Dab pumps are crucial for many water systems, ensuring efficient water flow. But, like any machinery, they can face issues.

Understanding common problems with Dab pumps can save time and prevent bigger issues. Troubleshooting these pumps may seem daunting, but it can be manageable with the right guidance. Regular maintenance and basic troubleshooting can often solve many issues. This guide will help you identify common problems and offer simple solutions.

By the end, you’ll feel more confident in handling basic Dab pump issues. Let’s dive into the essentials of Dab pumps troubleshooting.

Introduction To Dab Pumps

Dab pumps are essential in many industries. They help move water and other fluids efficiently. Understanding their function and maintenance is crucial.

What Are Dab Pumps?

Dab pumps are high-quality pumps used for various applications. They are known for their reliability and efficiency. These pumps are often used in residential, commercial, and industrial settings. They can handle different types of fluids, including water, chemicals, and oils.

Here are some key features of Dab pumps:

- High efficiency

- Durable construction

- Low maintenance

- Energy-saving

Importance Of Proper Maintenance

Regular maintenance of Dab pumps ensures their long lifespan. It also helps in avoiding unexpected breakdowns. Proper maintenance involves checking for wear and tear, cleaning the components, and ensuring proper lubrication.

Here are some basic maintenance tips:

- Inspect the pump regularly for any signs of damage.

- Clean the pump and its components to remove any debris.

- Lubricate moving parts to reduce friction.

- Check and replace worn-out parts as needed.

By following these tips, you can ensure that your Dab pump works efficiently. This will save you money and time in the long run.

Credit: www.dabpumps.com

Common Issues With Dab Pumps

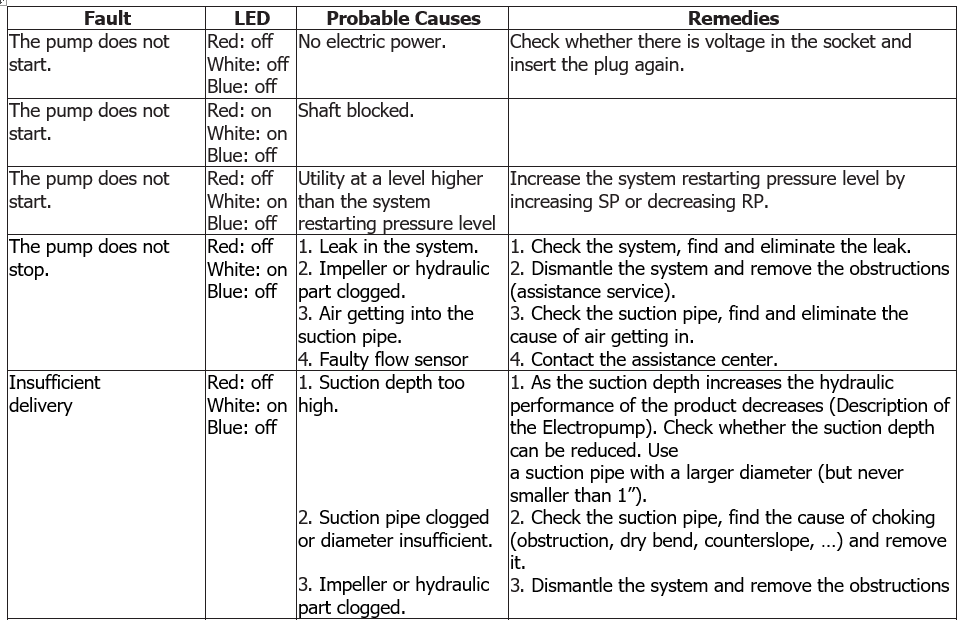

Dab pumps are reliable tools used in various applications. However, like any machine, they can face some common issues. Understanding these problems can help you troubleshoot and maintain your pump effectively. This section addresses two frequent issues: low water pressure and the pump not starting.

Low Water Pressure

Low water pressure is a common issue with Dab pumps. It can make tasks like watering the garden difficult. Often, a clogged filter is the cause. Check and clean the filter regularly. Another reason could be air trapped in the pump. Bleed the air out by following the manual’s instructions. Additionally, inspect the pipes for any leaks or blockages. Ensure the water source is adequate and not running low.

Pump Not Starting

If your Dab pump does not start, check the power supply first. Ensure the pump is plugged in and the circuit breaker is not tripped. A blown fuse could also be the problem. Replace it if necessary. Next, examine the motor for any signs of damage or overheating. Allow the motor to cool down before trying again. The pressure switch might also be faulty. Test and replace it if needed. Lastly, ensure the pump is primed correctly. An unprimed pump cannot start.

Identifying The Problem

When your Dab pump stops working, you need to find the problem. This is the first step to fixing it. Identifying the problem can save you time and money. Here, we will cover two ways to find issues: visual inspection and listening for unusual noises.

Visual Inspection

Start by looking at your pump. Check for visible signs of damage. Common issues include leaks, rust, or broken parts.

- Leaks: Water on the ground or around the pump.

- Rust: Corrosion on metal parts.

- Broken parts: Cracks or missing pieces.

Make sure the pump is clean. Dirt and debris can cause problems. Remove any blockages you find. Also, check the power supply. Ensure the pump is plugged in and the switch is on.

Listening For Unusual Noises

A working pump should be quiet. Listen carefully when the pump is on. Strange noises can indicate problems.

- Grinding: May suggest a damaged impeller or motor.

- Buzzing: Could point to an electrical issue.

- Humming: Might mean the motor is running but the pump is not working.

Compare the sounds with a normally functioning pump. This helps to identify unusual noises. If you hear strange sounds, turn off the pump. Investigate further to avoid more damage.

Tools You Need

Having the right tools is vital for troubleshooting Dab Pumps. A well-prepared toolkit ensures you can handle any issue efficiently. Let’s explore the tools you need for successful troubleshooting.

Basic Tools

Every technician should have a set of basic tools for Dab Pumps troubleshooting. These tools are essential for performing routine maintenance and minor repairs.

- Wrenches: Different sizes for tightening or loosening nuts and bolts.

- Screwdrivers: Both flathead and Phillips, for adjusting screws.

- Pliers: Useful for gripping and bending wires or pipes.

- Multimeter: Important for measuring electrical values and ensuring components are working correctly.

- Pipe Cutter: Handy for cutting pipes to the required length.

- Flashlight: Essential for working in low-light conditions.

Specialized Equipment

In addition to basic tools, some issues require more specialized equipment. These tools help diagnose and fix complex problems.

| Tool | Purpose |

|---|---|

| Pressure Gauge | Checks the pressure levels in the pump system. |

| Flow Meter | Measures the flow rate of water through the pump. |

| Thermal Camera | Detects overheating parts in the pump system. |

| Ultrasonic Leak Detector | Identifies leaks in the pump or pipe connections. |

| Clamp Meter | Measures the current flowing through the pump’s wires. |

These tools are crucial for ensuring your Dab Pumps operate efficiently. Regular use can help prevent serious issues and extend the life of your pumps.

Fixing Low Water Pressure

Experiencing low water pressure in your Dab pump system can be frustrating. It affects daily activities like showering and washing dishes. Let’s explore common troubleshooting steps to fix this issue.

Checking For Blockages

First, inspect the pump for any blockages. Blocked pipes or filters can reduce water flow. Follow these steps:

- Turn off the pump and disconnect it from the power source.

- Remove and inspect the filters. Clean if necessary.

- Check the pipes for any visible debris or clogs.

- Reassemble the system and test the water pressure.

Regular maintenance can prevent blockages. Make it a habit to check the filters and pipes periodically.

Adjusting The Pressure Switch

If blockages are not the problem, the pressure switch might need adjustment. The pressure switch controls the pump’s on and off cycles. Adjusting it can help improve water pressure. Follow these steps:

- Turn off the power to the pump.

- Locate the pressure switch. It is usually near the pressure tank.

- Use a screwdriver to adjust the switch settings. Increase the cut-in and cut-out pressure settings slightly.

- Turn the power back on and test the system.

Carefully adjust the switch to avoid damaging the pump. If unsure, consult the user manual or contact a professional.

Low water pressure can be resolved with these steps. Regular maintenance and timely adjustments ensure a smooth-running Dab pump system.

Credit: dabpumps.us

Resolving Pump Not Starting

A Dab pump not starting can cause many problems. It can disrupt your water supply and create inconvenience. Understanding the common reasons can help you fix the issue quickly. Below, we discuss how to inspect electrical connections and test the motor to get your Dab pump working again.

Inspecting Electrical Connections

First, check the power supply to the pump. Ensure the pump is properly plugged in. Verify that the circuit breaker is not tripped. Sometimes, a loose or damaged wire can be the problem.

Use a multimeter to test the voltage at the pump terminals. The voltage should match the pump’s specifications. If it does not, you may have an electrical issue.

Here’s a quick checklist for inspecting electrical connections:

- Check the power outlet

- Verify the circuit breaker

- Inspect all wiring

- Test the voltage with a multimeter

If the electrical connections are fine, move on to testing the motor.

Testing The Motor

The motor is the heart of your Dab pump. If the motor fails, the pump will not start. First, listen for any unusual sounds. A humming noise can indicate a motor issue.

Next, use a multimeter to check the motor windings. You should see a consistent resistance reading. If the reading is too high or too low, the motor windings may be faulty.

Follow these steps to test the motor:

- Turn off the power supply

- Disconnect the motor wires

- Use a multimeter to check the resistance

- Compare the reading with the pump’s manual

If the motor windings are fine, the problem might be with the capacitor. Test the capacitor using a multimeter. Replace it if needed.

Testing the motor and inspecting electrical connections can resolve many pump issues. Keep your pump running smoothly by performing regular checks.

Preventative Maintenance Tips

Preventative maintenance is key to keeping your Dab Pumps running smoothly. Regular care can help you avoid unexpected breakdowns and extend the life of your equipment. In this section, we will cover essential tips for maintaining your pumps.

Regular Cleaning

Keeping your Dab Pumps clean ensures optimal performance. Dirt and debris can clog the system, causing inefficiency.

- Check the pump for any visible dirt or blockages.

- Use a soft brush to remove any buildup on the external parts.

- Inspect the filters and clean or replace them if needed.

Ensure you turn off the pump before cleaning. This prevents any accidents or damage.

Scheduled Professional Checkups

Regular checkups by a professional can identify potential issues early. This can save you time and money in the long run.

- Schedule a professional inspection at least once a year.

- Ensure the technician checks all parts, including the motor and impeller.

- Address any minor issues before they become major problems.

Professional checkups can also include performance tests. These tests ensure your pump is operating at its best.

Preventative maintenance involves both regular cleaning and scheduled checkups. Together, these steps keep your Dab Pumps in top condition.

Credit: dabpumps.us

When To Call A Professional

Troubleshooting Dab pumps can be tricky. Sometimes, you need professional help to avoid further damage and ensure safety. Knowing when to call a professional can save you time and money. Below are some signs that indicate you need an expert.

Signs You Need Help

- No Water Flow: If your pump is running but no water comes out, there may be a serious issue.

- Strange Noises: Loud or unusual sounds can indicate internal problems.

- Frequent Cycling: If your pump turns on and off too often, it may need a professional’s touch.

- Leaking: Water leaks around the pump should be addressed immediately.

- Overheating: If the pump is too hot to touch, call a technician.

Choosing A Reliable Technician

Finding a trustworthy technician ensures your pump is in good hands. Here are some tips:

- Check Credentials: Ensure the technician is certified and experienced with Dab pumps.

- Read Reviews: Look for reviews online to gauge the quality of their work.

- Ask for Recommendations: Friends and family can provide reliable referrals.

- Get Multiple Quotes: Compare prices and services before making a decision.

Using these guidelines will help you find a skilled professional.

Frequently Asked Questions

What Causes Dab Pump Not To Start?

Check power supply, wiring, and fuse. Ensure the motor is not overheated.

Why Is My Dab Pump Making Noise?

Noise can be from air in the system, worn bearings, or cavitation.

How Can I Fix Low Pressure In Dab Pumps?

Inspect for leaks, clogged filters, or blocked pipes. Check pump settings and valves.

Why Does My Dab Pump Keep Shutting Off?

Overheating or low water levels can cause automatic shutoff. Check for these issues.

What Should I Do If Dab Pump Leaks?

Tighten connections, inspect seals, and replace damaged parts. Ensure proper installation.

Conclusion

Troubleshooting Dab Pumps can seem challenging, but it’s manageable with the right steps. Regular maintenance prevents most issues. Always check the basics first: power supply, water source, and connections. A clean pump works better and lasts longer. If problems persist, consult a professional.

Keeping a troubleshooting guide handy saves time and stress. Proper care ensures your Dab Pump runs smoothly. Remember, a little attention now avoids bigger problems later. Happy pumping!