Imagine setting up your Brother label maker, eager to organize your space, only to find it isn’t working as expected. Frustrating, right?

But don’t worry—you’re not alone. Many users encounter hiccups with their label makers, and the good news is, most issues have simple solutions. In this guide, we’ll walk you through the most common troubleshooting steps, ensuring you can get back to labeling efficiently and stress-free.

Whether you’re dealing with printing errors, connectivity issues, or unexpected shutdowns, we’ve got you covered. Dive in, and let’s tackle those pesky problems together!

Common Issues

Brother label makers often face issues like jamming or connectivity problems. Regular cleaning can help prevent these issues. Updating the software may resolve connectivity challenges effectively.

When you rely on your Brother label maker for organization, a glitch can disrupt your productivity. Whether it’s a label jam, poor print quality, or power problems, knowing how to troubleshoot these common issues can save you time and frustration. Let’s dive into practical solutions that can get your label maker back on track.Label Jams

Label jams are a frequent issue and can be incredibly frustrating. You might notice your label tape getting stuck or misaligned. First, check if the tape is properly loaded. Ensure the roll is not twisted and fits snugly in its compartment. If the jam persists, gently remove the tape and inspect for any debris inside the label maker. Cleaning with a soft cloth can help. Have you ever wondered if a simple cleaning could be the key to smoother operation? It often is.Poor Print Quality

Poor print quality can turn perfectly good labels into unreadable smudges. A common cause is dirty print heads. Simply wipe the print head with a cotton swab dipped in alcohol. This quick fix can improve clarity significantly. Another issue might be low-quality tape. Ensure you’re using genuine Brother label tape for optimal results. Have you noticed how using the right tape can make a world of difference? It’s worth considering.Power Problems

Power problems can halt your label-making process entirely. If your device won’t turn on, check the batteries. Are they inserted correctly and fresh? Sometimes, a simple battery replacement can do the trick. If the problem persists, try using a power adapter to rule out battery issues. Have you ever thought about how a small adjustment like this can restore functionality quickly? It’s often overlooked but can be effective. By addressing these common issues, you can keep your Brother label maker running smoothly. What problem-solving strategies have worked for you in the past? Your insights might help others in the same predicament.

Credit: www.enkoproducts.com

Label Jam Solutions

Brother label makers are handy tools for organizing and labeling. Sometimes, they face label jams, causing frustration. Understanding how to fix these jams is crucial for smooth operation. Below, you will find effective solutions to tackle label jams in Brother label makers.

Clearing The Jam

Start by turning off the label maker. Open the cover gently to access the jammed label. Carefully pull the jammed label out without tearing it. Use tweezers if needed for precision. Ensure all pieces are removed completely. Once cleared, close the cover securely. Test with a new label to ensure functionality.

Preventing Future Jams

Choose quality label tape for best results. This reduces the risk of jams. Ensure the label tape is properly aligned. Follow the guide on the label maker for accuracy. Keep the label maker clean and free of debris. Regular cleaning extends the life of the device. Store the label maker in a dust-free environment for optimal performance.

Improving Print Quality

Struggling with print quality on your Brother label maker? You’re not alone. Many users face this issue. Improving print quality ensures your labels are clear and professional. Let’s explore ways to enhance your Brother label maker’s print quality.

Adjusting Print Settings

Start with the print settings. These settings impact the label’s appearance. Access the settings menu on your device. Look for print quality options. Choose a higher quality setting for better results. Adjust the darkness level if needed. This can help create sharper prints. Experiment with different settings. Find what works best for your labels.

Cleaning The Print Head

A dirty print head affects print quality. Regular cleaning is essential. First, turn off your label maker. Open the machine to access the print head. Use a soft cloth or cotton swab. Dampen it with alcohol or water. Gently wipe the print head. Remove any dust or residue. Allow it to dry completely. Close the machine and test print. Notice the improved clarity and detail. Repeat as needed for optimal results.

Credit: www.youtube.com

Resolving Power Issues

Troubleshoot power issues in Brother label makers easily. Check battery placement and power connections. Ensure the power cord is secure.

Resolving power issues with your Brother label maker can be a straightforward task, but it’s essential to pinpoint the exact problem. Imagine the frustration of needing to label your files, only to find your label maker won’t turn on. Let’s dive into practical solutions that can save you time and effort.Battery Replacement

First, consider the batteries. Have you replaced them recently? Old or depleted batteries are a common culprit. Replacing them can often solve the issue. Check your label maker’s battery compartment. Are the batteries inserted correctly? Sometimes, a simple adjustment can make a big difference. Using fresh batteries not only powers up your device but can also improve its performance. It’s a quick fix, yet highly effective.Checking Power Connections

Another area to explore is power connections. Ask yourself: Is the power cord securely connected? Loose connections might prevent your device from turning on. Inspect the cord for any signs of damage. A frayed or broken cord needs immediate replacement. This ensures consistent power flow. If using an adapter, ensure it’s compatible with your model. An incorrect adapter can lead to power issues. Double-check the specifications to avoid this pitfall. Troubleshooting doesn’t have to be daunting. By focusing on these areas, you can resolve power issues quickly and get back to labeling. What steps will you take today to keep your label maker running smoothly?Software And Connectivity Fixes

Experiencing issues with your Brother label maker can be frustrating. Software and connectivity problems often disrupt smooth operations. This section guides you through essential fixes to ensure your label maker functions seamlessly.

Updating Firmware

Firmware updates enhance performance and fix bugs. To update your Brother label maker’s firmware, visit the Brother support website. Download the latest firmware version specific to your model. Follow the instructions carefully during installation. A successful update can resolve many issues. Keep your label maker up-to-date for optimal functionality.

Troubleshooting Usb Connection

USB connection issues are common. First, check if the USB cable is securely connected. Try using a different USB port on your computer. Ensure the USB cable is not damaged. If problems persist, reinstall the USB driver. Access your computer’s device manager and locate the USB driver. Right-click and choose ‘Update driver’ or ‘Uninstall driver’, then restart your computer. This often solves connectivity issues.

Credit: support.brother.com

Tape Cartridge Problems

Brother label makers are handy tools that help you organize your life, but they can sometimes present tape cartridge problems. These issues can be frustrating, especially when you’re in the middle of a project. Understanding how to troubleshoot these problems can save you time and stress. Let’s explore how to tackle common tape cartridge issues efficiently.

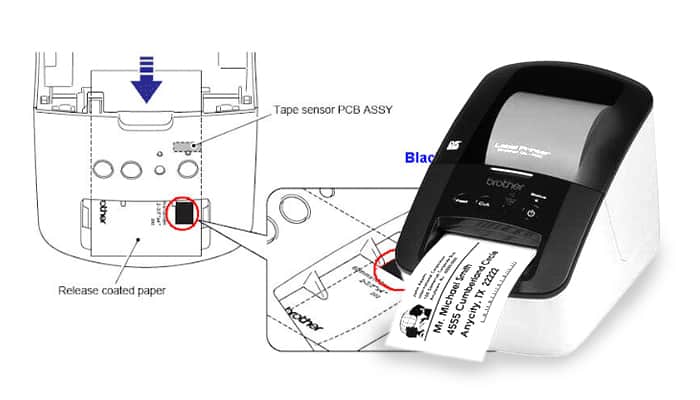

Ensuring Proper Installation

Imagine the excitement of getting a new label maker, only to face installation issues with the tape cartridge. Proper installation is crucial for smooth operation. When installing the tape cartridge, make sure the tape feeds correctly and isn’t twisted or jammed. A simple trick is to pull out a small length of tape before inserting the cartridge. This ensures it’s ready to print once installed.

If you’ve installed the cartridge but it’s not working, check if the cartridge clicks firmly into place. Sometimes, it may appear installed but isn’t fully seated. A gentle push can make all the difference. Have you ever wondered if you’re pressing too hard or too soft? Finding that balance is key.

Handling Tape Compatibility

Not all tapes are created equal. Using the wrong tape can lead to printing errors or even damage the label maker. Brother label makers have specific tape requirements, so ensure you’re using compatible cartridges. Check your model number and match it with the tape specifications. This can prevent unnecessary headaches and wasted labels.

Have you ever used a tape that seemed perfect but didn’t work? It might be tempting to try different tapes, but sticking to the recommended types can save you from long-term issues. If a tape isn’t working, double-check the packaging for compatibility information. This simple step can prevent a lot of trial and error.

By focusing on proper installation and compatibility, you can minimize tape cartridge problems and keep your labeling projects on track. Have you faced any other challenges with your label maker? Share your experiences and solutions below!

Maintenance Tips

Keeping your Brother label maker in top condition is essential. Regular maintenance ensures smooth operation and extends its lifespan. These maintenance tips help troubleshoot issues and keep your label maker functioning efficiently.

Regular Cleaning

Dust and debris can affect label maker performance. Clean the exterior with a soft, damp cloth. Avoid harsh chemicals which might damage the surface. Open the label compartment and gently remove any label residue. Use a cotton swab dipped in alcohol to clean the print head. This prevents smudging and keeps prints clear.

Safe Storage Practices

Proper storage ensures your label maker stays in good condition. Store it in a cool, dry place away from direct sunlight. High temperatures can warp plastic components. Keep it away from moisture to prevent internal damage. Protect it from dust by covering it when not in use. Ensure the label cassette is removed if storing for long periods.

Conclusion

Solving Brother label maker issues is easier than it seems. Basic checks often fix common problems. Ensure the machine is clean and well-maintained. Regularly update the software for optimal performance. Double-check connections to avoid simple errors. Seek expert help if problems persist.

This ensures long-term reliability. Remember, patience and careful inspection help solve most issues. Your label maker can work efficiently again. Troubleshooting doesn’t have to be complicated. With these tips, you can handle any challenge confidently. Keep your label maker running smoothly.

Enjoy hassle-free labeling tasks.