Are you facing issues with your HWH leveling system? Don’t worry, you’re not alone.

Many RV owners encounter problems with their HWH leveling systems at some point. Troubleshooting these issues can seem daunting, but with the right guidance, it becomes manageable. Understanding the common problems and their solutions can save you time and frustration.

Whether it’s a malfunctioning control panel, hydraulic leaks, or leveling jacks not extending, knowing where to start is key. This guide will help you identify and fix the most frequent issues. We’ll walk you through each step, making sure you can get back on the road without delays. Let’s dive into the world of HWH leveling system troubleshooting and ensure your RV remains stable and secure.

Introduction To Hwh Leveling Systems

HWH leveling systems are essential for RV enthusiasts. They ensure stability and comfort. Proper leveling prevents wear and tear. Let’s dive into the basics.

What Is An Hwh Leveling System?

An HWH leveling system is a hydraulic leveling system. It is used primarily in RVs and motorhomes. The system consists of hydraulic jacks. These jacks adjust the vehicle’s height. This helps maintain a level position on uneven ground.

The system is automated. It uses sensors to detect the ground level. The jacks are controlled by a central unit. This unit makes the necessary adjustments. The process is quick and efficient.

There are different types of HWH leveling systems. Some are manual, while others are automatic. Both types have their advantages. Automatic systems are more convenient. Manual systems give more control.

Importance Of Proper Leveling

Proper leveling is crucial for several reasons. First, it ensures the safety of the vehicle. An unlevel RV can tip over. This poses a risk to occupants.

Second, it protects the RV’s components. Appliances and furniture can get damaged. A level vehicle prevents such issues. It also extends the life of the RV.

Third, it improves comfort. Sleeping and living in an unlevel RV is uncomfortable. Proper leveling creates a stable environment. This makes the RV experience more enjoyable.

Lastly, it aids in the proper functioning of appliances. Refrigerators, for example, need to be level. This ensures they work efficiently. Proper leveling is essential for a smooth RV experience.

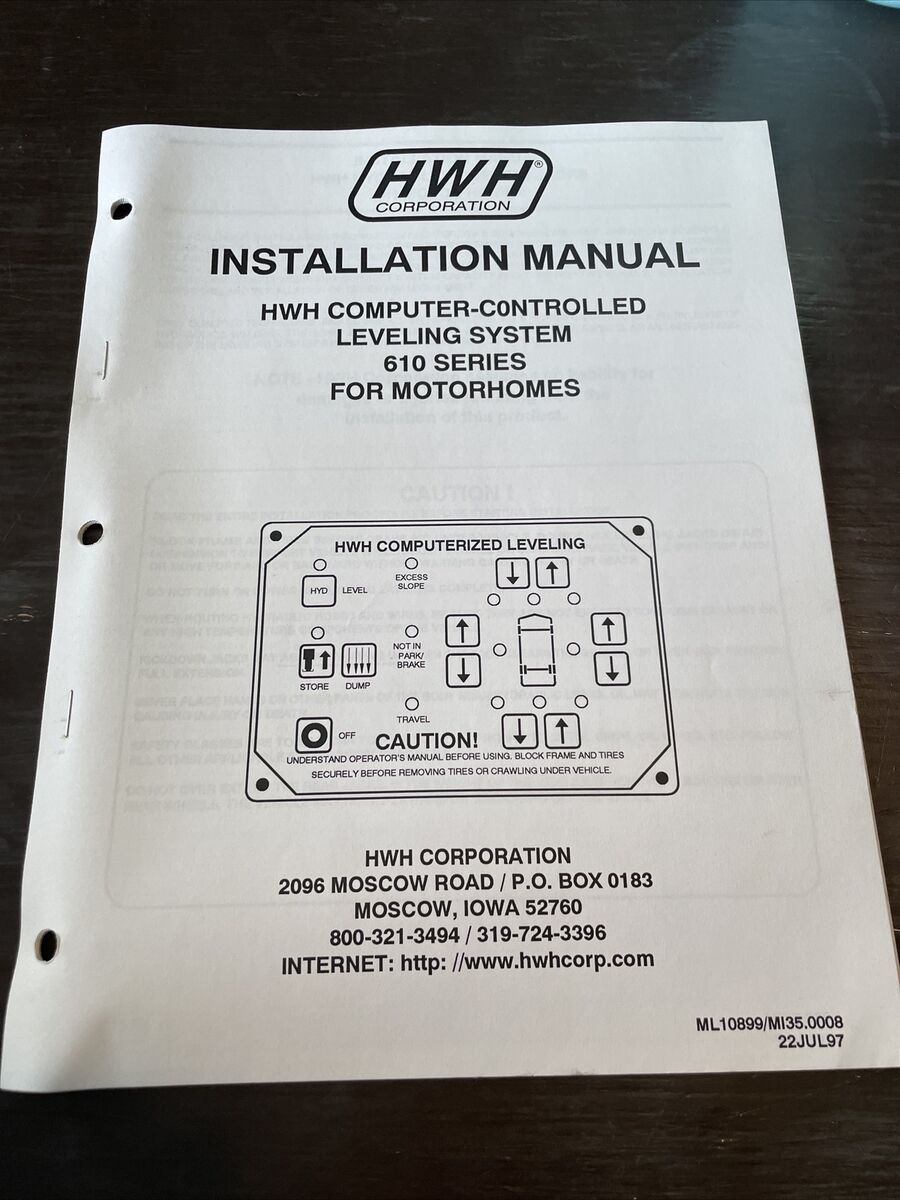

Credit: www.ebay.com

Common Issues With Hwh Leveling Systems

HWH leveling systems are vital for RV owners. They ensure stability and comfort. Yet, these systems sometimes face issues. Understanding common problems helps in quick troubleshooting. This can save time and avoid frustration.

Hydraulic Leaks

Hydraulic leaks are a frequent problem with HWH leveling systems. Leaks can occur due to worn-out seals or damaged hoses. Look for puddles under the RV. Low hydraulic fluid levels also indicate a leak. Regular inspection helps catch issues early. This prevents further damage and keeps the system working well.

Sensor Malfunctions

Sensors play a crucial role in leveling systems. They detect the RV’s position and signal adjustments. Sometimes, sensors fail or give incorrect readings. Dirty sensors can cause problems too. Clean them regularly. If a sensor malfunctions, the system may not level the RV correctly. Replacing faulty sensors ensures accurate readings. This keeps the leveling system efficient and reliable.

Diagnosing Hydraulic Leaks

Hydraulic leaks can cause serious problems in your HWH leveling system. They lead to system malfunctions and potential damage. Diagnosing these leaks is crucial. This guide will help you identify and fix them.

Identifying Leak Sources

Start by inspecting all hydraulic lines. Look for visible oil spots or damp areas. Check the connections and fittings. Sometimes, leaks occur at these junctions. Use a flashlight to see better in tight spaces.

Next, operate the leveling system. Watch for fluid drips during movement. Take note of where the leaks appear. This can help pinpoint the problem area.

Also, pay attention to the hydraulic fluid level. A drop in fluid level indicates a leak. Check the reservoir for any signs of leakage around it.

Repairing Hydraulic Lines

First, clean the area around the leak. This helps in identifying the exact spot. Use a degreaser for effective cleaning. Ensure the system is off before you start repairs.

If the leak is from a fitting, tighten it gently. Avoid over-tightening, which can cause further damage. If tightening doesn’t work, replace the fitting.

For leaks in the hydraulic lines, consider using a hydraulic repair kit. These kits contain everything you need. Follow the instructions carefully. If the damage is extensive, replace the entire line.

After repairs, refill the hydraulic fluid. Check for leaks again by operating the system. This ensures the problem is resolved.

Credit: www.scribd.com

Addressing Sensor Malfunctions

Sensor malfunctions in the HWH leveling system can be frustrating. Understanding and addressing these issues can save time and avoid costly repairs. This section will guide you through the common symptoms of sensor failures and how to replace faulty sensors effectively.

Symptoms Of Sensor Failures

Sensors play a critical role in the HWH leveling system. When they fail, the system can malfunction. Here are some common symptoms to watch out for:

- Inaccurate leveling readings

- Unresponsive control panel

- Error codes on the display

- Unexpected system shutdowns

Inaccurate leveling readings are a clear sign of sensor issues. If the control panel becomes unresponsive, the sensors might be at fault. Error codes can also indicate a sensor problem. Unexpected system shutdowns often point to a faulty sensor.

Replacing Faulty Sensors

Once you identify a faulty sensor, replacing it is the next step. Follow these simple steps:

- Turn off the HWH leveling system.

- Locate the faulty sensor using the system manual.

- Disconnect the sensor carefully.

- Install the new sensor in the same position.

- Reconnect the sensor and secure it properly.

- Turn on the system and test the new sensor.

Make sure to turn off the system before starting. Locate the faulty sensor using the manual. Disconnect the sensor carefully to avoid damage. Install the new sensor in the same position. Reconnect the sensor and secure it properly. Finally, turn on the system and test the new sensor.

Regular maintenance and timely sensor replacement ensure optimal performance of your HWH leveling system. Understanding these steps can prevent unnecessary downtime and maintain the system’s reliability.

Electrical Problems In Hwh Systems

HWH leveling systems are crucial for many RV owners. They ensure stability and comfort. But, sometimes, electrical issues can arise. These problems can cause the system to malfunction. Understanding and troubleshooting these problems is essential.

Checking For Blown Fuses

Blown fuses are a common cause of electrical issues in HWH systems. Start by locating the fuse box. Check each fuse carefully. Look for any that appear burnt or broken. Replace any blown fuses with the correct type. Always use the same amperage for replacements.

Inspecting Wiring Connections

Loose or damaged wires can lead to electrical problems. Inspect all wiring connections in your HWH system. Ensure each wire is secure and undamaged. Look for any signs of wear or corrosion. Repair or replace any problematic wires immediately.

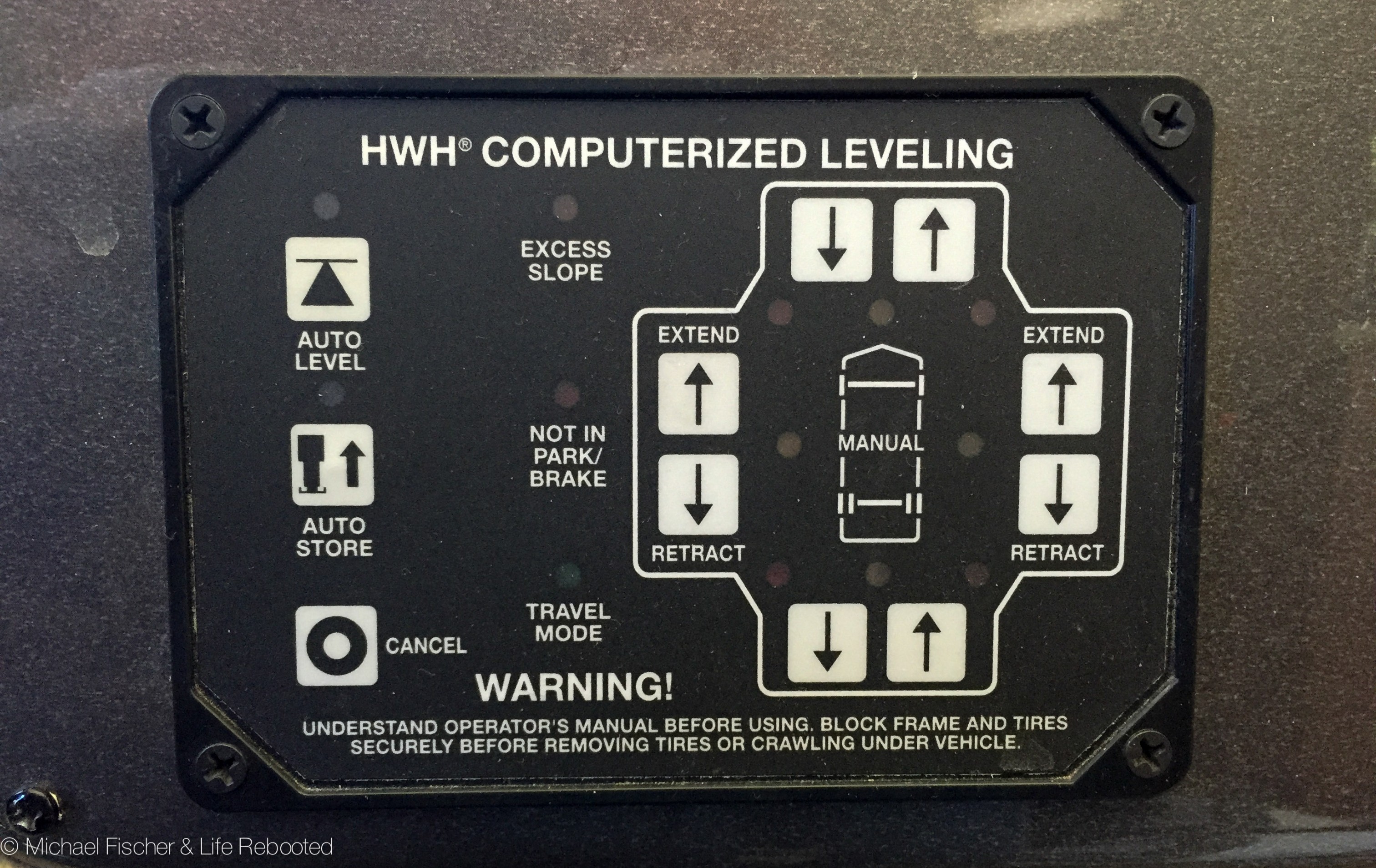

Credit: liferebooted.net

Calibrating The Hwh Leveling System

Calibrating the HWH Leveling System is essential for optimal performance. Correct calibration ensures your vehicle stays level, improving comfort and safety. This section will guide you through the calibration process, detailing the procedures and tools needed.

Calibration Procedures

Follow these steps to calibrate your HWH Leveling System:

- Park on a Level Surface: Ensure your vehicle is on a flat, stable surface.

- Turn On the System: Power on the HWH Leveling System using the control panel.

- Enter Calibration Mode: Access the calibration mode via the system’s manual or control panel instructions.

- Adjust Each Leg: Manually adjust each leveling leg to achieve a balanced position.

- Save Settings: Once the vehicle is level, save the calibration settings.

Tools Needed For Calibration

Gather these tools before starting the calibration process:

- Spirit Level: To check the level of the vehicle.

- Control Panel Manual: For specific instructions related to your system.

- Socket Wrench: For adjusting the leveling legs.

- Marker: To mark the position of each leg.

Using the right tools ensures accurate calibration. Keep these items handy for quick adjustments.

| Tool | Purpose |

|---|---|

| Spirit Level | Check vehicle level |

| Control Panel Manual | Instructions |

| Socket Wrench | Adjust leveling legs |

| Marker | Mark positions |

Calibrating the HWH Leveling System may seem daunting. With the right steps and tools, you can ensure your vehicle is always level. Enjoy a smooth, comfortable experience on the road.

Preventative Maintenance Tips

Proper maintenance of your HWH leveling system can prevent costly repairs. Regular care helps ensure the system works smoothly and efficiently. Here are some essential preventative maintenance tips to keep your HWH leveling system in top shape.

Regular System Checks

Inspect the system for any visible damage. Look for leaks or worn-out parts. Test the system regularly to ensure it functions correctly. Make a checklist of key components to review during each inspection. This will help catch issues early and avoid major problems.

Lubrication And Cleaning

Lubricate the moving parts of your HWH leveling system. Use the recommended lubricant to avoid damage. Clean the system to remove dirt and debris. This helps prevent clogs and ensures smooth operation. Regular lubrication and cleaning can extend the life of your system.

When To Seek Professional Help

Troubleshooting your HWH leveling system can be straightforward, but some issues require professional assistance. If the problem persists, it may be time to consult an expert. Recognizing when to seek help can save you time and prevent further damage.

Complex Issues Requiring Expertise

Sometimes, the issue with your HWH leveling system goes beyond basic troubleshooting. Complex electrical faults, such as wiring problems or sensor malfunctions, often need a technician. These problems might be invisible to the untrained eye and can worsen if not addressed properly.

Another instance is hydraulic system failures. These can be tricky and dangerous to repair without the right skills. Incorrect handling of hydraulic components can lead to leaks or even system breakdowns.

Software issues also fall under this category. Modern HWH systems often include sophisticated software. Software glitches may require specialized diagnostic tools, which professionals possess.

Finding A Qualified Technician

Once you decide to seek professional help, finding the right technician is crucial. Begin by checking the manufacturer’s website. They usually list certified technicians who are trained to handle HWH systems.

Online reviews can also provide insights. Look for technicians with high ratings and positive feedback. This can help you gauge their reliability and expertise.

Additionally, consider local RV repair shops. Many of them have experienced staff familiar with various leveling systems. Ensure they have specific experience with HWH systems for the best service.

Here’s a simple table to guide you in finding a qualified technician:

| Method | Description |

|---|---|

| Manufacturer’s Website | Lists certified technicians. |

| Online Reviews | Provides customer feedback. |

| Local RV Shops | Experienced in various systems. |

Following these steps will help you find the right professional. This ensures your HWH leveling system gets the attention it needs.

Frequently Asked Questions

Why Is My Hwh Leveling System Not Working?

Check if the power is on. Inspect for blown fuses. Verify hydraulic fluid levels.

How Do I Reset My Hwh Leveling System?

Turn off the system. Wait for 10 seconds. Turn it back on.

What Causes Hwh Leveling System Error Code?

Error codes can result from low fluid levels, sensor issues, or electrical faults.

How Can I Fix A Stuck Hwh Leveling Jack?

Lubricate the jack. Check for debris. Manually retract and extend the jack.

What Should I Do If My Hwh System Leaks?

Identify the leak source. Tighten connections. Replace damaged parts. Seek professional help if needed.

Conclusion

Troubleshooting your HWH leveling system doesn’t have to be tough. Follow the steps in this guide. You’ll save time and avoid stress. Remember, regular maintenance helps. Always check for leaks and keep parts clean. If you face issues, this guide is your go-to resource.

With patience, you can handle most problems. Stay safe and enjoy your travels.