Briggs and Stratton engines power many machines. They are reliable, yet issues can arise.

This guide helps you troubleshoot common problems. Briggs and Stratton engines are known for their durability and efficiency. But like all engines, they sometimes face issues. Whether your lawnmower won’t start, or the engine runs rough, this guide is here to help.

We’ll walk you through easy steps to identify and fix problems. Understanding these troubleshooting methods can save you time and money. No need for expensive repairs or replacements. With a bit of know-how, you can keep your engine running smoothly. Let’s dive into the common issues and solutions for Briggs and Stratton engines.

Credit: www.briggsandstratton.com

Common Engine Issues

Common engine issues with Briggs and Stratton engines can be frustrating. Understanding these problems can save you time and effort. In this guide, we will cover some typical issues and provide simple solutions.

Hard Starting

Hard starting is a common issue with Briggs and Stratton engines. This can occur due to various reasons. A dirty air filter often causes this problem. Clean or replace the air filter if it’s clogged. Another cause might be old or bad fuel. Always use fresh fuel to avoid this issue. Check the spark plug too. A faulty spark plug can make the engine hard to start. Replace it if it’s worn out or dirty.

Engine Stalling

Engine stalling is another frequent problem. This can happen if the fuel is not reaching the engine. Ensure the fuel tank is full and the fuel line is clear. A dirty carburetor can also cause stalling. Clean the carburetor to fix this. Sometimes, the problem might be with the air filter. Make sure the air filter is clean and not blocked. Lastly, check the spark plug. A bad spark plug can lead to engine stalling. Replace it if necessary.

Fuel System Problems

Fuel system problems are common in Briggs and Stratton engines. These issues can cause your engine to run poorly or not start at all. Understanding these problems can help you fix them quickly and keep your engine running smoothly.

Fuel Line Blockages

Fuel line blockages occur when dirt or debris clogs the fuel line. This prevents fuel from reaching the engine. Check the fuel line for any visible blockages. If you find any, clean the line thoroughly. Replace the fuel line if it is damaged or heavily clogged. Regular maintenance can prevent fuel line blockages.

Dirty Carburetor

A dirty carburetor can cause serious engine problems. It can prevent the engine from getting the right fuel mixture. This leads to poor performance or starting issues. To fix this, remove the carburetor and clean it with a carburetor cleaner. Make sure to clean all the small parts and passages. Reassemble the carburetor and test the engine. Regular cleaning can prevent carburetor issues.

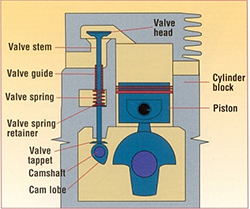

Ignition System Troubles

Briggs and Stratton engines are popular for their reliability and performance. Yet, like all engines, they can face issues. One common problem area is the ignition system. Ignition system troubles can stop your engine from starting or running properly. Below, we explore common ignition system issues and how to troubleshoot them.

Spark Plug Issues

Spark plugs are crucial for starting the engine. If your engine won’t start, check the spark plug first. A dirty or faulty spark plug can cause starting problems. Remove the spark plug and inspect it. Look for dirt, oil, or carbon build-up.

Clean the spark plug if it is dirty. Use a wire brush for cleaning. If the spark plug is damaged, replace it with a new one. Ensure the gap between electrodes is correct. This gap should meet the manufacturer’s specifications.

Ignition Coil Failure

The ignition coil sends power to the spark plug. If the coil fails, the spark plug won’t fire. This can prevent the engine from starting. To test the coil, use a multimeter. Check the resistance levels according to the manual.

If the coil shows abnormal readings, it might be faulty. Replacing the ignition coil can solve the problem. Ensure you use the correct coil for your engine model. An incorrect coil can cause more issues.

Air Filter Concerns

Maintaining your Briggs and Stratton engine is important. One key aspect is the air filter. A clean air filter ensures your engine runs smoothly. Neglecting it can lead to performance issues.

Clogged Air Filter

A clogged air filter can cause serious problems. It restricts the airflow to the engine. This leads to reduced power and efficiency. Here are some signs of a clogged air filter:

- Engine stalls or runs roughly.

- Black smoke from the exhaust.

- Reduced fuel efficiency.

- Difficulty starting the engine.

Regular inspection can prevent these issues. Check the air filter every 25 hours of use. If you operate in dusty conditions, check it more often.

Replacing Air Filter

Replacing the air filter is simple. Follow these steps:

- Turn off the engine and disconnect the spark plug.

- Locate the air filter cover. Unscrew or unclip it.

- Remove the old air filter. Dispose of it properly.

- Insert the new air filter. Ensure it fits snugly.

- Replace the cover and secure it.

- Reconnect the spark plug.

A new air filter can improve engine performance. It also prolongs the engine’s life. Always use the recommended air filter for your engine model.

Pro Tip: Keep a spare air filter on hand. This way, you can replace it as soon as needed.

Oil System Woes

Troubles with the oil system in your Briggs and Stratton engine can lead to severe issues. Understanding these problems helps maintain your engine’s health and performance. Below, we explore two common oil system woes: low oil levels and oil leaks. These issues, if not addressed, can cause significant damage to your engine.

Low Oil Levels

Low oil levels in your Briggs and Stratton engine can result in overheating. This occurs because oil lubricates and cools the engine’s moving parts. Without enough oil, these parts generate excess heat. Check the oil level using the dipstick. Ensure the engine is on a level surface for an accurate reading.

To add oil:

- Turn off the engine and let it cool.

- Remove the oil fill cap.

- Slowly pour the oil into the fill hole.

- Check the level with the dipstick.

Always use the oil type recommended by Briggs and Stratton. This ensures optimal engine performance.

Oil Leaks

Oil leaks are another common issue. Leaks can occur due to worn seals, gaskets, or loose bolts. Check for signs of oil around the engine and on the ground. Identifying the source of the leak is crucial.

Common leak sources include:

- Oil fill tube

- Crankcase gasket

- Oil drain plug

- Oil filter

To fix an oil leak:

- Identify the leak source.

- Tighten any loose bolts.

- Replace worn gaskets or seals.

- Clean the area thoroughly.

If the leak persists, consult a professional mechanic. Keeping your engine clean helps in spotting leaks early.

Credit: www.scribd.com

Cooling System Challenges

Briggs and Stratton engines are known for their reliability and performance. Yet, like all engines, they may encounter cooling system challenges. This can impact their efficiency and lifespan. Understanding these issues can help you maintain your engine better.

Overheating Engine

An overheating engine is a common problem. It happens when the cooling system fails to regulate the engine’s temperature. Overheating can cause severe damage to engine components.

Here are some common reasons for an overheating engine:

- Blocked Air Flow: Dust and debris can block air passages. This restricts air flow, causing the engine to overheat.

- Low Coolant Level: Insufficient coolant can reduce the cooling system’s efficiency. Always check the coolant level before use.

- Faulty Thermostat: A malfunctioning thermostat can prevent coolant from circulating properly. This leads to overheating.

Fan Malfunctions

The engine’s fan plays a crucial role in cooling. It draws air through the radiator to cool the engine. If the fan malfunctions, the engine can overheat quickly.

Common fan issues include:

- Broken Fan Blades: Damaged blades can reduce airflow. Inspect the fan regularly for any damage.

- Electrical Issues: Wiring problems can prevent the fan from operating. Check the electrical connections and repair if needed.

- Fan Motor Failure: The motor can wear out over time. If the fan doesn’t run, the motor might need replacement.

Regular maintenance of the cooling system can prevent these issues. Clean the air passages, check coolant levels, and inspect the fan regularly. This ensures your Briggs and Stratton engine runs smoothly.

Battery And Electrical Issues

Briggs and Stratton engines are reliable, but they can face battery and electrical issues. These issues often cause the engine to fail to start or function poorly. Understanding these problems can help you fix them quickly.

Dead Battery

A dead battery can stop your engine from starting. Check the battery terminals for corrosion. Clean them with a wire brush if needed. Use a multimeter to test the battery voltage. It should read around 12.6 volts.

If the battery is dead, you might need to charge or replace it. Ensure the battery connections are tight. Loose connections can cause the battery to drain quickly.

Electrical Shortages

Electrical shortages can also cause engine problems. Inspect the wiring for any visible damage. Look for frayed wires or loose connections.

Use a multimeter to check for continuity in the wires. Replace any damaged wires immediately. A table of common electrical parts and their issues can help:

| Part | Possible Issue | Solution |

|---|---|---|

| Battery | Dead or Low Voltage | Charge or Replace |

| Wiring | Frayed or Broken | Repair or Replace |

| Connections | Loose or Corroded | Tighten or Clean |

Regular inspection can prevent many electrical issues. Always keep your tools handy for quick fixes.

Maintenance And Prevention

Maintaining your Briggs and Stratton engine can prevent many common issues. Regular maintenance extends the life of your engine and keeps it running smoothly. This guide will cover essential tips for maintenance and prevention.

Regular Inspections

Performing regular inspections is crucial for engine health. Inspect the air filter, spark plug, and oil level frequently. Look for any signs of wear or damage.

- Air Filter: Check monthly. Clean or replace if dirty.

- Spark Plug: Inspect every 100 hours. Replace if worn or damaged.

- Oil Level: Check before each use. Add oil if needed.

Proper Storage Tips

Storing your engine correctly prevents many problems. Follow these steps for proper storage:

- Drain Fuel: Empty the fuel tank to avoid gum deposits.

- Change Oil: Replace old oil to keep engine parts lubricated.

- Clean Engine: Remove dirt and debris to prevent corrosion.

Cover the engine to protect it from dust and moisture. Store in a dry, cool place.

Credit: www.gregsmallengine.com

Frequently Asked Questions

What Causes A Briggs And Stratton Engine To Not Start?

A Briggs and Stratton engine may not start due to fuel issues, spark plug problems, or air filter blockages.

How Do You Fix A Briggs And Stratton Engine That Won’t Stay Running?

Check the fuel supply, clean the carburetor, and ensure the spark plug is working properly.

Why Is My Briggs And Stratton Engine Smoking?

Smoke can be caused by oil overfill, a dirty air filter, or worn-out parts.

How Do I Clean The Carburetor On A Briggs And Stratton Engine?

Remove the carburetor, clean it with carburetor cleaner, and reassemble it carefully.

What Type Of Oil Is Best For Briggs And Stratton Engines?

Use SAE 30 oil for warm temperatures and SAE 5W-30 for colder conditions.

Conclusion

Troubleshooting Briggs and Stratton engines can seem daunting, but it’s manageable. Use this guide to identify common problems. Follow the steps to fix them. Regular maintenance is key. Keep your engine clean. Check for wear and tear. Replace parts as needed.

Always consult your manual. Seek professional help if necessary. With patience and care, your engine will run smoothly again. Happy troubleshooting!