When troubleshooting Liftmaster Rsl12Ul, check power, connections, and programming for common issues. In the introduction, facing problems with your Liftmaster Rsl12Ul gate opener can be frustrating.

Understanding how to troubleshoot and resolve issues quickly is essential to keep your gate system running smoothly. Whether it’s a power supply problem, faulty connections, or programming issues, knowing how to diagnose and fix these issues can save you time and money.

In this guide, we will explore common troubleshooting steps to help you address any problems that may arise with your Liftmaster Rsl12Ul gate opener efficiently. By following these steps, you can ensure your gate operates reliably and securely.

Common Issues With Liftmaster Rsl12ul

Experiencing issues with the Liftmaster RSL12UL? Common troubleshooting problems include sensor alignment, electrical connection failures, and remote control malfunctions. These can often be resolved by recalibrating the sensors, checking wiring for loose connections, and replacing remote batteries.

Gate Not Opening/closing

If your Liftmaster RSL12UL gate opener is not opening or closing, there are several potential reasons for this issue. First, check the power source to ensure it is connected and operational. Next, inspect the gate for any obstructions or physical damage that may be preventing it from functioning properly.

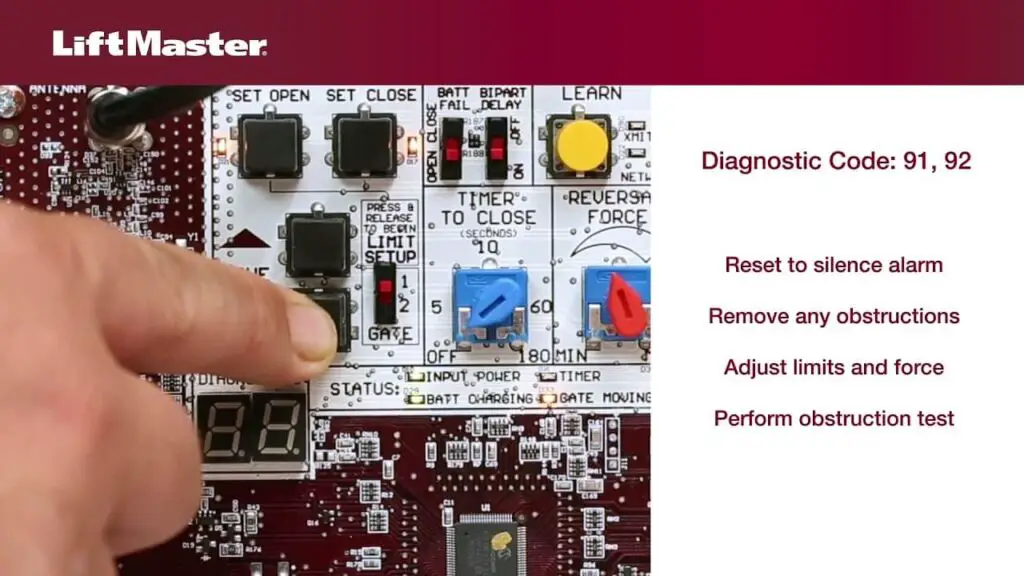

Error Codes Displayed

If you are seeing error codes displayed on your Liftmaster RSL12UL, it is important to understand what they mean. Refer to the manual for specific error code details. Common issues indicated by error codes include sensor misalignment, circuit board problems, or malfunctioning components.

Troubleshooting Steps

Explore the following Troubleshooting Steps to address Liftmaster Rsl12Ul issues effectively.

Check Power Supply

Determine if Liftmaster Rsl12Ul is properly connected to a power source.

- Verify power outlet is functioning by plugging in another device.

- If outlet works, check Rsl12Ul power cord for any damage.

- Ensure power switch on operator is in the ‘On’ position.

Inspect Safety Sensors

Check if the safety sensors are obstructed or misaligned.

- Clear any obstacles in front of the sensor beams.

- Adjust sensors to properly align with each other.

- Wipe sensors with a clean cloth to remove any dirt or debris.

Reset The Operator

Perform a reset on the Liftmaster Rsl12Ul to resolve operational issues.

- Locate the reset button on the operator unit.

- Press and hold the reset button for 10 seconds.

- Release the button once the LED light blinks to confirm the reset.

Advanced Troubleshooting

Welcome to the advanced troubleshooting section for Liftmaster RSL12UL. In this section, we will explore the diagnostic mode and the process of contacting technical support to effectively address any issues you may encounter with your Liftmaster RSL12UL gate operator.

Diagnostic Mode

If you are experiencing technical difficulties with your Liftmaster RSL12UL, the diagnostic mode can provide valuable insight into the system’s operation. Accessing the diagnostic menu allows you to review error codes, input/output status, and system parameters, providing essential information for troubleshooting.

Follow these steps to enter the diagnostic mode:

- Press the Menu button on the control board.

- Use the arrow keys to navigate to the “Diagnostics” option.

- Press the Enter button to access the diagnostic menu.

Once in the diagnostic menu, carefully review the displayed information to identify any irregularities or error codes that may point to the source of the issue. Additionally, consult the user manual for specific error code meanings and recommended actions to resolve them.

Contacting Technical Support

If you encounter challenges that are beyond your expertise or the diagnostic mode does not provide a solution, reaching out to Liftmaster technical support can offer professional assistance to resolve the issue.

Before contacting technical support, gather all relevant information about the problem, including error codes, observed symptoms, and any attempted troubleshooting steps. This will enable the support team to efficiently assess the situation and provide tailored guidance for resolving the issue.

When contacting technical support, be prepared to provide the following details:

- Serial number of the gate operator

- Specific error codes or system behavior

- Any recent maintenance or modifications performed on the system

By effectively conveying these details to the technical support team, you can expedite the troubleshooting process and swiftly restore the optimal functionality of your Liftmaster RSL12UL gate operator.

Maintenance Tips

Proper maintenance is essential to keep your Liftmaster Rsl12Ul gate operator running smoothly and efficiently. Regular maintenance not only prolongs the life of your equipment but also ensures the safety of your property. In this section, we will discuss some crucial maintenance tips to help you troubleshoot any issues with your Liftmaster Rsl12Ul gate operator.

Lubrication Of Moving Parts

Lubricating the moving parts of your Liftmaster Rsl12Ul gate operator is an integral part of its maintenance. By doing so, you can prevent the wear and tear that may occur due to friction and extend the lifespan of your equipment. Here are the key steps you should follow to lubricate the moving parts efficiently:

- Clean the parts: Before applying lubricant, it is essential to clean the moving parts using a soft cloth or a brush to remove any dirt or debris.

- Choose the right lubricant: Use a high-quality lubricant recommended by the manufacturer. This ensures compatibility and optimal performance.

- Apply the lubricant: Apply a small amount of lubricant to the moving parts, such as hinges, rollers, and chains. Be cautious not to over-lubricate, as excess lubricant can attract dirt and cause additional friction.

- Wipe off excess lubricant: After applying lubricant, wipe off any excess with a clean, dry cloth to prevent accumulation.

Regular Safety Checks

Regular safety checks are vital to ensure the proper functioning of your Liftmaster Rsl12Ul gate operator. By making it a routine, you can identify potential issues early on and prevent any accidents or malfunctions. Here are a few essential safety checks you should perform:

- Inspect the gate: Regularly inspect the gate for any signs of damage, such as bent or broken parts. Replace or repair any damaged components promptly.

- Check the safety sensors: The safety sensors of your gate operator are crucial for detecting obstructions and preventing accidents. Make sure they are clean and aligned properly. Test their functionality regularly.

- Test the auto-reverse feature: The auto-reverse feature ensures that the gate reverses its direction if it encounters any obstruction. Test this feature by placing an object in the gate’s path while closing it. The gate should reverse immediately upon contact.

- Check the battery: If your gate operator has a battery backup, check the battery health regularly and replace it if necessary. A faulty battery can lead to gate operation issues during power outages.

By following these maintenance tips, you can keep your Liftmaster Rsl12Ul gate operator in excellent condition and address any troubleshooting issues efficiently. Regular lubrication and safety checks will not only ensure optimal performance but also enhance the safety and security of your property.

Preventive Measures

When it comes to ensuring the smooth functioning of your Liftmaster Rsl12Ul gate operator, taking preventive measures is essential. By implementing proper installation techniques and providing user training, you can minimize the chances of encountering troubleshooting issues. Let’s dive into the details of these preventive measures:

Proper Installation

Proper installation is the foundation of trouble-free operations for your Liftmaster Rsl12Ul gate opener. Paying attention to the following aspects during the installation process is crucial to prevent potential issues:

- Ensure a stable and sturdy mounting surface to support the weight of the gate operator.

- Properly align the gate operator with the gate, making sure it operates smoothly without any excessive strain.

- Securely fasten all bolts and screws to prevent loosening over time, which can lead to malfunctions.

- Verify that the power supply is compatible and meets the specifications recommended by Liftmaster.

User Training

Properly training the users of the Liftmaster Rsl12Ul gate operator is equally important in avoiding troubleshooting headaches. By providing comprehensive user training, you can ensure that your gate operator is operated correctly and that common mistakes are avoided. Consider the following tips for an effective user training program:

- Provide detailed instructions on how to safely operate the gate operator, including topics such as emergency stop procedures and gate obstruction detection.

- Highlight the importance of regular maintenance tasks, such as lubricating moving parts and cleaning sensors.

- Encourage users to report any unusual noises, irregular movements, or error codes immediately to avoid escalating problems.

In conclusion, preventing troubleshooting issues with your Liftmaster Rsl12Ul gate operator requires a proactive approach. By ensuring proper installation and adequately training your users, you can minimize the chances of encountering common problems and enjoy the convenience of a reliable gate system.

Frequently Asked Questions For Liftmaster Rsl12ul Troubleshooting

What Does It Mean If My Liftmaster Rsl12ul Won’t Open?

If your Liftmaster Rsl12Ul won’t open, it may indicate a power issue or a problem with the control board.

How Can I Fix A Liftmaster Rsl12ul That Won’t Close?

To fix a Liftmaster Rsl12Ul that won’t close, check the safety sensors, adjust the travel limits, and ensure the door is not obstructed.

Why Is My Liftmaster Rsl12ul Beeping Constantly?

A constant beeping from your Liftmaster Rsl12Ul could indicate a low battery or a malfunctioning component that needs attention.

How Do I Reset The Liftmaster Rsl12ul?

To reset the Liftmaster Rsl12Ul, locate the “Learn” button on the control board and follow the manufacturer’s instructions to reprogram it.

Why Is My Liftmaster Rsl12ul Remote Not Working?

If your Liftmaster Rsl12Ul remote is not working, try replacing the batteries, reprogramming it, or ensuring it is within range of the unit.

Conclusion

To sum up, tackling Liftmaster RSL12UL troubleshooting is essential for maintaining a seamless and efficient gate operation. By following the troubleshooting tips and guidelines discussed in this blog post, you can address common issues and ensure optimal performance. Remember to consult professional technicians for complex problems and regular maintenance.

Keep your gate functional and secure with proactive troubleshooting efforts.