Are you struggling to find solutions for your Atlas Copco equipment? Don’t worry—you’re not alone.

When machines act up, it can feel overwhelming, especially if you’re unsure where to start. That’s where an Atlas Copco troubleshooting PDF can be a real game-changer. Imagine having step-by-step guidance at your fingertips to pinpoint issues and fix them quickly.

Sounds helpful, right? We’ll show you why this resource is essential, how to use it effectively, and where to find it. Stick around, because the time you spend here could save you hours of frustration later.

Common Issues With Atlas Copco Machines

Atlas Copco machines are known for their reliability and performance. However, like any industrial equipment, they can face occasional hiccups. Understanding these common issues can save you time, effort, and costly repairs.

Frequent Air Compressor Problems

Air compressors are the backbone of many Atlas Copco machines. But, they may sometimes lose efficiency due to clogged filters or leaks in the system. Keeping an eye on pressure drops or unusual noises can help you catch these issues early.

Another common problem is overheating. Dust accumulation or poor ventilation can restrict airflow, causing the machine to heat up. Cleaning the vents and maintaining the recommended ambient temperature can prevent this.

Electrical System Failures

Electrical issues can be tricky and dangerous if left unchecked. One frequent issue is a blown fuse, often caused by overloaded circuits. Always ensure the machine is operating within its specified electrical limits.

Loose wiring is another culprit. Vibrations from prolonged use can loosen connections, leading to intermittent faults or complete shutdowns. Regularly inspect and tighten electrical connections to avoid downtime.

Hydraulic System Malfunctions

Hydraulic systems are critical for the smooth functioning of many Atlas Copco machines. One common problem is fluid contamination. Dirt or moisture in the hydraulic fluid can lead to sluggish performance or complete system failure. Using clean, high-quality hydraulic fluid is essential.

Leaks in the hydraulic lines are another issue. Small cracks or worn-out seals can cause fluid loss, reducing the system’s efficiency. Inspecting hoses and seals regularly can help you spot and fix leaks before they escalate.

Have you encountered any of these issues with your Atlas Copco machines? Share your experiences and tips in the comments below! Let’s help each other keep our equipment running smoothly.

Understanding Error Codes

If you’ve ever faced equipment issues, you know how frustrating it can be when error codes pop up. Atlas Copco troubleshooting PDFs are invaluable for decoding these messages. They’re like your personal guide to understanding what your machine is trying to tell you.

But how do you make sense of the flashing indicators or cryptic codes? Let’s break it down so you can take quick and effective action.

Decoding Fault Indicators

Error codes often appear as numbers, letters, or a combination of both. Each code corresponds to a specific issue. For instance, a common Atlas Copco error code like “E03” might signal a temperature-related fault.

Your first step should always be to consult the troubleshooting PDF. It provides a detailed explanation of what each code means. Keep it handy, either digitally or printed, for quick access during maintenance.

Pay attention to patterns. Does the same code reappear frequently? That could point to an underlying issue that needs deeper inspection.

Steps To Resolve Error Warnings

Once you’ve identified the code, follow the recommended action in the troubleshooting PDF. For minor issues, the solution may involve simple adjustments, like resetting the machine or cleaning air filters.

- Step 1:Turn off the equipment and check all connections. Loose wiring is a common culprit.

- Step 2:Verify the environmental conditions. Is the machine overheating? Ensure proper ventilation.

- Step 3:Replace worn-out parts, if necessary. The PDF often suggests specific replacements.

If the error persists, don’t ignore it. Reach out to Atlas Copco’s support team or a certified technician. Solving the issue early can prevent costly downtime.

Have you ever solved an error code issue on your own? It feels empowering, doesn’t it? Understanding these codes not only saves time but also boosts your confidence in handling equipment.

Essential Tools For Troubleshooting

Effective troubleshooting requires the right tools and resources. Without them, diagnosing and fixing issues can become time-consuming. Atlas Copco equipment often involves complex systems. Having reliable tools ensures smoother and more accurate repairs. This guide explores essential diagnostic equipment and repair manuals to support your troubleshooting process.

Recommended Diagnostic Equipment

Diagnostic equipment helps identify issues quickly. For Atlas Copco systems, multimeters and pressure gauges are essential. Multimeters measure electrical currents, voltage, and resistance. Pressure gauges monitor system pressure levels, ensuring they meet specifications. Thermal cameras are also helpful. They detect overheating components without dismantling machinery. Vibration analyzers are another critical tool. They assess the health of rotating parts like motors and fans. Invest in quality diagnostic tools for better results.

Software And Manuals For Repair

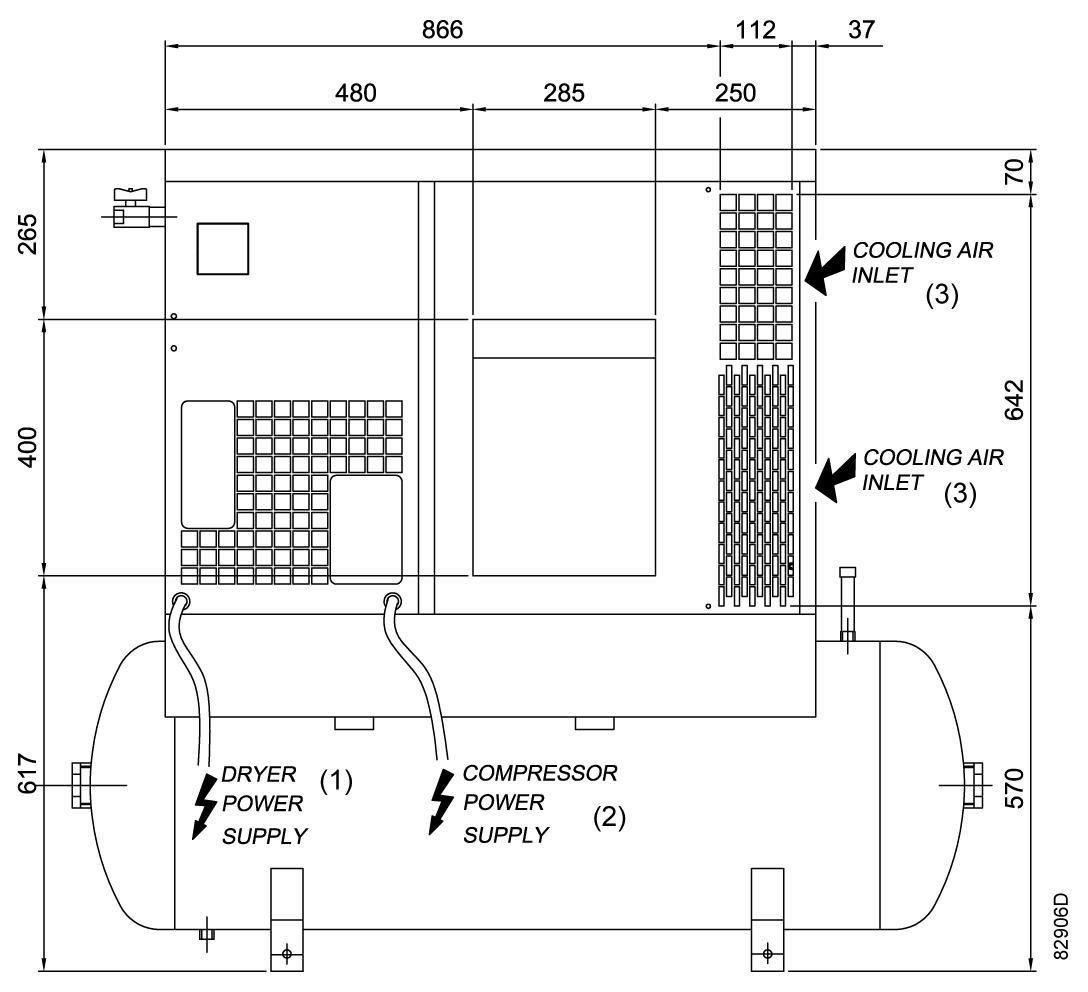

Software plays a key role in troubleshooting modern systems. Atlas Copco provides specialized software to diagnose and repair their equipment. These tools help monitor real-time performance and identify faults. Accessing detailed repair manuals is equally important. Manuals provide step-by-step instructions for fixing issues. They also include system diagrams for better understanding. Always ensure your software and manuals are up-to-date. This keeps your troubleshooting process accurate and efficient.

Step-by-step Repair Process

When working on complex machinery like Atlas Copco equipment, having a clear and structured approach to troubleshooting is essential. The Atlas Copco Troubleshooting PDF often serves as a lifeline, but knowing the step-by-step repair process can save you time and frustration. Let’s break down the key steps to ensure your repairs are efficient and effective.

Inspection And Diagnosis

Before diving into repairs, start with a thorough inspection. Look for visible signs of wear, leaks, or loose components. For example, a loose belt or oil leak can often point you in the right direction.

Next, identify the root cause of the problem. Use diagnostic tools or refer to error codes mentioned in the troubleshooting PDF. If your equipment isn’t starting, check the power supply and fuses first—simple fixes can save hours of unnecessary work.

Ask yourself: Are you addressing the symptom or solving the actual issue? Taking the time to diagnose properly prevents further damage and ensures a long-term solution.

Repairing Mechanical Components

Once you’ve pinpointed the issue, gather the right tools and replacement parts. Working with worn-out tools can lead to mistakes, so double-check your kit before starting.

Follow the repair instructions step by step, as outlined in the PDF. For instance, if you’re replacing a valve, ensure all connections are sealed tightly to avoid future leaks. Don’t rush—precision matters more than speed here.

Keep track of disassembled parts by organizing them in labeled trays. This simple trick can save you from the headache of reassembly errors later.

Testing After Repairs

Testing isn’t just about turning the machine back on—it’s about ensuring it performs as expected. Run the equipment under normal working conditions to verify all systems are functioning properly.

Pay attention to unusual noises, vibrations, or temperature changes during testing. These can indicate underlying issues that need further attention.

Document the results for future reference. If the problem persists, you’ll have a clearer path for further troubleshooting.

Repairing Atlas Copco equipment doesn’t have to be intimidating. By breaking the process into manageable steps, you’ll not only fix the issue but also improve your confidence for future repairs. So, what’s your next repair challenge?

Preventive Maintenance Tips

Preventive maintenance is essential for keeping Atlas Copco equipment running smoothly. Regular checks and care reduce downtime and improve efficiency. This section highlights practical tips to maintain your machinery effectively. Follow these steps to ensure your equipment performs at its best.

Daily And Weekly Checks

Inspect the machine daily for visible signs of wear or damage. Look for loose bolts, oil leaks, and unusual noises during operation. Check fluid levels, including oil and coolant, to avoid overheating. Clean filters regularly to prevent debris buildup that hampers performance.

Conduct weekly checks on more detailed components like belts and hoses. Ensure all connections are secure and free from cracks or frays. Review the control panel for error messages or alerts. Test safety systems to confirm they are functioning properly.

Long-term Care Strategies

Schedule professional servicing every few months to address deeper issues. Replace worn-out components before they fail and impact performance. Use only recommended parts and fluids for repairs and replacements.

Store equipment in dry, clean environments to prevent rust and corrosion. Implement a maintenance log to track inspections and repairs. Train operators on proper usage to minimize operational stress on the machinery.

By following these strategies, you extend the lifespan of your Atlas Copco equipment. Consistent care ensures reliability and saves costs over time.

When To Call A Professional

Atlas Copco equipment is built for durability and reliability. Yet, even the best machines can develop complex issues. Some problems require professional expertise to ensure safety and efficiency. Knowing when to call a professional can save time and prevent costly mistakes.

Signs Of Severe Damage

Unusual noises or vibrations often indicate severe internal damage. Persistent air leaks may point to worn-out seals or broken components. Excessive overheating is another red flag that needs expert inspection. If the machine fails to start despite troubleshooting, it could signal a deeper issue. Delaying professional help in these cases can worsen the damage.

Cost-benefit Of Expert Repairs

Professional repairs may seem costly upfront, but they save money long term. Experts have specialized tools to diagnose and fix problems quickly. They can replace faulty parts with high-quality components, extending your machine’s life. DIY fixes might lead to further damage, increasing overall repair costs. Hiring a professional ensures the equipment operates at peak performance.

Accessing The Troubleshooting Pdf

Having the right guide can save you hours of frustration when dealing with Atlas Copco equipment. The Troubleshooting PDF is your go-to resource for resolving issues efficiently. But how do you find and use this essential document? Let’s break it down step by step.

Finding The Right Document

Start by visiting the official Atlas Copco website. Use their search bar to locate the troubleshooting PDF specific to your equipment model. Make sure you input the exact model number to avoid downloading the wrong document.

If you’re unsure of your model, check the user manual or the label on your equipment. Both typically have this information readily available. Accuracy here is key; the wrong file may not address your specific issue.

Many users overlook the importance of verifying the source. Always ensure you’re downloading from an official or trusted platform to avoid outdated or incorrect information. Is the file coming from the official Atlas Copco website? If not, it’s worth double-checking.

Downloading And Using The Guide

Once you’ve found the right document, click the download button. Save it to a folder where you can easily access it later. If you often troubleshoot equipment, create a dedicated folder for all your guides.

Open the PDF using a free reader like Adobe Acrobat or your browser. PDFs are designed for easy navigation. Use the built-in search function to quickly jump to sections that address your specific issue.

Don’t forget to bookmark important pages for future reference. If your equipment frequently encounters the same issue, having those pages readily available can save you time. Have you thought about printing a hard copy for fieldwork? It’s always helpful to have a physical guide when working offline.

Conclusion

Understanding the Atlas Copco troubleshooting PDF can save time and reduce stress. It provides clear steps to fix common equipment issues. By following the guide, users can handle problems quickly and safely. Regular maintenance and proper usage also help prevent breakdowns.

Always keep the PDF handy for future reference. A well-maintained machine ensures smooth operations and better efficiency. Take time to familiarize yourself with the guide. It’s a valuable resource for anyone using Atlas Copco equipment. Stay proactive to avoid unexpected challenges.