American Farmworks Electric Fence Troubleshooting: A Simple Guide for You Is your American Farmworks electric fence not working as it should? You’re not alone.

A faulty fence can leave you feeling frustrated and worried about the safety of your property or livestock. But don’t stress just yet—most issues are easier to fix than you might think. In this guide, we’ll walk you through the most common problems and solutions step by step.

Whether it’s a power drop, grounding issue, or something else entirely, you’ll get the tips you need to troubleshoot like a pro. Stick around, because a few small tweaks could save you time, money, and a whole lot of headaches. Let’s get that fence back in action!

Common Issues With Electric Fences

Electric fences are an essential tool for managing livestock and protecting properties, but they’re not without their challenges. When your American Farmworks electric fence isn’t working as expected, frustration can set in quickly. Understanding the common issues can save you time, money, and keep your fence functioning efficiently.

Fence Not Delivering Shock

A fence that doesn’t deliver a shock is one of the most common problems. Start by testing the voltage with a fence tester. If there’s no reading, check the fence charger to ensure it’s working.

Sometimes, vegetation touching the fence can sap the energy. Walk along the fence line and clear grass, branches, or weeds that may be grounding the current. Also, ensure the ground rods are properly installed and connected—poor grounding can significantly reduce shock.

Power Supply Problems

If your fence isn’t powering up, the problem could lie in the power source. Ensure the power cord is securely plugged in and check the outlet. Test the outlet with another device to confirm it’s working.

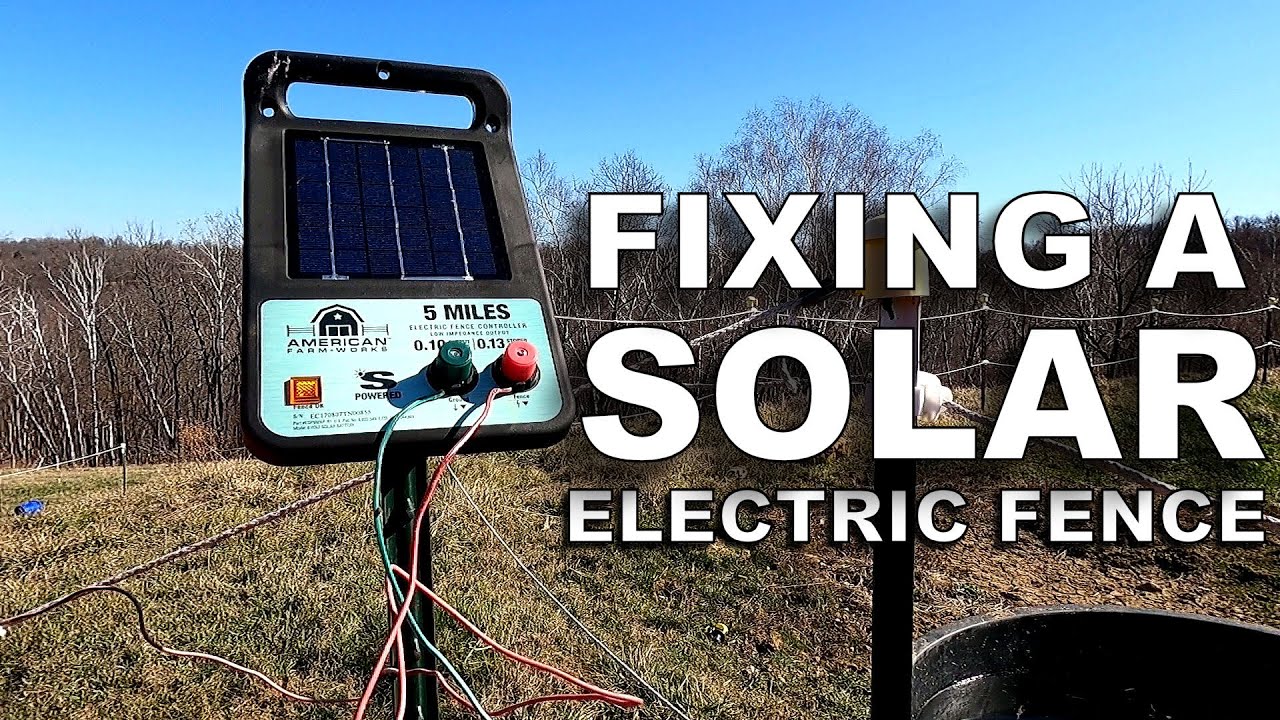

For solar-powered chargers, inspect the solar panel for dirt or damage. Clean the panel to allow maximum sunlight exposure, and make sure the battery is charged. Is your area experiencing cloudy weather? Consider using a battery backup to keep your fence operational during low-sunlight days.

Broken Or Loose Wires

Broken or loose wires can disrupt the electrical flow in your fence. Inspect the entire fence line for visible breaks or sagging sections. Use a wire joiner or splice kit to fix any breaks quickly.

Loose connections at the charger or grounding system can also cause issues. Tighten any loose screws or connectors to restore the flow of electricity. Regularly walking your fence line can help you catch these problems early.

Faulty Insulators

Insulators are small but critical components that prevent the electric current from grounding out. Cracked, broken, or improperly installed insulators can lead to power loss. Check each insulator along your fence for damage.

Replace damaged insulators immediately to maintain the fence’s efficiency. Use high-quality insulators designed for your specific type of fence wire, whether it’s polywire, tape, or steel wire. A small investment in good insulators can save you countless headaches down the road.

Have you experienced these issues before? Troubleshooting electric fences doesn’t have to be complicated. With a little patience and attention to detail, you can keep your fence running smoothly and protect your property effectively.

Tools Needed For Troubleshooting

When troubleshooting an American Farmworks electric fence, having the right tools can make all the difference. Without proper equipment, you might miss key issues or spend hours trying to fix something that could have been resolved in minutes. Let’s dive into the essential tools you need to get your fence up and running efficiently.

Voltage Tester

A voltage tester is your go-to tool for diagnosing electric fence problems. It allows you to measure the amount of electricity running through the fence and pinpoint weak spots or areas where the power drops. Look for a digital model with clear readings to make the job easier.

Using one is simple. Start near the energizer and test the voltage. Then, walk along the fence, testing different sections. If the voltage suddenly drops, you’ve likely found the problem area. Keep this tool handy—it’s the fastest way to figure out what’s wrong.

Insulation Tools

Proper insulation is crucial for an electric fence to function well. Insulation tools help you fix or replace insulators that might be cracked or loose. Broken insulators can cause electricity to leak, leading to poor fence performance.

Don’t underestimate this step. If you don’t have insulation tools, you risk overlooking small issues that can grow into bigger problems. A simple screwdriver or pliers paired with replacement insulators is often enough to get the job done.

Repair Kits

Repair kits are lifesavers when wires snap or connectors fail. These kits usually include splices, crimps, and other essential items to fix broken sections of the fence. You can find kits designed specifically for electric fences, which ensures compatibility.

Imagine you’re out in the field and notice a wire has snapped. Instead of leaving the fence compromised, you can repair it on the spot with the tools from your kit. Always keep one in your shed or vehicle—it saves time and keeps your fence operational.

Are you using all these tools already, or is there one you need to add to your toolbox? Having the right tools means less frustration and more efficiency when troubleshooting your electric fence. Take stock of what you have and make sure you’re fully prepared for any issues that come your way.

Inspecting The Power Source

Electric fences are an essential tool for keeping livestock safe and protecting your property. But when your American Farmworks electric fence isn’t working as expected, the power source is often the first place to look. A thorough inspection of the energizer, batteries, and electrical connections can save you time, money, and frustration.

Checking The Energizer

The energizer is the heart of your electric fence system. Start by ensuring it is plugged in securely and receiving power. If it’s a plug-in model, test the outlet with another device like a phone charger to confirm the outlet works.

If you’re using a solar-powered energizer, check if it’s getting enough sunlight. Dirt or debris on the solar panel can limit its efficiency. Clean it gently with a damp cloth and position it in an area with maximum sun exposure.

Still no power? Verify the energizer’s indicator light. If it’s off or blinking abnormally, consult your user manual. A faulty energizer might need repair or replacement.

Inspecting Batteries

Batteries are another common culprit. If your energizer relies on batteries, check their charge level. A simple voltmeter can tell you if they’re running low.

Dead or corroded batteries won’t power your fence effectively. Remove them and look for corrosion on the terminals. Clean any buildup with a mixture of baking soda and water, using a toothbrush for precision.

Replace old batteries if necessary. Always use the type recommended by the manufacturer. Using the wrong kind can damage your system and lead to frequent outages.

Verifying Electrical Connections

Loose or damaged connections can disrupt the power flow to your fence. Start at the energizer and follow the wires, checking for any visible breaks or fraying.

Ensure all clamps and connectors are tight. A loose wire can cause inconsistent voltage and reduce the fence’s effectiveness. Give each connection a gentle tug to confirm it’s secure.

If your system uses underground cables, inspect for any signs of wear or exposure. Rodents and weather can damage buried cables, so replace them if needed.

Have you inspected every connection? If not, you might miss the one weak link causing the issue. Taking the time to double-check ensures your fence operates at peak efficiency.

Testing The Fence Line

Testing the fence line is one of the most important steps in troubleshooting your American Farmworks electric fence. A properly functioning fence not only keeps your livestock safe but also gives you peace of mind. If you’re unsure about where to start, breaking the process into smaller steps can make it manageable and efficient.

Using A Fence Tester

A fence tester is your go-to tool for checking the voltage across your electric fence. Choose a digital fence tester, as it provides precise readings, unlike traditional neon testers. Start by testing near the energizer to confirm it’s working correctly.

Hold the tester against the live wire and push its probe into the soil. A healthy fence typically reads between 6,000 and 10,000 volts, depending on your setup. If the reading is lower, you’ll need to investigate further along the fence line.

Don’t forget to test multiple points along the fence. This helps you identify whether the issue is isolated to one area or spread across the system.

Identifying Voltage Drops

Voltage drops are a common issue and can compromise your fence’s effectiveness. Start by comparing voltage readings at different points along the fence line. A significant drop in voltage indicates an issue between the two points.

Look for visible signs of trouble, like broken wires, loose connections, or vegetation touching the fence. Even a small branch can drain power, so clear the area as you go.

If the problem persists, check the insulators. Damaged or improperly installed insulators can cause the current to leak into the posts, reducing overall voltage.

Locating Grounding Issues

Grounding problems are often overlooked but can severely impact your electric fence’s performance. A proper ground system is essential for completing the electrical circuit. Check the ground rods near your energizer to ensure they are securely placed in moist soil.

If you’re unsure about the grounding system, use your fence tester to check the voltage on the ground rods. A reading higher than 200 volts suggests a grounding issue. You may need to add more ground rods or relocate them to a wetter area for better conductivity.

Don’t forget to inspect the connecting wires. Corroded or damaged wires can weaken the grounding system, so replace them as needed.

Testing your fence line might seem like a chore, but it’s a necessary step to maintain a strong and reliable system. What’s the strangest issue you’ve discovered while troubleshooting your fence? Share your experience—it might help someone else solve their problem faster!

Fixing Common Problems

Electric fences are reliable but can face occasional issues. Fixing common problems ensures your fence works efficiently. Regular maintenance prevents malfunctions and keeps your fence secure.

This section focuses on solving frequent issues with American Farmworks electric fences. Follow these tips to keep your electric fence functioning properly.

Replacing Damaged Wires

Damaged wires reduce the effectiveness of your electric fence. Inspect wires regularly for breaks, cuts, or wear. Use wire cutters to remove damaged sections. Replace them with new wire of the same gauge.

Ensure the replacement wire is tightly secured. Test the connection after replacement to confirm the current flows properly.

Tightening Loose Connections

Loose connections cause power loss and weaken the fence. Check all connection points, including splices, clamps, and terminals. Tighten screws or clamps securely using pliers or a wrench.

Ensure connections are snug but not overly tight to avoid damage. After tightening, test the fence to confirm consistent voltage.

Cleaning And Replacing Insulators

Dirty or broken insulators can disrupt the electric current. Inspect insulators for cracks, dirt, or wear. Clean dirty insulators with a damp cloth to remove debris. Replace cracked or worn insulators immediately.

Use high-quality insulators to prevent future issues. Secure them firmly to the fence posts. Check the fence after replacing insulators to ensure proper functionality.

Maintaining Your Electric Fence

Keeping your electric fence in top condition ensures it works effectively. A well-maintained fence delivers consistent power, protects livestock, and prevents escapes. Regular upkeep also extends the lifespan of your fence system. Neglecting maintenance can lead to weak currents or system failures. Follow these simple steps to maintain your American Farmworks electric fence.

Regular Inspections

Inspect your electric fence weekly or after extreme weather. Check for visible damage, such as broken wires or loose connections. Look for sagging wires that may disrupt the current flow. Examine insulators for cracks or wear that may cause energy loss. Use a fence tester to confirm the voltage is consistent across the fence. Promptly address any issues to avoid bigger problems.

Clearing Vegetation

Vegetation touching your fence can drain electricity and reduce efficiency. Remove grass, weeds, and branches near the fence line regularly. Use a weed trimmer or herbicide to keep vegetation under control. Ensure nothing touches the wires, especially after storms. Clear paths create a stronger barrier and improve the fence’s performance.

Upgrading Components

Old components can weaken your electric fence system over time. Replace worn-out wires, insulators, and posts as needed. Consider upgrading to higher-quality materials for better durability. Install a stronger energizer if the fence covers a larger area. Use modern tools like digital testers for more accurate maintenance checks. Small upgrades can make a big difference in efficiency.

When To Seek Professional Help

Troubleshooting an electric fence can be challenging for most users. While many issues are easy to fix, some problems require expert assistance. Knowing when to call a professional can save time and avoid further damage to your system.

Below are situations that may warrant professional support for your American Farmworks electric fence.

Persistent Voltage Issues

If your fence consistently delivers low or no voltage, it may need expert attention. Voltage problems can stem from broken wires, faulty insulators, or poor grounding. Testing and repairing each part can be complex without specialized tools. Professionals have the expertise to identify voltage issues and restore your fence’s functionality.

Energizer Malfunctions

The energizer powers your electric fence. If it stops working, it impacts the entire system. Common energizer issues include internal damage, worn-out components, or improper installation. Diagnosing these problems requires electrical knowledge and experience. A professional can inspect, repair, or replace the energizer efficiently.

Extensive System Repairs

Large-scale damage to the fence system may call for professional help. Extensive issues include multiple broken wires, damaged posts, or a faulty grounding system. Repairing these problems can take time and precise work. Professionals can handle complex repairs and ensure your fence operates smoothly again.

Conclusion

Troubleshooting your American Farmworks electric fence doesn’t have to be stressful. Start with basic checks like connections, settings, and power supply. Identify issues step by step to find quick solutions. Regular maintenance can help prevent future problems and save time.

Always prioritize safety when working with electric fences. A well-functioning fence ensures better protection for your property and livestock. With patience and attention, most common issues can be resolved easily. Keep learning and stay proactive to maintain your electric fence in top condition.

A reliable fence means peace of mind for you and your farm.