wires during repairs. Secure wiring away from heat and moving parts. Protecting wiring prevents electrical problems and ABS warnings.

Keeping Brake Components Clean

Brake parts like rotors and calipers must stay clean for proper ABS function. Dirt, dust, and metal shavings can build up over time. Clean brake components with brake cleaner and a brush. Avoid using water, which may cause rust. Regular cleaning improves sensor readings and brake performance. It also helps prevent ABS malfunctions caused by debris.

Credit: millerautopartsandpaint.com

Frequently Asked Questions

What Is The Most Common Abs Problem?

The most common ABS problem is faulty wheel speed sensors. Dirt, debris, or damaged wiring often cause sensor failure.

How To Troubleshoot Abs Braking Systems?

Use a diagnostic tool to read ABS fault codes. Inspect and clean wheel speed sensors. Check sensor wiring for damage. Replace faulty sensors. Clear codes and test drive to confirm repair.

Can I Fix Abs Issues Without A Mechanic?

You can fix simple ABS sensor or wiring issues if you have the right tools and experience. Complex ABS problems need a mechanic for safety and accuracy.

How To Diagnose Abs Problems?

Use a diagnostic tool to read ABS fault codes. Check wheel speed sensors and wiring for damage or debris. Look for ABS warning lights or wheel lock during braking. Replace faulty sensors and repair wiring to fix ABS issues.

What Causes The Abs Warning Light To Turn On?

The ABS warning light usually turns on due to faulty wheel sensors or damaged wiring. Dirt or metal shavings on sensors can also trigger the light. It warns you that the ABS system needs attention.

Conclusion

ABS brakes need regular checks to keep you safe on the road. Faulty sensors or wiring often cause most ABS problems. Use simple tools to read error codes and spot issues early. Fix small problems quickly to avoid bigger, costly repairs later.

Always stay calm and follow safety steps when troubleshooting. Taking care of your ABS brakes helps maintain control during sudden stops. Remember, timely attention keeps your vehicle running smoothly and safely every day.