Dealing with a Briggs and Stratton motor issue? Don’t worry.

This guide will help you troubleshoot common problems. Briggs and Stratton motors are known for their reliability and durability. Yet, like any machine, they can sometimes face issues. Whether it’s a startup problem, strange noise, or performance drop, understanding the root cause is key.

This blog aims to provide clear, step-by-step troubleshooting tips. You’ll learn how to diagnose and fix these issues, saving time and money. So, let’s dive in and get your Briggs and Stratton motor running smoothly again!

Credit: www.scribd.com

Common Issues

Troubleshooting a Briggs and Stratton motor can be challenging. Identifying common issues is the first step. This guide will help you understand and fix these problems.

Engine Won’t Start

An engine that won’t start is frustrating. Check the fuel level first. Make sure there’s enough gas. Inspect the spark plug. A dirty or damaged spark plug can prevent starting. Clean or replace it if needed. Also, examine the air filter. A clogged air filter restricts airflow. This can stop the engine from starting. Replace the air filter if it’s dirty.

Engine Stalls

An engine that stalls is another common issue. Begin by checking the fuel. Bad fuel can cause stalling. Drain old fuel and refill with fresh gas. Next, inspect the carburetor. A dirty carburetor can lead to stalling. Clean the carburetor thoroughly. Check the ignition system too. A faulty ignition can cause the engine to stall. Replace any damaged parts in the ignition system.

Overheating Problems

Overheating is a serious issue. It can damage the engine. Start by checking the oil level. Low oil can cause overheating. Add oil if needed. Ensure proper ventilation. Blocked vents can lead to overheating. Clean any debris around the engine vents. Inspect the cooling fins. Dirty cooling fins reduce heat dissipation. Clean the fins to improve cooling.

Preliminary Checks

Troubleshooting a Briggs and Stratton motor requires some preliminary checks. These initial steps help identify common issues that may affect your motor’s performance. Let’s examine the most important areas to inspect first.

Fuel Supply

The fuel supply is a critical component for engine operation. Ensure the fuel tank is full and the fuel is fresh. Old fuel can lead to clogs and poor engine performance. Check the fuel lines for leaks or cracks. Replace any damaged lines to ensure a proper fuel flow.

| Check | Action |

|---|---|

| Fuel level | Fill the tank with fresh fuel |

| Fuel quality | Use new, clean fuel |

| Fuel lines | Inspect and replace if damaged |

Spark Plug Inspection

The spark plug is essential for igniting the fuel-air mixture in the engine. Remove the spark plug and inspect it for damage or wear. A dirty or worn spark plug can prevent the engine from starting. Clean or replace the spark plug as needed. Ensure the spark plug gap is set to the manufacturer’s specification.

- Remove and inspect the spark plug

- Clean or replace if dirty or worn

- Check and set the spark plug gap

Air Filter Condition

The air filter prevents dirt and debris from entering the engine. A clogged air filter can restrict airflow and reduce engine performance. Remove the air filter and inspect it for dirt and damage. Clean the filter if it is reusable or replace it with a new one. Ensure the air filter cover is secure to avoid unfiltered air entering the engine.

- Remove and inspect the air filter

- Clean or replace if clogged or damaged

- Secure the air filter cover

Fuel System Problems

Briggs and Stratton motors are known for their reliability. But, like all engines, they can experience fuel system problems. Understanding these issues can help keep your motor running smoothly. Let’s explore some common fuel system problems you might face.

Clogged Carburetor

A clogged carburetor can cause your engine to run poorly. Dirt and debris can block the carburetor jets. This restricts the flow of fuel. Cleaning the carburetor can help restore proper fuel flow. Regular maintenance prevents future clogs.

Fuel Line Blockages

Fuel line blockages can stop fuel from reaching the engine. This can cause your motor to sputter or not start at all. Inspect the fuel lines for cracks or leaks. Replace damaged lines to ensure a steady fuel supply. Keep the lines clean and free of debris.

Contaminated Fuel

Contaminated fuel can lead to various engine problems. Water or dirt in the fuel can cause poor performance. Always use clean, fresh fuel. Store fuel in a clean, sealed container. This prevents contamination and keeps your engine running smoothly.

Ignition System Troubles

The ignition system is critical for starting your Briggs and Stratton motor. Problems in this system can stop your engine from working. Let’s look at some common issues and how to fix them.

Faulty Spark Plug

A faulty spark plug can cause many problems. It may not create a spark to start the engine. Remove the spark plug and inspect it. Look for signs of wear or damage. If it’s dirty, clean it. If damaged, replace it. Always check the spark plug gap. It should match the specifications in your manual.

Ignition Coil Issues

The ignition coil is vital. It sends the spark to the plug. If the coil fails, the engine won’t start. Test the coil with a multimeter. Compare the reading with the manual. If the reading is outside the range, replace the coil. Also, check for loose or broken connections.

Wiring Problems

Wiring problems can stop the ignition system from working. Inspect all wires for damage or corrosion. Look for loose connections. Replace damaged wires. Tighten any loose connections. Ensure all wires are correctly connected. This can resolve many ignition issues.

Air And Exhaust System

Troubleshooting your Briggs and Stratton motor’s air and exhaust system can seem daunting. But, understanding its basic components can simplify the process. The air and exhaust system ensures your engine breathes well and expels gases efficiently. Let’s dive into common issues you might face.

Blocked Air Filter

A blocked air filter can cause engine troubles. The air filter keeps dirt and debris out of the engine. Over time, it can become clogged. This restricts airflow, leading to poor performance. Check your air filter regularly. Clean or replace it if it looks dirty.

Exhaust Blockages

Exhaust blockages can also affect engine performance. Debris or carbon buildup can block exhaust pipes. This prevents gases from exiting the engine. Inspect the exhaust system. Look for any obstructions. Clear any blockages you find to keep your engine running smoothly.

Muffler Issues

The muffler reduces noise and directs exhaust gases out of the engine. Muffler issues can cause loud noises and reduced performance. Check the muffler for cracks or damage. Replace it if needed. A well-functioning muffler ensures your engine runs quietly and efficiently.

Credit: www.gregsmallengine.com

Mechanical Failures

Mechanical failures in Briggs and Stratton motors can affect their performance. Identifying and fixing these issues is crucial for smooth operation. Below, we discuss some common mechanical problems.

Compression Issues

Compression issues can lead to starting problems or loss of power. These issues occur when the engine fails to maintain the right pressure.

- Check for leaks in the cylinder head gasket.

- Inspect the piston rings for wear or damage.

- Ensure the valves are sealing properly.

Use a compression tester to measure the pressure. Low readings indicate a problem.

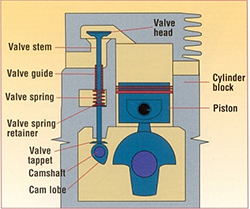

Valve Problems

Valve problems can disrupt the engine’s air-fuel mixture. This can cause poor performance and increased fuel consumption.

- Check for bent or broken valves.

- Inspect the valve seats for wear.

- Ensure the valve springs are not weak or damaged.

Regular maintenance can prevent most valve issues. Replace faulty parts as needed.

Worn-out Pistons

Pistons play a key role in the engine’s operation. Worn-out pistons can cause knocking sounds and reduced power.

- Check for scoring or scratches on the pistons.

- Inspect the piston rings for wear.

- Measure the piston clearance using a feeler gauge.

Replace worn pistons to restore engine efficiency.

Routine Maintenance

Routine maintenance is essential for keeping your Briggs and Stratton motor running smoothly. It helps prevent issues before they start. Proper maintenance ensures your motor remains reliable and efficient. Let’s break down the key aspects of routine maintenance.

Oil Changes

Regular oil changes are vital for your Briggs and Stratton motor. Fresh oil lubricates engine parts, reducing wear and tear. Old oil can cause sludge buildup, leading to poor performance.

To change the oil:

- Warm up the engine for a few minutes.

- Turn off the engine and remove the oil drain plug.

- Drain the old oil into a suitable container.

- Replace the drain plug and add new oil.

- Check the oil level and adjust if necessary.

Filter Replacements

Filter replacements are crucial for maintaining clean air and fuel flow. Dirty filters can restrict airflow and fuel, affecting performance.

Replace air filters every 25 hours of use or yearly, whichever comes first. Fuel filters should be checked regularly and replaced as needed.

| Filter Type | Replacement Frequency |

|---|---|

| Air Filter | Every 25 hours of use or yearly |

| Fuel Filter | Check regularly, replace if dirty |

Regular Inspections

Perform regular inspections to identify potential issues early. This helps avoid costly repairs.

During inspections, check the following:

- Spark plug condition

- Fuel lines for cracks or leaks

- Throttle and choke cables

- Cooling fins and muffler for debris

Replace any worn or damaged parts immediately.

Professional Help

Dealing with Briggs and Stratton motor issues can be frustrating. Sometimes, DIY fixes are not enough. When facing persistent problems, seeking professional help is wise. Expert technicians ensure your motor runs smoothly and safely.

When To Consult A Technician

Not all motor issues are DIY-friendly. Here are some signs that indicate the need for professional intervention:

- Persistent Noise: Unusual sounds that do not fade with basic troubleshooting.

- Overheating: Motor gets too hot despite regular maintenance.

- Starting Issues: Motor fails to start after multiple attempts.

- Smoke: Excessive smoke from the exhaust.

If you notice any of these signs, consulting a technician is crucial. Ignoring them may lead to costly damages.

Finding A Certified Service Center

Choosing the right service center ensures quality repairs. Follow these steps to find a reliable one:

- Check Certification: Ensure the center is Briggs and Stratton certified.

- Read Reviews: Look for customer feedback online.

- Ask for Referrals: Get recommendations from friends or family.

- Visit the Center: Inspect the facility and meet the technicians.

Certified centers use genuine parts and have trained technicians. This guarantees effective repairs and enhances motor longevity.

Cost Considerations

Understanding the cost structure helps in budgeting for repairs. Here are some factors that influence repair costs:

| Factor | Impact on Cost |

|---|---|

| Type of Repair: | Minor fixes are cheaper than major overhauls. |

| Parts Required: | Genuine parts may be pricier but last longer. |

| Labor Charges: | Experienced technicians may charge higher rates. |

Consider all these factors to get a clear picture of the potential expenses. Always request a detailed estimate before starting any repairs.

By following these guidelines, you can ensure your Briggs and Stratton motor gets the professional care it deserves. This not only fixes current issues but also prevents future problems.

Credit: www.briggsandstratton.com

Frequently Asked Questions

How Do I Start My Briggs And Stratton Engine?

Check the fuel level, spark plug, and air filter. Ensure the choke is in the correct position.

Why Is My Briggs And Stratton Engine Not Starting?

Possible reasons include a dirty air filter, bad spark plug, or old fuel. Check and replace if necessary.

What Causes My Briggs And Stratton Engine To Stall?

It might be due to a clogged air filter, bad fuel, or a faulty spark plug. Inspect these parts.

How Do I Maintain My Briggs And Stratton Engine?

Regularly change the oil, clean the air filter, and check the spark plug. Follow the manual.

Why Is My Briggs And Stratton Engine Smoking?

This could be due to oil overfill, clogged air filter, or worn piston rings. Check and fix as needed.

Conclusion

Troubleshooting a Briggs and Stratton motor is manageable with these steps. Regular maintenance prevents many common issues. Simple checks often resolve problems quickly. Keep your motor clean and well-oiled. Always use the correct fuel. Replace spark plugs as needed. Check air filters regularly.

Don’t ignore unusual noises or smells. Addressing issues early saves time and money. Happy motor maintenance!