Cummins M11 engines are known for their durability and reliability. Yet, even the best engines encounter issues.

In this guide, we will explore troubleshooting techniques for the Cummins M11. Understanding common problems can save time and money. Whether you’re a seasoned mechanic or a DIY enthusiast, knowing how to diagnose and fix issues is crucial. The Cummins M11 engine is a workhorse in many commercial vehicles.

But like all machinery, it can have its hiccups. From coolant leaks to starting problems, learning to troubleshoot these issues is essential. This guide will help you identify and solve common problems, ensuring your engine runs smoothly. Get ready to dive into practical tips and solutions for maintaining your Cummins M11 engine. Your journey to a well-functioning engine starts here.

Introduction To Cummins M11

Discover essential tips for Cummins M11 troubleshooting. Learn to diagnose common issues and maintain peak performance. Enhance engine reliability with these straightforward techniques.

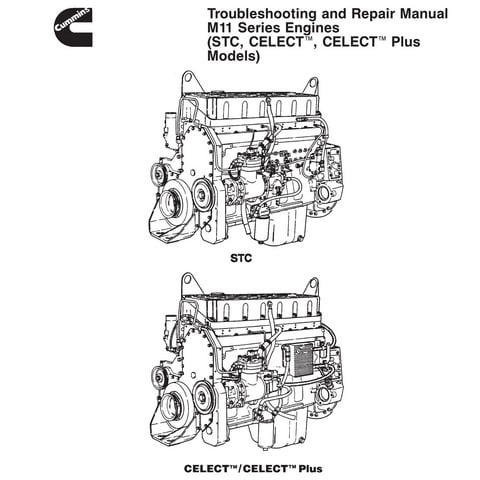

The Cummins M11 is a popular diesel engine known for its reliability. It is widely used in various industries. This engine delivers exceptional performance. It is favored for its durability and efficiency.Engine Overview

The Cummins M11 engine comes with advanced features. It includes a robust design. The engine has a displacement of 10.8 liters. It operates with six cylinders. This engine can produce up to 450 horsepower. It also has a torque range of 1,350 to 1,550 lb-ft. It meets emission standards effectively.Common Applications

The Cummins M11 engine is versatile. It is used in many applications. Trucks and buses often use this engine. It is also found in construction equipment. Agricultural machinery benefits from its power. Marine vessels use it too. The engine’s adaptability makes it popular.

Credit: www.pinterest.com

Starting Problems

Starting problems can be frustrating for any vehicle owner. The Cummins M11 engine is no exception. Identifying the root cause helps to get the engine up and running. Common issues often stem from the battery or the starter motor. This section will guide you through these potential culprits.

Battery Check

First, ensure the battery is in good condition. A weak or dead battery can prevent the engine from starting. Check the battery terminals for corrosion. Clean them if necessary. Use a multimeter to test the battery voltage. It should read around 12.6 volts when fully charged. If the voltage is low, try charging the battery. Replace it if it does not hold a charge.

Starter Motor Issues

The starter motor is crucial for starting the engine. Listen for a clicking sound when turning the key. This often indicates a faulty starter motor. Check the connections between the starter motor and the battery. Ensure they are tight and free of corrosion. Test the starter motor by bypassing the ignition switch. Use a jumper wire to connect the positive battery terminal to the starter solenoid terminal. If the engine cranks, the issue might be with the ignition switch or wiring.

Remember, regular maintenance and checks can prevent many starting problems. Keep your Cummins M11 in top shape for reliable performance.

Fuel System Troubles

Fuel system troubles in the Cummins M11 can cause many engine problems. Issues with the fuel system can lead to poor performance and reduced efficiency. Two common problems in the fuel system are fuel filter clogging and injector failures.

Fuel Filter Clogging

The fuel filter removes contaminants from the fuel before it reaches the engine. Over time, dirt and debris can clog the filter. This restricts fuel flow and affects engine performance. Regularly check and replace the fuel filter to keep the system clean. A clogged filter can cause the engine to run rough or even stall.

Injector Failures

Fuel injectors deliver fuel into the engine’s combustion chamber. If an injector fails, it can lead to uneven fuel distribution. This results in poor combustion and reduced power. Signs of injector failure include misfiring, black smoke, and increased fuel consumption. Cleaning or replacing faulty injectors can restore proper engine function.

Overheating Issues

Overheating in Cummins M11 engines can cause severe damage. Understanding the common causes helps prevent costly repairs. This section focuses on two main areas: Coolant Levels and Radiator Functionality.

Coolant Levels

Low coolant levels often lead to engine overheating. Regularly check coolant levels to ensure they are within the recommended range. If levels are low, refill with the appropriate coolant mix. Always use the correct type for the Cummins M11 engine.

Leaks can also cause coolant loss. Inspect hoses and connections for any signs of leaks. Replace damaged parts immediately to prevent further coolant loss.

Radiator Functionality

The radiator plays a crucial role in cooling the engine. Ensure it is clean and free from blockages. Dirt and debris can obstruct airflow, causing the engine to overheat.

Check the radiator cap for proper sealing. A faulty cap can lead to pressure loss, reducing cooling efficiency. Replace it if necessary to maintain optimal performance.

Inspect the radiator fan. A malfunctioning fan can lead to insufficient cooling. Ensure the fan operates correctly to prevent overheating issues.

Oil Pressure Problems

Oil pressure problems can cause serious damage to your Cummins M11 engine. It is important to understand the potential issues and how to troubleshoot them. Oil pressure issues often result from sensor malfunctions or oil pump performance problems. Addressing these problems promptly can prevent costly repairs and downtime.

Sensor Malfunctions

Oil pressure sensors can fail or give inaccurate readings. Faulty sensors can make the oil pressure gauge display incorrect levels. This can lead to unnecessary panic or neglect of real issues. To check the sensor, use a mechanical gauge to verify the pressure. If the readings differ, replace the faulty sensor. Regular checks can help avoid misdiagnosis of oil pressure problems.

Oil Pump Performance

The oil pump ensures proper lubrication of the engine components. A failing oil pump can cause low oil pressure. Signs of a failing pump include unusual noises and fluctuating pressure readings. To troubleshoot, inspect the pump for wear and tear. Ensure the pump is free of debris and blockages. If the pump is damaged, replace it immediately. Regular maintenance can extend the life of the oil pump and maintain optimal oil pressure.

Credit: payhip.com

Exhaust Smoke Diagnosis

Exhaust smoke can reveal a lot about your Cummins M11 engine’s health. Different colors of smoke signal various issues. Understanding these can help you diagnose and fix problems early. Let’s explore the causes of black and white smoke in your Cummins M11 engine.

Black Smoke Causes

Black smoke from the exhaust indicates incomplete combustion. This can be caused by several factors. One common cause is a dirty air filter. A clogged air filter restricts airflow, resulting in a rich fuel mixture. Another cause could be faulty injectors. Injectors that do not spray fuel properly can lead to unburned fuel. Additionally, poor-quality fuel can also cause black smoke. Using low-grade fuel may result in incomplete combustion.

White Smoke Causes

White smoke usually means there is coolant or water in the combustion chamber. One possible cause is a blown head gasket. A damaged gasket allows coolant to leak into the engine. Another cause could be a cracked engine block. Cracks in the block can let coolant seep into the combustion chamber. Fuel-related issues can also produce white smoke. Cold engine start-ups may cause white smoke temporarily. But persistent white smoke needs immediate attention.

Electrical System Faults

The electrical system in a Cummins M11 engine is crucial. Faults in this system can cause major issues. Identifying and fixing these faults helps maintain engine performance. Focus on common electrical problems, including wiring inspections and alternator issues.

Wiring Inspections

Wiring issues can lead to engine problems. Inspect the wiring for wear and tear. Look for frayed wires or loose connections. Replace damaged wires immediately. Ensure all connections are tight and secure. This prevents electrical faults and keeps the engine running smoothly.

Alternator Problems

The alternator charges the battery and powers the electrical system. A faulty alternator can cause a dead battery. Check the alternator regularly. Listen for unusual noises or check for warning lights. Test the alternator output with a multimeter. If it is not working properly, replace it. This ensures the engine’s electrical system functions correctly.

Credit: www.scribd.com

Regular Maintenance Tips

Regular maintenance of your Cummins M11 engine is essential. It ensures optimal performance and extends the engine’s life. Follow these tips to keep your engine running smoothly.

Scheduled Inspections

Regular inspections are crucial. Check your engine at scheduled intervals. Look for leaks, wear, and damage. Here are some key areas to inspect:

- Oil levels and quality

- Coolant levels

- Air filters

- Fuel system

Keeping these components in check will prevent major issues. Make sure to follow the manufacturer’s guidelines for inspection frequency.

Preventive Measures

Preventive measures can save time and money. Here are some tips:

- Change the oil and filters regularly. Use high-quality oil.

- Keep the cooling system clean. Check for blockages.

- Inspect and replace air filters as needed. Clean filters improve efficiency.

- Monitor the fuel system. Clean injectors ensure smooth operation.

These measures help maintain engine health. They reduce the risk of unexpected breakdowns.

When To Seek Professional Help

Facing persistent issues with your Cummins M11 engine? Unusual noises, frequent breakdowns, or poor performance are signs to seek professional help. Expert technicians can diagnose and fix complex problems quickly.

When dealing with Cummins M11 engine issues, knowing when to seek professional help can save you time and money. Some problems require expert knowledge and advanced tools. Here, we’ll discuss signs of major issues and how to choose a reliable mechanic.Signs Of Major Issues

Certain signs indicate major problems with your Cummins M11 engine. If you notice unusual noises, such as knocking or grinding, it’s a red flag. These sounds can signal internal damage. Another serious sign is excessive smoke from the exhaust. Black, blue, or white smoke can point to fuel, oil, or coolant issues.Frequent stalling or difficulty starting the engine is another warning. These problems can stem from fuel system or electrical issues. If your engine is overheating, this needs immediate attention. Overheating can cause severe damage to internal components.Lastly, a significant drop in power or performance is troubling. This might indicate issues with the turbocharger, injectors, or other critical parts.Choosing A Reliable Mechanic

Finding a reliable mechanic is essential for proper engine care. Start by researching mechanics with experience in Cummins engines. Look for certifications or endorsements from Cummins or other reputable organizations. These credentials show the mechanic’s expertise.Read customer reviews and testimonials. Feedback from other customers can reveal the mechanic’s reliability and quality of work. Ask about their diagnostic tools and methods. A good mechanic uses advanced equipment to accurately identify and fix problems.Request a detailed estimate before any work begins. A trustworthy mechanic will provide a clear breakdown of costs. This helps you understand what you are paying for and prevents unexpected charges.Building a relationship with a reliable mechanic ensures your Cummins M11 engine stays in top condition. Regular maintenance and timely repairs keep your engine running smoothly and extend its lifespan.Frequently Asked Questions

What Causes A Cummins M11 Engine To Overheat?

A Cummins M11 engine can overheat due to low coolant, faulty thermostat, or a clogged radiator.

How To Troubleshoot Cummins M11 Fuel Issues?

Check fuel filters, fuel pump, and injectors. Look for leaks or blockages in the fuel lines.

Why Does My Cummins M11 Lose Power?

Loss of power may be due to clogged air filters, fuel issues, or turbocharger problems.

How To Fix A Cummins M11 Starting Problem?

Inspect the battery, starter motor, and fuel system. Ensure connections are tight and components are functioning.

What Are Common Cummins M11 Oil Leaks?

Oil leaks often come from valve cover gaskets, oil pan gaskets, or seals. Check for cracks or loose bolts.

Conclusion

Solving Cummins M11 issues can be straightforward with the right steps. Regular maintenance helps prevent many problems. Always check for common issues first. Consult your manual for specific details. Use proper tools for accurate diagnostics. Seek professional help when needed.

Stay patient and thorough. Your engine’s performance depends on it. Follow these tips to keep your Cummins M11 running smoothly. Happy troubleshooting!