For Pitco Frialator troubleshooting, refer to the manual and check for common issues. Ensure proper maintenance for optimal performance.

When it comes to ensuring your commercial kitchen runs smoothly, troubleshooting the Pitco Frialator is essential. Understanding the common problems and how to fix them can save time and money. By following the manufacturer’s guidelines and performing regular maintenance, you can prevent breakdowns and keep your fryer operating efficiently.

This article will provide you with a comprehensive guide to troubleshooting your Pitco Frialator, allowing you to address any issues quickly and effectively.

Common Issues With Pitco Frialator

Learn about potential issues with Pitco Frialator and how to troubleshoot them. Resolve common problems like overheating, oil leakage, or uneven frying to keep your equipment running smoothly and safely. Understanding these problems will help you maintain your fryer’s performance and extend its lifespan.

Ignition Problems

Troubleshooting ignition problems is crucial for optimal fryer performance.

Oil Temperature Fluctuations

Addressing oil temperature fluctuations helps maintain food quality consistency.

Fryer Not Heating Up

Resolving issues with fryer not heating up ensures efficient cooking operations.

Troubleshooting Steps

When your Pitco Frialator is not functioning properly, follow these troubleshooting steps:

Checking Gas Supply

- Ensure gas supply valve is open.

- Check for any gas leaks using soapy water.

- Verify gas pressure is within recommended range.

Calibrating Oil Temperature

- Use a reliable thermometer to check oil temperature.

- Adjust thermostat settings if necessary.

- Allow sufficient time for oil temperature to stabilize.

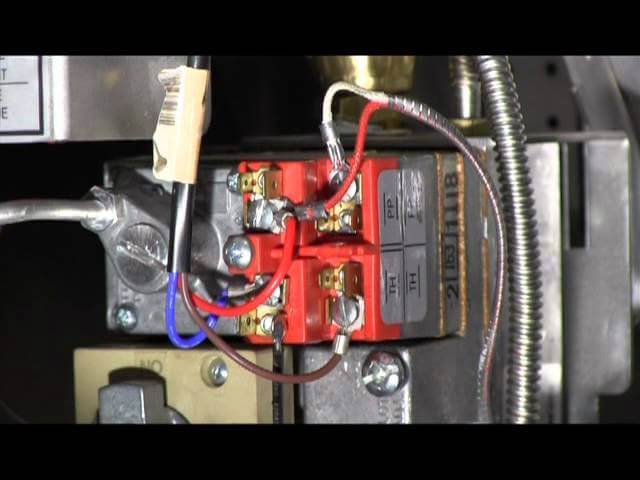

Inspecting Heating Elements

- Visually inspect heating elements for any signs of damage.

- Clean heating elements to ensure proper function.

- Test heating elements for continuity using a multimeter.

Preventive Maintenance Tips

When it comes to maintaining your Pitco Frialator, preventive maintenance is key to ensuring its efficient operation and longevity. By following some simple preventive maintenance tips, you can prevent costly breakdowns and avoid downtime. Let’s delve into some essential preventive maintenance practices for your Pitco Frialator.

Regular Cleaning And Inspection

Regularly cleaning and inspecting your Pitco Frialator is crucial to prevent potential issues. Clean the fryer daily, ensuring all components are free from debris, carbon build-up, and oil residue. Pay close attention to the heating elements, the thermostat, and the drain valve, as these are common areas for grease accumulation, which can lead to equipment malfunctions.

- Wipe down the exterior of the fryer regularly to prevent the build-up of dirt and grime, which can affect the efficiency of the unit.

- Inspect the fryer’s wiring for any signs of wear or damage, and replace any worn-out components immediately to avoid electrical hazards.

Proper Oil Filtration And Replacement

Effective oil management is vital for maintaining the performance of your Pitco Frialator. Proper filtration and regular oil replacement are essential preventive maintenance measures.

- Use a high-quality oil filtration system to remove food particles and impurities from the oil, extending its lifespan and maintaining the quality of fried products.

- Regularly monitor the oil level and quality, and replace the oil as recommended by the manufacturer to prevent flavor transfer and ensure consistent food quality.

By adhering to these preventive maintenance tips, you can ensure the optimal performance of your Pitco Frialator, minimize downtime, and maximize its lifespan.

Utilizing Manufacturer Resources

When it comes to troubleshooting your Pitco Frialator, there’s no need to feel overwhelmed. Pitco offers a range of valuable resources to help you resolve any issues you might encounter with your fryer. By utilizing the manufacturer resources available to you, you can quickly and efficiently diagnose and fix problems, getting your fryer back up and running in no time.

Online Manuals And Troubleshooting Guides

One of the most valuable resources provided by Pitco is their collection of online manuals and troubleshooting guides. These comprehensive documents provide step-by-step instructions and detailed information about your specific Pitco Frialator model. Whether you’re a seasoned professional or a first-time fryer owner, these resources are designed to be easy to understand and follow.

By referring to the online manuals, you can quickly access important information such as operating instructions, maintenance tips, and troubleshooting steps. Each manual is specific to a particular Pitco Frialator model, ensuring that you have the most accurate and relevant information at your fingertips.

Additionally, the troubleshooting guides offer helpful solutions to common problems that may arise with your fryer. From issues with temperature control to concerns about oil filtration, these guides provide clear and concise troubleshooting steps to help you identify and resolve the problem quickly.

Contacting Customer Support

If you’re unable to find a solution to your Pitco Frialator issue using the online resources, don’t worry. Pitco’s customer support team is available to assist you. Getting in touch with a knowledgeable representative is as simple as reaching out to their customer support hotline or sending an email inquiry.

When contacting customer support, be sure to provide them with specific details about the issue you’re facing. This will enable the support team to provide targeted assistance and minimize any downtime for your fryer.

Pitco’s customer support team is trained to handle a wide range of technical issues and can help troubleshoot problems over the phone or via email. They may even be able to walk you through a solution step by step, saving you time and money on potential service calls.

Remember, the manufacturer resources provided by Pitco are there to support you in resolving any issues you may encounter with your Pitco Frialator. By utilizing the online manuals and troubleshooting guides, as well as reaching out to customer support when needed, you can keep your fryer operating at its best and ensure uninterrupted service in your kitchen.

Seeking Professional Assistance

While some minor issues with your Pitco Frialator can be resolved through troubleshooting, there may be instances when it becomes necessary to seek professional assistance. Authorized service centers and technicians are equipped with the knowledge, expertise, and specialized tools required to diagnose and repair more complex problems. In this section, we will discuss how to identify authorized service centers and when it is appropriate to call a technician.

Identifying Authorized Service Centers

When facing a malfunctioning Pitco Frialator, it is crucial to seek assistance from authorized service centers. These centers have been officially recognized by Pitco and are authorized to repair and maintain their products. Here’s how you can identify them:

- Visit the official Pitco website and navigate to the “Service & Support” section.

- Look for a list of authorized service centers, which is typically provided along with their contact information.

- Note down the address and phone number of the nearest service center to your location.

Keep in mind that only authorized service centers have direct access to genuine Pitco replacement parts, ensuring the quality and longevity of your Frialator.

When To Call A Technician

While you can troubleshoot and address minor issues with your Pitco Frialator by following the manufacturer’s guidelines, certain situations may require the expertise of a qualified technician. Here are some instances in which it is wise to contact a professional:

- If you encounter complex or recurring problems that cannot be resolved through basic troubleshooting.

- If your Frialator is producing unusual noises or emitting strange odors.

- If you notice a significant decrease in performance, such as longer cooking times or inconsistent temperature settings.

- If there are visible signs of damage or wear, such as leaks, frayed cords, or broken components.

By calling a technician, you can ensure that any potential issues are accurately diagnosed and promptly addressed, preventing further damage and minimizing downtime.

Frequently Asked Questions On Pitco Frialator Troubleshooting

How Do I Troubleshoot My Pitco Frialator?

Check if the power switch is on, the outlet is working, and the unit is properly plugged in.

What Should I Do If My Pitco Frialator Won’t Turn On?

Make sure the thermostat is set correctly, check the circuit breaker, and inspect the power cord for any damage.

Why Is My Pitco Frialator Not Heating Up?

Verify that the gas or electricity supply is connected, check the thermostat setting, and clean the burner assembly.

What Can Cause My Pitco Frialator To Overheat?

Possible causes include a dirty heat exchanger, blocked flue, incorrect thermostat calibration, or a malfunctioning high limit switch.

How Do I Fix A Leaking Pitco Frialator?

Inspect the oil tank for cracks or damage, tighten any loose connections, and replace any faulty gaskets or seals.

Conclusion

Troubleshooting Pitco Frialator issues is essential for maintaining kitchen efficiency. By following the steps outlined in this guide, you can identify and resolve common problems with ease. Regular maintenance and thorough cleaning are also crucial for preventing future issues. With proper care, your Pitco Frialator can continue to operate at its best.