Is your Beckett igniter acting up and leaving you frustrated? Don’t worry—you’re not alone.

When your heating system isn’t working as it should, it’s not just inconvenient; it can also leave you worried about costly repairs. But here’s the good news: many common issues with Beckett igniters are surprisingly simple to troubleshoot and fix on your own.

In this guide, we’ll walk you through practical solutions to get your igniter back on track. Whether it’s a no-start issue, irregular sparks, or something else entirely, you’ll find clear steps to solve the problem without feeling overwhelmed. Stick with us, and by the end, you’ll feel confident about tackling the issue head-on. Ready to save time, money, and stress? Let’s dive in!

Common Signs Of Igniter Problems

Dealing with a malfunctioning Beckett igniter can be frustrating, especially when you’re relying on your heating system to keep your home warm. Recognizing the common signs of igniter problems is the first step to resolving the issue. If you catch these signs early, you can save time, money, and a lot of unnecessary stress.

1. The Burner Won’t Ignite

Is your burner refusing to start? This is one of the clearest signs of an igniter issue. If the system is supplying fuel but the burner won’t fire up, the igniter might not be generating the spark needed for ignition.

Check for a clicking sound when the burner attempts to ignite. No sound? The igniter could be damaged or misaligned. Make sure you also inspect the wiring to rule out a loose connection.

2. Intermittent Ignition Problems

Does your burner start sometimes but fail at other times? This inconsistency can point to a weak or failing igniter. Over time, igniters can wear out and lose their efficiency.

Consider when this happens. Is it during colder temperatures or after long periods of inactivity? These clues can help you narrow down the issue.

3. Visible Cracks Or Damage To The Igniter

Have you taken a closer look at the igniter? Physical damage such as cracks, chips, or discoloration are warning signs. Even small cracks can prevent the igniter from working properly.

If you notice any damage, it’s time to replace the igniter. Igniters are delicate, so handle them carefully during inspection.

4. Unusual Odors During Operation

Does your system emit strange smells when it tries to start? A faulty igniter can cause incomplete combustion, leading to unpleasant odors. This is not only inconvenient but can also be unsafe.

If you detect any unusual smells, shut off the system and investigate further. Igniter issues could be at the root of the problem.

5. Frequent Reset Button Usage

Do you find yourself pressing the reset button more often? While the reset button can temporarily solve startup issues, frequent use could signal an underlying igniter problem.

Try to track how often you’re using it. If it’s becoming a habit, it’s time to address the root cause.

Identifying these signs early can save you from bigger headaches later. Don’t wait until the system completely fails—take action now. Have you experienced any of these symptoms with your Beckett igniter? What steps did you take to troubleshoot the problem?

Safety Precautions To Follow

Before diving into Beckett igniter troubleshooting, it’s crucial to discuss safety precautions. Igniters deal with high voltage, and mishandling can lead to serious injury or damage. Taking the right precautions is not just a formality—it’s your first step to ensuring a smooth and safe repair process.

Wear Proper Protective Gear

Always wear safety gloves to protect your hands from electrical shocks and burns. Insulated gloves are especially useful when working with igniters. Don’t forget safety goggles to shield your eyes from sparks or debris.

Turn Off Power

Never attempt to troubleshoot an igniter while power is on. Locate the circuit breaker and switch it off. Double-check that no electricity is flowing to the unit before you begin.

Use Insulated Tools

Regular tools can conduct electricity, which increases your risk. Opt for insulated screwdrivers and pliers designed for electrical work. These tools provide an added layer of safety while handling high-voltage components.

Work In A Well-ventilated Area

If the igniter is connected to a furnace, ensure proper ventilation. Combustion gases can escape during your inspection. A well-ventilated workspace reduces the risk of inhaling harmful fumes.

Keep Water Away

Water and electricity don’t mix. Ensure your workspace is dry before starting. If you’re working in a basement or damp area, take extra precautions to avoid moisture near electrical components.

Test For Voltage

Don’t assume the power is off—test it. Use a multimeter or voltage tester to confirm there’s no current. This simple step can prevent a painful mistake.

Have you ever skipped a safety step because you were in a hurry? That one shortcut can turn a minor repair into a major hazard. Take your time, follow these precautions, and prioritize your safety above all else.

Tools Needed For Troubleshooting

When your Beckett igniter isn’t firing up as it should, the right tools can make troubleshooting faster and less frustrating. Imagine wasting hours trying to diagnose an issue, only to realize you’re missing a crucial tool. Having a well-prepared toolkit ensures you can identify the problem accurately and fix it efficiently.

Here’s a breakdown of the essential tools you’ll need to troubleshoot your Beckett igniter.

1. Multimeter

A multimeter is your best friend when diagnosing electrical issues. Use it to check voltage, continuity, and resistance in the igniter system. For example, you can test whether your igniter is receiving the proper 120 volts it needs to function.

If you don’t already own one, choose a digital multimeter with clear readings and an easy-to-use interface. A reliable option doesn’t have to break the bank—most hardware stores carry budget-friendly models.

2. Insulated Screwdrivers

Working with electricity requires safety, and insulated screwdrivers help protect you from accidental shocks. You’ll need these to remove the igniter cover or secure loose connections. Make sure the screwdriver’s insulation is rated for at least 1000 volts for added peace of mind.

Tip: Keep both a flathead and a Phillips-head screwdriver in your toolkit, as you’ll likely encounter different screw types.

3. Needle-nose Pliers

Ever tried handling small wires with your bare hands? It’s not fun. Needle-nose pliers make it easier to grip, twist, or pull wires during your troubleshooting process. They’re especially useful for adjusting the igniter’s electrode gap or removing stubborn connectors.

4. Flashlight Or Headlamp

Most Beckett igniters are tucked away in dimly lit spaces, making a flashlight essential. A headlamp is even better since it frees up both of your hands for the task. You don’t want to misplace a wire or screw because you couldn’t see clearly.

5. Combustion Analyzer

While not strictly necessary, a combustion analyzer can be a game-changer. It measures the efficiency of your burner and helps you detect issues like incomplete combustion. If your igniter troubleshooting involves performance tuning, this tool is invaluable.

6. Electrical Tape

Electrical tape is a simple yet versatile tool for securing loose wires or insulating exposed connections. Use it to prevent short circuits during your testing. Keep a roll handy—it’s one of those items you’ll end up using more than you think.

7. Owner’s Manual

Don’t underestimate the power of your Beckett igniter’s owner’s manual. It often includes wiring diagrams, troubleshooting tips, and specific instructions for your model. If you’ve misplaced yours, check the manufacturer’s website for a downloadable version.

Does your toolkit include all these essentials? If not, consider upgrading it before tackling your igniter issues. The right tools don’t just save time—they save headaches too.

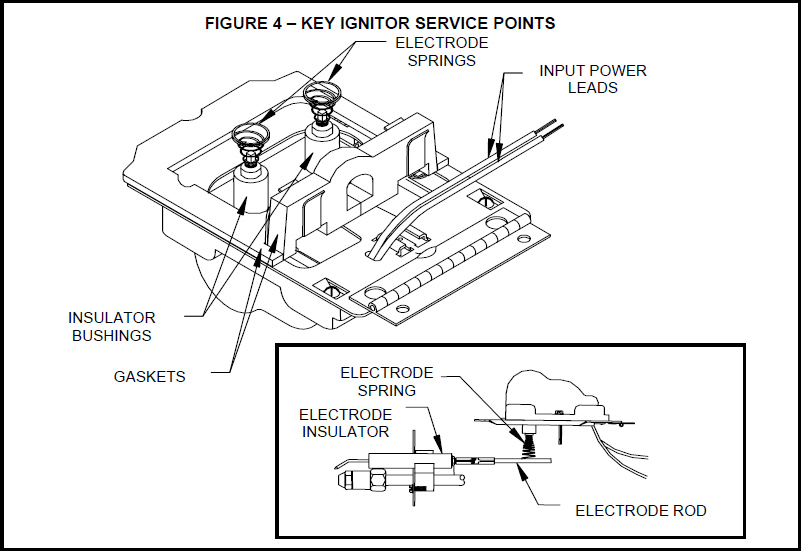

Credit: www.beckettcorp.com

Inspecting The Igniter

The igniter is the heart of your Beckett burner system, responsible for creating the spark that gets your equipment running. If your burner is giving you trouble, the igniter should be one of the first components you inspect. A quick but careful check can save you hours of frustration and might even prevent an unnecessary service call.

Checking For Physical Damage

Start by visually inspecting the igniter for any signs of physical damage. Look for cracks, burn marks, or corrosion on its surface. Even small cracks can disrupt its ability to function properly.

Check the mounting screws and brackets as well. A loose or misaligned igniter can lead to inconsistent sparking. If something looks off, tighten the screws or adjust its position to ensure proper alignment.

Don’t forget the electrodes. Are they bent out of shape or covered in soot? Clean them gently with a fine-grit sandpaper if needed, or replace them if they’re beyond repair. A clean and correctly positioned electrode is crucial for a strong spark.

Testing The Electrical Connections

Inspect the wires leading to the igniter. Are they frayed, loose, or disconnected? Damaged wires can interrupt the flow of electricity and render the igniter useless.

Use a multimeter to test the voltage at the igniter terminals. A healthy igniter should be receiving the correct voltage specified in your Beckett burner manual. If the voltage reading is too low, the issue might be with the transformer or another upstream component.

Double-check all connectors. Push them in firmly to ensure a solid connection. A slightly loose connector can cause intermittent failures that are tricky to diagnose.

Have you noticed any unusual odors or heat around the electrical components? That could indicate a short circuit or overheating issue. If you suspect this, turn off the burner immediately and consult a professional.

Taking a few minutes to inspect your igniter thoroughly can often pinpoint the problem. What did your inspection reveal? If nothing seems amiss but the igniter still doesn’t work, it might be time to test other components of your burner system.

Cleaning The Igniter

A Beckett igniter plays a vital role in maintaining efficient heating systems. Regular cleaning ensures it functions properly and prevents unnecessary wear. Dirt and carbon buildup can reduce performance and cause ignition issues. This guide explains how to clean the igniter effectively.

Removing Dirt And Carbon Buildup

Dirt and carbon deposits often accumulate on the igniter over time. These residues can block electrical conductivity and reduce heating efficiency. To remove the buildup, start by turning off the power supply to the unit. This ensures safety while handling the equipment.

Carefully inspect the igniter for visible dirt, soot, or carbon buildup. Use a soft cloth or brush to wipe away loose debris. For stubborn deposits, gently scrape the surface with a non-metallic tool. Avoid using excessive force to prevent damage to the igniter.

Using Proper Cleaning Tools

Using the right tools makes cleaning more effective and safe. A soft-bristle brush is ideal for removing loose dirt without scratching the igniter. Non-abrasive cloths help wipe away smaller particles. Avoid metal tools, as they can damage the surface.

If needed, apply a mild cleaning solution to dissolve tough carbon buildup. Ensure the solution is safe for electrical components. After cleaning, use a dry cloth to remove any moisture from the igniter. Proper cleaning tools protect the igniter and ensure better performance.

Replacing The Igniter

Replacing the igniter in your Beckett burner might sound like a daunting task, but it’s simpler than you think. A faulty igniter can cause your burner to stop working, leaving you with no heat at the most inconvenient times. By learning how to replace it yourself, you’ll save both time and money while keeping your home warm and comfortable.

Choosing The Right Replacement

Before you begin, ensure you’re choosing the correct replacement igniter for your Beckett burner. Not all igniters are universal, so you’ll need to match the model and specifications of your burner. Check your burner’s manual or look for the part number on the existing igniter to confirm compatibility.

Pay attention to details like voltage and mounting style. Using the wrong igniter may not only fail to fix the problem but could also damage your burner. If you’re unsure, consult a professional or your local hardware store for guidance.

Step-by-step Replacement Guide

Here’s how you can replace the igniter in just a few simple steps:

- Turn Off Power:Safety first! Make sure to disconnect the power supply to the burner to avoid any risk of electric shock.

- Access the Igniter:Open the burner’s access panel to locate the igniter. This will usually involve removing a few screws or unclipping a cover.

- Disconnect the Old Igniter:Carefully unplug the wires connected to the faulty igniter. Take note of how they’re connected so you can replicate it with the new one.

- Remove the Old Igniter:Unscrew or unclip the igniter from its mounting bracket. Set it aside for disposal.

- Install the New Igniter:Position the replacement igniter in the same spot, securing it with screws or clips. Ensure it’s mounted firmly.

- Reconnect the Wires:Attach the wires to the new igniter, following the same setup as the old one.

- Test the Igniter:Restore power to the burner and test the igniter. You should hear a clicking sound or see a small spark, indicating it’s working.

Always double-check your work before closing the access panel. A loose connection or improper installation can lead to further issues.

Does this seem manageable, or do you still feel hesitant? Trust yourself! With the right tools, a little patience, and this guide, you can tackle this repair confidently. Let me know how it goes or if you have additional questions in the comments below!

Testing The System After Repairs

After completing repairs on a Beckett igniter, testing ensures the system works efficiently. Proper testing prevents further issues and guarantees smooth operation. This step is crucial for long-term reliability and safety.

Below are essential checks to perform during this phase. Each test focuses on ignition functionality and performance consistency.

Verifying Proper Ignition

Start by turning on the system and observing the ignition process. Look for a steady spark that ignites the burner immediately. A delay or weak spark signals potential issues. Inspect wiring connections and verify they are secure.

Check the igniter’s position relative to the burner. Misalignment can hinder ignition performance. Adjust its placement if necessary to ensure proper contact with the flame area.

Ensuring Consistent Performance

Run the system for several cycles to monitor consistency. Pay attention to how the system starts and stops during each cycle. Consistent operation indicates the repair was successful.

Listen for unusual noises or irregular patterns. These could point to ongoing issues with the igniter or other components. Address them promptly to maintain efficiency.

Regular testing after repairs minimizes downtime and keeps the system reliable.

Credit: www.youtube.com

Preventative Maintenance Tips

Maintaining your Beckett igniter doesn’t have to feel like a chore. Preventative maintenance not only keeps your system running smoothly but also saves you from sudden breakdowns. With a few simple habits, you can extend the lifespan of your equipment and keep your heating system reliable.

Regular Cleaning Schedule

Dust and debris are silent killers for your Beckett igniter. Over time, they can hinder its performance and even cause malfunctions. Make it a habit to clean the igniter at least once every three months.

Use a soft brush or cloth to remove dirt from the surface. If you spot stubborn grime, a mild cleaning solution can help. Avoid using abrasive materials that could damage the igniter.

Don’t forget to check for soot buildup around the electrodes. Excess soot can block the ignition spark. A quick wipe can make a big difference in keeping your system efficient.

Monitoring System Performance

Keeping an eye on how your igniter performs is just as important as cleaning. Does your furnace take longer to ignite? Is the flame weaker than usual? These are signs your igniter might need attention.

Test the igniter periodically to ensure it sparks quickly and consistently. If you notice irregular behavior, address it sooner rather than later. Small issues can snowball into expensive repairs.

Consider keeping a record of system performance. A simple notebook or digital log can help track changes over time. Patterns in performance can alert you to potential problems before they happen.

Preventative maintenance is your best defense against igniter troubles. What small step can you take today to protect your heating system tomorrow?

When To Call A Professional

Some Beckett igniter issues are easy to fix with basic tools. Others require expert knowledge to ensure safety and efficiency. Knowing when to call a professional can save time and prevent costly damage. Igniters handle high voltage and are a critical part of your heating system. Attempting repairs without proper skills can be dangerous.

If you notice repeated issues or unusual system behavior, professional help is essential. A trained technician can diagnose and resolve complex problems quickly. Below are situations where calling a professional is the best choice.

1. Igniter Fails To Spark

An igniter that won’t spark could indicate a wiring or control issue. Professionals have the tools to test electrical components safely. They can identify if the igniter or another part needs replacement. Attempting to fix this yourself may lead to further damage.

2. Persistent Fuel Odors

Strong fuel odors around your unit can signal incomplete combustion. This can happen if the igniter is not functioning properly. A professional can check the burner settings and ensure safety standards are met. Ignoring this issue can pose a fire hazard.

3. Frequent System Lockouts

If your heating system locks out repeatedly, it may be an igniter problem. This could be caused by a misaligned electrode or weak spark. A technician can recalibrate or replace the igniter to restore normal operation. Diagnosing this on your own is often challenging.

4. Visible Damage To The Igniter

Cracks, burns, or corrosion on the igniter are signs of wear. A damaged igniter cannot produce the spark needed for ignition. Replacing it requires expertise to avoid further system damage. A professional ensures the replacement is done correctly.

5. Irregular Flame Patterns

An unstable or flickering flame may be linked to the igniter. This can affect heating performance and increase fuel usage. Technicians can inspect the burner and ignition system for alignment or faults. Proper adjustments ensure optimal operation.

6. Lack Of Proper Tools

Some troubleshooting steps require specialized tools for testing and repair. Without these, diagnosing the issue accurately is difficult. Professionals carry the necessary equipment for precision repairs.

Credit: blog.beckettcorp.com

Conclusion

Regular maintenance keeps your Beckett igniter running smoothly. Always check connections and wiring. Replace worn-out parts promptly to avoid bigger issues. A well-functioning igniter ensures reliable heating performance. Troubleshooting small problems early saves time and money. Don’t hesitate to consult a professional for complex issues.

Safety should always come first during repairs or inspections. Following these steps helps extend your igniter’s lifespan. Keep your heating system efficient and dependable year-round.