Craftsman Hydrostatic Transmission Troubleshooting: Expert Tips

Are you struggling with your Craftsman’s hydrostatic transmission? You’re not alone.

Many Craftsman lawnmower owners face similar challenges. Imagine effortlessly mowing your lawn without the frustration of a stuttering or stalled machine. Sounds like a dream, right? This guide is here to help you turn that dream into reality. We’ll walk you through simple steps to troubleshoot and fix your transmission issues, saving you time and money.

Say goodbye to the headache of malfunctioning equipment and hello to smooth, stress-free lawn care. Ready to reclaim your weekend? Let’s get started!

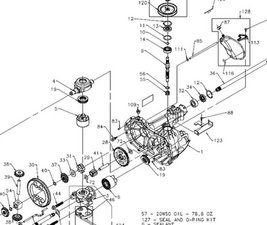

Credit: www.ebay.com

Common Issues With Hydrostatic Transmission

Dealing with a Craftsman hydrostatic transmission can sometimes feel like solving a puzzle. You might find yourself wondering why your once smooth-running mower now seems to have a mind of its own. Understanding common issues can save you time and frustration. Here, we’ll tackle some of the frequent problems you might encounter and offer practical solutions to get your transmission back on track.

Transmission Slipping

Transmission slipping can be a real headache. You press the pedal, expecting your mower to move, but it hesitates or doesn’t move at all. This often stems from low hydraulic fluid levels. Imagine running a marathon on an empty stomach; your mower feels just as sluggish without adequate fluid. Check the fluid level and top it up if necessary. Don’t forget to inspect the drive belt for any wear or damage—it could also be the culprit.

Unusual Noises

Have you ever been startled by strange noises while mowing? These sounds can be a sign that something’s amiss. Grinding or whining noises often indicate worn gears or bearings. It’s like the mower is crying out for help. Regular maintenance checks can prevent these issues from escalating. Tighten loose bolts and replace worn components to silence those unsettling sounds. How often do you listen to your mower’s cries?

Loss Of Power

Loss of power can make mowing an uphill battle. You might find your mower struggling to climb even small inclines. This can result from clogged filters or a malfunctioning fuel pump. Think of it as your mower being out of breath. Cleaning or replacing air filters and checking the fuel pump can rejuvenate your mower’s energy. Have you checked if a simple cleaning could restore your mower’s vigor?

Tackling these common issues doesn’t require you to be a mechanical genius. With a little patience and attention, you can troubleshoot most problems on your own. Always remember, regular maintenance goes a long way in keeping your hydrostatic transmission healthy and efficient.

Credit: www.youtube.com

Initial Checks And Maintenance

Keeping your Craftsman mower running smoothly needs regular checks. Proper maintenance can prevent many common issues. Start with initial checks for your hydrostatic transmission. This helps in identifying problems early.

Fluid Levels And Quality

Check the fluid levels first. Low fluid can cause performance problems. Make sure to use the right type of fluid. The fluid should be clear and clean. Dirty fluid indicates contamination or wear. Replace or top up as needed.

Inspecting Hoses And Connections

Next, inspect all hoses. Look for cracks, leaks, or loose connections. Damaged hoses can cause fluid loss. Tighten any loose connections. Replace hoses that look worn out. This step ensures proper fluid flow.

Assessing The Drive Belt

Finally, check the drive belt. A worn or loose belt can affect transmission. Look for cracks or fraying. Ensure the belt tension is correct. Replace the belt if it shows signs of wear. A well-maintained belt keeps your mower moving smoothly.

Advanced Troubleshooting Techniques

Diagnosing issues with Craftsman hydrostatic transmissions often involves checking fluid levels and examining belts for wear. Identifying unusual noises can point to internal problems. Regular maintenance prevents common malfunctions, ensuring smooth operation.

Advanced troubleshooting techniques can help resolve complex issues with Craftsman hydrostatic transmissions. These techniques involve a deeper understanding of the system. They also require specialized tools and methods. By focusing on key aspects, you can identify and fix problems efficiently. This section outlines techniques that can assist in diagnosing and repairing your transmission.Testing Pressure Levels

Testing the pressure levels is crucial for transmission performance. Use a pressure gauge to measure the hydraulic fluid pressure. Ensure the engine runs at the correct RPM during testing. Compare the results with the manufacturer’s specifications. Low pressure may indicate a fluid leak or pump issue. High pressure might suggest a blockage or restriction. Regular pressure checks help maintain optimal performance.Evaluating Pump And Motor Function

Evaluate both the pump and motor functions for signs of wear. Listen for unusual noises during operation. Check for vibrations or irregular movements. Inspect the pump for visible damage or leaks. Ensure the motor rotates smoothly without resistance. Faulty pumps or motors can cause transmission failure. Replace damaged components promptly to avoid further issues.Using Diagnostic Tools

Diagnostic tools offer precise insights into transmission health. Digital multimeters can check electrical connections and sensors. Use a stethoscope to identify unusual sounds in the system. Infrared thermometers can detect overheating parts. These tools help pinpoint specific areas of concern. They provide accurate data for effective troubleshooting. Regular diagnostics prevent minor issues from becoming major problems.Repair And Replacement Solutions

Dealing with Craftsman hydrostatic transmission issues can be tricky. They require understanding and patience. Repair and replacement solutions offer paths to get your machine running smoothly again. Identifying faulty components early can save time and money. Whether you choose DIY methods or professional help, knowing your options is key.

Replacing Faulty Components

Faulty components can affect performance. Identify worn-out parts promptly. Check drive belts, filters, and fluid levels. Replace them if necessary. Use quality parts for longevity. Follow the manual for guidance. Ensure all connections are secure.

Professional Repair Services

Sometimes, professional help is best. Experts diagnose complex issues efficiently. They have access to specialized tools. This ensures accurate repairs. Professional services offer warranties for peace of mind. It’s a reliable solution for major problems.

Diy Repair Tips

Consider DIY repairs for minor issues. Gather necessary tools first. Follow safety guidelines strictly. Watch tutorials for visual guidance. Take notes from your manual. Start with simple tasks like oil changes. Gradually, move to more complex repairs. Keep your workspace organized. This prevents mistakes and confusion.

Preventative Measures

Taking care of your Craftsman hydrostatic transmission can save you time and money. Regular upkeep keeps your equipment in good working order. It helps prevent issues before they start. A little care goes a long way. Let’s dive into some simple yet effective preventative measures.

Regular Maintenance Schedule

A regular maintenance schedule is crucial for your transmission. Check your owner’s manual for guidance. Follow recommended service intervals closely. Replace fluids as per the manufacturer’s instructions. Clean the transmission area regularly to prevent dirt buildup.

Inspect belts for wear or cracks. Make sure they are tight and in good condition. This helps avoid sudden breakdowns. Keep a log of all maintenance activities. It’s a handy record for future reference.

Proper Usage Guidelines

Use your transmission wisely to extend its life. Avoid overloading the equipment. This puts extra strain on the transmission. Follow the recommended operating speeds. This keeps the transmission functioning smoothly.

Do not switch gears abruptly. This can cause internal damage. Allow the engine to warm up before use. It ensures the transmission fluid flows properly. Treat your equipment gently for a longer lifespan.

Monitoring For Early Signs Of Issues

Keep an eye out for early signs of trouble. Listen for unusual noises during operation. Grinding or whining sounds can indicate problems. Pay attention to any changes in performance. Sluggish or jerky movements need immediate attention.

Check for fluid leaks regularly. Leaks can lead to significant issues if ignored. Inspect the area beneath your equipment for any signs of oil. Address any concerns quickly to prevent further damage.

Credit: www.ifixit.com

Conclusion

Troubleshooting Craftsman hydrostatic transmissions can seem tricky, but it’s manageable. Start by checking the basics like oil levels and belts. Listen for unusual sounds that might indicate a problem. Regular maintenance helps prevent bigger issues. If you face persistent problems, consult a professional.

Remember, safety first. Always follow the manual’s guidelines. These steps can ensure a smoother operation of your Craftsman mower. By understanding the common issues, you can extend its lifespan. Keep learning and stay informed to tackle any future challenges confidently.

With patience and attention, your mower will perform efficiently.