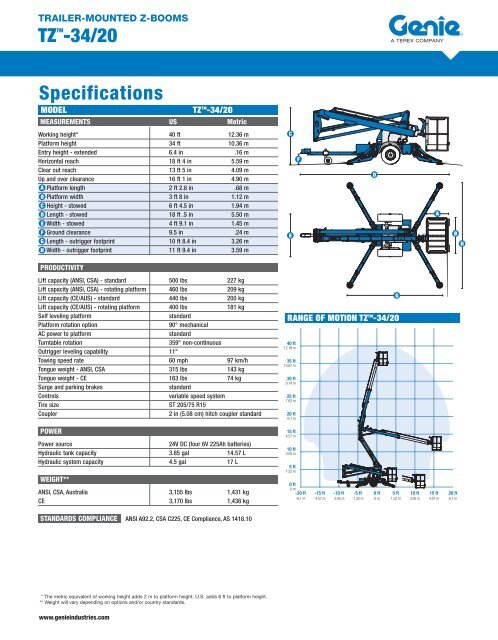

The Genie Tz 34/20 is a popular lift machine. It helps with various tasks.

But, like any machine, it can have issues. Understanding how to troubleshoot the Genie Tz 34/20 is vital. Knowing common problems and solutions can save time and money. This guide will help you navigate through common troubles. From power failures to hydraulic issues, we will cover it all.

You will learn how to diagnose and fix problems easily. Regular maintenance tips are also included. This will ensure your machine runs smoothly. Stay tuned to keep your Genie Tz 34/20 in top condition. Let’s dive into troubleshooting and keep your projects on track.

Common Issues

The Genie Tz 34/20 is a powerful tool. But, like any machine, it can have problems. Knowing these common issues helps you troubleshoot faster. Below are some of the most frequent issues users face.

Battery Problems

Battery problems are common with the Genie Tz 34/20. Here are some signs and solutions:

- Low Battery Life: If the battery drains quickly, it may be old. Consider replacing it.

- Battery Not Charging: Check the charger and connections. Make sure they are secure.

- Battery Corrosion: Look for white powder on the battery terminals. Clean it with baking soda and water.

A clean and well-maintained battery lasts longer. Regular checks can prevent major issues.

Hydraulic System Failures

Hydraulic system failures can disrupt your work. Here are key issues to watch for:

- Leaking Hydraulic Fluid: Look for fluid on the ground. Tighten loose connections and replace damaged hoses.

- Slow Movement: If the lift moves slowly, check the fluid level. Low fluid can cause this issue.

- No Movement: If the lift does not move, the pump might be faulty. Inspect the pump and repair or replace it.

Regularly check the hydraulic fluid levels and connections. This can save you from unexpected downtime.

Credit: www.liftincorporated.com

Battery Troubleshooting

Battery issues can bring your Genie TZ 34/20 to a halt. Understanding the basics of battery troubleshooting helps keep your equipment running smoothly. Here, we’ll cover the essential areas to check, ensuring your machine’s battery is always in top condition.

Battery Charge Levels

First, check the battery charge levels. A fully charged battery should read between 12.6 to 12.8 volts. Use a multimeter to measure the voltage. If the reading is below 12.4 volts, your battery may need charging.

| Battery State | Voltage (V) |

|---|---|

| Fully Charged | 12.6 – 12.8 |

| Needs Charging | 12.4 – 12.5 |

| Discharged | Below 12.4 |

Inspecting Battery Connections

Next, inspect the battery connections. Loose or corroded connections can cause power issues. Ensure the terminals are clean and tight.

- Check for corrosion on the terminals.

- Use a wire brush to clean any buildup.

- Ensure all connections are secure.

A clean, tight connection ensures your battery delivers power efficiently. Regular inspections help prevent unexpected downtime.

By following these simple steps, you can easily troubleshoot and maintain your Genie TZ 34/20’s battery.

Hydraulic System Checks

Maintaining the Genie Tz 34/20 requires regular hydraulic system checks. This ensures the machine operates smoothly. It also prevents unexpected breakdowns and costly repairs. Below, we dive into two crucial aspects of hydraulic system maintenance: checking fluid levels and inspecting hoses.

Hydraulic Fluid Levels

First, verify the hydraulic fluid levels. Low fluid can cause performance issues. Locate the hydraulic fluid reservoir. Check the fluid level using the dipstick. If the level is low, add the recommended hydraulic fluid. Always use the fluid specified in the manual. Overfilling can also cause problems. Maintain the fluid at the correct level. This ensures optimal performance.

Inspecting Hydraulic Hoses

Second, inspect the hydraulic hoses. Look for signs of wear or damage. Cracks, leaks, or bulges indicate problems. Damaged hoses can lead to fluid leaks. This affects the machine’s efficiency. Replace any damaged hoses immediately. Secure all hose connections. Loose connections can also cause leaks. Regularly inspect and maintain hoses. This prevents potential issues and ensures smooth operation.

Credit: www.youtube.com

Electrical System Diagnostics

Troubleshooting the electrical system of your Genie Tz 34/20 can be daunting. But with a focused approach, you can identify and resolve issues quickly. Here, we will explore two crucial steps: Checking Fuses and Inspecting Wiring.

Checking Fuses

Fuses protect the electrical system from overloads. If a component stops working, the fuse could be the issue. Follow these steps to check the fuses:

- Locate the fuse box. Refer to the user manual for its location.

- Turn off the power to avoid shocks.

- Remove the fuse with a fuse puller or pliers.

- Inspect the fuse. If the metal wire inside is broken, the fuse is blown.

- Replace the blown fuse with one of the same rating.

Use the table below for common fuse ratings and their functions:

| Fuse Rating | Function |

|---|---|

| 5A | Control System |

| 10A | Lights |

| 15A | Hydraulic Pump |

Inspecting Wiring

Faulty wiring can cause major issues. Inspect the wiring to ensure all connections are secure and undamaged.

- Visual Inspection: Look for exposed or damaged wires.

- Connection Check: Ensure all wires are connected properly.

- Continuity Test: Use a multimeter to check for continuity in the wires.

If you find damaged wires, repair them by cutting the damaged section and reconnecting the wires using wire connectors. Always use electrical tape to secure the connections.

Motor Issues

When dealing with Genie Tz 34/20, motor issues can arise. These problems can hinder your equipment’s performance. Understanding common motor issues can help you troubleshoot effectively. Two frequent motor issues include motor overheating and motor not starting.

Motor Overheating

Motor overheating is a common issue. It can cause the Genie Tz 34/20 to stop working. Overheating usually occurs due to a lack of ventilation. Ensure the motor has enough airflow. Check for any obstructions around the motor. Clean the air filters regularly. This helps maintain proper airflow. If the motor continues to overheat, inspect the electrical connections. Loose or damaged wires can lead to overheating. Tighten any loose connections. Replace damaged wires immediately. Keeping the motor clean and well-ventilated prevents overheating.

Motor Not Starting

If the motor does not start, there are a few things to check. First, ensure the battery is fully charged. A weak battery can prevent the motor from starting. Next, inspect the battery connections. Ensure they are tight and clean. Corroded connections can block power flow. Clean any corrosion with a wire brush. Check the fuses as well. A blown fuse can stop the motor from starting. Replace any blown fuses with the correct type. If the motor still does not start, test the start switch. A faulty start switch may need replacement. Regular maintenance can prevent starting issues.

Platform Controls

The platform controls of the Genie TZ 34/20 play a crucial role in its operation. Understanding how to troubleshoot common issues with these controls can enhance your efficiency and safety. This section will guide you through some common problems and their solutions.

Control Panel Malfunctions

Control panel malfunctions can cause significant disruptions. First, check for any visible damage. Broken or loose wires can lead to control failures. Ensure all connections are secure.

If the control panel lights are off, the battery might be dead. Charge the battery fully. Sometimes, the issue lies with the control panel fuse. Replace the fuse if necessary.

Another common problem is the control buttons not responding. Dirt or debris might be blocking the buttons. Clean the buttons and test them again. If the problem persists, you may need a professional inspection.

Joystick Response

The joystick controls the movement of the platform. If the joystick response is slow, check the hydraulic fluid levels. Low fluid can affect the joystick’s performance.

Ensure the joystick is not physically damaged. A cracked or broken joystick can cause erratic movements. Replace it if necessary.

Sometimes, the joystick calibration might be off. Recalibrate the joystick according to the manual instructions. This can resolve many response issues.

If the joystick still doesn’t respond correctly, inspect the wiring for any wear or damage. Secure any loose connections and replace damaged wires.

Safety Mechanisms

Ensuring the safety of operators and equipment is crucial for the efficient functioning of the Genie TZ 34/20. This aerial lift comes equipped with various safety mechanisms designed to prevent accidents and malfunctions. Understanding these safety features will help maintain the unit’s reliability and protect users from harm.

Safety Switches

Safety switches play a vital role in the Genie TZ 34/20. These switches cut off the power supply in unsafe conditions. They prevent the lift from operating if any component is malfunctioning. This feature ensures that the equipment only works when all parts are in good condition.

Emergency Stop Functions

The emergency stop functions are essential for immediate halting of operations. These functions allow users to stop the lift during emergencies. This helps to prevent accidents and damage. The Genie TZ 34/20 has easily accessible emergency stop buttons. This makes it simple to react quickly in dangerous situations.

Regular Maintenance Tips

Regular maintenance of your Genie TZ 34/20 is essential for smooth operation. Consistent checks help identify potential issues early. This can prevent costly repairs. Adhering to a maintenance schedule ensures safety and efficiency.

Routine Inspections

Routine inspections are vital. They keep your equipment in top shape. Follow a daily, weekly, and monthly inspection schedule. This helps catch issues before they escalate.

Daily Checks:

- Inspect for visible damage.

- Check fluid levels.

- Test all controls.

Weekly Checks:

- Examine hydraulic hoses and fittings.

- Check tire conditions.

- Inspect battery and charging system.

Monthly Checks:

- Inspect the entire machine for wear and tear.

- Lubricate all moving parts.

- Check and tighten bolts and screws.

Preventative Measures

Preventative measures extend the lifespan of your Genie TZ 34/20. They save you from unexpected breakdowns.

Lubrication: Regular lubrication prevents rust and reduces friction. Apply lubricants to all joints and moving parts.

Fluid Management: Keep hydraulic fluids at recommended levels. Change fluids as per the manufacturer’s guidelines.

Battery Care: Clean battery terminals regularly. Ensure proper charging. Replace old or weak batteries promptly.

Storage: Store the machine in a dry place. Protect it from extreme weather conditions.

Training: Ensure operators are well-trained. They should know the machine’s operation and safety protocols.

Credit: www.yumpu.com

Frequently Asked Questions

How Do I Reset My Genie Tz 34/20?

Press and hold the reset button for 5 seconds.

Why Is My Genie Tz 34/20 Not Starting?

Check the battery charge and connections. Ensure emergency stop is not engaged.

What Does The Error Code E02 Mean On Genie Tz 34/20?

E02 indicates a low battery voltage. Recharge or replace the battery.

How Can I Fix Hydraulic Issues On Genie Tz 34/20?

Check fluid levels, inspect for leaks, and ensure filters are clean.

Why Is My Genie Tz 34/20 Moving Slowly?

This could be due to low hydraulic fluid or a problem with the drive motors.

Conclusion

Troubleshooting the Genie Tz 34/20 can be straightforward with the right steps. Follow the guide carefully. Check each component systematically. This helps identify issues quickly. Regular maintenance is key. It prevents many common problems. Always use genuine parts for replacements.

This ensures durability and efficiency. Don’t hesitate to consult the user manual. It’s a valuable resource. For persistent issues, contact professional support. Your machine will thank you. Keep it in top shape for reliable performance. Happy troubleshooting!