CAV injection pumps are crucial for diesel engines. They ensure fuel is delivered efficiently.

Experiencing issues with your CAV injection pump can be frustrating. Your engine may fail to start, run rough, or lack power. Understanding how to troubleshoot these problems can save time and money. This guide will help you identify common issues and their solutions.

We’ll cover symptoms, potential causes, and steps to fix them. Whether you’re a seasoned mechanic or a DIY enthusiast, this information will be useful. Let’s dive into the essential aspects of CAV injection pump troubleshooting, ensuring your engine runs smoothly and reliably.

Credit: www.youtube.com

Introduction To Cav Injection Pumps

Cav injection pumps are essential components in diesel engines. They play a crucial role in the fuel injection system. Understanding these pumps helps maintain engine performance and efficiency.

Importance In Diesel Engines

Cav injection pumps deliver precise fuel amounts to the engine. This ensures optimal combustion. Proper fuel delivery improves engine power and reduces emissions. Efficient fuel injection is vital for diesel engine health.

Common Issues Faced

Cav injection pumps can face several issues. One common problem is air leaks. Air in the fuel system affects performance. Another issue is worn-out seals. This can cause fuel leaks. Dirty fuel can also clog the pump. This reduces efficiency and causes engine problems. Regular maintenance prevents these issues.

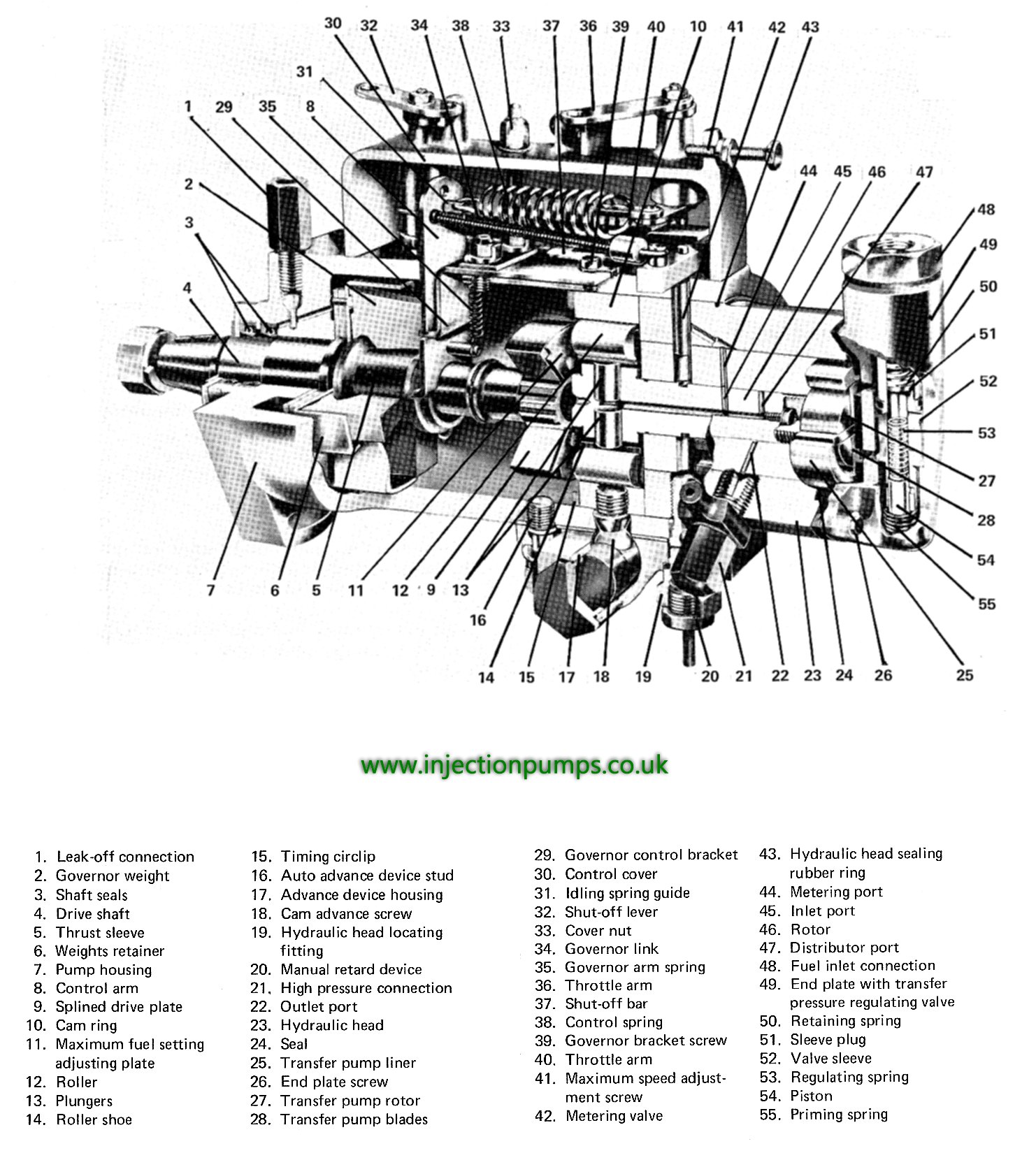

Credit: thefarmingforum.co.uk

Symptoms Of Cav Injection Pump Problems

Identifying issues with your Cav injection pump is crucial. Early detection helps prevent severe damage. In this section, we will explore common symptoms. These include engine performance issues and unusual noises.

Engine Performance Issues

One of the main symptoms of Cav injection pump problems is engine performance issues. These issues can manifest in several ways:

- Poor acceleration: The vehicle may struggle to pick up speed.

- Rough idling: The engine may feel rough or uneven when idling.

- Stalling: The engine may stop running unexpectedly.

- Hard starting: The engine may take longer to start.

These symptoms indicate fuel delivery problems. The injection pump may not be working correctly. Addressing these issues early can save you from costly repairs.

Unusual Noises

Unusual noises from the engine can also signal Cav injection pump problems. Listen for these specific sounds:

- Knocking: A repetitive knocking noise can indicate pump issues.

- Squealing: High-pitched squeals suggest possible pump failure.

- Grinding: Grinding noises can mean internal pump damage.

These noises are warning signs. They should not be ignored. Inspecting the pump immediately can prevent further damage.

Preliminary Checks

Before diving into complex diagnostics, start with some preliminary checks for your Cav injection pump. These checks can often identify straightforward issues and save you time and resources.

Visual Inspection

Begin with a visual inspection of the injection pump. Look for obvious signs of wear or damage. Check for loose or damaged connections. Inspect the pump body for cracks or leaks. Ensure all bolts and fittings are secure.

Fuel Quality Check

Next, perform a fuel quality check. Poor fuel quality can cause many problems. Ensure the fuel is free from water and contaminants. Check the fuel filter for clogs. Replace the filter if needed. Verify the fuel meets the required specifications.

Diagnosing Fuel Delivery Problems

Experiencing issues with your Cav injection pump? Diagnosing fuel delivery problems can seem daunting. But breaking down the process into manageable steps can help. Start by understanding the basic components involved. Then, focus on identifying any air leaks and inspecting the fuel lines. These steps will guide you to find and fix the problem.

Checking For Air Leaks

Air leaks can disrupt fuel delivery. To check for air leaks, begin by examining the fuel system. Ensure all connections are tight.

- Inspect the fuel filter for cracks.

- Examine the fuel pump for any signs of wear.

- Check the fuel tank cap. Make sure it is sealed properly.

Use soapy water to detect leaks. Apply it to the connections and look for bubbles. Bubbles indicate air escaping. This shows a leak. Fix any leaks you find. This ensures the fuel system is airtight.

Inspecting Fuel Lines

Next, inspect the fuel lines. Fuel lines transport fuel from the tank to the engine. Any damage can disrupt this process.

- Check for visible cracks or wear.

- Ensure the lines are not kinked or bent.

- Look for signs of fuel leakage along the lines.

If you find damaged lines, replace them immediately. Use high-quality fuel lines to ensure durability. Properly installed fuel lines enhance fuel delivery. They keep your Cav injection pump running smoothly.

By focusing on these steps, you can effectively diagnose and resolve fuel delivery problems. Ensuring an airtight system and intact fuel lines is key. This keeps your Cav injection pump performing at its best.

Assessing Pump Timing

Assessing pump timing is crucial for the proper functioning of your CAV injection pump. Incorrect timing can lead to poor engine performance and reduced fuel efficiency. You can solve timing issues with the right tools and a step-by-step guide.

Timing Adjustment Tools

Before you start, gather the necessary tools. You will need a timing light, a wrench set, and a timing pin. These tools will help you accurately adjust and check the timing of your CAV injection pump.

Step-by-step Timing Guide

Follow these steps to assess and adjust the pump timing:

First, locate the timing marks on the pump and engine. These marks are usually indicated with a line or dot.

Next, use the timing pin to lock the engine at the correct timing position. This step ensures the engine remains stationary during adjustment.

Then, use the wrench set to loosen the bolts securing the pump. This allows for movement and adjustment of the pump.

After that, rotate the pump slightly to align the timing marks. Use the timing light to verify the alignment.

Finally, once the marks are aligned, tighten the bolts to secure the pump. Remove the timing pin and start the engine to check the performance.

Following these steps ensures your CAV injection pump operates at optimal timing.

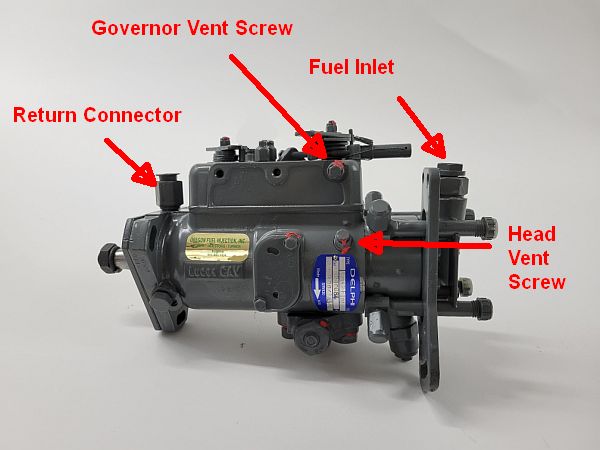

Credit: oregonfuelinjection.com

Cleaning And Maintaining The Pump

Cleaning and maintaining your CAV injection pump keeps your engine running smoothly. Proper upkeep extends the pump’s lifespan and ensures optimal performance. Below are some essential steps and tips to help you maintain your CAV injection pump effectively.

Regular Maintenance Tips

Regular maintenance is key to keeping your CAV injection pump in good shape. Here are some tips:

- Check fuel filters regularly for clogs.

- Inspect fuel lines for leaks or damage.

- Ensure the pump is lubricated properly.

- Monitor the engine’s performance and address any irregularities promptly.

Cleaning Procedures

Cleaning the CAV injection pump requires attention to detail. Follow these steps:

- Disconnect the pump from the engine.

- Use a clean, soft brush to remove debris from the pump’s exterior.

- Wipe down the pump with a damp cloth to eliminate any remaining dirt.

- Inspect and clean the fuel inlet screen to ensure it is free of blockages.

- Reassemble the pump and reconnect it to the engine.

Regular cleaning and maintenance of your CAV injection pump prevent common issues. Implement these practices to keep your engine running efficiently.

Replacing Faulty Parts

The CAV injection pump is crucial for engine performance. When it fails, replacing faulty parts becomes necessary. This guide focuses on identifying wear and tear, and sourcing replacement parts. Read on to ensure your engine runs smoothly.

Identifying Wear And Tear

Identifying wear and tear on your CAV injection pump is the first step. Look for obvious signs of damage. Examine the pump body for cracks or leaks. Check the seals and gaskets for wear.

Use a flashlight to inspect small parts. Look for corrosion or rust. Pay attention to the plunger and delivery valve. Any signs of damage indicate the need for replacement.

Sourcing Replacement Parts

Once you identify faulty parts, you need to source replacements. Start by checking the manufacturer’s website. They often have parts lists and diagrams.

Local auto parts stores may also carry what you need. Bring the old part for comparison. This ensures you get the correct replacement.

Online stores are another option. Websites like eBay and Amazon offer a variety of parts. Always check reviews and ratings before purchasing. Use OEM parts for the best fit and performance.

| Source | Pros | Cons |

|---|---|---|

| Manufacturer’s Website | Accurate, reliable, OEM parts | Higher cost, longer shipping |

| Local Auto Parts Store | Immediate availability, no shipping | Limited selection, possible higher cost |

| Online Stores | Wide selection, competitive prices | Shipping time, variable quality |

Replacing faulty parts in your CAV injection pump will restore its function. Identify wear and tear early to prevent further damage. Sourcing quality replacement parts ensures long-lasting repairs.

Professional Help And Advanced Solutions

Dealing with a faulty CAV injection pump can be frustrating. Sometimes, basic troubleshooting steps don’t fix the issue. In such cases, seeking professional help and advanced solutions becomes necessary. This section will guide you on when to consult a specialist and explore the latest technological fixes.

When To Consult A Specialist

If your CAV injection pump shows persistent problems, it’s time to call a specialist. Signs like unusual noises, engine misfires, or fuel leaks need expert attention. Professionals have the right tools and knowledge to diagnose these issues accurately. They can save you time and prevent further damage. Regular maintenance checks by a specialist can also ensure your pump runs smoothly.

Latest Technological Fixes

The automotive industry constantly evolves, and so do the solutions for CAV injection pumps. Modern diagnostic tools can quickly identify the root cause of problems. Advanced software updates can also improve the pump’s performance. Some specialists use high-tech equipment to clean and recalibrate the pump. These methods ensure optimal fuel efficiency and engine performance. Keeping up with the latest technological fixes can extend the lifespan of your CAV injection pump.

Preventive Measures

Regular checks can prevent issues with the Cav injection pump. Clean filters and replace worn-out parts to ensure smooth operation. Proper maintenance extends the pump’s life and improves performance.

Preventive measures are key to keeping your Cav injection pump in top shape. Regular inspections and using high-quality fuel can save you from costly repairs. These steps ensure your pump runs smoothly and lasts longer.Routine Inspections

Routine inspections are essential. Check your Cav injection pump regularly. Look for any leaks or unusual noises. Make sure all parts are clean and well-lubricated. This helps spot problems early. It saves you from bigger issues later.Inspect the pump fittings. Ensure they are tight and secure. Loose fittings can cause leaks. Leaks can lead to fuel loss and pump damage. Checking these regularly can prevent such issues.Using Quality Fuel

Using quality fuel is crucial. Poor fuel can harm your Cav injection pump. It may contain impurities that clog the pump. Always use clean, high-grade fuel. This ensures smooth operation.Store fuel properly. Keep it in clean, sealed containers. Dirty fuel can introduce contaminants into your pump. This can lead to wear and tear. Regularly check your fuel source for quality.Following these preventive measures helps maintain your Cav injection pump. It ensures efficient performance and longevity. “`Frequently Asked Questions

What Are Common Symptoms Of A Faulty Cav Injection Pump?

A faulty CAV injection pump may cause rough idling, difficulty starting, reduced power, and excessive smoke.

How Can I Diagnose A Cav Injection Pump Issue?

Check for fuel leaks, listen for unusual noises, and test fuel pressure. Consult a professional if unsure.

Why Is My Engine Losing Power?

Engine power loss might be due to a clogged filter, air in the fuel system, or a failing injection pump.

How Often Should I Service My Cav Injection Pump?

Service your CAV injection pump every 2,000 to 3,000 hours of operation to ensure optimal performance.

Can I Repair A Cav Injection Pump Myself?

Basic maintenance is possible, but complex repairs need professional attention to avoid further damage.

Conclusion

Maintaining your CAV injection pump ensures your engine runs smoothly. Regular checks help spot issues early. Addressing problems quickly prevents bigger failures. Keep your engine manual handy for reference. Follow the steps carefully to troubleshoot effectively. Clean and replace parts as needed.

Seek professional help if problems persist. A well-maintained pump extends your engine’s life and performance. Stay proactive and enjoy a reliable vehicle.