To troubleshoot Allison Transmission PTO issues, consult Chelsea PTO troubleshooting guides or watch educational videos on YouTube to learn about PTO operations and common problems. Additionally, check for any wiring or harness issues and ensure proper engagement of the PTO on the automatic transmission. Consider seeking professional help from a certified technician for a thorough diagnosis and repair.

Understanding Pto And Allison Transmission

Allison Transmissions are known for their reliability and durability, making them a popular choice in various industries such as construction, towing, and agriculture. One key component that sets Allison Transmissions apart is the Power Take-Off (PTO) system. Understanding how the PTO works and troubleshooting any issues that may arise is crucial for operators to ensure optimal performance and productivity. In this blog post, we will delve into the explanation of power take-off (PTO) and its role in Allison transmissions, as well as how a PTO works on an Allison transmission.

Explanation Of Power Take-off (pto) And Its Role In Allison Transmissions

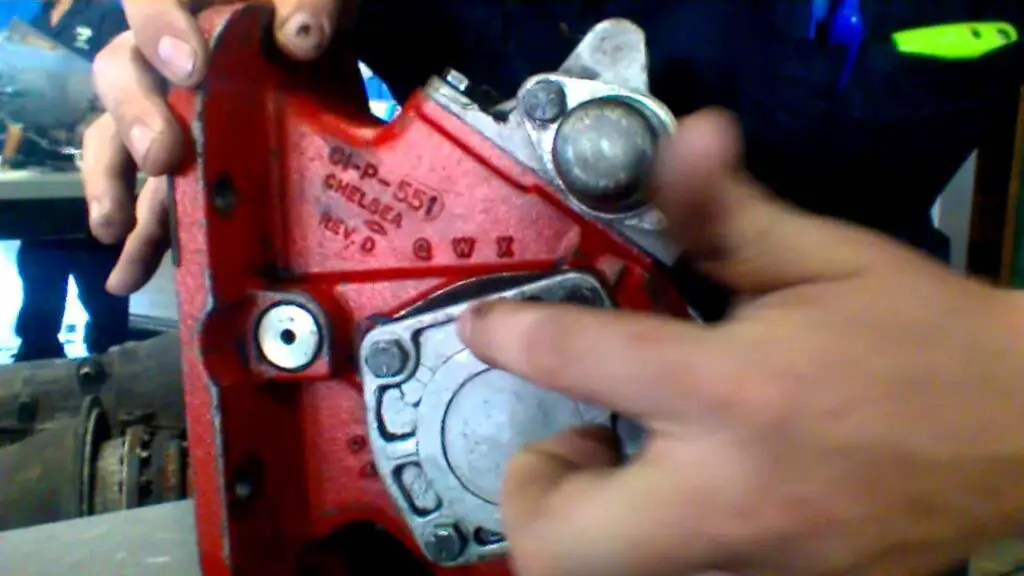

The power take-off, commonly referred to as PTO, is a mechanical device that allows power to be taken from the engine of a vehicle and transferred to auxiliary equipment. In the case of Allison Transmissions, the PTO is designed to transmit the engine power to operate additional equipment such as hydraulic systems, generators, and pumps. This additional equipment plays a vital role in various applications, including lifting heavy loads, powering auxiliary machinery, and operating specialized equipment.

The PTO is mounted directly to the transmission, providing a direct link between the engine and the auxiliary equipment. It employs a system of gears and clutches that engages and disengages power transfer as needed. When the PTO is engaged, power is transmitted through a driveshaft to the auxiliary equipment, allowing it to perform its intended function.

How Does a PTO Work on an Allison Transmission?

The operation of the PTO on an Allison transmission involves a series of steps to ensure smooth power transfer. Here is a breakdown of how it works:

- Ensure the vehicle is in a stationary position and the transmission is in neutral.

- Engage the parking brake to prevent any accidental movement.

- Locate the PTO control switch or lever, typically located within the driver’s reach.

- Engage the PTO control switch or move the lever to the “on” or “engage” position.

- Listen for any audible feedback, such as a clicking sound, indicating that the PTO is engaged.

- Once engaged, the auxiliary equipment connected to the PTO should start operating accordingly.

- To disengage the PTO, simply reverse the steps by moving the PTO control switch or lever to the “off” or “disengage” position.

It is important to note that the exact procedure for engaging the PTO may vary depending on the specific Allison Transmission model and the equipment being operated. Therefore, it is crucial to refer to the vehicle’s manual and consult with experts if any doubts or issues arise.

In conclusion, understanding the workings of the PTO system in Allison Transmissions is essential for operators to ensure the seamless operation of auxiliary equipment. By following the correct procedures and troubleshooting any potential issues, operators can maximize the efficiency and productivity of their vehicles for a wide range of applications.

Common Pto Problems And Troubleshooting Techniques

Overview Of Common Issues Faced With Pto Systems

PTO systems play a crucial role in various industries, providing power to auxiliary equipment such as hydraulic pumps, generators, and winches. However, like any mechanical component, they can experience issues that may hinder their performance. Understanding the common problems associated with PTO systems is essential for troubleshooting and resolving them effectively.

How To Diagnose Pto Problems In Allison Transmissions

Diagnosing PTO problems at Allison Transmissions requires a systematic approach to identify the root cause. Here are the steps to follow:

- Inspect the PTO system for any visible damage or loose connections. Ensure that all components are secure and properly aligned.

- Check the hydraulic fluid levels and ensure they are within the recommended range. Low fluid levels can affect the PTO’s operation.

- Test the PTO engagement switch or control lever to ensure it is functioning correctly. Faulty switches or controls can prevent the PTO from engaging.

- Use a diagnostic tool compatible with Allison Transmissions to scan for any error codes related to the PTO system. These codes can provide valuable insights into the underlying issue.

- If necessary, consult Allison Transmission’s troubleshooting manual or contact a professional technician for further assistance.

Troubleshooting Techniques For Resolving PTO Issues

Resolving PTO issues in Allison Transmissions involves applying specific troubleshooting techniques. Here are some effective ways to address common PTO problems:

1. Inspect and clean the PTO unit

Regularly inspecting and cleaning the PTO unit can help prevent debris or contaminants from interfering with its operation. Any buildup or obstructions should be carefully removed to ensure smooth functionality.

2. Verify power supply

Check the power supply to the PTO system to ensure it is receiving the required voltage and amperage. A weak or inadequate power supply can result in poor PTO performance or failure to engage.

3. Check for worn or damaged components

Inspect all PTO components for signs of wear, damage, or leaks. Worn-out gears, couplings, or seals can cause the PTO system to malfunction. If any issues are found, replace the damaged parts promptly.

4. Review and adjust PTO settings

Refer to Allison Transmission’s operating manual to verify the correct PTO settings for your specific application. Incorrect settings can lead to improper engagement or disengagement of the PTO. Adjust the settings accordingly to ensure optimal performance.

5. Test PTO with load

Engage the PTO system under load conditions to assess its performance. Ensure that the PTO can handle the intended workload without excessive noise or vibration. If any abnormalities are noticed, further investigation or adjustments may be necessary.

By following these troubleshooting techniques, you can effectively resolve PTO issues at Allison Transmissions, minimizing downtime and ensuring the smooth operation of auxiliary equipment.

Maintenance Tips To Extend Pto Lifespan

Maintaining your Allison Transmission PTO system is crucial for ensuring its longevity and torque capacity. Regular maintenance helps prevent breakdowns, improves performance, and extends the lifespan of your PTO. In this article, we will discuss the importance of regular maintenance for PTO systems, the recommended maintenance schedule for Allison Transmissions, and how to increase the lifespan and torque capacity of your PTO.

Importance Of Regular Maintenance For PTO Systems

Regular maintenance is essential to keep your PTO system functioning optimally. Neglecting maintenance can lead to issues such as decreased torque capacity, breakdowns, and costly repairs. By performing regular maintenance, you can identify and address any potential problems before they worsen.

Recommended Maintenance Schedule For Allison Transmissions

To ensure your Allison Transmission PTO system stays in top shape, it is recommended to follow a regular maintenance schedule. Here is a breakdown of the maintenance tasks and their recommended intervals:

| Maintenance Task | Recommended Interval |

|---|---|

| Fluid Level Check | Every 10,000 miles or annually |

| Filter Replacement | Every 25,000 miles or every 2 years |

| Seal Inspection | Every 50,000 miles or every 4 years |

| PTO Clutch Adjustment | Every 100,000 miles or every 8 years |

How To Increase The Lifespan And Torque Capacity Of Your Pto

Here are some tips to maximize the lifespan and torque capacity of your Allison Transmission PTO:

- Regularly inspect and clean the PTO system to ensure there are no obstructions or debris that could affect its operation.

- Monitor the PTO fluid levels and top up as necessary, following the manufacturer’s recommendations.

- Keep an eye on the PTO clutch to ensure it is properly adjusted and engaging smoothly.

- Perform regular seal inspections to detect any leaks or damage that could compromise the PTO’s performance.

- Follow the recommended maintenance schedule for fluid changes and filter replacements.

- Consider installing additional cooling mechanisms, such as an auxiliary cooler, to prevent overheating and prolong the lifespan of your PTO.

- If you notice any issues with your PTO, such as abnormal noises or vibrations, address them promptly to prevent further damage.

By following these maintenance tips, you can extend the lifespan and torque capacity of your Allison Transmission PTO system, ensuring smooth and reliable operation for years to come.

Chelsea Pto Troubleshooting Tips

Troubleshooting Guide For Chelsea Pto Systems

If you are experiencing issues with your Chelsea PTO system, it’s important to know how to troubleshoot and identify the

problem. Here’s a troubleshooting guide that will help you diagnose and resolve common issues:

Common Problems And Their Solutions

Here are some common problems you may encounter with your Chelsea PTO system and their possible solutions:

| Problem | Solution |

|---|---|

| PTO not engaging or disengaging | Check the PTO switch and wiring for any damages or loose connections. Also, inspect the PTO clutch and lubricate it if necessary. |

| Weird noises coming from the PTO | Inspect the PTO output shaft and gears for any signs of damage or wear. Replace any faulty components. |

| PTO shaft slipping out of gear | Inspect the PTO gear engagement mechanism and ensure it is properly aligned and functioning. Adjust as needed. |

Tips For Troubleshooting Specific PTO Issues

If you are facing specific PTO issues, here are some tips to help you troubleshoot and resolve them:

- If your PTO is not engaging or disengaging, check the PTO pressure switch and ensure it is functioning correctly. Adjust or replace if necessary.

- If you are experiencing leaks from the PTO, inspect the hydraulic lines and fittings for any damages or leaks. Replace any faulty components.

- If the PTO is not providing enough power or torque, check the PTO pump for any clogs or restrictions. Clean or replace if needed.

Professional Help And Resources For Pto Troubleshooting

When it comes to troubleshooting PTO problems with your Allison Transmission, sometimes seeking professional assistance can be the best course of action. The complexities of PTO systems and their integration with the transmission require specialized knowledge and expertise to diagnose and resolve issues effectively. This article will provide information on when to seek professional assistance for PTO problems, recommended resources and articles for additional troubleshooting help, and how to find expert technicians for Allison Transmission PTO troubleshooting.

When To Seek Professional Assistance For Pto Problems

There are several situations where it is advisable to seek professional assistance for PTO problems. These include:

- If you lack experience and knowledge in troubleshooting PTO systems,

- If you have already attempted basic troubleshooting methods without success,

- If you are facing complex issues that require advanced diagnostic tools and equipment,

- If you fear causing further damage to the transmission or PTO system by attempting repairs yourself,

Seeking professional assistance will help ensure that the problem is correctly diagnosed and resolved, saving you time, money, and frustration.

Recommended Resources And Articles For Additional Troubleshooting Help

When it comes to troubleshooting Allison Transmission PTO problems, having access to reliable resources and articles can be invaluable. Here are some recommended sources that can provide you with additional troubleshooting guidance:

| Resource | Description |

|---|---|

| Chelsea PTO Parts | A comprehensive resource for information on troubleshooting Chelsea PTO systems. |

| Muncie Power Products | Offers a troubleshooting article archive and valuable insights into PTO installation and operation. |

| Jon Wickham & Associates | A reliable source for troubleshooting articles related to PTO systems and their components. |

By referring to these resources, you can access expert knowledge and strategies for effectively troubleshooting Allison Transmission PTO problems.

How To Find Expert Technicians For Allison Transmission Pto Troubleshooting

When seeking professional help for Allison Transmission PTO troubleshooting, it’s essential to find expert technicians who have the necessary skills and experience. Here are some tips to help you find reliable technicians:

- Reach out to authorized Allison Transmission service centers or dealerships specializing in Allison Transmission repairs.

- Ask for recommendations from fellow truck owners or operators who have dealt with similar PTO issues.

- Search online directories and review platforms to find reputable technicians with positive customer feedback.

By choosing technicians with expertise in Allison Transmission PTO systems, you can ensure that your troubleshooting needs are effectively addressed.

Frequently Asked Questions

How Does a PTO Work on an Allison Transmission?

A PTO on an Allison Transmission works by engaging the power take-off, which allows the transmission to transfer power to auxiliary equipment such as hydraulic pumps. The PTO is engaged manually or automatically depending on the model.

How Do You Engage Pto On An Automatic Allison Transmission?

To engage PTO on an automatic Allison Transmission, start the truck and ensure it is in neutral. Press the PTO switch or engage the PTO control lever, then slowly release the clutch pedal to engage the PTO. Make sure to refer to the vehicle’s specific manual for detailed instructions.

What Is The Problem With The Allison Tcm Transmission?

The problem with the Allison TCM transmission is that the PTO (Power Take-Off) may not engage or spin properly. This could be due to issues with the PTO itself or with the transmission control module (TCM). It is important to diagnose and troubleshoot the problem to determine the exact cause and find a solution.

What Is The Function Of The Pto Pressure Switch?

The function of the PTO pressure switch is to monitor and control the pressure in the power take-off (PTO) system. It ensures that the pressure is maintained within the desired range for optimal performance of the PTO.

How Does A Pto Work On An Allison Transmission?

A power take-off (PTO) on an Allison Transmission allows the transfer of power from the engine to operate auxiliary equipment, such as hydraulic pumps or generators.

Conclusion

To troubleshoot Allison Transmission PTO issues, it is crucial to diagnose the problem accurately. Whether it’s a PTO or a TC issue, understanding the functioning of PTO on an Allison Transmission is essential. By engaging the PTO on an automatic transmission correctly, you can avoid any potential problems.

Additionally, understanding the role of the PTO pressure switch can help identify any flashing PTO light issues. Remember, diagnosing PTO problems requires careful attention to detail and knowledge of the specific transmission model.