Have you ever found yourself stuck with a lawn mower or tractor that just won’t start? You’re not alone.

One common culprit is the electric PTO clutch. This crucial component engages the mower’s blades or implements, and when it malfunctions, it can halt your gardening or farming activities in their tracks. Understanding how to troubleshoot your electric PTO clutch can save you both time and money.

Imagine the satisfaction of getting your machine running smoothly again without the hassle of waiting for repairs. You’ll discover straightforward steps to diagnose and fix issues, ensuring your equipment operates at its best. Let’s dive into the world of electric PTO clutch troubleshooting and empower you with the knowledge to keep your machinery in top shape.

Common Issues

Electric PTO clutches are essential in lawn tractors and garden machinery. They enable the transfer of power to the mower blades. Like any mechanical component, electric PTO clutches can experience issues. Understanding these common problems can help keep your machinery running smoothly. Let’s explore some typical troubles faced by electric PTO clutches.

Clutch Not Engaging

One frequent issue is the clutch not engaging. This might be due to electrical failures. Check the wiring for any signs of damage. Ensure connections are tight and clean. A faulty switch can also prevent engagement. Inspect the switch for proper function. If the clutch still doesn’t engage, consider testing the solenoid.

Clutch Slipping

Slipping clutches lead to inefficient power transfer. This can result from worn-out friction plates. Examine the plates for wear and tear. Replace them if necessary. Check for oil or grease on the clutch surfaces. Contaminants can reduce friction. Clean the surfaces thoroughly to restore functionality.

Clutch Overheating

Overheating is another common problem. It often stems from excessive use. Allow the clutch to cool down between uses. Overheating can damage internal components. Regularly inspect the clutch for signs of overheating. Ensure proper ventilation around the clutch area. Poor airflow can exacerbate overheating issues.

Credit: www.wheelhorseforum.com

Diagnostic Tools

Electric PTO clutch troubleshooting involves using diagnostic tools to identify issues in the system. These tools help pinpoint faulty connections, worn-out components, or electrical problems, ensuring efficient repairs. Understanding their functions can simplify maintenance and extend the life of your equipment.

When your electric PTO clutch isn’t working properly, having the right diagnostic tools can make troubleshooting much simpler. Knowing what to look for and how to use these tools can save you time and money. Let’s dive into the essential tools you need for diagnosing issues with your electric PTO clutch.Multimeter Usage

A multimeter is your first line of defense when diagnosing electrical problems. It helps you measure voltage, current, and resistance. Start by checking the power supply to the clutch. Set your multimeter to measure voltage and ensure that the battery is delivering the correct amount of power. If your readings are off, your battery might be the culprit. Have you ever had a situation where a simple battery test saved you hours of guesswork?Visual Inspection Techniques

Never underestimate the power of a good visual inspection. A quick look can reveal obvious issues like frayed wires or loose connections. Examine the clutch and its surroundings for signs of wear or damage. This step is crucial, especially if your machine operates in harsh conditions. I once found a tiny piece of debris lodged in the clutch, causing major issues. A quick visual check saved the day!Testers And Gauges

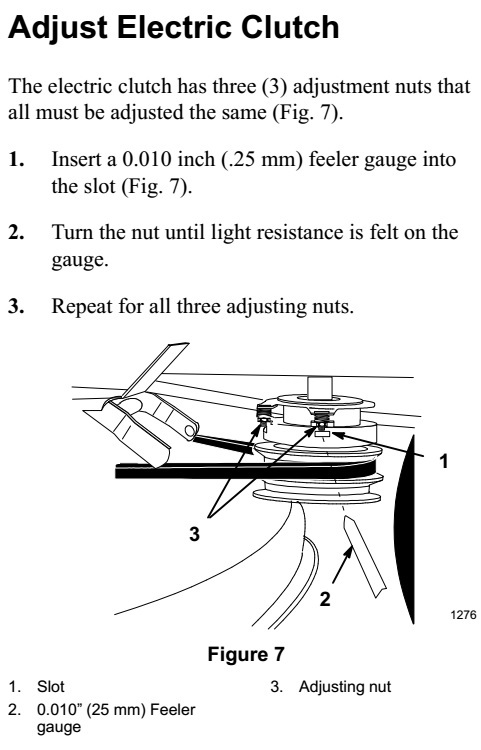

Testers and gauges help you dive deeper into the clutch’s functionality. Pressure testers can assess the hydraulic system, if applicable, to ensure proper operation. Use an ohmmeter to test the clutch coil’s resistance. Check the manufacturer’s specifications to know what readings are normal. Is your equipment showing erratic behavior? A gauge can help pinpoint if the clutch is engaging too early or late. Remember, having the right tools and knowing how to use them can make a world of difference. Are you ready to diagnose your electric PTO clutch with confidence?Quick Fixes

Electric PTO clutches can sometimes act up, causing frustration. Quick fixes can often resolve issues without much hassle. These simple solutions focus on common problems that affect performance.

Adjusting The Belt

A loose or worn belt can cause the clutch to slip. Check the belt tension first. Adjust it so it’s snug but not overly tight. Look for wear or cracks on the belt. Replace it if needed to ensure smooth operation.

Cleaning Contacts

Dirty contacts can disrupt the clutch’s function. Inspect the clutch contacts for dirt or corrosion. Use a soft brush or cloth to clean them. Ensure they’re dry before reconnecting. This simple step can restore proper clutch operation.

Checking Electrical Connections

Faulty connections can lead to clutch failure. Inspect all electrical wires and connectors. Look for signs of damage or loose connections. Tighten loose connections and replace damaged wires. Ensure all connections are secure to prevent future issues.

Maintenance Tips

Maintaining your electric PTO clutch ensures its longevity and efficiency. Proper care prevents breakdowns and costly repairs. Regular maintenance helps avoid unexpected issues. These tips will keep your clutch in top shape.

Regular Cleaning

Cleaning the clutch removes dirt and debris. Use a soft brush to clean it gently. Avoid using harsh chemicals. They can damage the clutch surfaces. A clean clutch operates more smoothly.

Lubrication Advice

Lubricating the clutch reduces friction. Use recommended lubricants only. Check the manufacturer’s guide for details. Apply lubricant sparingly to avoid buildup. Proper lubrication extends clutch life.

Routine Inspection

Inspect the clutch regularly for wear. Look for signs of damage or corrosion. Check all connections and wiring. Tighten any loose bolts or screws. Early detection prevents major problems.

When To Seek Professional Help

Sometimes DIY efforts aren’t enough for electric PTO clutches. Problems can be tough to solve. Recognizing when to call a professional is key. Avoiding further damage is crucial.

Identifying Complex Issues

Complex problems need expert eyes. Grinding noises or burnt smells often signal deeper issues. These may involve electrical components or intricate parts. Professionals have the tools to diagnose these problems. They ensure your clutch works smoothly again.

Safety Concerns

Working with electric components carries risks. Incorrect handling can lead to electric shocks. Professionals follow strict safety protocols. They have the training to safely handle repairs. This minimizes risks to both the machine and the user.

Warranty Considerations

Warranties often require professional service. DIY repairs may void the warranty. Check your warranty terms before attempting fixes. Professional services help maintain your warranty coverage. This ensures you stay protected against future issues.

Credit: mechanics.stackexchange.com

Credit: www.youtube.com

Conclusion

Understanding electric PTO clutch issues can save time and money. A well-maintained clutch ensures smooth lawn mower operations. Regular checks prevent unexpected breakdowns. Listen for unusual sounds. Inspect wiring for wear or damage. Clean components regularly. Replace faulty parts promptly.

Simple steps make a big difference. Trust your observations. Use this guide for effective troubleshooting. Keep your equipment in good shape. Smooth mowing awaits with a reliable PTO clutch. Your lawn will thank you!