Mercury CDI ignition systems are crucial for your outboard motor’s performance. Troubleshooting these systems can be tricky without proper guidance.

In this Mercury CDI Ignition Troubleshooting Guide, we’ll explore common issues and their solutions. Understanding your ignition system is important to keep your boat running smoothly. If you face starting problems or engine misfires, this guide is for you. We will walk you through each step.

From identifying symptoms to fixing them, you’ll gain confidence in handling your Mercury CDI ignition system. Let’s dive into the details and get your outboard motor back in top shape.

Credit: issuu.com

Symptoms Of Cdi Ignition Problems

Understanding the symptoms of CDI Ignition Problems is crucial for diagnosing issues with your Mercury engine. Below are some common signs that indicate potential problems with your CDI ignition system.

Engine Misfires

One of the most noticeable symptoms is engine misfires. Misfires occur when the engine fails to ignite the fuel-air mixture properly. This can lead to a jerky or rough running engine.

- Irregular engine sound

- Decreased fuel efficiency

- Unstable engine RPM

Engine misfires can damage other engine components if not addressed promptly.

Starting Difficulties

Another common symptom is starting difficulties. If your engine struggles to start or takes longer than usual, it could be a CDI issue.

| Symptom | Possible Cause |

|---|---|

| Hard to start | Weak spark |

| Engine won’t start | Faulty CDI unit |

Starting difficulties can lead to increased wear on the starter motor.

Intermittent Power Loss

Experiencing intermittent power loss is another sign of CDI problems. The engine may lose power for short periods and then regain it.

- Sudden drop in speed

- Momentary loss of power

- Engine stalls and restarts

Intermittent power loss can affect the overall performance of your engine.

Addressing these symptoms early can prevent further damage and ensure your Mercury engine runs smoothly.

Preliminary Checks

When troubleshooting Mercury CDI ignition, start with preliminary checks. These checks often reveal common issues and save time. Let’s explore the key areas to inspect.

Visual Inspection

Begin with a thorough visual inspection of the ignition system. Look for damaged wires, corrosion, or burnt components. Ensure the ignition coils are in good condition. Check for any signs of wear and tear.

Make sure all parts are clean and properly secured. Dirt and grime can affect performance. A clean system runs better and lasts longer.

Battery Health

Next, verify the battery health. A weak or dead battery can cause ignition issues. Use a multimeter to check the voltage. The reading should be between 12.4 to 12.7 volts.

If the voltage is low, charge the battery. If it doesn’t hold a charge, replace it. A healthy battery ensures consistent power to the ignition system.

| Battery Condition | Action |

|---|---|

| 12.4 – 12.7 volts | Good |

| Below 12.4 volts | Charge or Replace |

Loose Connections

Finally, inspect for loose connections. Loose or corroded terminals can cause intermittent issues. Ensure all connections are tight and secure.

Check the connectors to the ignition switch, coils, and battery. Clean any corrosion with a wire brush. Apply a dielectric grease to prevent future corrosion. Secure all connections firmly.

Loose connections can lead to poor ignition performance. Ensuring they are tight improves reliability.

Testing Cdi Unit

Testing the CDI unit in your Mercury engine is vital for ensuring its smooth operation. The Capacitor Discharge Ignition (CDI) system plays a key role in the ignition process. This guide will help you test the CDI unit using simple tools and methods.

Using A Multimeter

To begin, you need a multimeter. This device measures electrical values like voltage and resistance. Set the multimeter to the correct setting before starting any test.

Follow these steps:

- Turn off the engine and disconnect the battery.

- Locate the CDI unit and remove any covers.

- Attach the multimeter probes to the CDI unit’s terminals.

Resistance Checks

Checking resistance ensures the CDI unit is not damaged. Use the multimeter to measure resistance between different points.

Here is a simple table for reference:

| Terminal Points | Expected Resistance (Ohms) |

|---|---|

| Primary Coil | 0.3 – 1.0 |

| Secondary Coil | 6k – 12k |

If the readings are outside these ranges, the CDI unit may need replacement.

Voltage Tests

Voltage tests are crucial for checking the CDI unit’s performance. Set the multimeter to the voltage setting. Measure the voltage at different terminals.

- Check the input voltage from the stator.

- Measure the output voltage going to the spark plug.

The input voltage should match the engine’s specifications. The output should be strong enough to create a spark.

If the voltage readings are incorrect, inspect the wiring and connections. Ensure all components are properly grounded.

Testing the CDI unit ensures your Mercury engine runs efficiently. Use these simple steps to diagnose and fix any issues.

Inspecting Spark Plugs

Inspecting spark plugs is crucial for Mercury CDI ignition troubleshooting. Spark plugs play a key role in engine performance. Regular checks can prevent bigger problems. Here is a guide on how to inspect spark plugs.

Signs Of Wear

Worn spark plugs can cause engine issues. Look for black soot on the plug tip. This indicates incomplete combustion. Also, check for oily deposits. This might mean oil is leaking into the combustion chamber. Cracked or chipped insulators are also signs of wear.

Proper Gapping

Spark plug gaps must be correct. Too wide or too narrow gaps can cause issues. Use a feeler gauge to measure the gap. Refer to your engine manual for the correct gap size. Adjust the gap carefully using the tool. Proper gapping ensures efficient ignition and smooth engine running.

Replacement Tips

Replace spark plugs if they show signs of wear. Use the right type and size for your Mercury engine. Always check the gap before installing new plugs. Apply a small amount of anti-seize compound on the threads. Tighten the plugs to the recommended torque. This prevents damage and ensures proper function.

Analyzing Stator And Trigger

Understanding the role of the stator and trigger in your Mercury CDI ignition system is crucial. These two components play a vital role in ensuring your engine runs smoothly. This guide will help you analyze and troubleshoot these parts effectively.

Stator Function

The stator is a key component of the ignition system. It generates the necessary electrical power to create a spark. The stator works by converting the rotational energy of the engine into electrical energy. This power is then used by the CDI unit to ignite the fuel mixture.

A faulty stator can lead to ignition problems. Symptoms include the engine not starting or running poorly. Regular checks and maintenance can prevent these issues.

Trigger Coils

The trigger coils are responsible for sending timing signals to the CDI unit. These signals tell the CDI when to fire the spark plug. The precise timing is crucial for optimal engine performance.

Issues with trigger coils can cause timing errors. Symptoms may include misfires or poor acceleration. Understanding the role of the trigger coils can help in diagnosing these issues.

Testing Procedures

Testing the stator and trigger coils involves a few key steps. Here’s a simple guide:

- Check the resistance of the stator using a multimeter. Refer to the manufacturer’s specs for correct values.

- Inspect the wiring and connectors for any signs of damage or corrosion.

- Test the trigger coils by measuring the resistance and voltage output. Compare these readings to the specs.

- If any readings are out of range, replace the faulty component.

Regular testing and maintenance can save you from unexpected breakdowns. Always refer to your engine’s manual for specific instructions.

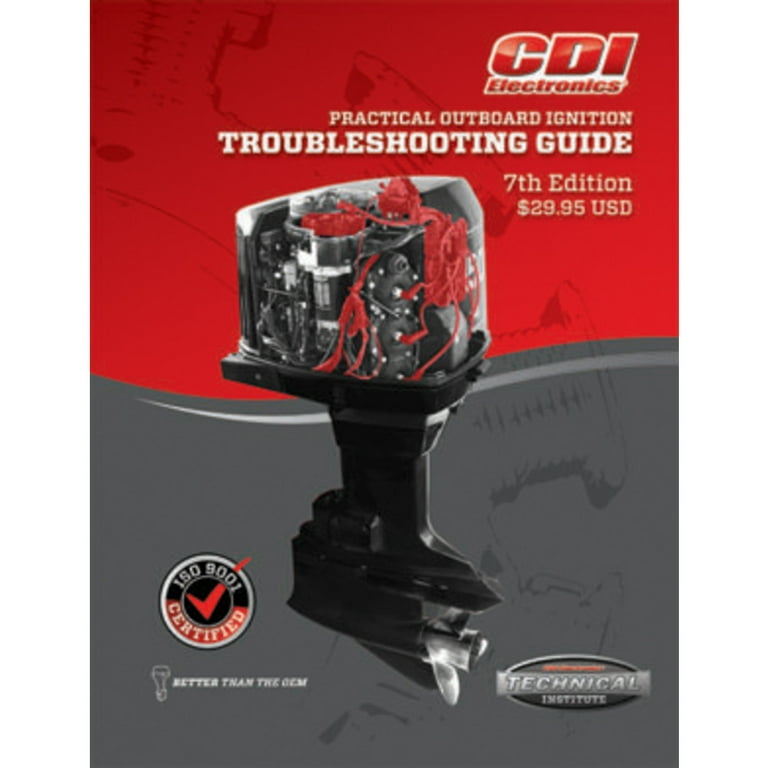

Credit: www.walmart.com

Checking Wiring And Connectors

When troubleshooting your Mercury CDI Ignition system, checking the wiring and connectors is crucial. Faulty wiring or connectors can lead to ignition problems. Follow these steps to ensure your system is in top shape.

Identifying Corrosion

Corrosion can cause significant issues in your ignition system. Inspect all the connectors and wiring for signs of rust or white powder. These are indicators of corrosion.

- Look for green or white deposits on connectors.

- Check for rust on metal parts.

- Examine wire ends for any signs of decay.

If you find any corrosion, it is crucial to address it immediately to prevent further damage.

Repair Techniques

Once you’ve identified corrosion, repair is the next step. Here are some techniques:

- Cleaning: Use a wire brush to clean rust off metal parts. For connectors, a contact cleaner spray works best.

- Replacing Wires: If a wire is heavily corroded, replace it with a new one. Ensure the replacement wire is of the same gauge and material.

After cleaning or replacing, apply a dielectric grease to prevent future corrosion.

Connector Replacement

If connectors are damaged, they may need replacing. Follow these steps:

| Step | Description |

|---|---|

| 1 | Disconnect the battery to ensure safety. |

| 2 | Remove the faulty connector using a connector removal tool. |

| 3 | Replace with a new connector of the same type. |

| 4 | Reattach the wiring and secure the new connector. |

Ensure all connections are tight and secure. This will help in maintaining a reliable ignition system.

Advanced Diagnostic Tools

When troubleshooting your Mercury CDI ignition system, using advanced diagnostic tools can save time and effort. These tools help pinpoint issues quickly and accurately. In this section, we will discuss three key tools: oscilloscopes, specialized testers, and data interpretation methods.

Oscilloscope Usage

An oscilloscope is a valuable tool for diagnosing ignition problems. It measures the voltage signals in your ignition system. By displaying these signals as waveforms, you can identify irregularities. Connect the oscilloscope to the ignition coil and observe the patterns. Look for any unusual spikes or dips. These anomalies can indicate issues like weak coils or faulty connections.

Specialized Testers

Specialized testers are designed for specific components in the ignition system. They can test coils, spark plugs, and CDI modules. These testers often have built-in instructions, making them user-friendly. Follow the manual to connect the tester to the component. The tester will provide readings or indicators of the component’s health. Replace any parts that fail the test.

Data Interpretation

Interpreting data from your diagnostic tools is crucial. Waveforms from an oscilloscope can reveal timing issues. A drop in voltage might suggest a weak connection. Use the data to guide your troubleshooting steps. Compare readings with manufacturer specifications. Consistent deviations from the norm often point to specific problems. Use this information to address the root cause.

Preventive Maintenance

Ensuring your Mercury CDI ignition system runs smoothly is vital. Regular preventive maintenance can help avoid unexpected failures. In this section, we’ll cover three key aspects: routine inspections, cleaning procedures, and storage tips.

Routine Inspections

Conducting routine inspections helps identify issues early. Check the ignition system’s components regularly for signs of wear or damage.

- Inspect the wires for fraying or cracks.

- Ensure connections are secure and free of corrosion.

- Look for any signs of moisture or water damage.

Use a multimeter to test the CDI unit. Verify that voltage levels match the manufacturer’s specifications.

Cleaning Procedures

Cleaning is crucial for maintaining the performance of your Mercury CDI ignition system. Follow these steps to ensure optimal functionality:

- Disconnect the battery to avoid electrical hazards.

- Use a soft brush to remove dirt and debris from the components.

- Clean the connectors with contact cleaner. Let them dry completely.

- Reattach the battery and test the system.

Avoid using water or harsh chemicals. These can damage the sensitive electronic components.

Storage Tips

Proper storage can extend the life of your Mercury CDI ignition system. Follow these tips:

- Store the boat in a dry, climate-controlled environment.

- Disconnect the battery to prevent drainage and corrosion.

- Cover the ignition components to protect them from dust and moisture.

By taking these steps, you can ensure your ignition system remains in good condition during the off-season.

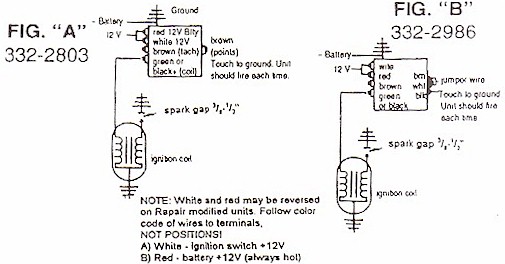

Credit: www.outboardparts.com

Frequently Asked Questions

How Can I Tell If My Mercury Cdi Ignition Is Faulty?

Check for no spark or weak spark. These are common signs.

What Tools Do I Need For Mercury Cdi Ignition Troubleshooting?

You need a multimeter, spark tester, and basic hand tools.

Why Is My Mercury Outboard Engine Not Starting?

A faulty CDI ignition could prevent the engine from starting.

Can I Fix A Mercury Cdi Ignition Issue Myself?

Yes, with basic tools and a guide. Follow safety precautions.

What Are Common Symptoms Of A Bad Cdi Ignition?

Engine misfires, hard starts, and poor performance are common symptoms.

Conclusion

Troubleshooting Mercury CDI ignition can be easy with the right steps. Regular maintenance is key. Check connections, inspect the wiring, and test the CDI unit. Replacing faulty parts helps avoid bigger problems. Remember, careful attention ensures a smooth-running engine. Follow this guide, and you’ll fix issues quickly.

Happy boating!