Is your Mercury outboard engine acting up unexpectedly? You might be facing issues with the stator, a small but crucial part that powers your boat’s electrical system.

When the stator starts to fail, you’ll notice problems like a dead battery, flickering lights, engine stalling, or sluggish acceleration. These symptoms can leave you stranded or frustrated on the water. But don’t worry—understanding how to troubleshoot your Mercury stator can save you time and money.

You’ll learn simple, step-by-step methods to test and diagnose your stator’s condition using basic tools. Keep reading to take control of your boat’s performance and avoid costly repairs down the line.

Common Symptoms

Identifying common symptoms of a faulty Mercury stator helps avoid serious engine damage. These signs show the stator is not supplying power properly. Early detection saves time and repair costs. Watch for electrical, engine, and physical clues that point to stator troubles.

Electrical Issues

- Dead or weak battery that loses charge fast.

- Dim or flickering lights that change with engine speed.

- Engine stalls or cuts out, especially at low RPMs.

- Electronic accessories like gauges or heated grips act erratically.

Engine Performance Problems

- Engine misfires or runs rough due to inconsistent spark.

- Slow acceleration and weak power response.

- Backfiring caused by unburned fuel igniting in the exhaust.

- Difficulty starting or failure to crank properly.

Physical Signs

- Burning smell from the engine area, often plastic or wires.

- Stator or nearby parts feel unusually hot to the touch.

Credit: www.outboardspares.com.au

Basic Stator Checks

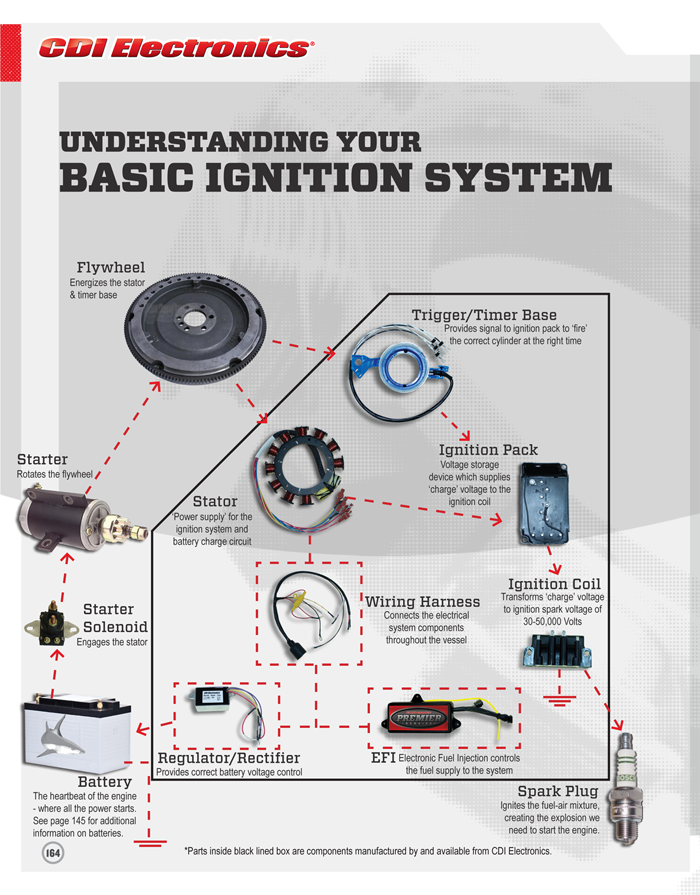

The stator is a key part of your Mercury outboard motor’s electrical system. Basic checks on the stator help find faults early. These tests need a simple digital multimeter. They show if the stator works well or if it needs repair or replacement.

Start with these three simple checks. They cover continuity, resistance, and output voltage. Each test gives important clues about the stator’s health. Follow these steps carefully to avoid mistakes.

Measuring Continuity

Continuity shows if the stator coils are connected properly. Set your multimeter to the continuity mode. Touch the leads to the stator coil terminals. A beep or low reading means the circuit is complete. No beep or infinite reading means a broken coil wire. This test finds open circuits inside the stator.

Testing Resistance

Resistance tells if the coil windings have the right electrical flow. Set the multimeter to ohms (Ω). Measure resistance between each pair of coil terminals. Compare your readings to the motor’s manual specs. High or low resistance means coil damage. This test spots short circuits or winding problems.

Checking Output Voltage

Output voltage shows if the stator generates power correctly. Start the engine and set the multimeter to AC volts. Measure voltage at the stator output wires. Voltage should rise smoothly as engine speed increases. No voltage or unstable readings indicate a faulty stator. This test confirms if the stator charges the battery properly.

Tools Needed

Troubleshooting a Mercury stator requires the right tools for accurate diagnosis. Using proper equipment helps identify issues quickly. It also prevents damage to the stator and other parts. Below are the essential tools needed for effective troubleshooting.

Digital Multimeter

A digital multimeter measures voltage, current, and resistance. It is crucial to check the stator’s electrical output. This tool helps find shorts and open circuits. It also measures the voltage generated by the stator at different engine speeds. A reliable multimeter ensures precise readings for better troubleshooting.

Ohmmeter

An ohmmeter measures resistance within the stator coils. It helps detect broken wires or damaged coils. Checking resistance values against specifications reveals faults. This tool is simple but very effective. It confirms if the stator windings are intact or need replacement.

Safety Gear

Wearing safety gear protects you during testing. Use insulated gloves to avoid electric shocks. Safety glasses shield your eyes from sparks or debris. Proper gear minimizes injury risks while working on electrical parts. Always prioritize safety during any stator troubleshooting task.

Step-by-step Testing

Testing the Mercury stator involves a clear, step-by-step process. This helps find faults quickly and safely. Follow these steps carefully to check if the stator works well. Use a digital multimeter for accurate results. Start by isolating the stator from the rest of the system. Then, check the resistance and voltage output to find issues.

Disconnecting Stator Wires

Begin by turning off the engine and removing the key. Locate the stator wires, usually connected to the wiring harness. Gently unplug the stator wires from the connector. This stops current from flowing during tests. Keep wires clean and dry for better contact. Label wires if needed to avoid confusion later.

Performing Ohm Tests

Set your multimeter to the ohm (Ω) setting. Test between each stator wire and ground to check resistance. The reading should match the manufacturer’s specifications. A very high or infinite resistance means a broken wire inside. Very low resistance may indicate a short circuit. Record all values carefully for comparison.

Voltage Output Testing

Reconnect the stator wires after ohm testing. Set the multimeter to AC voltage mode. Start the engine and let it run at low RPMs. Measure voltage between stator wires one by one. Voltage should rise smoothly with engine speed. Fluctuating or no voltage shows a faulty stator. Turn off the engine after testing to stay safe.

Common Causes Of Failure

Understanding the common causes of Mercury stator failure helps save time and money. Faulty stators can stop your engine from charging properly. This leads to battery problems and poor engine performance. Identifying the root cause is key to effective troubleshooting. Below are the main reasons why stators fail.

Overheating Damage

Excess heat is a leading cause of stator failure. High temperatures melt insulation and damage wiring. Overheating often happens when the engine runs too long or under heavy load. Poor cooling or blocked airflow can worsen this issue. Once damaged, the stator stops producing the needed electrical power.

Shorted Switch Box

The switch box controls power flow to the stator. A short circuit inside it causes electrical faults. This results in inconsistent voltage output and engine stalling. Moisture or corrosion inside the box often triggers shorts. Replacing or repairing the switch box usually restores normal function.

Wiring Issues

Loose, frayed, or corroded wires disrupt the stator’s electrical circuit. Vibrations and exposure to water cause wiring damage over time. Faulty connections lead to weak or no electrical output. Regular inspection and proper repairs keep wiring in good condition. This prevents many stator-related problems.

Credit: www.boats.net

Quick Fixes

Quick fixes for Mercury stator issues often resolve common problems fast. These solutions require basic tools and minimal experience. Acting early prevents bigger electrical faults and costly repairs. Focus on three main areas: connections, wiring, and electrical components. Each step helps restore proper function and extends your outboard’s life.

Cleaning Connections

Dirty or corroded connections block electrical flow. Start by disconnecting the battery and stator wires. Use a wire brush or sandpaper to clean terminals and connectors. Remove rust and corrosion until metal shines. Apply dielectric grease to protect surfaces from moisture. Reconnect wires tightly for a solid connection. This simple step often fixes charging issues and weak spark problems.

Replacing Damaged Wires

Worn or broken wires cause shorts and power loss. Inspect all stator wiring for cracks, cuts, or burns. Replace any damaged wires with marine-grade cables. Use proper connectors and secure cables to avoid vibration damage. Check for pinched or stretched wires that might fail soon. New wiring restores consistent power and prevents sudden engine stalls.

Resetting Electrical Components

Electrical components can malfunction due to temporary faults. Reset by disconnecting the battery for 10 minutes. This clears error codes and resets the outboard’s computer. Reconnect the battery and test the engine. Resetting can fix sensors and regulators that affect stator performance. Repeat the reset if problems persist after repairs.

When To Replace

Knowing when to replace your Mercury stator is key to keeping your outboard engine running smoothly. The stator plays an important role in charging the battery and powering electrical systems. Over time, wear and damage reduce its effectiveness. Recognizing the right moment to replace the stator helps avoid breakdowns and costly repairs.

Signs Of Severe Damage

Severe damage to the stator shows clear symptoms. A burning smell near the engine often means the stator is overheating or wires are melting. The engine may stall or fail to start altogether. Flickering or dim lights and a dead battery that won’t hold a charge also point to serious issues. Physical damage like burnt coils or corrosion confirms the stator needs replacement.

Cost Vs Repair Considerations

Repairing a stator can sometimes save money, but it depends on the damage extent. Minor faults like loose connections or worn wires may be fixed. Major problems with coils or insulation usually require a full replacement. Compare the repair cost with the price of a new stator. Often, replacing the stator offers better reliability and longer life. Factor in labor costs and potential downtime when deciding.

Preventive Tips

Preventing stator problems saves time and money. Simple care extends your Mercury outboard motor’s life. Follow these tips to keep the stator in good shape. Regular checks and proper handling stop many common issues.

Regular Inspections

Check the stator often for signs of wear or damage. Look for frayed wires, corrosion, or loose connections. Early detection helps fix small issues before they get worse. Clean the stator and surrounding parts to avoid dirt buildup. Use a flashlight to spot cracks or burn marks. Inspections every few months keep your motor reliable.

Proper Cooling Maintenance

Cooling keeps the stator from overheating. Make sure the water pump works well and delivers enough water flow. Clean any blockages in the cooling system. Replace worn or damaged hoses and clamps. Overheated stators fail faster and cause engine problems. Keep the cooling system in good condition to avoid costly repairs.

Avoiding Electrical Overloads

Do not add extra electrical accessories without checking the system. Too much load stresses the stator and wiring. Use the correct fuses and circuit breakers to protect the motor. Inspect the battery and charging system regularly. Poor electrical connections cause voltage drops and damage. Keep electrical demands within the manufacturer’s limits for best results.

Credit: www.youtube.com

Frequently Asked Questions

How Do I Know If My Stator Is Bad On My Outboard?

Check for a weak battery, dim or flickering lights, engine stalling, poor acceleration, or a burning smell. Test stator resistance and output voltage with a multimeter for accurate diagnosis.

What Are The Symptoms Of A Faulty Stator?

Symptoms of a faulty stator include a dead or weak battery, dim or flickering lights, engine stalling, misfiring, sluggish acceleration, and a burning smell. Electrical accessories may fail, and the engine might backfire or fail to start. Overheating near the stator is also common.

What Are The Three Basic Checks That Can Be Performed On A Stator?

Perform continuity, resistance, and output voltage checks using a digital multimeter to test a stator effectively.

How To Tell If The Stator Or Rectifier Is Bad?

Test the stator with a multimeter for resistance and continuity; check the rectifier for voltage output. Signs include dim lights, dead battery, engine stalling, or burning smell. Faulty readings or no voltage indicate a bad stator or rectifier.

What Are Common Signs Of A Faulty Mercury Stator?

Common signs include a dead or weak battery, dim lights, and engine stalling. Poor acceleration and a burning smell near the stator also indicate issues.

Conclusion

Mercury stator issues often show clear signs like dim lights or engine stalls. Testing with a multimeter helps find electrical faults quickly. Check resistance, continuity, and voltage to spot problems early. Fixing or replacing a faulty stator prevents bigger engine damage.

Regular inspections keep your Mercury outboard running smoothly. Simple troubleshooting saves time and costly repairs. Stay alert to symptoms and act fast for best results.