Flojet air pumps are reliable. But they can face issues sometimes.

Troubleshooting these pumps can save time and money. Flojet air pumps are widely used in various industries. They are known for their durability and efficiency. But like any equipment, they can develop problems over time. Common issues include loss of pressure, irregular flow, and unusual noises.

Understanding these problems can help you fix them quickly. This blog will guide you through common troubleshooting steps. Whether you are a novice or an expert, these tips can help. Let’s dive into the world of Flojet air pump troubleshooting and get your pump running smoothly again.

Introduction To Flojet Air Pumps

Flojet air pumps are known for their reliability and efficiency. These pumps are used in various industries and applications. Understanding how they work can help you troubleshoot them effectively.

Why Choose Flojet?

Flojet air pumps offer several advantages:

- Durable construction

- Efficient performance

- Wide range of models

- Easy to maintain

Their durability ensures long-lasting service. They are built to handle tough conditions. With a wide range of models, you can find the right pump for your needs.

Common Applications

Flojet air pumps are versatile and can be used in many settings:

| Application | Usage |

|---|---|

| Agriculture | Pumping water and chemicals |

| Marine | Water transfer and bilge pumping |

| Food and Beverage | Dispensing drinks and cleaning |

| Industrial | Handling various fluids and chemicals |

In agriculture, they are used for pumping water and chemicals. In the marine industry, they are used for water transfer and bilge pumping. The food and beverage industry uses them for dispensing drinks and cleaning tasks.

In industrial settings, Flojet pumps handle various fluids and chemicals. Their versatility makes them a popular choice across different sectors.

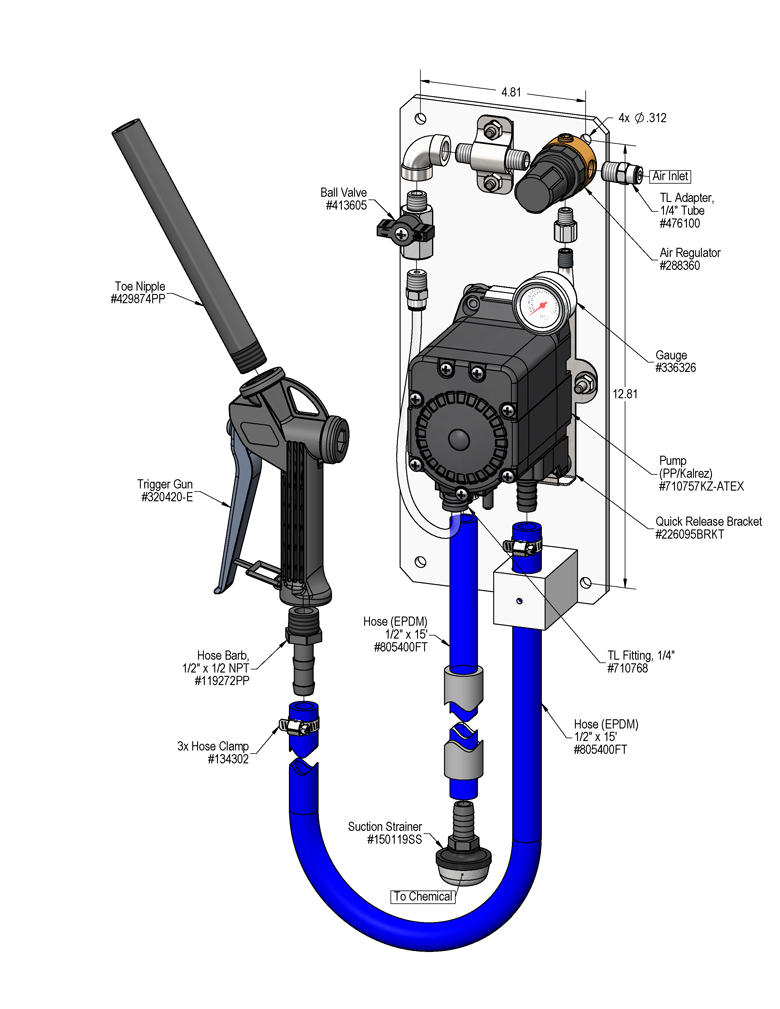

Credit: learning.laffertyequipment.com

Identifying Common Problems

Identifying common problems with a Flojet air pump can save time. It ensures efficient operation. Understanding typical issues helps maintain the pump’s performance. Two frequent problems are the pump not turning on and low or no pressure.

Pump Not Turning On

First, check the power supply. Ensure the pump is plugged in. Verify the power switch is on. If the pump still doesn’t work, inspect the fuse. Replace it if necessary. Next, check the motor. It might be overheated. Allow it to cool down. If the pump still doesn’t turn on, the problem could be internal. Seek professional help.

Low Or No Pressure

Low or no pressure can indicate a blockage. Check the inlet and outlet for debris. Clean them if needed. Inspect the hoses for leaks. Replace damaged hoses. Another cause could be a worn diaphragm. This part needs replacement over time. Ensure the air pump is not damaged. If these steps don’t help, consult a technician.

Diagnosing Pump Not Turning On

Is your Flojet air pump not turning on? This can be frustrating. There are a few common reasons for this issue. By following these steps, you can diagnose the problem.

First, ensure the power supply is working. Then, inspect the wiring connections. Let’s dive into these steps in more detail.

Checking Power Supply

Start by checking the power supply. Is the pump plugged in securely? Sometimes, the plug can come loose. Also, check the outlet. Plug another device into the same outlet to see if it works. If the outlet is not working, you may need an electrician.

Next, check the fuse or circuit breaker. A blown fuse or tripped breaker can stop the pump from turning on. Replace the fuse or reset the breaker if needed. Ensure the power switch on the pump is turned on.

Inspecting Wiring Connections

Inspect the wiring connections next. Look for any loose or damaged wires. Loose wires can cause the pump to stop working. Tighten any loose connections. If you see damaged wires, they may need replacing.

Check the wires for signs of wear or corrosion. Corroded wires can stop the pump from getting power. Clean the corrosion carefully or replace the wires if needed. Ensure all connections are secure and in good condition.

Fixing Low Or No Pressure

Experiencing low or no pressure in your Flojet air pump can be frustrating. But don’t worry, with some basic troubleshooting, you can often resolve the issue yourself. In this section, we will cover two key steps to help you fix the problem: cleaning the inlet filter and checking for air leaks.

Cleaning The Inlet Filter

The inlet filter can often become clogged with debris, affecting the pump’s performance. To clean the filter, follow these steps:

- Turn off the pump and disconnect the power supply.

- Locate the inlet filter. It is usually found near the inlet valve.

- Remove the filter carefully. Use a wrench if needed.

- Rinse the filter under running water. Remove any visible debris.

- Reinstall the filter and ensure it is tightly secured.

- Reconnect the power supply and turn on the pump.

A clean inlet filter can significantly improve the pump’s pressure. If the issue persists, move on to the next step.

Checking For Air Leaks

Air leaks can also cause low or no pressure in your Flojet air pump. To check for leaks, follow these instructions:

- Inspect all connections and hoses for any visible damage or wear.

- Use soapy water to check for leaks. Apply the solution to the connections.

- Turn on the pump and look for bubbles forming at the connections. Bubbles indicate a leak.

- If a leak is found, tighten the connections or replace damaged parts.

- Ensure all connections are secure and free from defects.

By checking and fixing air leaks, you can restore the proper pressure in your Flojet air pump.

Dealing With Frequent Cycling

Experiencing frequent cycling with your Flojet air pump can be frustrating. It may cause unnecessary wear and tear on the pump. This guide will help you troubleshoot this issue. By following these steps, you can identify and fix the problem.

Inspecting Pressure Switch

The pressure switch regulates the pump’s operation. If it’s faulty, the pump may cycle too often. Here’s how to inspect it:

- Turn off the power to the pump.

- Locate the pressure switch near the pump’s motor.

- Check for any visible damage or wear.

- Use a multimeter to test the switch’s continuity.

- If the switch is faulty, replace it with a new one.

Checking For Water Leaks

Water leaks can cause the pump to cycle more frequently. Even small leaks can lead to big problems. Follow these steps to check for leaks:

- Inspect all connections and fittings for signs of water.

- Look for damp spots or puddles under the pump.

- Tighten any loose connections.

- Replace any damaged hoses or fittings.

- Use a water leak detector if the leak is hard to find.

By inspecting the pressure switch and checking for water leaks, you can solve the frequent cycling issue. This will help your Flojet air pump run smoothly and last longer.

Credit: www.youtube.com

Addressing Unusual Noises

Strange sounds from your Flojet air pump can indicate a problem. Check for loose parts or blockages. Regular maintenance helps keep the pump running smoothly.

Is your Flojet air pump making strange noises? Unusual sounds can indicate a problem. Let’s explore some common issues. Fixing these can restore your pump’s quiet operation.Tightening Loose Components

Loose components often cause unusual noises. Check all screws and bolts. Ensure they are tight. Even a slightly loose part can make noise. Use the right tools to avoid damage.Inspect the hoses and connections. Ensure they are secure. Loose hoses can vibrate and cause noise. Tightening these can reduce or eliminate the noise.Replacing Worn-out Parts

Worn-out parts can also cause noise. Examine your pump for signs of wear. Look at the diaphragm and valves. These parts wear out over time.Replace any parts that look damaged. This can reduce noise and improve performance. Consult your Flojet air pump manual. Follow the instructions for part replacement.Regular maintenance prevents unusual noises. Keep your Flojet air pump in top condition. This will ensure it runs smoothly and quietly. “`Maintaining Your Flojet Air Pump

Maintaining your Flojet Air Pump ensures longevity and optimal performance. A well-maintained pump reduces unexpected breakdowns. Follow these steps to keep your Flojet Air Pump in top condition.

Regular Cleaning

Regular cleaning is crucial for your Flojet Air Pump. Dirt and debris can clog the pump. This can lead to poor performance or even failure.

- Disconnect the pump from power sources before cleaning.

- Use a soft brush to remove dirt from the pump exterior.

- Inspect and clean the pump’s filters. Clogged filters can reduce efficiency.

- Wipe down the pump with a damp cloth. Avoid using harsh chemicals.

Clean your pump every few months. More frequent cleaning may be needed in dirty environments.

Scheduled Inspections

Scheduled inspections help detect issues early. Regular checks can prevent costly repairs.

- Check for leaks around connections and seals.

- Listen for unusual noises. Unusual sounds may indicate a problem.

- Inspect hoses for cracks or wear. Replace damaged hoses promptly.

- Ensure all mounting hardware is secure. Loose parts can cause vibrations.

Conduct inspections at least twice a year. Adjust the frequency based on usage.

| Maintenance Task | Frequency |

|---|---|

| Cleaning the pump | Every 3-6 months |

| Inspecting for leaks | Twice a year |

| Checking hoses | Twice a year |

| Securing hardware | Twice a year |

Proper maintenance enhances the lifespan of your Flojet Air Pump. A little effort now saves a lot of trouble later.

When To Seek Professional Help

Dealing with a Flojet air pump can be tricky. Sometimes, you may fix minor issues on your own. Yet, there are times when seeking professional help is necessary. Knowing when to contact a technician can save time and prevent further damage.

Identifying Complex Issues

Some problems with a Flojet air pump are more complex. These issues often need expert attention. Here are some signs that indicate a more complicated problem:

- Strange noises: Unusual sounds may signal internal damage.

- Leaks: Persistent leaks can lead to significant issues.

- Unresponsive pump: If the pump doesn’t start, it might need professional repair.

- Inconsistent performance: A pump that works intermittently can be a sign of deeper issues.

If you notice any of these signs, it is best to seek professional help. Ignoring them can worsen the problem and increase repair costs.

Finding A Qualified Technician

Not every technician is skilled in Flojet air pumps. Here’s how to find a qualified technician:

- Check credentials: Ensure they have experience with Flojet pumps.

- Read reviews: Look for feedback from other customers.

- Ask for references: Speak with previous clients if possible.

- Compare prices: Get quotes from multiple technicians.

Choosing the right technician can save time and money. Always ensure they understand your specific needs. By following these steps, you can find a reliable expert to handle your Flojet air pump issues.

Credit: learning.laffertyequipment.com

Frequently Asked Questions

Why Is My Flojet Air Pump Not Working?

Check for power supply issues, clogs, or air leaks in the system.

How Can I Fix A Noisy Flojet Air Pump?

Tighten loose parts, check for debris, and ensure proper installation to reduce noise.

What Causes Low Pressure In My Flojet Air Pump?

Low pressure can be due to clogs, leaks, or worn-out components.

How Do I Clean My Flojet Air Pump?

Disconnect power, remove debris, and clean filters and pump parts with water.

Why Does My Flojet Air Pump Keep Turning On And Off?

This may be caused by air leaks, pressure switch issues, or electrical problems.

Conclusion

Troubleshooting your Flojet air pump can be straightforward with these tips. Check connections, inspect for blockages, and ensure proper voltage. Regular maintenance prevents most issues. Keep your manual handy for specific guidance. Addressing problems early saves time and money. Happy pumping!