Is your HVAC system acting up right when you need it most? You’re not alone.

When your heating or cooling equipment starts to fail, it can disrupt your comfort and peace of mind. But before you reach for your phone to call a technician, why not try some simple troubleshooting steps? Knowing how to quickly identify and fix common HVAC problems can save you time, money, and hassle.

In this guide, you’ll discover easy-to-follow tips that put you in control of your HVAC equipment. Whether it’s strange noises, weak airflow, or unexpected temperature swings, you’ll learn what to look for and how to tackle these issues head-on. Keep reading, and take the first step toward restoring comfort to your home today.

Common Hvac Problems

HVAC systems often face issues that affect their performance and comfort levels. Identifying common problems helps in quick fixes and prevents bigger damage. Regular checks can keep your system running efficiently and save money on repairs.

Warm Air Issues

Warm air blowing from vents is a frequent HVAC problem. It can mean low refrigerant levels or a dirty air filter. Faulty compressors or frozen coils also cause this issue. Fixing these ensures cool air flows properly in your home.

Airflow Restrictions

Blocked airflow reduces system efficiency and comfort. Dirty filters, closed vents, or clogged ducts restrict air movement. Poor airflow makes your HVAC work harder and raises energy bills. Cleaning or replacing filters and clearing vents can restore airflow.

Thermostat Malfunctions

Thermostats control your HVAC system’s temperature. Incorrect settings or dead batteries cause malfunctions. Faulty wiring or sensors may also lead to errors. Checking thermostat settings and replacing batteries often solve these problems quickly.

Noisy Or Odorous Systems

Unusual noises or smells from your HVAC system signal trouble. Squealing or banging sounds may mean loose parts or motor issues. Musty or burning odors often indicate mold or electrical problems. Addressing these signs early prevents bigger repairs and health risks.

Basic Troubleshooting Steps

Basic troubleshooting steps help identify common HVAC problems quickly. These steps save time and money by solving simple issues. Following a clear process avoids unnecessary repairs. Start with easy checks before calling a professional.

Checking Air Filters

Dirty air filters block airflow and reduce efficiency. Remove the filter and inspect it for dust and debris. Replace the filter if it looks clogged or dirty. Clean filters improve air quality and system performance. Check filters every month during heavy use seasons.

Inspecting Circuit Breakers

HVAC units rely on circuit breakers for power safety. Locate the breaker panel and find the HVAC breaker. Ensure the breaker is in the “on” position. Flip the breaker off and on to reset it if needed. Tripped breakers may indicate electrical problems.

Verifying Thermostat Settings

Incorrect thermostat settings cause many HVAC issues. Check the temperature setting and mode (cool or heat). Make sure the thermostat is set below room temperature for cooling. Replace batteries if the display is blank or unresponsive. Proper settings ensure the system runs correctly.

Examining Refrigerant Levels

Low refrigerant causes poor cooling and system strain. Look for signs like ice buildup on coils or hissing sounds. Refrigerant should only be checked by a licensed technician. Avoid adding refrigerant yourself to prevent damage. Proper levels keep the system efficient and safe.

Diagnosing Specific Equipment Issues

Diagnosing specific equipment issues is a key step in HVAC troubleshooting. Understanding the common problems helps fix the system faster. Identifying the exact fault reduces downtime and saves money.

Each part of an HVAC system can show unique symptoms. Clear signs point to specific failures. Knowing these signs helps in accurate diagnosis and repair.

Frozen Evaporator Coils

Frozen evaporator coils stop proper cooling. Ice blocks airflow and lowers system efficiency. Causes include dirty filters, low refrigerant, or poor airflow. Check the air filter and clean it regularly. Inspect refrigerant levels and fix any leaks. Clear blocked vents to improve airflow. Defrost the coils carefully to avoid damage.

Faulty Motors And Fans

Motors and fans move air through the system. Faulty motors cause weak airflow or no airflow. Listen for unusual noises like grinding or squealing. Check if the fan blades spin freely. Test the motor for electrical continuity. Replace or repair motors that fail these tests. Clean fan blades to prevent imbalance and wear.

Electrical Fuse Problems

Electrical fuses protect HVAC components from damage. A blown fuse cuts power to parts of the system. Check fuses in the control board and disconnect box. Use a multimeter to test fuse continuity. Replace blown fuses with the correct type and rating. Inspect wiring for shorts that cause fuse failure.

Sensor And Control Failures

Sensors and controls regulate system operation. Faulty sensors cause incorrect temperature readings. This leads to poor heating or cooling. Test sensors with a multimeter for resistance. Replace sensors that show wrong values. Check control boards for signs of damage or burnt components. Reset or replace controls as needed.

Credit: www.sportyard.sa

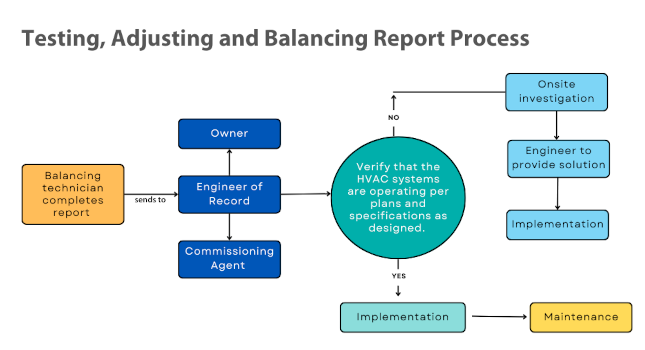

Using Order Of Operation For Troubleshooting

Using the order of operation for troubleshooting HVAC equipment helps technicians find problems faster. This method follows a set sequence of steps. It reduces guesswork and improves accuracy. The process breaks down complex issues into smaller parts. Each step builds on the previous one. This approach saves time and avoids unnecessary repairs.

Step-by-step Diagnostic Process

Start by checking the power supply. Make sure the unit is receiving electricity. Next, inspect fuses and circuit breakers. Then, examine the thermostat settings for errors. After that, assess airflow by checking filters and vents. Finally, test motors and compressors for proper function. Follow these steps in order to spot the root cause quickly.

Flowchart Techniques

Flowcharts map out the troubleshooting process visually. They show each decision and action clearly. Use simple yes/no questions to guide the checks. Flowcharts help avoid skipping important steps. They make it easier to train new technicians. This visual tool reduces mistakes and speeds up problem-solving.

Prioritizing Checks For Efficiency

Focus on the most common issues first. Start with easy-to-fix parts like filters or power sources. Look for signs of wear or damage early. Prioritizing saves time and reduces downtime. It also lowers repair costs by fixing small problems before they get worse. Efficient checks keep HVAC systems running smoothly longer.

Tools And Resources For Troubleshooting

Effective HVAC equipment troubleshooting depends on having the right tools and resources. These help diagnose problems quickly and accurately. Proper tools make it easier to find issues and fix them with confidence.

Using the right resources also improves your understanding of the system. This can reduce downtime and save costs on repairs. Below are key tools and resources every HVAC technician should have.

Essential Hvac Tools

Basic tools include screwdrivers, pliers, and wrenches. A multimeter is vital to check electrical connections and voltage. Refrigerant gauges help measure pressure in cooling systems. Thermometers monitor temperature differences. A flashlight is useful for inspecting dark parts of the unit. Having these tools ready speeds up troubleshooting.

Troubleshooting Checklists

Checklists guide the step-by-step process of diagnosing HVAC issues. They ensure no part is overlooked. Common checklists cover airflow, electrical systems, and refrigerant levels. Using a checklist prevents guesswork and improves accuracy. It also helps new technicians learn the correct procedure.

Diagnostic Codes And Manuals

Modern HVAC units often display diagnostic codes. These codes point to specific problems. Access to the unit’s manual is essential to interpret these codes correctly. Manuals also provide wiring diagrams and component details. They are a reliable source for exact troubleshooting steps.

Credit: apexelectricmechanical.ca

Tips For Faster Repairs

Faster repairs save time and reduce costs in HVAC troubleshooting. Following clear tips helps technicians work efficiently. Speed depends on quick diagnosis, smart checks, and clear communication. These tips improve repair times and customer satisfaction.

Recognizing Common Symptoms Quickly

Learn to spot frequent HVAC problems fast. Warm air from the system often signals dirty filters or low refrigerant. Strange noises may mean loose parts or motor issues. Check thermostat settings early. These signs narrow down causes swiftly.

Avoiding Repetitive Checks

Don’t waste time repeating the same tests. Use a checklist to track what you have checked. Inspect airflow, electrical connections, and filters once thoroughly. Follow logical steps to avoid going back and forth. This method speeds up diagnosis.

Effective Customer Communication

Ask customers clear questions about the problem. Understand when issues started and what changed. Explain your findings simply and what you will do next. Good communication prevents misunderstandings and helps prepare for parts or tools needed.

Preventive Maintenance To Avoid Issues

Preventive maintenance is key to keeping HVAC systems running smoothly. It helps avoid common problems that cause discomfort and costly repairs. Simple, regular care keeps equipment efficient and extends its life. This section highlights essential maintenance tasks that prevent issues before they start.

Regular Filter Changes

Changing air filters often improves air quality and system performance. Dirty filters block airflow and force the system to work harder. This raises energy costs and risks overheating. Replace filters every 1 to 3 months, depending on use and environment. Clean filters reduce dust buildup and protect internal parts.

Routine Coil Cleaning

Coils collect dirt and debris, which lowers heat exchange efficiency. Dirty coils make the system less effective and increase energy use. Clean evaporator and condenser coils at least once a year. Use gentle brushes or vacuum tools to avoid damage. Clean coils help maintain proper airflow and cooling power.

Scheduled System Inspections

Regular inspections catch small issues before they grow into big problems. A technician checks electrical connections, refrigerant levels, and moving parts. Inspections ensure safe operation and optimal performance. Schedule visits twice a year, ideally before heating and cooling seasons. Timely inspections reduce breakdowns and improve system reliability.

Credit: www.csemag.com

Frequently Asked Questions

What Are Common Causes Of Hvac Equipment Failure?

Common causes include dirty filters, refrigerant leaks, and thermostat issues. Regular maintenance helps prevent these problems.

How Can I Identify Airflow Problems In Hvac Systems?

Check for weak airflow or unusual noises from vents. Dirty coils or blocked filters often cause airflow issues.

Why Is My Hvac Blowing Warm Air When Cooling?

This usually happens due to dirty air filters or low refrigerant levels. Thermostat missettings can also cause warm air.

How Do I Troubleshoot A Frozen Evaporator Coil?

Turn off the system and let the coil thaw. Check airflow and refrigerant levels to prevent freezing.

When Should I Call A Professional For Hvac Troubleshooting?

Call a technician if the system won’t start or if you smell burning odors. Complex electrical issues need expert care.

Conclusion

Troubleshooting HVAC equipment helps keep your system running smoothly. Start by checking filters, airflow, and thermostat settings. Small issues often cause big problems. Regular maintenance can prevent many common faults. Knowing basic steps saves time and money. Always act quickly to avoid damage.

Stay calm and follow simple checks first. This approach ensures comfort in your home or office. Keep your HVAC system healthy with these easy tips.