Are you facing issues with your Ditch Witch equipment? This troubleshooting manual can help you fix common problems quickly.

Ditch Witch machines are reliable and efficient, but like any equipment, they can encounter issues. Understanding how to troubleshoot these problems can save you time and money. This manual provides straightforward solutions to common Ditch Witch issues. Whether you are dealing with engine troubles, hydraulic problems, or electrical faults, this guide has you covered.

With easy-to-follow steps and clear instructions, you can get your Ditch Witch equipment back in working order. Dive into this manual to keep your machinery running smoothly and efficiently.

Credit: www.repairmanual.com

Common Issues

Encountering problems with your Ditch Witch equipment can be frustrating. Knowing the common issues and their solutions can save you time and money. This section of the troubleshooting manual highlights frequent problems and offers practical fixes.

Engine Problems

Engine problems are a common concern. They can range from minor hiccups to major failures. Below are some frequent engine issues:

- Engine won’t start: Check the fuel level and battery. Ensure connections are tight.

- Overheating: Inspect the coolant level and radiator. Clean any debris blocking airflow.

- Strange noises: Listen for unusual sounds. This could indicate a loose part or a serious internal issue.

Proper maintenance can prevent many engine problems. Regularly check and replace filters, oil, and other fluids.

Hydraulic System Failures

Hydraulic system failures can halt your operations. Here are some common hydraulic issues:

- Leaking fluid: Inspect hoses and seals for damage. Replace faulty components.

- Slow response: Check hydraulic fluid levels. Ensure there is no air in the system.

- No pressure: Examine the pump and valves. Look for clogs or damage.

Keeping the hydraulic system clean and well-maintained is crucial. Regular inspections can help identify and fix issues early.

Electrical Issues

Electrical issues can be tricky to diagnose. Here are some common electrical problems:

- Dead battery: Check the battery’s charge and connections. Replace if necessary.

- Faulty wiring: Look for frayed or disconnected wires. Secure or replace as needed.

- Malfunctioning lights: Inspect bulbs and fuses. Ensure proper connections.

Routine electrical system checks can prevent unexpected failures. Always handle electrical components with care.

By being aware of these common issues, you can troubleshoot and maintain your Ditch Witch equipment more effectively.

Safety Precautions

Ensure safety by following the Ditch Witch Troubleshooting Manual. Always wear protective gear and keep hands clear of moving parts. Regularly inspect equipment for any signs of wear or damage.

Before diving into troubleshooting your Ditch Witch, prioritize safety. Always remember that proper safety measures can prevent accidents and injuries. This section outlines critical safety precautions you should follow.Personal Protective Equipment

Always wear appropriate Personal Protective Equipment (PPE). This includes a hard hat, gloves, safety glasses, and steel-toed boots. PPE protects you from potential hazards while working with the machine.Ensure your clothing is snug. Loose clothing can get caught in moving parts. High-visibility vests help others see you clearly. Hearing protection is necessary in noisy environments.Machine Shutdown Procedures

Always shut down the machine before troubleshooting. Turn off the engine and remove the key. This step prevents accidental start-up. Wait for all moving parts to stop completely.Engage the parking brake to secure the machine. Disconnect the battery for added safety. Follow the manufacturer’s guidelines for shutdown procedures. These steps ensure a safe working environment. “`Engine Troubleshooting

The engine is the heart of your Ditch Witch equipment. When it fails, your work stops. This guide helps you understand and solve common engine problems. Follow these steps to keep your machine running smoothly.

Starting Problems

Engine starting issues can be frustrating. Here are common reasons and solutions:

- Dead Battery: Check the battery charge. Replace if needed.

- Loose Connections: Tighten all electrical connections.

- Faulty Starter: Test the starter motor. Replace if faulty.

- Fuel Supply: Ensure fuel is fresh and lines are clear.

Overheating

Overheating can damage the engine. Here are some causes and fixes:

| Cause | Solution |

|---|---|

| Low Coolant: | Check coolant level. Refill if low. |

| Blocked Radiator: | Clean the radiator. Remove any debris. |

| Faulty Thermostat: | Replace the thermostat if it is not working. |

| Fan Issues: | Inspect the fan. Repair or replace if necessary. |

Unusual Noises

Strange engine noises can indicate problems. Here’s what to check:

- Knocking Sounds: This could be due to low oil. Check the oil level and quality.

- Squealing Noise: Belts may be loose or worn out. Inspect and replace if needed.

- Rattling Sounds: Check for loose components. Tighten or replace parts as necessary.

By following this guide, you can troubleshoot and fix common engine problems in your Ditch Witch equipment. Always refer to the official manual for detailed instructions.

Credit: diyrepairmanuals.com

Hydraulic System Fixes

The hydraulic system is crucial to the smooth operation of your Ditch Witch equipment. When it fails, productivity drops. This section helps you troubleshoot common hydraulic issues. Follow these steps to ensure your equipment runs smoothly.

Low Pressure

Low hydraulic pressure can cause your Ditch Witch to underperform. Here are some steps to diagnose and fix low pressure:

- Check Hydraulic Fluid Levels: Ensure the fluid is at the correct level. Low fluid can cause pressure issues.

- Inspect Filters: Clogged filters can restrict fluid flow. Clean or replace them regularly.

- Examine Hoses and Fittings: Look for any signs of wear or damage. Replace any faulty parts.

Fluid Leaks

Hydraulic fluid leaks can cause significant issues. Finding and fixing them promptly is vital:

- Inspect Seals and Gaskets: These components can wear out and cause leaks. Replace them as needed.

- Check Hoses: Look for cracks or signs of wear. Replace any damaged hoses.

- Look at Connections: Ensure all connections are tight and secure. Loose connections can lead to leaks.

Pump Issues

The hydraulic pump is the heart of the system. If it fails, the entire system suffers:

- Listen for Unusual Noises: Grinding or whining noises may indicate a problem. Have the pump inspected.

- Check for Overheating: If the pump is too hot, it could be failing. Ensure it has proper ventilation.

- Inspect the Relief Valve: The relief valve protects the pump. Make sure it is functioning correctly.

Regular maintenance and prompt troubleshooting can keep your Ditch Witch’s hydraulic system in top shape. This ensures that your equipment performs efficiently and reliably.

Electrical System Solutions

The electrical system of your Ditch Witch is crucial for its performance. Troubleshooting electrical issues can be complicated. This guide will help you address common problems. We’ll cover battery issues, wiring problems, and fuse replacement. These solutions can save time and prevent downtime.

Battery Issues

A faulty battery can cause your Ditch Witch to malfunction. Check the battery for wear and tear. Ensure connections are clean and tight. If the battery is old, it might need replacement.

Steps to check the battery:

- Inspect the battery terminals for corrosion.

- Use a multimeter to check the battery voltage.

- Ensure the battery holds a charge over time.

If the battery voltage is low, charge it fully. If it doesn’t hold a charge, replace it.

Wiring Problems

Wiring issues can interrupt the electrical system. Inspect all wires for damage or disconnection. Look for frayed wires and loose connections. Use a continuity tester to check for breaks in the wiring.

Common wiring issues include:

- Loose connections

- Corroded wires

- Broken wires

Fix these issues by tightening connections, cleaning corrosion, or replacing damaged wires.

Fuse Replacement

Blown fuses can stop your Ditch Witch from operating. Check the fuse box for any blown fuses. Replace any blown fuses with the correct type and rating.

Steps to replace a fuse:

- Locate the fuse box.

- Identify the blown fuse (it will look burned or broken).

- Remove the blown fuse using a fuse puller.

- Replace it with a new fuse of the same rating.

Ensure the new fuse fits properly. This will restore the electrical system.

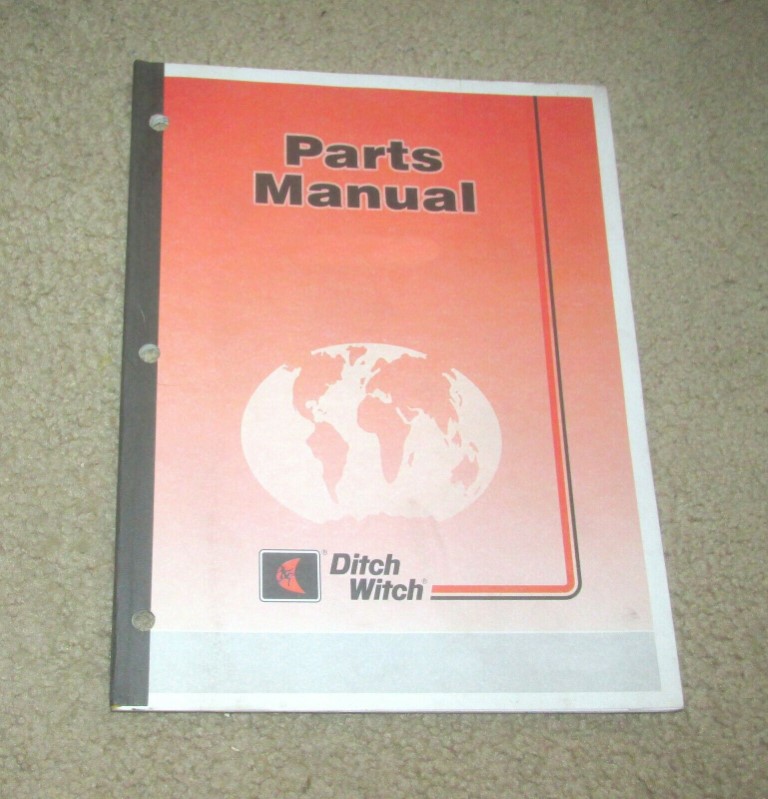

Credit: www.etsy.com

Routine Maintenance

Proper routine maintenance ensures the longevity of your Ditch Witch equipment. Regular checks and servicing help prevent costly repairs. Follow these steps to keep your machine in top condition.

Daily Checks

Perform daily checks before starting your machine. Inspect the fluid levels. Check the oil, coolant, and hydraulic fluids. Ensure they are at the correct levels.

Look for any visible leaks. Examine hoses and connections for wear or damage. Check the air filter for dirt and debris. A clean air filter ensures optimal performance.

Inspect the tires for proper inflation. Uneven tire pressure can affect machine stability. Check the battery connections for corrosion. Clean if necessary.

Scheduled Servicing

Scheduled servicing is crucial for your Ditch Witch. Follow the manufacturer’s service intervals. Change the engine oil and filter regularly. Replace the hydraulic fluid and filters as needed.

Check the drive belts for wear and tension. Replace them if necessary. Inspect and clean the fuel system. Ensure the fuel filter is in good condition.

Lubricate all moving parts. Proper lubrication reduces wear and tear. Follow the recommended grease points and intervals.

Component Inspections

Regularly inspect key components of your Ditch Witch. Examine the cutting tools for wear. Replace them if they are dull or damaged.

Check the hydraulic system for leaks and proper operation. Inspect the hoses, fittings, and cylinders. Ensure they are in good condition.

Look at the electrical system. Check the wiring and connections. Ensure all lights and gauges are functioning properly.

Monitor the track or wheel system. Check for any signs of wear or damage. Proper maintenance of these components ensures smooth operation.

Tool Requirements

Understanding the tool requirements for troubleshooting your Ditch Witch equipment is crucial. Having the right tools ensures that you can effectively diagnose and fix issues. This section will guide you through the essential and specialized equipment needed for the job.

Essential Tools

To start, you’ll need some basic tools for general maintenance and minor repairs. These tools are commonly found in most tool kits.

- Wrenches: Various sizes for tightening and loosening bolts.

- Screwdrivers: Both flathead and Phillips for different screws.

- Pliers: For gripping and manipulating parts.

- Socket Set: A comprehensive set for various bolt sizes.

- Measuring Tape: For precise measurements.

- Multimeter: For electrical diagnostics.

Specialized Equipment

In addition to the basic tools, some specialized equipment is necessary for specific troubleshooting tasks. These tools are designed for more complex repairs and diagnostics.

- Hydraulic Pressure Tester: To check the hydraulic system.

- Engine Diagnostic Tool: For reading engine error codes.

- Bore Scope: To inspect hard-to-reach areas.

- Wire Stripper: For electrical wiring tasks.

- Torque Wrench: To apply precise torque to bolts.

- Laser Level: For accurate leveling and alignment.

Having both essential tools and specialized equipment will make troubleshooting your Ditch Witch machinery more efficient. It ensures you are prepared for a wide range of issues, from basic fixes to complex diagnostics.

Professional Help

When dealing with complex equipment like Ditch Witch machinery, sometimes the troubleshooting manual isn’t enough. Professional help can save time and prevent costly mistakes. Knowing when to seek expert assistance and how to find certified professionals is crucial.

When To Call A Technician

Not all problems can be fixed with a manual. If you notice unusual noises, persistent issues, or error codes, it’s time to call a technician. Handling these issues on your own can lead to further damage. A trained expert can quickly diagnose and fix the problem.

Safety concerns also warrant professional help. If any part of the equipment seems unsafe, don’t hesitate to get expert advice. Technicians ensure that the machine operates safely and efficiently.

Finding Certified Experts

Finding the right technician is essential. Certified experts have the training and experience needed for Ditch Witch machinery. Start by checking the manufacturer’s website. They often provide a list of authorized service centers.

Local dealerships can also be a good resource. They usually have certified technicians on staff. Always verify their credentials and ask about their experience with your specific equipment model.

Online reviews and word-of-mouth recommendations are valuable too. Look for feedback from other Ditch Witch users. Positive reviews can guide you to reliable professionals.

Frequently Asked Questions

How To Fix A Ditch Witch That Won’t Start?

First, check the fuel level. Ensure the battery is charged. Inspect and clean spark plugs.

Why Is My Ditch Witch Overheating?

Overheating can be caused by a blocked radiator. Clean it. Check coolant levels and fan operation.

What Causes A Ditch Witch To Lose Power?

Loss of power may be due to fuel line blockages. Inspect filters and fuel lines for clogs.

How To Troubleshoot Hydraulic Issues On A Ditch Witch?

Check for hydraulic fluid leaks. Ensure fluid levels are adequate. Inspect hoses and connections for damage.

Why Is My Ditch Witch Not Digging Properly?

Dull teeth or worn digging chain can cause this issue. Inspect and replace them as necessary.

Conclusion

A well-maintained Ditch Witch ensures smooth operations and fewer headaches. Regular checks and timely repairs can save costs. This troubleshooting manual helps identify and fix common issues efficiently. Clear guidance improves machine lifespan and performance. Taking care of your equipment is crucial.

Remember, consistent maintenance keeps your Ditch Witch running strong. Happy digging!