Owen Generator Troubleshooting: Simple Steps to Get Yours Running Again Is your Owen generator giving you trouble? Don’t worry—you’re not alone.

When a generator won’t start or isn’t working as it should, it’s easy to feel frustrated, especially when you’re relying on it for power. But here’s the good news: most issues can be fixed with just a little know-how and the right steps.

In this guide, we’ll walk you through common Owen generator problems and how to troubleshoot them quickly and effectively. Whether it’s a stubborn engine, odd noises, or a complete shutdown, you’ll discover practical tips to get your generator back on track. Stick around, because solving the problem might be easier than you think—and it could save you both time and money. Ready to dive in? Let’s get started!

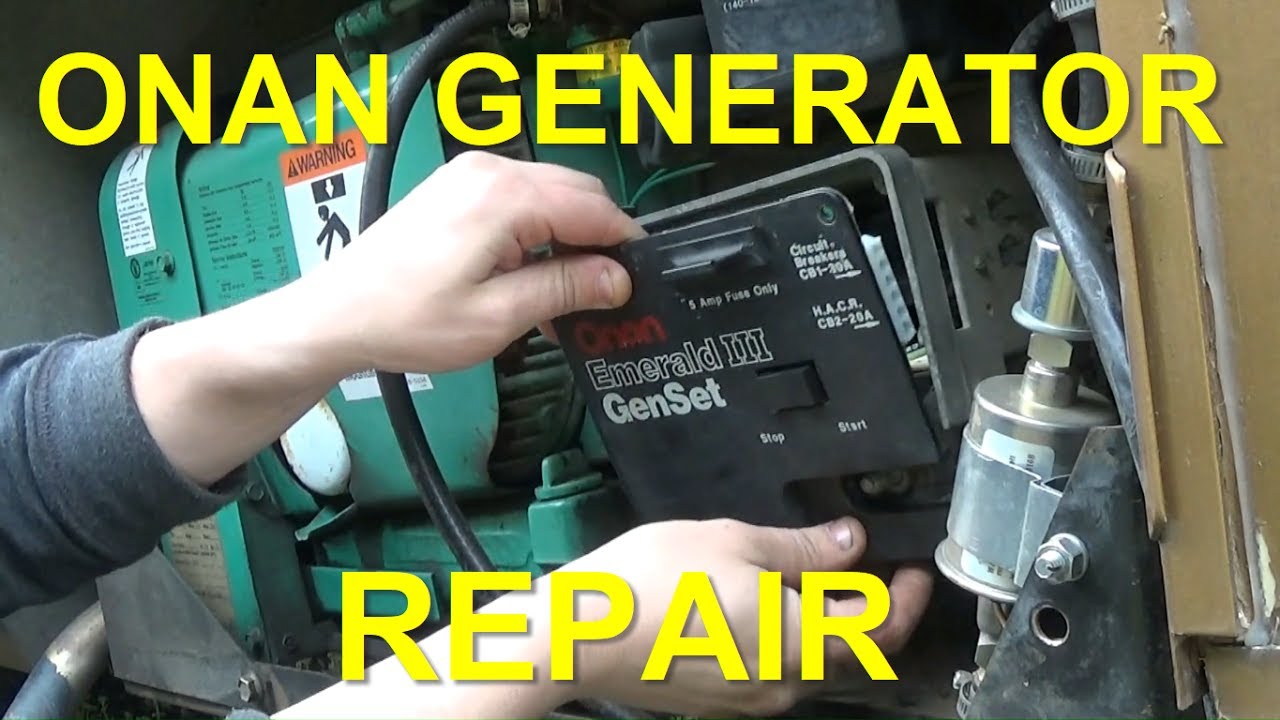

Credit: www.reddit.com

Common Issues With Owen Generators

Owen generators are reliable machines, but like any equipment, they can face problems over time. Knowing the common issues and how to address them can save you time, money, and frustration. Let’s break down some frequent problems you might encounter and how to troubleshoot them effectively.

Generator Won’t Start

A generator that refuses to start can be incredibly frustrating, especially during a power outage. One common culprit is a drained or faulty battery. Check the battery connections for corrosion and make sure they’re secure.

Another reason could be stale fuel. If the generator has been sitting idle for months, the fuel might have degraded. Draining old fuel and refilling with fresh gasoline can often resolve the issue.

Don’t forget to inspect the spark plug. A dirty or worn-out spark plug can prevent the engine from firing. Cleaning or replacing it is a quick and inexpensive fix.

Unusual Noises

Generators are not silent machines, but certain noises can indicate trouble. A rattling sound could mean loose components. Inspect the screws, bolts, and panels to ensure everything is tight.

Grinding noises might suggest issues with the bearings or internal components. In such cases, it’s best to stop using the generator and consult a professional to avoid further damage.

Sometimes, a loud knocking sound points to low oil levels. Always check and maintain proper oil levels to keep the generator running smoothly.

Low Power Output

If your generator is running but not producing enough power, it might be due to a clogged air filter. A dirty filter restricts airflow, reducing the engine’s efficiency. Cleaning or replacing the air filter can often restore performance.

Another potential issue is the generator’s load. Are you connecting more devices than the generator can handle? Check the wattage of your appliances and ensure it doesn’t exceed the generator’s capacity.

Faulty wiring or connections can also cause low power. Inspect all cables and outlets for damage or loose connections.

Overheating Problems

Overheating is a common issue that can seriously damage your generator. Blocked ventilation is often the root cause. Ensure the generator is placed in a well-ventilated area, away from walls or obstructions.

Low coolant levels can also lead to overheating in liquid-cooled generators. Regularly check and refill the coolant as needed to prevent the engine from running too hot.

Lastly, running your generator continuously for long periods without breaks can cause it to overheat. Follow the manufacturer’s recommendations for operating times to avoid unnecessary strain on the machine.

Have you faced any of these issues with your Owen generator? Share your experience in the comments—your insights might just help someone else troubleshoot their problem!

Credit: m.youtube.com

Pre-troubleshooting Steps

Before diving into generator troubleshooting, take a moment to address basic checks that can save you time and effort. These pre-troubleshooting steps often resolve issues without needing deeper technical fixes. Think of them as your first line of defense in ensuring your Owen generator runs smoothly.

Check Fuel Levels

Low or empty fuel levels are one of the most common causes of generator problems. Always verify that your fuel tank has enough gas or diesel to power the generator. Running out of fuel might sound trivial, but it happens more often than you’d expect, especially during extended usage.

If your generator uses diesel, check for signs of contamination or water in the fuel. Contaminated fuel can clog injectors and cause the engine to stall. Keeping a spare can of clean fuel handy is a smart move.

Inspect Battery Connections

A loose or corroded battery connection can prevent your generator from starting. Check the terminals for any visible rust or debris. Clean them with a wire brush and tighten the connections securely.

Pay attention to the battery itself. If it’s old or weak, it might not hold a charge. Testing the battery voltage with a multimeter is a quick way to confirm it’s in good condition. Is your battery overdue for replacement?

Examine Oil And Coolant Levels

Low oil or coolant levels can trigger safety shutoffs in your Owen generator. Locate the dipstick and check the oil level. If it’s below the recommended level, add oil gradually until it reaches the mark.

Similarly, inspect the coolant reservoir. Low coolant can lead to overheating, which may damage your generator’s engine. Use the manufacturer-recommended coolant type to avoid compatibility issues.

Do these checks seem basic? They are—but skipping them could mean hours wasted troubleshooting something that’s easily fixable.

Quick Fixes For Starting Problems

Starting problems with your Owen generator can be frustrating. Often, the issue stems from minor faults that are easy to fix. Before seeking professional help, try these quick troubleshooting steps. They might save you time and money.

Resetting The Generator

Sometimes, a simple reset can resolve starting issues. Locate the reset button on your generator. Press and hold it for about 10 seconds. Release the button and attempt to start the generator. This process often clears minor errors in the system.

Inspecting The Spark Plug

A dirty or damaged spark plug can prevent your generator from starting. Remove the spark plug using the appropriate tool. Check for dirt, corrosion, or wear on the tip. Clean it with a dry cloth if it’s dirty. Replace it if you notice visible damage. Reinstall the spark plug tightly and test the generator again.

Cleaning The Air Filter

A clogged air filter can restrict airflow and cause starting problems. Open the generator’s air filter compartment. Carefully remove the air filter and inspect it for debris. Wash it with soapy water if it’s reusable. Allow it to dry completely before reinstalling. Replace it with a new one if it’s disposable or badly damaged.

Dealing With Power Output Issues

Power output issues can disrupt the performance of your Owen Generator. These problems may stem from minor faults or worn-out components. Identifying and fixing the issue quickly ensures uninterrupted power supply. Follow these steps to troubleshoot and resolve power output problems effectively.

Testing Voltage Levels

Start by testing the voltage output of your generator. Use a reliable multimeter to measure voltage at the terminals. Compare the reading with the generator’s rated voltage. Low or fluctuating voltage indicates a possible fault in the system. Consistent readings outside the normal range may need professional attention.

Inspecting Circuit Breakers

Check the circuit breakers for any signs of tripping or damage. Faulty circuit breakers can disrupt power delivery. Reset tripped breakers and ensure they function correctly. Replace damaged breakers immediately to avoid further complications. Always prioritize safety while inspecting electrical components.

Replacing Worn-out Components

Examine the generator for worn-out or damaged parts. Components like brushes, wires, or connectors may degrade over time. Replace these parts with compatible replacements to restore optimal performance. Regular maintenance can help prevent such issues in the future.

Handling Overheating Concerns

Generators are essential for keeping power running during outages. Overheating is a common issue that can disrupt their efficiency. Addressing overheating concerns can improve performance and prevent damage. Below are practical steps to handle overheating issues with your Owen Generator.

Ensuring Proper Ventilation

Ventilation is crucial for keeping your generator cool. Place it in an open area with sufficient airflow. Avoid confined spaces as they trap heat, causing the generator to overheat. Ensure no objects block the air intake and exhaust ports.

Cleaning Cooling Vents

Dirty cooling vents can restrict airflow, causing the generator to run hot. Inspect the vents for dirt, debris, or buildup regularly. Use a soft brush or compressed air to clean the vents. This helps maintain consistent airflow and prevents overheating.

Checking The Radiator

The radiator plays a key role in cooling the generator. Check for leaks or blockages to ensure it functions properly. Refill coolant levels if they are low. Clean the radiator fins to remove dirt and debris. This helps the radiator work efficiently to cool the generator.

Credit: www.reddit.com

Tips For Regular Maintenance

Regular maintenance keeps your Owen generator running smoothly and efficiently. It helps prevent unexpected breakdowns and prolongs the generator’s lifespan. By following a maintenance routine, you can save money on costly repairs. Here are some useful tips to maintain your generator effectively.

Scheduling Routine Inspections

Set a specific schedule for inspecting your generator. Regular checks help identify small issues before they become major problems. Inspect the fuel lines, filters, and connections for wear and tear. Check the oil level and replace it if necessary. Ensure the generator’s cooling system is free of blockages. A consistent inspection routine improves reliability.

Using High-quality Fuel

Always use clean, high-quality fuel for your generator. Low-quality fuel can clog the system and damage internal components. Store fuel in a clean, sealed container to avoid contamination. Replace old fuel that has been sitting for a long time. Using good fuel ensures smoother operation and reduces wear on engine parts.

Storing The Generator Correctly

Store your generator in a dry, well-ventilated space away from moisture. Moisture can cause rust and damage electrical components. Cover the generator with a breathable material to protect it from dust. Disconnect the battery if the generator will not be used for a long time. Proper storage keeps your generator in top condition.

When To Call A Professional

Generators are lifesavers during power outages, but troubleshooting one can quickly become overwhelming. Sometimes, the issue goes beyond basic maintenance or repair. Knowing when to call a professional can save you from frustration, unnecessary costs, and even safety risks. Let’s break down the key signs that it’s time to bring in an expert.

Identifying Complex Problems

Not all generator problems are straightforward. If your Owen generator isn’t starting despite checking the fuel, battery, and connections, the issue might be deeper. Complex electrical or mechanical failures are often invisible to the untrained eye.

For example, a faulty alternator or broken control panel could stop your generator from working. These aren’t fixes you can handle with a wrench and a manual. Attempting to resolve such problems without expertise can worsen the damage.

Ask yourself: Do I fully understand what’s wrong? If the answer is no, it’s time to call a certified technician to diagnose and repair it efficiently.

Recognizing Safety Hazards

Safety should always come first. If you smell gas near your generator or see exposed wires, stop using it immediately. These are clear signs of potential hazards that require professional attention.

Generators can also emit carbon monoxide if not properly ventilated. If you feel dizzy or notice unusual smells while operating the unit, it’s not worth the risk. Shut it down and call an expert.

Would you risk injury for a DIY fix? Serious problems like these demand professional handling to ensure your safety and the safety of those around you.

Finding Certified Technicians

Don’t just hire the first person you find online. Look for technicians certified to work on Owen generators. Certification ensures they have the right training and tools for the job.

Check reviews, ask for recommendations, and verify credentials before committing. Many companies offer warranties for their repairs, giving you peace of mind that the issue will be resolved correctly.

Think about it: Would you trust your generator—and your safety—to someone without proper qualifications? A certified technician is your best bet for a reliable fix.

Conclusion

Regular maintenance keeps your Owen generator running smoothly. Address issues early to prevent costly repairs. Use the troubleshooting tips shared here to identify common problems. Always prioritize safety when inspecting or repairing your generator. For complex issues, consult a professional to avoid further damage.

A well-maintained generator provides reliable backup power when you need it most. Stay proactive and ensure your generator is ready for any emergency. By caring for it properly, you extend its lifespan and improve its performance. Keep these insights handy for future use, and enjoy peace of mind during power outages.