Is your ice cube maker letting you down when you need it most? Whether it’s refusing to make ice, producing tiny cubes, or jamming up completely, a faulty ice maker can be frustrating—especially on a hot day or when you have guests over.

But before you call a repair service or replace the whole unit, there’s good news: many common ice cube maker problems are simple to identify and fix on your own. In this guide, you’ll discover easy troubleshooting tips that anyone can follow to get your ice maker back in action quickly.

Keep reading, and you’ll learn how to spot the cause of the issue, try quick fixes, and know when it’s time to call a professional. Your next perfectly chilled drink is just a few steps away!

Credit: www.maytag.com

Common Ice Maker Issues

Ice makers can stop working properly due to several common issues. These problems can affect ice production and quality. Knowing these issues helps in quick troubleshooting. Below are some frequent problems faced by ice maker users.

No Ice Production

Ice makers may stop making ice if the water supply is off. Check if the water line is connected and not frozen. The ice maker’s power switch might be off or the control arm raised. A clogged water filter can also block water flow. Sometimes, the freezer temperature is too high, preventing ice formation.

Slow Ice Formation

Slow ice production usually happens when the freezer is not cold enough. The ideal temperature is around 0°F (-18°C). A dirty condenser coil can reduce cooling efficiency. Low water pressure or a partially blocked water line slows water flow. Ice makers may also take longer to fill if the water filter is old or clogged.

Small Or Misshapen Ice Cubes

Ice cubes may become small or misshapen due to low water levels. Check the water inlet valve for proper operation. A frozen fill tube can cause irregular ice shapes. Mineral deposits in the water line or filter can affect ice quality. Sometimes, the ice mold is dirty or damaged, altering the shape of cubes.

Ice Maker Leaks

Leaks can happen if the water line is loose or cracked. Check all connections for tightness and damage. A clogged or frozen drain line may cause water to overflow. The ice bin may be improperly aligned, causing water to spill. Faulty water inlet valves can also lead to leaks inside the freezer.

Basic Checks

Basic checks are the first step in solving ice cube maker problems. These simple inspections help identify common issues. Most ice maker troubles happen due to small, easy-to-fix problems. Checking these basics saves time and avoids unnecessary repairs.

Control Arm Position

The control arm tells the ice maker to start or stop making ice. If the arm is raised, the ice maker will not produce ice. Make sure the arm is in the down position. This signals the machine to begin ice production. Check for any obstructions that block the arm from moving freely.

Water Supply Connection

The ice maker needs water to make ice. Check if the water supply line is connected tightly. Look for kinks or leaks in the hose. A blocked or loose water supply stops ice production. Turn off the water valve, inspect the connection, and turn it back on if needed.

Freezer Temperature Settings

The freezer temperature affects ice making. The ideal temperature is between 0°F and 5°F (-18°C to -15°C). If it is too warm, ice will not form properly. If it is too cold, the water line may freeze and block water flow. Adjust the thermostat to keep the freezer at the right temperature.

Ice Bin Alignment

The ice bin collects the ice cubes. If it is not aligned correctly, the ice maker may stop working. Make sure the bin is pushed fully into place. A misaligned bin can block the ice maker’s sensors. Proper alignment helps the machine detect when to stop or start making ice.

Water Line Problems

Water line problems often stop ice makers from working well. These issues block water flow to the ice maker. Without water, ice cubes cannot form. Checking the water line can solve many ice maker troubles quickly.

Water line problems come in different forms. Sometimes the fill tube freezes. Other times the water line gets bent or pinched. Low water pressure is another common cause. Each of these problems affects ice production.

Frozen Fill Tube

The fill tube carries water into the ice maker. If it freezes, water cannot reach the ice mold. This stops ice from forming. To fix this, unplug the fridge and thaw the tube. A hair dryer on low heat works well. Avoid using sharp objects to clear ice.

Kinked Or Pinched Water Line

A kink or pinch in the water line reduces water flow. This limits water reaching the ice maker. Check the line behind the fridge for bends. Straighten any kinks carefully. Replace the water line if it is damaged or cracked.

Low Water Pressure

Low water pressure means not enough water enters the ice maker. This causes small or no ice cubes. Check the home water supply valve. Make sure it is fully open. Clean or replace clogged water filters. Call a plumber if pressure stays low.

Clearing Ice Clogs

Ice clogs are a common problem in ice cube makers. They block the flow of ice and stop the machine from working. Clearing these clogs helps your ice maker run smoothly and produce ice again. This section explains easy ways to clear ice blockages safely and quickly.

Removing Jammed Ice Cubes

Jammed ice cubes block the ice chute or dispenser. First, turn off the ice maker to avoid damage. Use a plastic or wooden tool to gently push stuck cubes out. Avoid metal objects that can harm the machine. Remove loose cubes from the bin to prevent further jams. Clean the area with a dry cloth to remove any ice shards.

Thawing Ice Blockages

Ice blockages can freeze solid in pipes or trays. Unplug the ice maker to begin thawing. Let the machine sit at room temperature to melt the ice naturally. Use a hairdryer on low heat to speed up the process, keeping it at a safe distance. Do not pour hot water inside the machine; it may cause damage. After thawing, wipe excess water and restart the ice maker.

Filter And Valve Issues

Filter and valve problems often cause ice makers to stop working properly. These parts control water flow into the ice maker. Blockages or faults can slow or stop ice production. Regular checks help avoid bigger issues. Understanding common filter and valve troubles saves time and effort.

Clogged Water Filter

A clogged water filter blocks water flow to the ice maker. This reduces ice output or stops it completely. Dirt and minerals build up over time. Replacing the filter every six months keeps water clean and flow steady. A quick filter change often restores ice making quickly.

Faulty Water Inlet Valve

The water inlet valve opens to let water in for ice making. A faulty valve may not open or close properly. This causes no water or leaks inside the ice maker. Test the valve with a multimeter for electrical issues. Replacing a bad valve fixes most water supply problems.

Credit: www.kitchenaid.com

Electronic And Mechanical Fixes

Electronic and mechanical issues often cause ice cube makers to stop working properly. These problems can be fixed with simple steps. Understanding basic fixes saves time and money. This section covers easy electronic and mechanical solutions. Follow the steps below to get your ice maker running again.

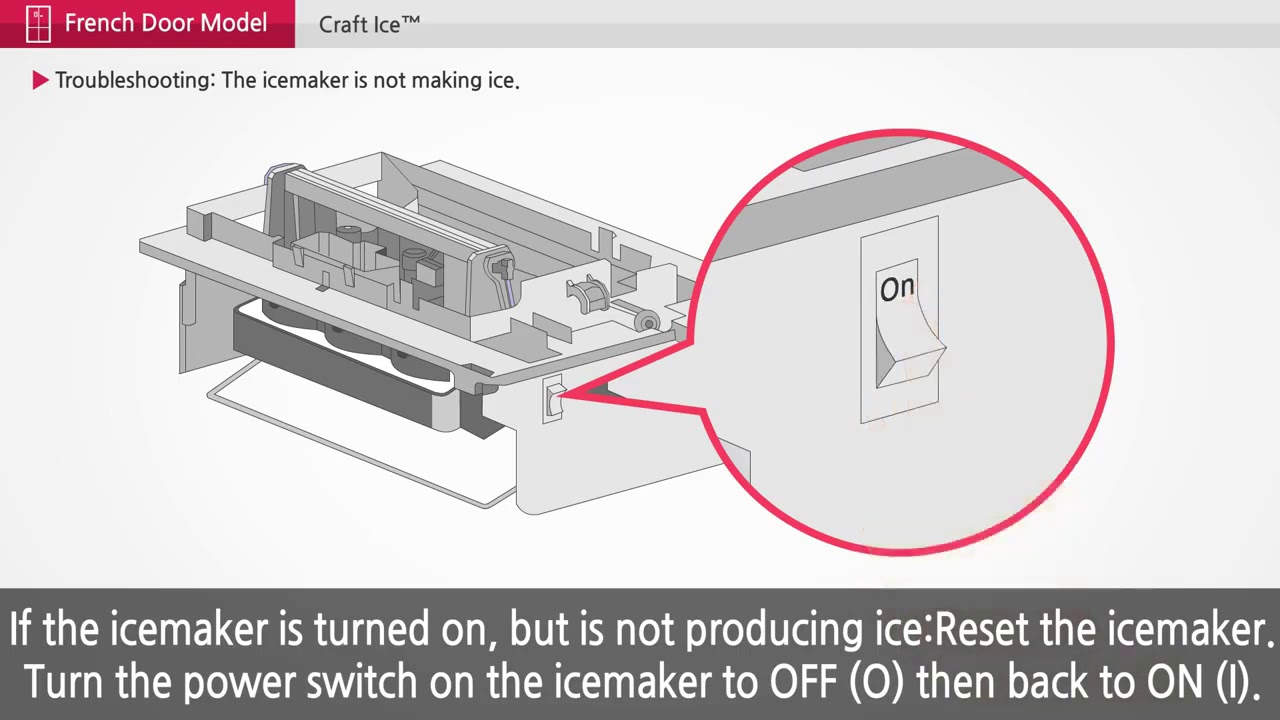

Resetting The Ice Maker

Resetting the ice maker can clear minor errors in its system. First, unplug the refrigerator for about 5 minutes. This action restarts the ice maker’s electronics. After plugging it back in, press the reset button if available. Some models require holding the button for 10 seconds. Wait for the ice maker to complete a full cycle. Check if ice production resumes. Resetting often fixes glitches without complex repairs.

Inspecting The Control Board

The control board manages the ice maker’s functions. A faulty board can stop ice production. Open the ice maker panel carefully to access the control board. Look for burnt marks or damaged components. Loose connections can also cause issues. Tighten any loose wires gently. Use a multimeter to test the board’s electrical signals if possible. Replace the control board if it shows signs of failure. This step requires caution to avoid further damage.

Checking The Ice Ejector Mechanism

The ice ejector pushes ice cubes out into the bin. Mechanical jams can block this process. Inspect the ejector for broken or stuck parts. Remove any ice clumps blocking movement. Spin the ejector gently by hand to test its motion. Lubricate moving parts lightly with food-safe lubricant. Avoid over-tightening screws or forcing parts. Proper ejector function ensures smooth ice delivery and prevents jams.

When To Call A Technician

Knowing when to call a technician for your ice cube maker saves time and prevents damage. Some problems need expert skills and tools. Simple issues you can fix yourself. Complex or persistent problems require professional help. Below are signs that it is time to call a technician.

Persistent Water Flow Problems

Water flow is crucial for ice production. A slow or no water flow often means a blocked or broken valve. Sometimes, the water line freezes or kinks. If you clear these and the problem continues, call a technician. They can test the water pressure and valve function. Persistent water flow issues may lead to no ice or small ice cubes.

Compressor And Overload Failures

The compressor cools the ice maker’s freezer. If the ice maker is warm or noisy, the compressor might fail. Overload protectors can trip if the compressor overheats. These problems need a technician to fix. They have tools to check electrical parts and replace damaged components. A failing compressor stops ice production completely.

Complex Mechanical Failures

Ice makers have many moving parts. Motors, gears, and sensors can break or wear out. If the ice maker stops making ice or jams often, mechanical failure might be the cause. Fixing these parts is tricky and needs experience. A technician can diagnose and repair complex mechanical issues safely. Do not try to fix these problems alone.

Credit: www.youtube.com

Maintenance Tips

Proper maintenance keeps your ice cube maker working well. It helps avoid common problems and extends the machine’s life. Follow these simple tips to maintain your ice maker and enjoy fresh ice daily.

Regular Cleaning

Clean your ice maker often to stop dirt and mold buildup. Use a soft cloth with warm water and mild soap. Wipe all parts that touch water or ice. Avoid harsh chemicals that can damage the machine.

Remove the ice bin and wash it regularly. Clean the ice tray and surrounding areas carefully. Dry everything before putting parts back. This keeps ice tasting fresh and prevents clogs.

Replacing Filters On Schedule

Change water filters as the manufacturer suggests. Filters trap impurities that affect ice quality and machine health. Old filters reduce water flow and can cause blockages.

Mark your calendar to remind you of replacement dates. Use only filters made for your ice maker model. Fresh filters improve ice taste and keep the system clean.

Monitoring Freezer Conditions

Keep your freezer at the right temperature for ice making. The ideal range is usually between 0°F and 5°F (-18°C and -15°C). Temperatures outside this range can stop ice production.

Check the freezer seals to prevent warm air from entering. Avoid overfilling the freezer, which can block airflow. Good freezer conditions help your ice maker work smoothly.

Frequently Asked Questions

What Are Common Ice Maker Problems?

Common ice maker problems include frozen fill tubes, clogged water filters, kinked water lines, low water pressure, and incorrect freezer temperatures. Control arms left off or electronic glitches may also stop ice production. Regular checks and resets often resolve these issues quickly.

How To Reset An Ice Cube Machine?

To reset an ice cube machine, unplug it for one minute or press the reset button if available. Reconnect power and align the ice bin properly. This clears electronic errors and restarts the ice-making cycle. Check water supply and control arm position for optimal function.

What Caused The Ice Maker To Stop Making Ice?

An ice maker stops making ice due to a turned-off control arm, clogged filter, frozen water line, low water pressure, or incorrect freezer temperature. Check water supply, thaw fill tube, replace filter, inspect lines for kinks, and reset the unit to fix common issues.

How To Fix An Ice Maker That’s Not Making Ice?

Check the control arm is down and water supply is on. Inspect for frozen fill tube or kinked water line. Replace clogged filter and reset the ice maker by unplugging it for a minute. Clear ice jams in the bin.

Call a technician if issues persist.

Why Is My Ice Cube Maker Not Producing Ice?

Ice makers stop making ice due to a turned-off arm, clogged filter, or frozen water line. Check if the control arm is down and the water supply is connected. Also, ensure the freezer temperature is between 0°F and 5°F.

Conclusion

Troubleshooting your ice cube maker can save time and money. Simple checks like water supply and control arm position often fix issues. Keep the freezer temperature steady for best results. Clearing frozen tubes or replacing filters also helps. If problems persist, resetting the machine may restore function.

Regular maintenance prevents common ice maker troubles. Stay patient and follow steps carefully to enjoy fresh ice again.