Is your air conditioner blowing warm air or making strange noises? If so, your AC condenser might be the culprit.

The condenser plays a crucial role in keeping your home cool by releasing heat from the refrigerant. When it malfunctions, your comfort can quickly turn into frustration. But don’t worry—you don’t have to be an expert to start troubleshooting. In this guide, you’ll learn simple ways to spot common AC condenser problems and what to check before calling a professional.

By understanding these signs early, you can save time, avoid costly repairs, and keep your AC running smoothly all summer long. Ready to take control of your cooling system? Let’s dive into the essentials of AC condenser troubleshooting.

Signs Of Ac Condenser Issues

Recognizing the signs of AC condenser issues helps prevent bigger problems. The condenser plays a key role in cooling your home. When it malfunctions, the entire system suffers. Watch for these common signs to catch problems early.

Warm Or Lukewarm Air

The AC blows warm or lukewarm air instead of cold air. This means the condenser is not cooling the refrigerant properly. You may notice the air feels less refreshing or barely cool.

Refrigerant Leaks

Look for oily or dark spots around the condenser unit. These stains often indicate refrigerant leaks. A leaking system loses cooling power and wastes energy. Low refrigerant levels reduce the AC’s ability to cool.

Unusual Noises

Listen for hissing, rattling, or buzzing sounds coming from the condenser. Strange noises can mean loose parts, debris, or motor problems. Ignoring these sounds can lead to system failure.

Burning Odors

A burning smell near the AC system is a warning sign. It may come from electrical issues or overheating parts. This smell should never be ignored as it poses a safety risk.

System Overheating

The condenser or the whole AC system may overheat during operation. Overheating can cause the AC to shut down or cycle frequently. It often results from clogged coils or poor airflow.

Reduced Cooling Efficiency

Your AC runs longer but cools less. This drop in efficiency often signals condenser trouble. It uses more energy while delivering weaker cooling, increasing utility bills.

Musty Smells From Vents

Musty or moldy odors from vents suggest moisture buildup. This can happen if the condenser cannot remove enough heat or moisture. It may also indicate blocked drainage or dirty coils.

Credit: www.youtube.com

Basic Visual And Physical Checks

Basic visual and physical checks are the first step in AC condenser troubleshooting. These checks help spot common issues that affect performance. Simple inspections can save time and money by identifying problems early. Anyone can perform these checks safely without special tools.

Inspecting For Dirt And Debris

Dirt and debris block airflow through the condenser. Leaves, grass, and dust often collect on the fins and coils. This buildup reduces cooling efficiency and strains the system. Clear all visible dirt by gently brushing or using low-pressure water. Keep the area around the condenser clean and free of clutter.

Checking For Bent Or Damaged Fins

The fins on the condenser help release heat from the refrigerant. Bent or damaged fins stop air from passing through easily. Check the fins closely for any bends or dents. Use a fin comb to straighten minor bends carefully. Avoid applying too much pressure to prevent further damage.

Identifying Oily Leaks

Oily spots or stains on the condenser indicate refrigerant leaks. These leaks reduce cooling power and can damage the system. Look for dark, greasy patches on the coils and pipes. If you find any, contact a professional to repair the leak and recharge the refrigerant.

Listening For Strange Sounds

Unusual noises often signal mechanical or electrical problems. Listen for hissing, rattling, or grinding sounds near the condenser. Hissing may indicate a refrigerant leak, while rattling could mean loose parts. Grinding sounds often point to worn-out motors or fans. Note any strange sounds and seek professional help if needed.

Feeling Vent Air Temperature

Check the air temperature coming from the vents inside your home. The air should be cool and refreshing. Warm or lukewarm air suggests the condenser is not working well. This could be due to clogged coils, leaks, or electrical faults. Regularly monitor vent air temperature to detect issues early.

Common Ac Condenser Problems

AC condensers face several common problems that can reduce cooling performance. These issues often cause the air conditioner to blow warm air or stop working entirely. Identifying these problems early helps prevent costly repairs and keeps your AC running smoothly.

Clogged Condenser Coils

Dirt and debris can build up on condenser coils over time. This blocks heat transfer and forces the AC to work harder. Clogged coils lead to poor cooling and higher energy use. Regular cleaning keeps coils clear and efficient.

Damaged Or Bent Fins

Thin metal fins cover the condenser coils to help release heat. Bending or damage reduces airflow and cooling ability. Bent fins can be straightened carefully with a fin comb tool. Protect fins from impact and debris.

Refrigerant Leaks

Leaks in the refrigerant lines cause a loss of cooling power. Signs include oily spots or a hissing sound near the condenser. Low refrigerant levels make the AC less effective and may damage the compressor. Professional repair is needed to fix leaks.

Faulty Condenser Fan Motor

The condenser fan motor moves air over the coils to cool the refrigerant. A broken or failing motor stops this airflow. The AC may overheat or shut down without proper fan operation. Testing the fan motor helps diagnose this problem.

Electrical Issues

Wiring problems or blown fuses can stop the condenser from working. Faulty capacitors and relays also cause electrical failures. These issues may result in the unit not starting or running inconsistently. An electrician should inspect the electrical components.

Credit: www.youtube.com

Quick Fixes For Common Issues

Quick fixes for common AC condenser issues can save time and money. Many problems arise from simple causes. These can be addressed without professional help. Regular checks and maintenance keep the system running well. Below are easy steps to troubleshoot and fix common condenser problems.

Cleaning The Condenser Coils

Dirty coils reduce cooling efficiency and cause the unit to overheat. Turn off the power before cleaning. Use a soft brush or coil cleaner to remove dirt and debris. Rinse gently with water, avoiding high pressure. Clean coils improve airflow and help the AC run smoothly.

Straightening Bent Fins

Bent fins block airflow and reduce cooling performance. Use a fin comb to carefully straighten bent fins. Work slowly to avoid damaging the fins further. Proper airflow helps the condenser release heat effectively. Straight fins improve the AC’s overall function.

Tightening Loose Wiring

Loose wiring can cause the condenser to stop working or short cycle. Turn off the power and open the unit’s panel. Check for loose or disconnected wires. Use a screwdriver to tighten any loose connections. Secure wiring ensures safe and reliable operation.

Replacing The Fan Motor

A broken fan motor stops the condenser from cooling properly. Listen for unusual noises or no fan movement. Disconnect the power and remove the fan blades. Replace the motor with a compatible new one. Proper fan operation keeps the condenser cool and efficient.

Refilling Refrigerant Safely

Low refrigerant causes poor cooling and can damage the system. Only certified technicians should handle refrigerant refilling. Check for leaks before adding refrigerant. Use the correct type and amount specified by the manufacturer. Safe refilling restores cooling power and protects the environment.

Compressor Short Cycling Prevention

Compressor short cycling causes frequent starts and stops in your AC system. This issue stresses the compressor and reduces its lifespan. Preventing short cycling keeps your air conditioner running smoothly and saves energy. It also avoids costly repairs and keeps your home comfortable.

Importance Of Waiting Between Cycles

Waiting between compressor cycles lets pressure balance inside the system. This pause avoids rapid switching that can damage parts. It also prevents overheating and electrical issues. A short delay helps the compressor start easily and safely.

Pressure Equalization Benefits

Pressure equalization reduces stress on the compressor valves. It allows refrigerant pressures to stabilize before restarting. This process stops the compressor from working too hard. Balanced pressure improves efficiency and lowers the risk of failure.

Protecting The Compressor

Protecting the compressor extends the life of your AC unit. Short cycling causes overheating and electrical shorts. Proper controls and waiting times reduce these risks. This care keeps the compressor safe and functioning well.

Avoiding Rapid On-off Cycling

Rapid on-off cycling wastes energy and increases wear. It makes your AC noisy and less effective. Avoiding this cycling improves comfort and saves money. Use timers or control boards to manage the compressor run time.

System Reboot Advantages

System reboot clears errors and resets controls. It helps the compressor recover from short cycling. A reboot can fix minor faults and improve performance. Regular rebooting keeps the system stable and reliable.

When To Call A Professional

Knowing when to call a professional for AC condenser issues can save time and money. Some problems require specialized tools and skills. Ignoring serious signs may cause further damage or safety risks. Here are key signs that mean you should contact an expert technician.

Signs Of Severe Refrigerant Leaks

Refrigerant leaks reduce cooling and harm the environment. Look for oily stains or greenish spots on the condenser. A noticeable drop in cooling power also signals a leak. Handling refrigerant needs special training and equipment. Professionals can fix leaks safely and recharge the system correctly.

Persistent Cooling Problems

When your AC blows warm air despite basic fixes, call a pro. Persistent cooling issues may come from clogged coils or failing parts. Experts diagnose the root cause with precise tools. They ensure your system works efficiently and prevents future breakdowns.

Electrical Component Failures

Electrical problems often cause the condenser to stop working. Flickering lights, buzzing sounds, or frequent breaker trips show electrical faults. These issues can be dangerous if not handled properly. A professional can inspect wiring, capacitors, and motors safely and make needed repairs.

Overheating Issues

Overheating can damage your AC system. If the condenser shuts down or heats up quickly, it needs professional attention. Causes include dirty coils, blocked airflow, or motor problems. Experts clean, repair, or replace parts to keep the system cool and running smoothly.

Complex Repairs Beyond Diy

Some condenser repairs require special tools and knowledge. Bent fins, compressor problems, or refrigerant recharging are complex tasks. Attempting these without training risks more damage. Professionals have the experience and equipment to fix complex issues correctly the first time.

Maintenance Tips To Avoid Future Issues

Proper maintenance keeps your AC condenser running smoothly and avoids costly repairs. Small steps prevent common problems and improve efficiency. Consistent care extends the life of your unit. Follow these simple tips to maintain your AC condenser and reduce breakdown risks.

Regular Coil Cleaning

Dirt and debris reduce coil efficiency and cause overheating. Clean the coils gently with a soft brush or water spray. Avoid harsh chemicals that damage coil fins. Clean coils help your AC cool better and save energy.

Routine Visual Inspections

Look for bent fins, leaks, or debris around the unit. Check for rust or corrosion on metal parts. Early spotting of issues prevents bigger damage. Inspect your condenser every few weeks during cooling season.

Timely Fan Motor Checks

The fan motor moves air over the coils to cool refrigerant. Listen for unusual sounds like grinding or rattling. Ensure the fan spins freely without wobbling. Replace or repair a faulty motor quickly to maintain airflow.

Monitoring Refrigerant Levels

Low refrigerant causes poor cooling and damages the compressor. Check refrigerant levels regularly with a professional gauge. Watch for oily stains or leaks around the unit. Proper refrigerant levels keep your AC efficient and cool.

Scheduling Professional Servicing

Hire a certified technician at least once a year for thorough inspection. Professionals clean, test, and fix hidden issues. Regular servicing improves performance and prevents unexpected failures. Book service early before the hot season begins.

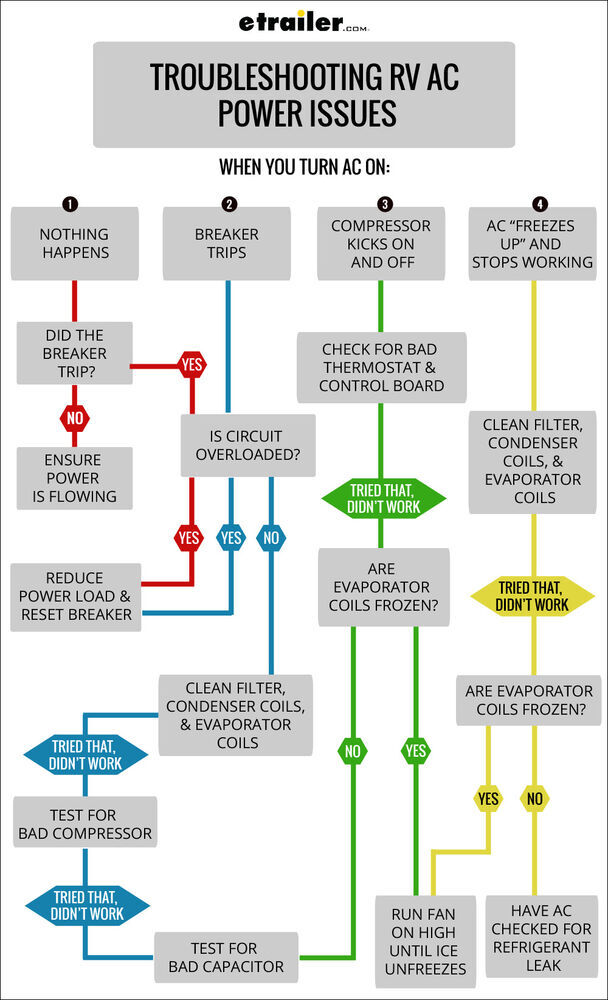

Credit: www.etrailer.com

Frequently Asked Questions

How To Tell If An Ac Condenser Is Bad?

A bad AC condenser causes warm air, refrigerant leaks, strange noises, burning smells, or system overheating. Check for bent fins, leaks, and poor cooling performance.

What Is The 3 Minute Rule For Ac?

The 3-minute rule for AC advises waiting three minutes before restarting the compressor. This prevents system damage and short cycling.

What Is The $5000 Rule For Ac?

The $5000 rule for AC means spending up to $5000 on repairs before considering a full system replacement.

Why Is My Ac Condenser Not Kicking On?

Your AC condenser may not kick on due to a tripped breaker, faulty capacitor, or thermostat issues. Check power supply and wiring.

What Are Common Signs Of A Bad Ac Condenser?

A bad AC condenser often causes warm air instead of cold air. You might see leaks, hear strange noises, or smell burning odors.

Conclusion

Troubleshooting an AC condenser helps keep your system cool and efficient. Watch for warm air, strange noises, or leaks as warning signs. Clean debris and bent fins to improve performance. Regular checks prevent bigger problems and save repair costs. Knowing these simple steps makes maintenance easier and your home more comfortable.

Stay alert to changes and act quickly for best results. A well-functioning condenser ensures cool air all year round.