Kaeser compressors are known for their reliability. Yet, even the best machines can face issues.

Understanding how to troubleshoot your Kaeser compressor can save time and money. Knowing common problems and their solutions helps keep your compressor running smoothly. This guide will walk you through the basics of Kaeser compressor troubleshooting. From identifying the most frequent issues to offering practical solutions, we aim to help you resolve problems quickly.

Whether you’re a seasoned professional or a new user, this guide will provide valuable insights. Stay with us as we explore how to maintain the efficiency and longevity of your Kaeser compressor.

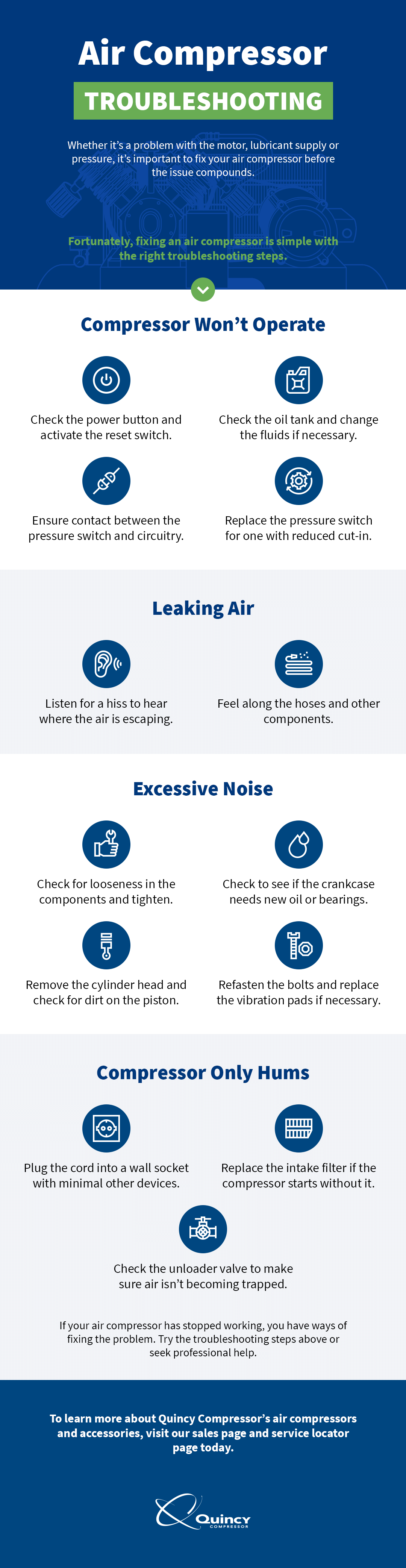

Credit: www.quincycompressor.com

Common Issues

Maintaining the efficiency of your Kaeser compressor is crucial for optimal performance. Common issues can disrupt your operations. Identifying and troubleshooting these issues can save time and resources.

Startup Problems

Startup issues are frequent with compressors. Your Kaeser compressor might fail to start. This can be due to electrical problems. Check for blown fuses or tripped breakers. Ensure power supply connections are secure. Inspect the control panel for any error messages. Faulty wiring can also be a cause. Regular maintenance helps prevent startup issues.

Pressure Drops

Pressure drops can affect the performance of your Kaeser compressor. Leaks in the system are a common cause. Inspect hoses, fittings, and connections for leaks. Clogged filters can also lead to pressure drops. Replace or clean filters regularly. Ensure the air intake is not blocked. Monitor the pressure gauge closely. Regular checks and maintenance can minimize pressure drops.

Credit: us.kaeser.com

Error Codes

Dealing with Kaeser compressor error codes can be challenging. Error codes help identify issues and guide you to solutions. Knowing how to read and understand these codes is vital for maintaining your compressor.

Reading Codes

Error codes appear on the compressor’s control panel. To read them, consult your user manual. Each code corresponds to a specific problem. It is crucial to note the exact code displayed. This will help in diagnosing and fixing the issue accurately.

Frequent Error Messages

Some error messages are more common than others. “E001” often indicates a power supply problem. “E002” usually signals a motor overload. “E003” might mean there is an air filter issue. Understanding these frequent error codes can save time and prevent further damage.

Regularly encountering these error messages suggests a need for routine checks. Ensure your compressor is well-maintained to avoid these common issues. Addressing problems early can extend the life of your compressor.

Maintenance Tips

Maintaining your Kaeser compressor ensures efficiency and longevity. Regular maintenance can prevent unexpected downtime and costly repairs. Below are some essential maintenance tips to keep your compressor in top shape.

Regular Inspections

Conducting regular inspections is crucial. Check all parts for wear and tear. Inspect the belts, filters, and hoses. Look for leaks and unusual noises. Regular inspections help identify potential issues early, preventing major problems.

Lubrication Guidelines

Proper lubrication is key to your compressor’s performance. Use the recommended oil type. Change the oil regularly as per the manufacturer’s guidelines. Monitor oil levels and top up when necessary. Ensure the oil is clean and free from contaminants.

Air Filter Problems

Air filters play a crucial role in the performance of Kaeser compressors. They keep dust and debris out, ensuring smooth operation. Problems with air filters can lead to significant issues. These include reduced efficiency and potential damage to the compressor.

Clogged Filters

Clogged filters are a common problem in Kaeser compressors. Dust and dirt accumulate over time, blocking airflow. This can cause the compressor to work harder, reducing efficiency. A clogged filter also puts more strain on the motor, leading to potential breakdowns.

Regular inspection helps identify clogged filters early. If you notice a drop in performance, check the filter first. Cleaning or replacing a clogged filter can restore normal function.

Replacement Schedule

Following a replacement schedule is vital for maintaining air filters. Each filter has a recommended lifespan. This varies based on usage and environment. Check the manufacturer’s guidelines for specific intervals.

Adhering to the replacement schedule prevents clogging issues. It also ensures the compressor operates at peak efficiency. Mark your calendar or set reminders to keep track of replacements.

Consistent maintenance extends the life of your Kaeser compressor. It also reduces the risk of unexpected failures and costly repairs.

Overheating Solutions

Is your Kaeser compressor overheating? Overheating can cause serious issues. Identifying the problem early can save you from costly repairs. Here are some solutions.

Cooling System Check

First, check the cooling system. Inspect the coolant levels. Low levels can cause overheating. Refill if necessary. Look for leaks in the cooling system. A leak can reduce coolant levels. Also, clean the radiator. Dust and debris can block airflow. Use compressed air to clean it.

Ambient Temperature Management

Next, manage the ambient temperature. Compressors work best in cooler environments. Ensure the room has proper ventilation. Install exhaust fans if needed. They help remove hot air. Also, avoid placing the compressor near heat sources. This keeps it from overheating.

Electrical Issues

Electrical issues are common in Kaeser compressors. These issues often disrupt operations. Troubleshooting electrical problems is essential. It ensures the compressor runs smoothly. Below are some key areas to check.

Power Supply Check

First, verify the power supply. Ensure the compressor receives proper voltage. Use a multimeter to check the voltage. Compare it to the compressor’s requirements. If the voltage is low, the compressor may not start. High voltage can damage the compressor.

Check the power cord for damage. Look for any cuts or frayed wires. Replace the cord if needed. Make sure the plug is secure in the outlet. Loose connections can cause power issues.

Fuse And Circuit Breakers

Next, inspect the fuses and circuit breakers. A blown fuse can stop the compressor. Locate the fuse box. Identify the fuse for the compressor. Check if it is blown. Replace it if necessary.

Circuit breakers protect the compressor from overloads. Find the circuit breaker panel. Locate the breaker for the compressor. Ensure it is in the “ON” position. If tripped, reset it. If it trips again, there may be an overload or short circuit.

Regular checks can prevent many issues. Ensure all connections are tight. Replace any faulty components. These steps keep your compressor running smoothly.

Noise Reduction

Noise reduction in Kaeser compressors is essential for a quieter work environment. Excessive noise can be disruptive and affect productivity. Understanding and addressing noise sources can help reduce sound levels significantly.

Identifying Noise Sources

First, identify where the noise is coming from. Common sources include the motor, fans, and air intake. Listen carefully to pinpoint the exact location. Use a decibel meter to measure noise levels. This helps in identifying the loudest parts of the compressor. Regular inspections can also reveal loose parts causing vibration.

Soundproofing Techniques

Soundproofing can greatly reduce compressor noise. Enclose the compressor in a soundproof box. Use materials like foam or acoustic panels to absorb sound. Ensure proper ventilation to prevent overheating. Installing vibration pads under the compressor can reduce noise from vibrations. Regular maintenance ensures all parts are secure, reducing noise further.

Professional Help

Troubleshooting a Kaeser compressor can be complex. Sometimes, professional help is necessary. Understanding when to call a technician and finding certified experts can save time and money. Here’s what you need to know.

When To Call A Technician

Not all issues can be fixed alone. Call a technician if the compressor won’t start. Strange noises are another sign. Also, if the unit overheats, seek help. Low pressure issues often need expert attention. Regular maintenance can prevent many problems. But some issues need professional skills.

Finding Certified Experts

Certified experts have the right training. They know Kaeser compressors well. Check for certifications before hiring. Experience is key. Look for technicians with years of service. Read reviews online. Good reviews indicate reliable service. Ask for recommendations from other users. Quality service ensures your compressor runs smoothly.

Credit: commercialaircompressor.ca

Frequently Asked Questions

How Do I Reset My Kaeser Compressor?

To reset your Kaeser compressor, press the reset button. Check the manual for location details.

Why Is My Kaeser Compressor Not Starting?

Common reasons include power issues, tripped breakers, or faulty wiring. Check connections and power supply.

What Causes Kaeser Compressor Overheating?

Overheating can be due to blocked filters, poor ventilation, or low coolant levels. Clean filters and check airflow.

How Often Should I Service My Kaeser Compressor?

Service your Kaeser compressor every 2,000 hours or annually. Regular maintenance ensures optimal performance.

How To Fix Kaeser Compressor Low Pressure?

Check for leaks, clean air filters, and ensure proper valve function. Maintain correct pressure settings.

Conclusion

Troubleshooting a Kaeser compressor can be simple with the right steps. Regular maintenance ensures optimal performance. Always check filters and oil levels. Listen for unusual noises. Address minor issues promptly to avoid bigger problems. Keep a log of any recurrent issues.

This helps in identifying patterns. Use the manual as a guide. Consulting a professional is wise for complex issues. Regular attention keeps your compressor running smoothly. Stay proactive and ensure your Kaeser compressor serves you well.