Is your electric power washer acting up just when you need it most? You’re not alone.

Many users face frustrating issues like low pressure, leaks, or the washer simply not starting. But before you toss it aside or call for expensive repairs, there’s good news: most problems are easier to fix than you think. In this guide, you’ll discover simple, step-by-step troubleshooting tips that put you back in control.

By learning how to quickly identify and solve common electric power washer problems, you’ll save time, money, and the hassle of downtime. Ready to get your washer working like new again? Let’s dive in and troubleshoot your electric power washer together.

Common Pressure Issues

Low pressure is a common problem with electric power washers. It often stops the machine from cleaning effectively. Several simple issues cause this problem. Knowing these helps you fix the washer quickly and get back to work. Below are the common pressure issues and how to spot them.

Clogged Nozzle And Filter

The nozzle and filter can block with dirt and debris. This reduces water flow and pressure. Check the nozzle for clogs by removing it and cleaning with a pin. Soak the filter in vinegar to clear mineral deposits. Clean parts improve water flow and restore pressure.

Kinked And Blocked Hoses

Hoses that bend sharply or get blocked stop water from moving freely. Look for any kinks or twists along the hose. Straighten the hose or replace it if damaged. A clear hose allows smooth water flow, increasing pressure.

Insufficient Water Supply

Pressure washers need enough water to work well. Make sure the water tap is fully open. Check the hose for leaks or damage that reduce water supply. Low water flow causes weak pressure and poor cleaning results.

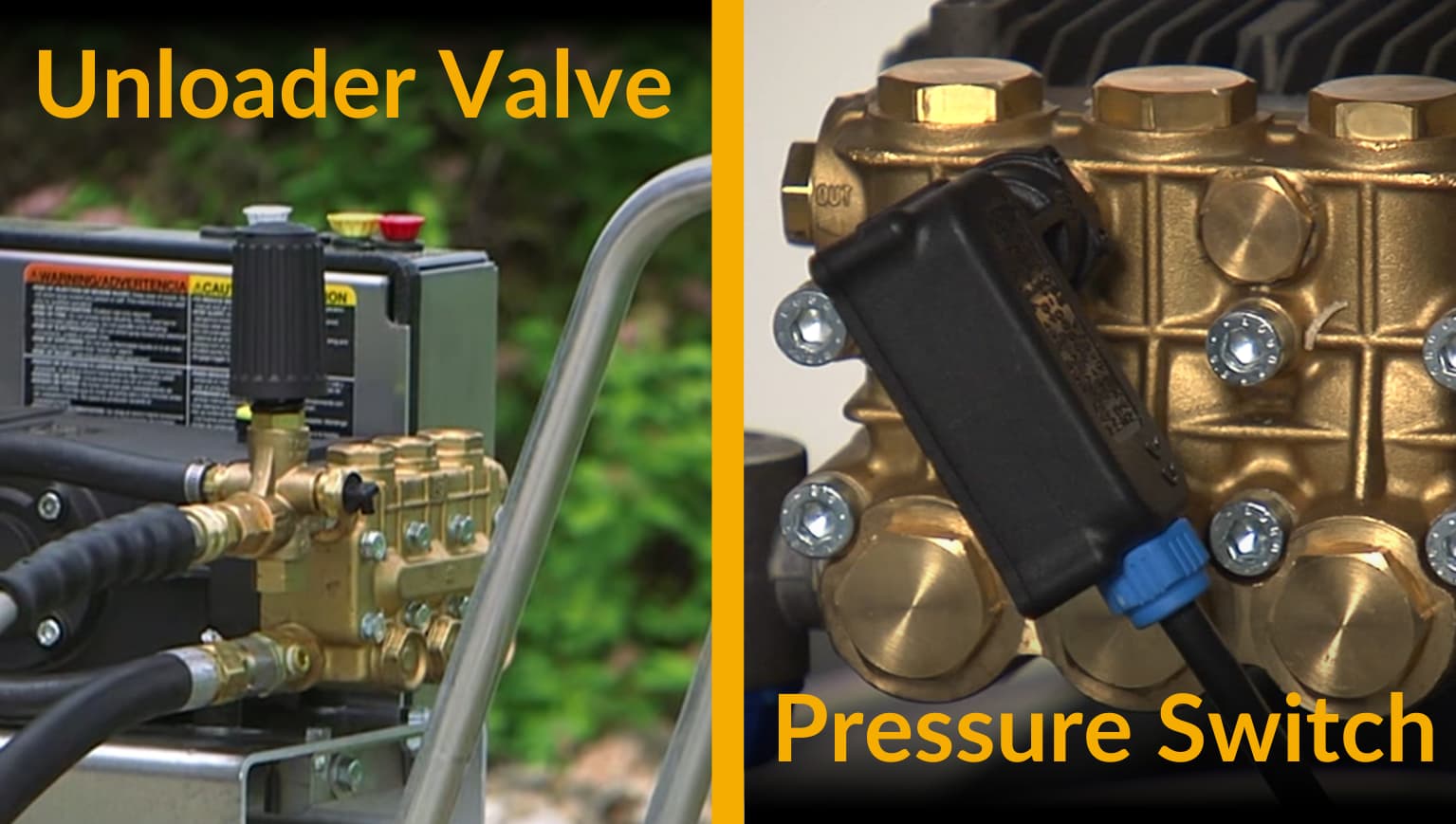

Pump Wear And Tear

The pump moves water under high pressure. Over time, its seals and valves wear out. Worn parts cause leaks and low pressure. If pressure stays low after cleaning, the pump may need repair or replacement. Regular maintenance helps extend pump life.

Credit: www.mitm.com

Leak Detection And Repair

Detecting and fixing leaks in an electric power washer is crucial for its performance. Leaks reduce pressure and waste water. Early leak detection saves time and prevents bigger damage. Check all connections and parts regularly for signs of moisture or drips. Small leaks often come from worn seals or fittings. Repairing these quickly keeps your washer running smoothly.

Worn O-rings At Connections

O-rings create a tight seal at hose and pump connections. Over time, these rings wear out or crack. This causes leaks around fittings and reduces pressure. Inspect O-rings for cracks, flattening, or brittleness. Replace any damaged rings to stop leaks. Lubricate new O-rings with silicone grease for a better seal. Proper O-ring care extends the life of your power washer.

Seal Replacement Tips

Replacing seals requires careful handling to avoid further damage. Always turn off and unplug the washer before starting. Clean the area around the seal to remove dirt. Use the correct seal size for your model to ensure a proper fit. Apply a small amount of lubricant to help installation. Avoid over-tightening connections after replacing seals. Test the washer for leaks after repair to confirm success.

Pressure Fluctuations

Pressure fluctuations in an electric power washer can disrupt your cleaning job. These changes cause the water stream to pulse or weaken unexpectedly. Such irregular pressure affects cleaning performance and can damage the machine. Understanding common causes helps fix this issue quickly. Two main reasons for pressure fluctuations are air in the system and blockages from debris and dirt.

Air In The System

Air can enter the water lines if the washer runs without enough water. This creates pockets of air that cause the pressure to pulse. The motor may sound uneven or the spray might sputter. Stop the machine immediately. Check that the water supply is steady and fully open. Turn the power washer off, then back on after restoring water flow. This helps push air out of the system and smooth out the pressure.

Debris And Dirt Blockages

Dirt and debris can clog the nozzle, hose, or filter. Blockages reduce water flow and cause pressure to fluctuate. The spray may weaken or stop suddenly. Remove the nozzle and clean it with a pin or soak it in vinegar. Inspect the hose for kinks or dirt. Flush the filter to clear trapped particles. Keeping these parts clean ensures steady water pressure and better cleaning results.

Credit: www.youtube.com

Electrical Troubleshooting

Electrical issues often cause electric power washers to stop working. Troubleshooting electrical components can solve many common problems quickly. Checking power sources and fuses helps find where the issue lies. Resetting the machine can also restore proper function.

Power Cord And Outlet Checks

Begin by examining the power cord for cuts or damage. A damaged cord can stop electricity flow and cause failure. Plug the washer into a different outlet to rule out outlet problems. Ensure the outlet has power by testing it with another device. Avoid using long or low-quality extension cords that reduce power.

Fuse Inspection And Replacement

Check the power washer’s fuse if it does not turn on. A blown fuse interrupts the electrical circuit. Locate the fuse holder, usually near the power switch or motor. Remove the fuse and inspect it for breaks or discoloration. Replace the fuse with one of the same type and rating if it is damaged. Use fuses recommended by the manufacturer to avoid risks.

Resetting The Power Washer

Many electric power washers have a reset button or switch. Find the reset button near the motor or control panel. Press and hold the reset button for a few seconds. This clears minor electrical faults and overloads. If the washer still does not work, unplug it for a few minutes then plug it back in. This can help restart the internal electronics safely.

Motor And Engine Issues

Motor and engine issues are common challenges with electric power washers. These problems affect the washer’s ability to start and run smoothly. Understanding how to identify and fix motor troubles helps keep your machine working well. Gas models require special care because their engines have parts like carburetors that need regular attention.

Carburetor Cleaning For Gas Models

Carburetors mix air and fuel for the engine. Dirt and old fuel create blockages inside. This causes rough running or failure to start. Remove the carburetor carefully. Use a carburetor cleaner spray to clear the jets and passages. Let it soak for a few minutes. Then blow air through it to remove debris. Reassemble and test the engine. Clean carburetors improve fuel flow and engine performance.

Starting And Rpm Problems

Starting problems often relate to the spark plug, fuel supply, or battery. Check the spark plug for wear or dirt. Replace it if needed. Make sure the fuel is fresh and clean. For electric motors, check the power cord and switch. RPM issues may happen if the engine runs unevenly or stalls. This can result from air leaks, clogged filters, or carburetor trouble. Inspect these parts and fix any faults. Proper maintenance prevents frequent engine problems.

Soap And Detergent Problems

Soap and detergent problems can reduce your electric power washer’s cleaning power. These issues often cause poor soap flow or no foam at all. Knowing how to handle these problems helps maintain strong cleaning results. Focus on using the correct nozzle and adjusting chemical valve settings properly. Both are key to effective soap application.

Correct Nozzle For Chemicals

Using the right nozzle is essential for soap and detergent use. Chemical nozzles have a low-pressure setting. They allow the detergent to mix with water gently. High-pressure nozzles can block soap flow or damage the machine. Identify the chemical nozzle by its color or label. Always replace worn or damaged nozzles to keep soap flowing smoothly.

Chemical Valve Settings

The chemical valve controls detergent release. Make sure the valve is open to allow soap through. A closed or partially closed valve stops detergent from entering the water stream. Adjust the valve slowly to control the amount of soap used. Too much soap can cause clogging and waste detergent. Too little soap reduces cleaning efficiency.

Maintenance Tips

Proper maintenance keeps your electric power washer running smoothly. Regular care prevents breakdowns and extends its life. Simple daily steps help avoid costly repairs and downtime.

Regular Cleaning Routines

Clean the nozzle after each use to remove dirt and debris. Use a small pin or brush to clear clogs. Rinse the water filter often to prevent blockages. Wipe down the exterior to remove dust and grime. Store the washer in a dry place to avoid rust. Check hoses for cracks or leaks regularly.

Preventing Common Failures

Inspect O-rings and seals for wear and tear. Replace damaged parts immediately to stop leaks. Avoid running the washer without water to prevent pump damage. Use the correct extension cord with proper gauge and length. Keep electrical connections dry and secure. Follow the manufacturer’s instructions for detergent use to protect internal parts.

Credit: www.bisonindustry.com

Frequently Asked Questions

Why Is My Electric Pressure Washer Suddenly Not Working?

Check the power switch and cord connection first. Inspect the fuse, extension cord, and water supply. Clear clogged nozzles or hoses. Release trapped pressure by squeezing the trigger. Persistent issues may indicate pump or motor failure requiring professional repair.

What Is The Most Common Cause Of A Pressure Washer Going Faulty?

The most common cause of a pressure washer going faulty is low or no pressure. This often results from clogged nozzles, blocked filters, kinked hoses, or insufficient water supply. Checking these simple issues first helps avoid major repairs like pump failure.

How To Reset An Electric Power Washer?

Turn off and unplug the electric power washer. Squeeze the trigger to release pressure. Check and reset the circuit breaker or fuse if needed. Plug it back in and turn it on. This resets the machine and clears minor electrical issues.

Is There A Fuse In An Electric Pressure Washer?

Yes, many electric pressure washers include a fuse in the power plug to protect against electrical faults. Check the fuse if the washer won’t start.

Why Is My Electric Power Washer Not Starting?

Check the power source and ensure the washer is plugged in correctly. Inspect the on/off switch and any extension cords for damage. Faulty wiring or a blown fuse can also prevent starting.

Conclusion

Electric power washer troubles often come from small, easy fixes. Check the nozzle, hose, and water supply first. Clean any clogs and remove kinks in the hose. Make sure the unit has enough water flow. Watch for leaks and worn parts that need replacing.

If pressure pulses or drops, clear air or dirt from the system. These simple checks can save time and money. Stay patient and follow each step carefully. Regular maintenance keeps your washer working well longer. Troubleshooting becomes easier with practice and attention.