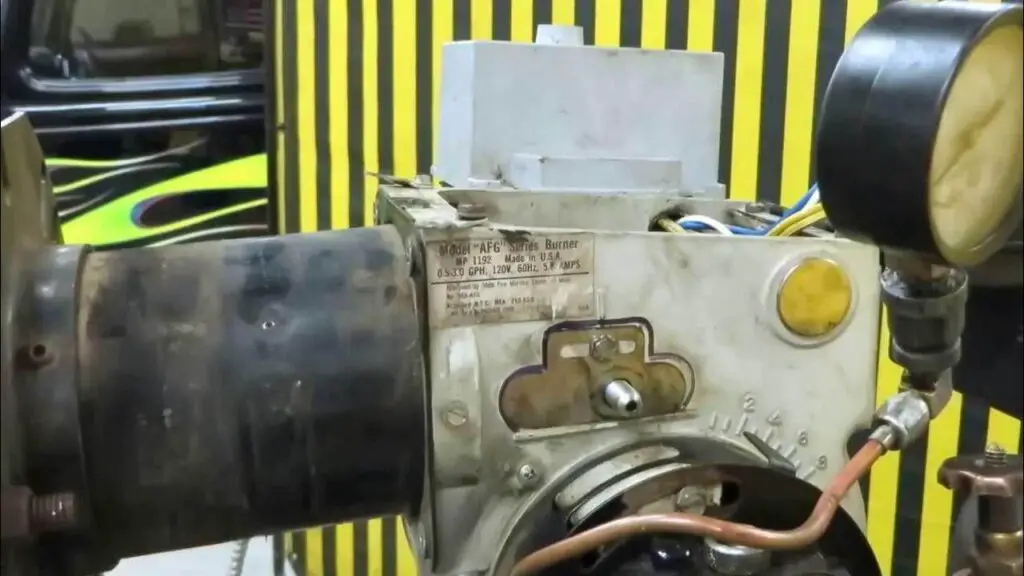

If your Beckett burner is malfunctioning, check the fuel supply and nozzle for blockages. Clean or replace parts as needed.

Proper maintenance of your Beckett burner is essential to ensure efficient operation and prevent costly repairs. Understanding common issues and troubleshooting techniques can help you address problems quickly and effectively. By following a few simple steps, you can troubleshoot your Beckett burner and keep your heating system running smoothly.

In this guide, we will discuss common Beckett burner issues, how to diagnose them, and simple solutions to get your burner back up and running in no time. Whether you are a homeowner or a professional HVAC technician, these troubleshooting tips will help you keep your Beckett burner in top condition.

Common Beckett Burner Issues

When dealing with Beckett burner issues, it’s crucial to address Common Beckett Burner Issues promptly.

No Ignition

If the Beckett burner fails to ignite, check the fuel supply line for blockages.

Flame Failure

Inspect the electrode for corrosion or misalignment to resolve flame failure problems.

Let me know if you need any more assistance.

Checklist For Troubleshooting

The ‘Checklist for Troubleshooting’ breaks down the key areas to focus on when dealing with Beckett Burner issues. Let’s examine the critical aspects under Electrical Components, Fuel Supply, and Air Intake:

Electrical Components

- Check for loose connections in the wiring.

- Ensure the burner motor is receiving power.

- Inspect the ignition system for malfunctions.

Fuel Supply

- Verify the fuel tank has an adequate level of fuel.

- Check for clogs or blockages in the fuel line.

- Inspect the fuel pump for any issues.

Air Intake

- Ensure the air intake pipe is clear of obstructions.

- Check the air filter for dirt or debris accumulation.

- Inspect the combustion chamber for proper airflow.

Adjusting Burner For Optimal Performance

To ensure optimal performance of your Beckett burner, it’s essential to properly adjust the burner. Adjusting fuel and air ratios, cleaning the burner, and checking for any obstructions can help troubleshoot and improve the burner’s efficiency. Keeping the burner well-maintained will ensure smooth operations and energy savings.

Adjusting your Beckett burner for optimal performance is essential to ensure efficient and reliable heating in your home or commercial space. Fortunately, troubleshooting common issues and making necessary adjustments can help maintain the burner’s functionality. Here are some key steps to consider when adjusting your burner for optimal performance.

Cleaning Electrodes

Regularly cleaning the electrodes is crucial in ensuring the burner operates efficiently. Over time, carbon buildup can occur on the electrodes, leading to improper ignition and potential burner malfunctions. To clean the electrodes:

- Turn off the power to the burner

- Carefully remove the electrodes

- Use a fine-grit sandpaper to gently remove any carbon deposits

- Inspect the electrodes for signs of wear or damage

- Reinstall the electrodes securely

Calibrating Air/fuel Ratio

Maintaining the proper air/fuel ratio is crucial for optimal burner performance and fuel efficiency. A balanced ratio ensures complete combustion, reducing excess soot and minimizing fuel consumption. To calibrate the air/fuel ratio:

- Check the manufacturer’s guidelines for the recommended air/fuel ratio settings

- Use a combustion analyzer to measure the current ratio

- Adjust the air intake and fuel flow to achieve the optimal ratio

- Monitor the combustion process to ensure the desired ratio is maintained

By following these steps and addressing any potential issues with cleaning electrodes and calibrating the air/fuel ratio, you can ensure your Beckett burner continues to operate at its best, providing efficient and reliable heating for your space.

Enhancing Efficiency

When it comes to maintaining the performance of your Beckett burner, enhancing efficiency should be a top priority. Not only does an efficient burner save you money on fuel costs, but it also reduces environmental impact. In this section, we’ll explore two key factors that can significantly improve the efficiency of your burner: insulation upgrades and regular maintenance.

Insulation Upgrades

One effective way to enhance the efficiency of your Beckett burner is by investing in insulation upgrades. Proper insulation helps to minimize heat loss and ensure that the heat produced is directed towards heating your space rather than being wasted. By taking the time to inspect and upgrade the insulation in your burner system, you can make a significant difference in how efficiently it operates.

Here are a few key areas to focus on when considering insulation upgrades:

- The burner housing: Ensure that the burner housing is properly insulated to prevent heat loss. This can be done by adding insulation material such as fiberglass or foam insulation.

- Piping and ductwork: Insulating the pipes and ductwork that connect the burner to your heating system can help prevent heat loss during transportation. This is especially important for long runs of pipes or ducts.

- Combustion chamber: Insulating the combustion chamber not only helps to maintain high temperatures for efficient combustion but also helps prevent heat loss through the walls of the chamber.

By paying attention to these areas and making the necessary insulation upgrades, you can maximize the efficiency of your Beckett burner and reduce energy waste.

Regular Maintenance

Regular maintenance is essential for the ongoing efficiency of your Beckett burner. Neglecting maintenance tasks can result in reduced performance and increased fuel consumption. To ensure that your burner continues to operate at its best, here are some maintenance tasks you should prioritize:

- Cleaning the burner components: Regularly clean the burner components, including the nozzle, electrodes, and combustion chamber. This helps to maintain proper fuel atomization and combustion, leading to enhanced efficiency.

- Inspecting and replacing filters: Clogged or dirty filters can restrict airflow and affect burner efficiency. Check and clean or replace filters regularly to ensure optimal airflow.

- Checking fuel supply: Monitor the fuel supply to ensure that there are no leaks or issues that could impact burner performance. Address any fuel supply problems promptly.

- Adjusting combustion settings: Periodically check and adjust the combustion settings to ensure efficient and clean burning. This can help optimize fuel consumption and reduce emissions.

- Checking for leaks: Regularly inspect the burner system for any signs of leaks, such as fuel odors or soot buildup. Address any leaks promptly to prevent fuel waste and potential safety hazards.

By staying on top of regular maintenance tasks, you can keep your Beckett burner operating at peak efficiency, prolong its lifespan, and minimize the risk of costly repairs.

In conclusion, enhancing the efficiency of your Beckett burner is crucial for both cost savings and environmental sustainability. By considering insulation upgrades and prioritizing regular maintenance, you can significantly improve the efficiency of your burner and ensure optimal performance for years to come.

Professional Assistance And Maintenance Contracts

Troubleshooting Beckett Burners can be a daunting task, especially if you don’t have the necessary knowledge and expertise. That’s why seeking professional assistance and considering maintenance contracts can save you time and stress in the long run. In this section, we will explore the benefits of finding certified technicians and the advantages of maintenance contracts for your Beckett Burner.

Finding Certified Technicians

When facing issues with your Beckett Burner, it’s crucial to rely on certified technicians who specialize in troubleshooting these burners. A certified technician possesses the necessary skills and knowledge to diagnose and repair burner problems efficiently. By choosing a qualified professional, you can ensure that your Beckett Burner is in the hands of experts who understand the intricacies of its mechanics.

Benefits Of Maintenance Contracts

A maintenance contract offers several advantages when it comes to keeping your Beckett Burner running smoothly. First and foremost, regular maintenance ensures early detection of potential issues. Through routine inspections and cleaning, problems can be identified and resolved before they escalate into major complications. This proactive approach can save you from expensive repairs down the line.

Moreover, with a maintenance contract, you have peace of mind knowing that a professional will be regularly checking your Beckett Burner. This preventive care extends the lifespan of your burner, maximizing its efficiency and reducing the risk of unexpected breakdowns. Additionally, many maintenance contracts include priority service, meaning that in case of emergencies, you will receive prompt assistance.

Lastly, having a maintenance contract can also save you money in the long run. Regular servicing optimizes the burner’s performance, leading to increased energy efficiency. This, in turn, translates into savings on your energy bills. Moreover, with scheduled maintenance, you can prevent larger issues from occurring that might require costly replacement parts or even a whole new burner.

Frequently Asked Questions On Beckett Burner Troubleshooting

How Do I Troubleshoot A Beckett Burner That Won’t Ignite?

To troubleshoot a Beckett burner that won’t ignite, check the fuel supply, clean the nozzles, and ensure proper electrode positioning.

Why Is My Beckett Burner Producing Excessive Smoke?

Excessive smoke from a Beckett burner can be due to clogged filters, incorrect air-to-fuel ratio, or blocked chimney.

What Causes The Beckett Burner To Cycle On And Off Frequently?

Frequent cycling of a Beckett burner may indicate issues with the flame sensor, fuel pump pressure, or thermostat settings.

How Can I Fix A Beckett Burner That Is Not Heating Enough?

To fix a Beckett burner that is not heating enough, check for obstructions in the air intake, clean the heat exchanger, and adjust the burner nozzle.

Why Is My Beckett Burner Making Strange Noises?

Strange noises from a Beckett burner can be caused by loose components, a faulty motor, or air trapped in the fuel line.

Conclusion

Troubleshooting Beckett burners can be a straightforward process with attention to detail. By following the steps mentioned above, you can identify and resolve common issues with ease. Remember to perform regular maintenance and seek professional assistance when needed. Stay proactive in addressing any concerns to ensure efficient burner performance and maximize its lifespan.