Owning a boat comes with its challenges. One common issue is windlass trouble.

The Lewmar windlass, a key piece of boating equipment, can sometimes fail. Troubleshooting these issues ensures your boating experience remains smooth and stress-free. Understanding common problems and their solutions can save time and prevent frustration. Whether it’s an electrical issue or a mechanical fault, knowing how to handle these situations is crucial.

This blog post will guide you through the troubleshooting process. You’ll learn the basics of diagnosing and fixing common Lewmar windlass problems. With this knowledge, you can keep your windlass in top shape and enjoy your time on the water. Let’s dive into the details and get your windlass working perfectly again.

Credit: www.youtube.com

Introduction To Lewmar Windlass

Lewmar windlasses are essential for boat owners. They help in raising and lowering the anchor. This process is made simple and efficient. The windlass reduces the manual effort needed. It ensures smooth operations while anchoring.

Lewmar is known for its reliability. It provides high-quality windlasses. Their products are durable and trusted by many. But like any mechanical device, issues can occur. Understanding these problems is crucial. It helps in maintaining the windlass effectively.

Importance Of Windlass

A windlass is vital for safe anchoring. It saves time and energy. It ensures the anchor is securely set. This is critical for the safety of the boat. Without a windlass, anchoring can be a tiring task. Manual anchoring is hard and time-consuming.

The windlass also protects the anchor chain. It prevents tangling and damage. This extends the life of the anchor and chain. It also reduces repair costs. A well-maintained windlass ensures smooth sailing. It provides peace of mind to boat owners.

Common Issues

Windlasses can face several issues. One common problem is power loss. This can be due to battery issues. Corrosion in electrical connections can also cause this. Regular checks can prevent power loss.

Another issue is the windlass not holding the anchor. This can be due to worn-out parts. The gypsy and clutch might need replacement. Regular maintenance can prevent this problem.

Motor overheating is another common issue. This can happen due to overuse. Allow the motor to cool down between uses. Lubrication issues can also cause overheating. Ensure the windlass is properly lubricated.

Strange noises from the windlass can indicate problems. It can be due to mechanical wear. Inspect the windlass for any worn-out parts. Replace them as needed.

Basic Troubleshooting Steps

Encountering issues with your Lewmar Windlass can be frustrating. Knowing some basic troubleshooting steps can save you time and effort. Follow these steps to identify and possibly resolve common problems with your Lewmar Windlass.

Safety Precautions

Before starting any troubleshooting, ensure safety first. Turn off the power to the windlass. Remove any loose clothing or jewelry. Use gloves to protect your hands. Keep a fire extinguisher nearby. Follow all safety instructions in the user manual.

Initial Checks

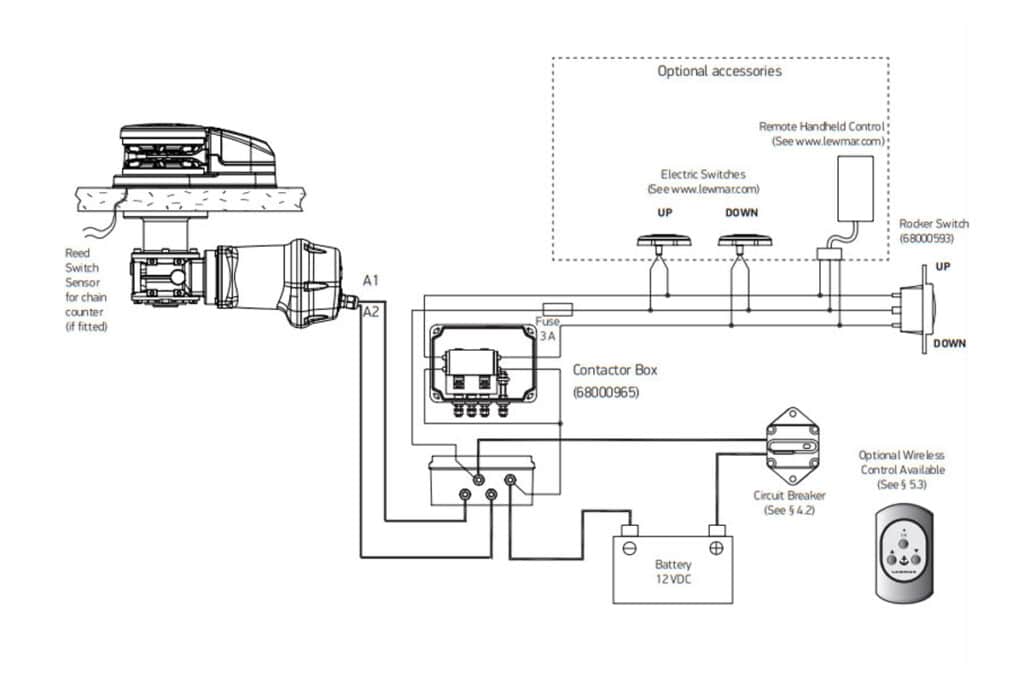

Begin with some initial checks. Ensure the power supply is connected. Verify that the circuit breaker is not tripped. Check the control switch for proper operation. Inspect the windlass for any visible damage. Look for loose or corroded connections.

If these checks do not resolve the issue, further troubleshooting may be required. Always refer to the Lewmar Windlass manual for detailed guidance. Contact a professional if needed.

Electrical Issues

Lewmar windlass systems can face various issues, especially electrical problems. These issues can hamper the performance of your windlass. It’s crucial to identify and resolve them quickly. This section covers some common electrical issues you might encounter.

Battery Problems

Low or dead batteries can cause your windlass to malfunction. Always check the battery voltage. It should be within the recommended range. If not, charge or replace the batteries. Corroded battery terminals can also create problems. Clean the terminals regularly to ensure a good connection.

Wiring And Connections

Loose or damaged wires can disrupt the power supply. Inspect all wiring for any signs of wear or damage. Tighten any loose connections. Replace any worn-out wires. Poor connections can cause intermittent operation or complete failure. Secure all connections firmly to avoid electrical issues.

Mechanical Problems

Windlasses are crucial for anchoring systems. Mechanical problems can disrupt their function. Understanding common issues can help you fix them. In this section, we focus on motor malfunctions and gear and chain issues.

Motor Malfunctions

The motor is the heart of the windlass. Sometimes, it may not run. Check the power supply first. Ensure the battery is charged. Inspect connections for corrosion or damage. Clean or replace them if necessary. If the motor still does not work, it might be faulty. Consult a professional for a thorough check.

Gear And Chain Issues

Gears and chains are vital for smooth operation. Worn gears can cause the windlass to jam. Inspect the gears for wear and tear. Replace them if needed. Chains can also stretch over time. This can cause slippage. Measure the chain length regularly. Replace it if it exceeds the manufacturer’s recommendation. Lubricate gears and chains to ensure smooth movement.

Control And Switch Troubles

Lewmar windlass systems are reliable. But sometimes, control and switch issues can arise. These problems can disrupt your boating experience. Understanding these issues helps in quick troubleshooting. Let’s look at some common control and switch troubles.

Faulty Switches

Faulty switches are a common problem. These can cause the windlass to operate erratically. Check the switch connections first. Loose connections can cause issues. Tighten them if necessary. If the problem persists, the switch might be defective. Replace it with a new one. Always use Lewmar-approved parts.

Sometimes, dirt can clog the switch. Clean it using a soft brush. Avoid water contact. Ensure the switch is dry before reinstalling. Regular maintenance can prevent such issues.

Remote Control Issues

Remote controls can also fail. Dead batteries are the main cause. Replace the batteries regularly. If the remote still does not work, check the signal. Ensure there are no obstructions. Interference can block the signal.

If replacing the batteries and clearing obstructions doesn’t help, check the receiver. It may need resetting. Consult the Lewmar manual for instructions. If necessary, seek professional help. Regular checks can keep your remote control in good condition.

Credit: www.yachtingmagazine.com

Maintenance Tips

Proper maintenance of your Lewmar windlass ensures its longevity and reliable performance. Regular upkeep helps prevent unexpected issues and costly repairs. Below are some essential maintenance tips to keep your windlass in top shape.

Regular Cleaning

Keeping your windlass clean is crucial. Salt, sand, and debris can accumulate and cause damage over time.

- Use fresh water to rinse the windlass after every use.

- Pay special attention to the gypsy, as it often collects the most debris.

- Use a soft brush to remove stubborn dirt and grime.

Lubrication

Lubrication is essential for smooth operation and to prevent wear. Follow these steps to ensure proper lubrication:

- Check the manual for recommended lubricants.

- Apply lubricant to the gypsy, clutch cones, and bearings.

- Do not over-lubricate; excess grease can attract dirt.

- Wipe off any excess lubricant after application.

| Component | Frequency | Lubricant Type |

|---|---|---|

| Gypsy | Monthly | Marine-grade grease |

| Clutch Cones | Every 3 months | Marine-grade grease |

| Bearings | Annually | Light oil |

Regular maintenance not only extends the life of your windlass but also ensures it operates smoothly when you need it most. By following these simple tips, you can keep your Lewmar windlass in excellent condition.

Advanced Troubleshooting

Dealing with a Lewmar windlass can sometimes be tricky. Basic fixes might not solve the problem. Advanced troubleshooting might be necessary. This involves more detailed checks and repairs. Below are steps to guide you through advanced troubleshooting.

Professional Help

Advanced issues with your Lewmar windlass may need expert help. A marine technician can diagnose complex problems. They have the right tools and knowledge. This ensures accurate repairs. Contact a certified Lewmar service provider. They can offer specialized support and solutions.

Replacement Parts

Sometimes, parts of the windlass may be worn out. Inspect the motor, solenoid, and switches. Damaged parts will need replacing. Use genuine Lewmar parts for compatibility. Check the user manual for part numbers. Ordering the right parts ensures proper function. Replacing parts can resolve many advanced issues.

Preventive Measures

Regular maintenance and inspections help avoid common Lewmar windlass issues. Checking the wiring and cleaning components ensures smooth operation.

Maintaining your Lewmar windlass involves more than just repairs. Preventive measures can save time and avoid costly damage. Knowing how to prevent issues keeps your windlass in top shape.Routine Inspections

Regular checks are essential. Inspect the windlass for wear and tear. Look for corrosion on metal parts. Check the bolts and screws. Ensure everything is tight and secure. Examine the electrical connections. Clean any dirt or salt buildup.Routine inspections help spot problems early. This can prevent bigger issues later. Use a checklist to keep track.Proper Usage

Using your windlass correctly extends its life. Avoid overloading it. Know the weight limit. Follow the manufacturer’s guidelines. Use the windlass only for its intended purpose.Operate the windlass smoothly. Avoid jerky movements. This reduces strain on the motor. Be gentle with the controls. Let the windlass work at its own pace.Proper usage helps maintain the windlass. It reduces the risk of breakdowns. “`

Credit: www.yachtingmagazine.com

Frequently Asked Questions

Why Is My Lewmar Windlass Not Working?

A common issue is a dead battery. Check power and connections.

How Do I Reset My Lewmar Windlass?

Turn off the power. Wait a few seconds. Turn it back on.

What Should I Do If My Windlass Is Slow?

Inspect for debris in the gypsy. Clean it out. Check the wiring.

How Can I Fix A Windlass That Won’t Retrieve?

Look for a jam in the chain. Clear it. Check the motor function.

Why Is My Windlass Making Strange Noises?

Strange noises often come from a worn gypsy or motor. Inspect and replace if needed.

Conclusion

Troubleshooting your Lewmar windlass can seem challenging at first. But with patience and basic tools, you can solve most issues. Regular maintenance helps prevent many problems. Always check the manual for specific guidance. If issues persist, consult a professional. Keeping your windlass in good shape ensures smooth sailing.

Remember, a well-maintained windlass boosts safety and reliability. Happy boating!