When your Cat P5000 forklift isn’t responding as it should, it can throw a wrench into your productivity. You rely on this robust machine to keep your operations running smoothly, but when the throttle control switch starts acting up, it can be frustrating and time-consuming to figure out what’s wrong.

Don’t worry; you’re not alone in facing these challenges. Many have been in your shoes, scratching their heads over why their reliable forklift suddenly seems uncooperative. You’ll discover straightforward troubleshooting steps to tackle the throttle control switch issues. You’ll feel empowered knowing how to identify the problem, fix it, and get your forklift back on track.

Keep reading, and you’ll uncover the secrets to maintaining your Cat P5000’s efficiency and reliability, ensuring your workflow stays uninterrupted.

Common Throttle Control Issues

Dealing with throttle control issues in your Cat P5000 can be frustrating, especially when you rely on smooth operation for your daily tasks. Understanding the common problems and how to troubleshoot them can save you time and effort. Whether it’s unresponsive throttle or erratic speed changes, being informed can make all the difference.

Unresponsive Throttle

Ever pushed the throttle and felt like you were talking to a brick wall? You’re not alone. An unresponsive throttle can often stem from wiring issues or a faulty sensor. Check the connections first. A loose wire might be all that’s causing your headache. If everything seems connected, consider looking into the sensor. It’s a small component that packs a punch in terms of impact.

Erratic Speed Changes

Erratic speed can turn a smooth ride into a roller coaster. Imagine driving with the throttle behaving like a mood swing. This usually points to problems with the throttle position sensor or calibration issues. You might want to recalibrate the throttle. It’s a quick fix that can stabilize the speed. If calibration doesn’t work, replacing the sensor may be necessary.

Intermittent Power Loss

Power loss can leave you stranded, wondering what went wrong. Is the engine gasping for air or fuel? Check the fuel lines and air filters. They might be clogged. A clean filter can breathe life back into your engine. Also, inspect the ignition system. Sometimes a worn-out spark plug can be the culprit. Have you ever overlooked such a small detail?

Remember, troubleshooting is about patience and precision. Could these issues be pointing to something bigger, like a sign of wear and tear? You don’t have to be a mechanic to solve these problems, but knowing where to look helps. Share your experiences or ask questions. Your insight could assist others facing similar challenges.

Credit: www.conger.com

Diagnostic Tools And Techniques

Diagnosing issues with the Cat P5000 throttle control switch requires the right tools and techniques. Proper diagnostics can save time and prevent costly repairs. This section covers both software and manual inspection methods.

Using Diagnostic Software

Diagnostic software is crucial for identifying electronic issues. It connects to the vehicle’s computer system. This software reads error codes and provides detailed information. These codes help pinpoint the problem quickly. Many professionals rely on these tools for accurate diagnostics.

Ensure your software is updated. Older versions may miss newer error codes. Always refer to the manufacturer’s guidelines. This ensures the software is compatible with your Cat P5000 model.

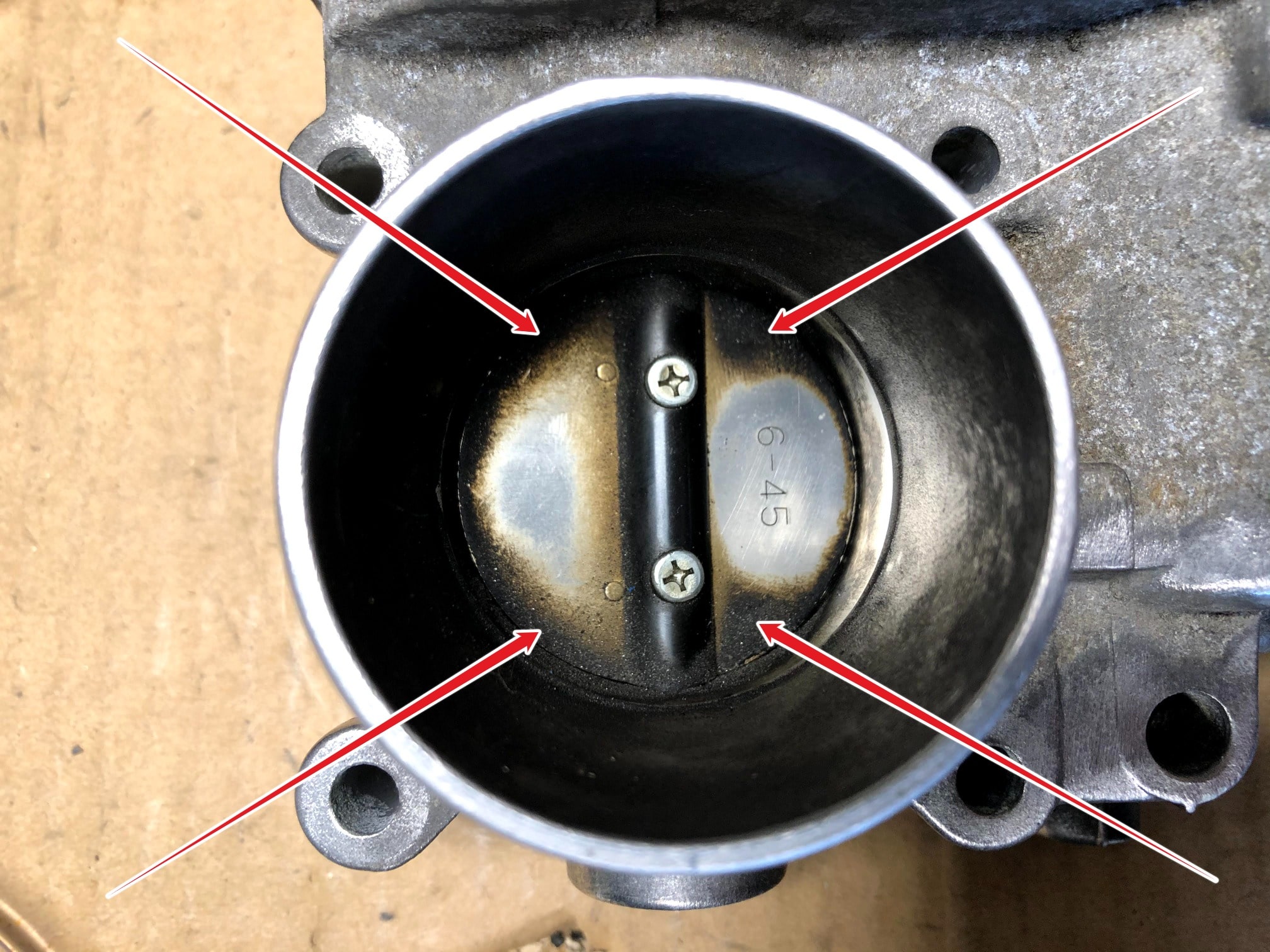

Manual Inspection

Manual inspection is a hands-on approach. Start by examining the throttle control switch. Look for any physical damage or wear. Check the wiring connections for looseness or corrosion. A simple loose connection can cause major issues.

Listen for unusual noises when the switch is activated. Unusual sounds can indicate a malfunction. Ensure all components are clean and free of debris. Dust and dirt can impede proper functioning.

Simple Fixes For Throttle Problems

Experiencing throttle control issues with your Cat P5000 can be frustrating, but you don’t always need a technician to solve the problem. Often, simple fixes can address these issues effectively. By focusing on a few key areas, you can get your machine running smoothly again. Let’s dive into practical solutions for throttle problems.

Checking Connections

One of the simplest steps is to check the connections. Loose or corroded wiring can lead to erratic throttle behavior. You might be surprised how often this is the culprit. Carefully inspect the wiring harness for signs of wear or looseness. Tighten any loose connectors and replace damaged wires. This straightforward check can sometimes resolve the issue entirely.

Resetting The Control System

Resetting the control system can clear minor glitches that might cause throttle issues. Have you ever rebooted your computer to solve a problem? The same concept applies here. Locate the reset switch or button, usually found on the dashboard or under the seat. Press it for a few seconds and watch for any changes in throttle response. This reset can often restore normal operation without further intervention.

Cleaning And Maintenance Tips

Regular cleaning and maintenance are crucial for preventing throttle problems. Dust and debris can accumulate and interfere with the throttle sensor. Use a soft brush and compressed air to clean around the throttle assembly. Have you ever noticed how a clean kitchen makes cooking easier? Similarly, a clean throttle system enhances performance. Regularly check for buildup and clean as needed to ensure smooth operation.

By addressing these areas, you can often solve throttle control issues yourself. Are there other simple fixes you’ve tried that worked? Share your experiences and help others keep their machines in top shape.

Credit: www.vanderhaags.com

When To Seek Professional Help

Experiencing persistent issues with the Cat P5000 throttle control switch? Consider professional help when troubleshooting efforts fail. Expert technicians can efficiently diagnose and resolve complex problems, ensuring optimal performance and safety for your equipment.

When dealing with the Cat P5000 throttle control switch, there are times when DIY troubleshooting just isn’t enough. Knowing when to seek professional help can save you time, money, and frustration. It’s crucial to recognize the signs that indicate a problem beyond your expertise. Let’s dive into identifying these signs and find out how to reach out to the right professionals for help.Signs Of Major Issues

Sometimes, it’s easy to dismiss a minor glitch, but ignoring signs of a major issue can lead to costly repairs. Is the throttle control switch completely unresponsive? This might indicate a deeper electrical problem. Does the throttle act erratically even after a reset? Persistent issues like these often require professional attention. Strange noises or burning smells? These are red flags. Your equipment might be heading for a significant malfunction.Finding Qualified Technicians

Locating a qualified technician doesn’t have to be daunting. Start by checking your equipment’s warranty. Often, manufacturers have a list of certified professionals who can assist you. Ask for recommendations from fellow Cat P5000 owners. Personal experiences can guide you to reliable service providers. Ensure the technician has specific experience with Cat machinery. An expert familiar with your equipment model can diagnose and fix issues more efficiently. Have you considered the long-term costs of neglecting professional help? A quick assessment by a qualified technician can prevent more severe problems down the line, ensuring your Cat P5000 continues to run smoothly.

Credit: www.epcatalogs.com

Conclusion

Troubleshooting the Cat P5000 throttle control switch can seem daunting. But with patience and the right steps, it’s manageable. Always check connections first. They can often be the main issue. Inspect the switch and wiring for any damage. Replace faulty components promptly to ensure safety.

Regular maintenance can prevent future problems. Keep your forklift running smoothly. Your efforts will pay off in the long run. Remember, a well-maintained machine is more reliable. Stay proactive and attentive to your equipment’s needs. This will ensure its longevity and efficiency.