The Chelsea PTO, or Power Take-Off, is essential for many vehicles. It transfers power from the engine to auxiliary equipment.

Troubleshooting issues with the Chelsea PTO can be daunting. Problems can disrupt your work and lead to downtime. Understanding common issues and their solutions is vital. This blog will guide you through the most frequent problems with the Chelsea PTO.

We will provide clear steps to diagnose and fix these issues. Whether you are a mechanic or a vehicle owner, this information will be useful. Let’s dive into the world of Chelsea PTO troubleshooting and keep your equipment running smoothly.

Introduction To Chelsea Pto

The Chelsea PTO (Power Take-Off) is a crucial component for many industrial vehicles. It transfers power from the vehicle’s engine to auxiliary equipment. Understanding its function and troubleshooting can save time and money.

What Is A Pto?

A Power Take-Off (PTO) is a device that connects to the vehicle’s transmission. It allows the transfer of mechanical power to another piece of equipment. This equipment could be a hydraulic pump, generator, or other machinery.

There are different types of PTOs:

- Mechanical Shift PTO: Operated manually using levers or cables.

- Electric Shift PTO: Uses electrical controls for engagement.

- Hydraulic Shift PTO: Engages using hydraulic fluid pressure.

Importance Of Chelsea Pto

The Chelsea PTO is vital for operating auxiliary equipment. It ensures efficient power transfer from the vehicle’s engine. This efficiency leads to better performance and reliability.

Some key benefits include:

- Improved vehicle versatility.

- Enhanced productivity of industrial tasks.

- Reduced operational costs due to efficient power use.

Regular maintenance and troubleshooting keep the PTO in good condition. It helps avoid unexpected breakdowns and ensures smooth operations.

Common Pto Issues

Experiencing problems with your Chelsea PTO? Understanding common issues can help. Addressing these problems early can prevent bigger headaches. Let’s explore some typical issues and how to tackle them.

Leaking Seals

Leaking seals are a frequent issue in PTO systems. They can cause fluid loss and other complications. Here are some signs of leaking seals:

- Visible fluid around the PTO unit.

- Reduced performance of the PTO system.

- Unusual noises during operation.

To fix leaking seals, follow these steps:

- Identify the source of the leak.

- Replace the damaged seal with a new one.

- Check the fluid levels and top up if necessary.

Overheating Problems

Overheating can damage your PTO and other vehicle systems. Key signs of overheating include:

- High temperature readings on the PTO gauge.

- Burning smell near the PTO unit.

- PTO shutting down unexpectedly.

To address overheating, you can:

- Check for adequate ventilation around the PTO.

- Ensure the fluid levels are correct.

- Inspect the PTO for any blockages or debris.

By understanding these common PTO issues, you can maintain your system better. Regular checks and timely repairs can keep your PTO running smoothly.

Diagnosing Pto Problems

Experiencing issues with your Chelsea PTO can be frustrating. Diagnosing problems early helps prevent further damage. Let’s explore some methods to identify common PTO issues.

Visual Inspections

Start by checking the PTO unit for visible damage. Look for cracks, leaks, and wear. Ensure all bolts and connections are tight. Loose or missing parts can cause major problems.

Inspect the hydraulic lines. Look for signs of leaks or damage. Check the fluid levels and quality. Dirty or low fluid can affect performance. Make sure the PTO shaft is straight and free of debris. Bent or obstructed shafts can hinder operation.

Listening For Unusual Noises

Turn on the PTO and listen carefully. Grinding or squealing sounds indicate possible issues. These noises often mean there are problems with gears or bearings.

Listen for any clicking or knocking sounds. These can signal loose parts or misalignment. Unusual noises should not be ignored. They can lead to bigger problems if not addressed quickly.

Pay attention to vibrations as well. Excessive vibrations can cause damage over time. Addressing these signs early can save you time and money.

Fixing Leaking Seals

Fixing leaking seals on your Chelsea PTO can help avoid costly repairs. Leaks can cause damage to other parts of the system. This guide will help you fix the leaks quickly and easily.

Tools Needed

Before you start, gather all necessary tools. You will need a wrench set, seal puller, screwdrivers, and a clean cloth. Having everything ready will make the process smoother.

Step-by-step Guide

First, park your vehicle on a level surface. Engage the parking brake for safety. Next, locate the leaking seal on the PTO. Clean the area around the seal using a clean cloth. This helps you see the problem clearly.

Use a wrench to remove bolts around the seal. Carefully take out the old seal with a seal puller. Be gentle to avoid damaging the surrounding area.

After removing the old seal, clean the area again. This ensures no debris enters the system. Now, place the new seal in the correct position. Make sure it fits snugly and is properly aligned.

Reattach the bolts and tighten them with a wrench. Check the seal to ensure it’s secure. Finally, test the PTO to make sure the leak is fixed. If the leak persists, you may need professional help.

Preventing Overheating

Preventing overheating in your Chelsea PTO (Power Take-Off) is vital for its longevity and efficiency. Overheating can cause serious damage and lead to costly repairs. Understanding key preventive measures can save you from these troubles.

Proper Lubrication

Proper lubrication is essential for preventing overheating. Use the correct type of lubricant as specified in the manual. Check lubricant levels regularly. Insufficient lubrication increases friction. This leads to overheating. Ensure seals are intact to prevent leaks. Replace old or contaminated lubricants to maintain optimal performance.

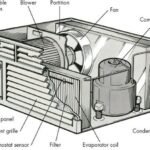

Cooling Techniques

Effective cooling techniques can significantly reduce the risk of overheating. Ensure your PTO has adequate airflow. Clean any debris from cooling fins and vents. Consider installing additional cooling fans if necessary. Monitor temperature gauges closely during operation. Use thermal sensors to provide real-time temperature data. Shut down the PTO if it exceeds safe temperature limits.

Addressing Gear Issues

Having trouble with your Chelsea PTO gears? Gear issues can disrupt your workflow. Let’s explore how to identify and fix these common problems.

Identifying Gear Wear

Gears often show signs of wear and tear. Look for these indicators:

- Noise: Unusual sounds during operation.

- Vibration: Excessive shaking or wobbling.

- Performance: Reduced efficiency and power.

Inspect the gears visually. Check for visible damage or deformation. Use a flashlight for a closer look. If you see any cracks or chips, the gears need attention.

Replacing Worn Gears

Replacing worn gears is crucial for smooth operation. Follow these steps:

- Gather Tools: Wrenches, screwdrivers, and replacement gears.

- Safety First: Wear gloves and safety goggles.

- Remove Cover: Open the PTO housing carefully.

- Extract Old Gears: Use a wrench to unscrew and remove them.

- Install New Gears: Position the new gears and tighten screws.

- Close Housing: Replace the cover and secure it.

Test the PTO after replacing the gears. Listen for any unusual sounds. Check for smooth operation. If everything works fine, you are good to go.

Regular maintenance can prevent these issues. Inspect gears periodically and replace them as needed. This ensures your Chelsea PTO runs efficiently.

Electrical Troubleshooting

Electrical issues can often be the root cause of problems with the Chelsea PTO. Troubleshooting these issues involves a series of steps to identify the fault. This section covers two critical aspects: checking connections and testing voltage.

Checking Connections

The first step in electrical troubleshooting is checking connections. Ensure all wires are securely connected. Loose or corroded connections can cause intermittent issues. Use a multimeter to check for continuity in the wires. This helps verify that the electrical path is intact.

Here are steps to follow:

- Inspect all connectors for damage.

- Clean any corroded terminals.

- Tighten loose connections.

- Replace any damaged wires.

Testing Voltage

After checking the connections, the next step is testing voltage. Use a voltmeter to measure the voltage at various points in the circuit. This helps identify if the power supply is reaching the PTO.

Follow these steps to test voltage:

- Turn off the PTO and disconnect the power source.

- Set the voltmeter to the correct voltage range.

- Connect the voltmeter leads to the terminals.

- Turn on the power source and read the voltage.

Compare the measured voltage with the expected values. If the voltage is too low or too high, it indicates a problem. You may need to check the power source or replace faulty components.

Credit: www.ebay.com

Routine Maintenance Tips

Routine maintenance of your Chelsea PTO (Power Take-Off) system ensures smooth operation. It also helps in preventing unexpected breakdowns. Adhering to a few simple tips can extend your system’s lifespan. This section will cover essential maintenance tasks.

Scheduled Inspections

Regularly inspect your Chelsea PTO system. Look for any signs of wear and tear. Check for loose bolts and ensure all parts are securely fastened. Identifying issues early can save time and money.

Regular Fluid Checks

Keep an eye on fluid levels. Low fluid can cause the system to overheat. Always use the recommended fluid type. This ensures the system runs efficiently. Replace fluids as needed to maintain performance.

When To Seek Professional Help

Understanding when to seek professional help for Chelsea PTO (Power Take-Off) issues is crucial. Minor issues can often be resolved with basic troubleshooting. Major problems, however, require the expertise of a qualified technician. This section will help you identify signs of major problems and how to choose a qualified technician for your Chelsea PTO.

Signs Of Major Problems

Not all issues with your Chelsea PTO are easy to fix. Here are some signs that indicate major problems:

- Unusual Noise: Grinding, whining, or clunking sounds.

- Overheating: The PTO becomes excessively hot.

- Fluid Leaks: Leaking hydraulic fluid or oil.

- Failure to Engage: The PTO does not engage or disengage properly.

- Reduced Performance: Decreased power output or efficiency.

Choosing A Qualified Technician

When major problems arise, selecting the right technician is important. Here are some tips:

| Criteria | Details |

|---|---|

| Certification | Ensure the technician is certified in PTO systems. |

| Experience | Look for technicians with years of experience in PTO repair. |

| Reviews | Check online reviews and testimonials from other customers. |

| Warranty | Choose a technician who offers a warranty on their work. |

Following these guidelines can help you find a reliable technician to fix your Chelsea PTO issues.

Credit: mpparts.com

Credit: www.chelseaptopart.com

Frequently Asked Questions

How Do I Know If My Chelsea Pto Is Faulty?

Check for unusual noises, leaks, or loss of power. These are signs of a problem.

What Causes A Chelsea Pto To Stop Working?

Common causes are low fluid levels, worn-out gears, or electrical issues. Regular maintenance helps prevent these.

Can I Fix A Chelsea Pto Problem Myself?

Yes, minor issues like fluid refill or cleaning can be done at home. Major repairs need a professional.

How Often Should I Service My Chelsea Pto?

Service your PTO every 6 months. Regular checks ensure it works well and lasts longer.

What Are The Main Parts Of A Chelsea Pto?

The main parts include the gear, housing, and output shaft. Each part needs regular inspection.

Conclusion

Effective Chelsea PTO troubleshooting ensures smooth operation of your equipment. Regular maintenance and quick fixes can prevent larger issues. Always check for common problems and address them early. Consult your manual or a professional for persistent issues. Keeping your PTO in good shape saves time and money.

Stay vigilant and proactive with your maintenance routine. Your equipment will thank you with better performance and longevity.