Are you facing issues with your Briggs and Stratton engine, particularly with its governor? You’re not alone.

Many engine owners encounter similar challenges, and understanding how to troubleshoot can save you time and money. The governor plays a crucial role in regulating the engine speed, ensuring everything runs smoothly. When it malfunctions, it can lead to erratic engine performance or even damage.

In this guide, we’ll dive into simple, effective steps you can take to identify and resolve common governor problems. By the end of this article, you’ll feel more confident in handling your engine issues, potentially turning a frustrating situation into a manageable task. Let’s get your engine back to peak performance!

Credit: www.briggsandstratton.com

Governor Functionality

Understanding the functionality of the governor in a Briggs and Stratton engine is crucial for maintaining optimal performance. The governor acts as a regulator, ensuring the engine maintains a consistent speed regardless of load changes. This mechanism not only enhances efficiency but also prevents potential damage, making it a key component of your engine’s health.

Role In Engine Performance

The governor plays a vital role in engine performance by automatically adjusting the throttle position. Imagine mowing your lawn; you want the engine to power through thick grass without bogging down. The governor steps in to increase fuel supply, keeping the engine running smoothly. It’s like having an invisible helping hand that ensures your engine doesn’t stall under pressure.

Have you ever noticed how your engine adjusts itself when you hit a dense patch of grass? That’s the governor working to keep your engine at a steady pace. Without it, you’d manually have to tweak the throttle every time the load changes. This automatic adjustment not only saves you time but also extends the life of your engine by minimizing wear and tear.

Components Of The Governor System

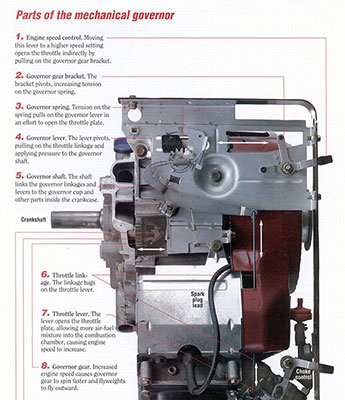

The governor system comprises several key components that work in harmony. These include the governor gear, spool, and linkages. Each part has a specific function, contributing to the overall effectiveness of the system.

The governor gear, often connected to the crankshaft, spins as the engine runs. This movement is crucial for activating the spool, which then regulates the throttle. It’s fascinating how such small parts can have such a significant impact on engine performance.

Linkages connect the governor to the throttle, ensuring precise adjustments. Have you ever tinkered with your engine and noticed these tiny rods moving? They’re the unsung heroes, translating the governor’s actions into tangible changes in speed. Understanding these components can empower you to troubleshoot issues effectively.

Next time you’re dealing with engine performance issues, consider the governor system. Could it be that a small adjustment in one of these components might solve your problem? Understanding how these parts interact could be the difference between a frustrating day and a smooth-running engine.

Credit: www.youtube.com

Common Governor Problems

Briggs and Stratton engines often face governor issues like incorrect speed control and throttle response. These problems can result in uneven engine performance, causing frustration and inefficiency. Proper troubleshooting involves checking linkage, springs, and ensuring that the governor is adjusted correctly for optimal operation.

Common governor problems can affect engine performance. These issues often lead to frustrating experiences for users. Understanding these problems can help in maintaining a smooth-running engine. Below are some common governor problems with Briggs and Stratton engines.Engine Speed Fluctuations

Engine speed fluctuations can be a common issue. This problem occurs when the engine speed varies unexpectedly. It can cause the engine to run inefficiently. Often, this is due to a worn or damaged governor spring. A simple inspection of the spring can reveal if it’s stretched or broken. Replacing the spring usually resolves this issue. Keeping the governor spring in good condition ensures steady engine speed.Idle Issues

Idle issues are another common governor problem. The engine may stall or run rough at idle. This is often due to improper governor adjustment. Checking the governor linkage and making necessary adjustments can help. Sometimes, cleaning the carburetor also resolves idle problems. A well-adjusted governor ensures a smooth idle.Governor Sticking

Governor sticking can cause serious engine problems. The governor may not respond to speed changes. This usually happens when dirt or debris gets inside the governor mechanism. Regular cleaning can prevent this issue. Lubricating the governor parts also helps in smooth operation. Ensuring the governor is clean and lubricated keeps it functioning properly.Diagnosing Governor Issues

Diagnosing governor issues in Briggs and Stratton engines is crucial for smooth operation. The governor regulates engine speed, ensuring consistent performance. Common problems may include erratic speed or poor throttle response. By examining the governor thoroughly, one can pinpoint and resolve issues effectively.

Visual Inspection Techniques

Start by visually inspecting the governor components. Look for wear or damage on parts. Check for loose or missing screws that may affect operation. Ensure all components are properly aligned. Misalignment can cause erratic engine speed.

Testing Governor Linkages

Governor linkages connect to the throttle and carburetor. Test these linkages for smooth movement. They should not be sticking or binding. A gentle push should move them freely. Replace any linkage showing wear or damage. This ensures accurate speed control.

Checking Spring Tension

Inspect the tension of the governor spring. A weak spring affects engine speed regulation. Use a tension gauge if available. Springs should be firm but flexible. If the spring is stretched or broken, replace it immediately. Proper tension ensures optimal engine performance.

Repairing Governor Faults

Briggs and Stratton engine issues often include governor faults. Troubleshooting involves checking linkages, springs, and adjustments. Proper maintenance ensures smooth operation and prevents performance problems.

Repairing the governor faults in your Briggs and Stratton engine can feel like a daunting task, but with some practical guidance, it becomes manageable. Whether you’re a seasoned mechanic or a curious DIY enthusiast, understanding the intricate details of how to adjust, replace, and maintain the governor system is crucial for optimal engine performance. You might have noticed fluctuations in engine speed or erratic behavior. These are signs that your governor might need attention. Let’s dive into some actionable insights to get your engine back in top shape.Adjusting Governor Settings

Properly adjusting the governor settings is pivotal for maintaining a steady engine speed. Begin by loosening the clamp bolt that holds the governor lever to the shaft. You should be able to move the lever freely now. Rotate the throttle plate until it is fully open, then turn the governor shaft in the same direction. Tighten the clamp bolt to secure the lever on the shaft. Test your adjustments by running the engine and observing any changes in speed. Notice any improvements? This simple adjustment can make a world of difference.Replacing Damaged Parts

Sometimes, adjustments aren’t enough, and damaged parts need replacing. Inspect the governor spring, lever, and linkage for any signs of wear and tear. If you find a broken or bent spring, it’s time to replace it. This might be a good moment to reflect on how often you check these parts. Could regular inspections prevent future breakdowns? Visit your local hardware store or order parts online, ensuring you choose quality components. A small investment in parts can save you a headache down the road.Lubrication And Maintenance Tips

Lubrication is the unsung hero in maintaining your governor’s efficiency. Apply a few drops of oil to the governor shaft and linkages, ensuring smooth operation and reducing friction. Are you keeping up with regular maintenance? A quick wipe down and lubrication every few months can extend the life of your engine significantly. Consider setting a reminder for maintenance checks. Wouldn’t it be satisfying to know your engine is always running smoothly because of your proactive care? In addressing these governor faults, remember that persistence and attention to detail are key. Each small repair adds up to a well-functioning engine, ready to tackle any task you throw its way.Preventive Measures

Ensure smooth engine operation with regular checks of the Briggs and Stratton governor system. Inspect for wear and proper adjustment. Addressing issues early prevents costly repairs and maintains optimal performance.

When it comes to ensuring the longevity and efficiency of your Briggs and Stratton engine, preventive measures are your best ally. These steps not only prevent unexpected breakdowns but also enhance the overall performance of your machinery. By focusing on consistent care and timely upgrades, you can avoid the headache of governor issues and enjoy a smoother engine operation.Regular Maintenance Practices

Regular maintenance is the cornerstone of a well-functioning engine. Make it a habit to check and change the oil, clean air filters, and inspect spark plugs. These simple steps can prevent debris build-up that might interfere with the governor’s operation. Schedule routine inspections to catch potential issues early. During a recent check-up, I noticed a minor wear in the linkage, which was easily fixed with a quick adjustment. This small action prevented a larger problem down the line. Create a maintenance checklist. This helps you stay on track and ensures no step is overlooked. A little effort now saves a lot of hassle later.Monitoring Engine Performance

Pay close attention to your engine’s performance. Listen for unusual sounds or changes in speed, which might indicate a governor issue. Regularly check the RPMs to ensure the engine runs smoothly. If you notice fluctuations, it might be time to look at the governor settings. Ask yourself: is the engine starting easily and running consistently? If not, this could be an early sign that the governor needs attention.Upgrading Governor Components

Consider upgrading governor components for enhanced performance. Sometimes, older parts wear out and need replacing for optimal functionality. Newer components can offer better precision and durability. I upgraded my governor springs last year, and the improvement in engine stability was noticeable. Research and choose high-quality parts that fit your engine model. Investing in quality components can save you from frequent repairs in the future. Taking these preventive measures can significantly extend your engine’s life and efficiency. Have you checked your engine today?Credit: www.lawnsite.com

Conclusion

Troubleshooting a Briggs and Stratton governor can be straightforward. Start by checking the basics. Ensure the springs and links are intact. Adjust the governor lever if needed. This can stabilize your engine performance. Regular maintenance prevents future issues. Always refer to the engine manual.

It offers specific guidance for your model. Remember, patience and care are key. With these steps, your engine should run smoothly. Keep your tools handy. And don’t hesitate to seek expert help if needed. Safe and efficient engines make for a successful project.

Happy troubleshooting!