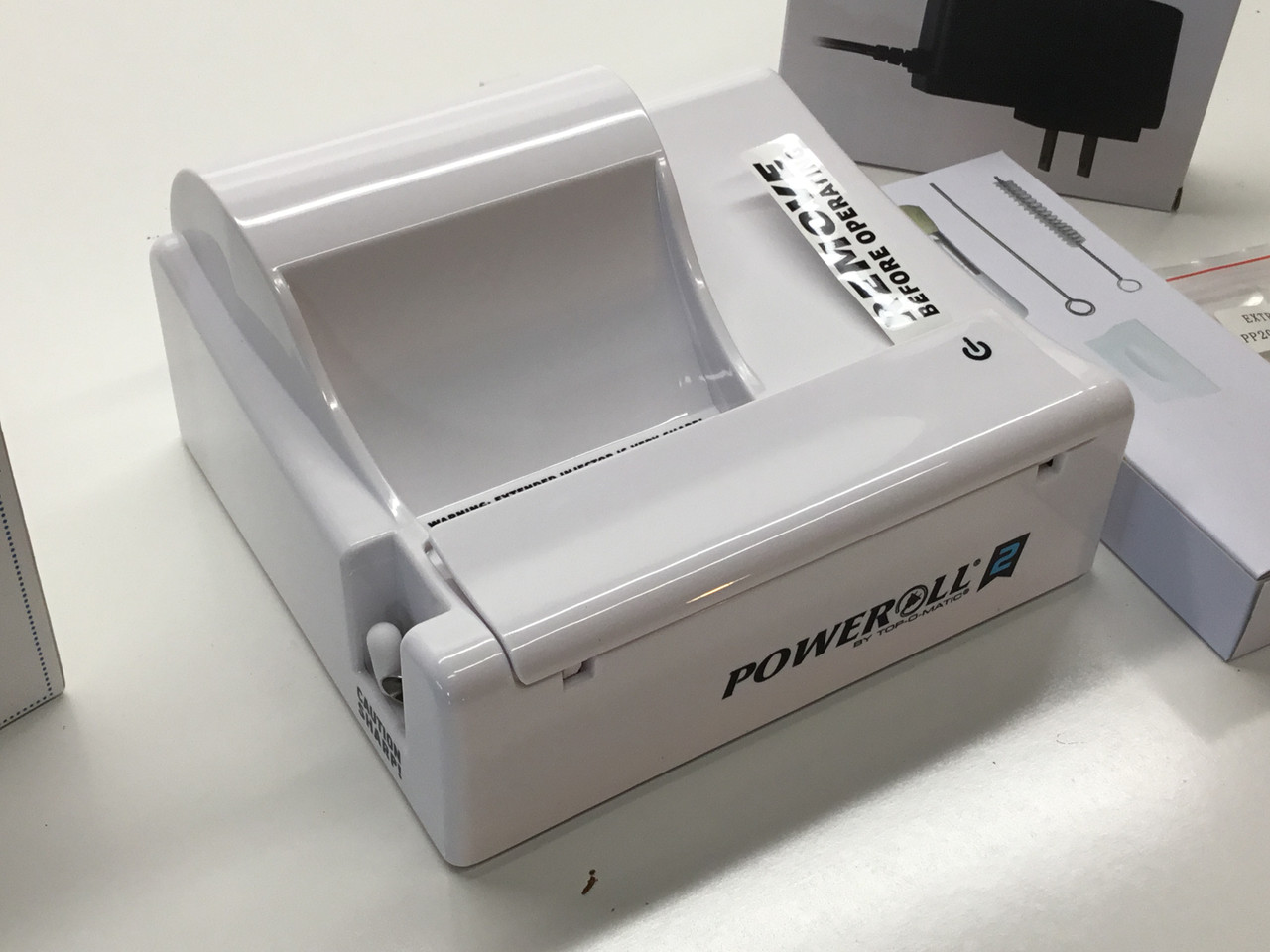

The Poweroll 2 by Top-O-Matic is a popular cigarette rolling machine. It promises convenience and efficiency.

But, like any device, it can sometimes face issues. Are you struggling with your Poweroll 2 machine? You are not alone. Many users encounter problems with their cigarette roller. These issues can be frustrating but are often simple to fix.

This guide will help you understand common problems and how to solve them. From jamming issues to roller malfunctions, we cover it all. So, if your Poweroll 2 is giving you trouble, keep reading. Let’s make your cigarette rolling smooth and hassle-free again.

Common Issues

The Poweroll 2 by Top-O-Matic is a popular electric cigarette machine. But like all machines, it can face issues. Knowing the common problems can help you fix them quickly. This section will cover the most frequent issues users face.

Machine Not Turning On

If your Poweroll 2 isn’t turning on, check the power source. Ensure the machine is plugged in properly. Verify that the outlet works by plugging in another device. If the outlet works, check the machine’s power switch. Sometimes, it may not be fully switched on. If the switch is fine, inspect the power cord for any damage. Damaged cords can prevent the machine from turning on.

If all these checks don’t work, the issue might be internal. It could be a faulty motor or electrical component. In this case, contacting the manufacturer for repair or replacement is best.

Tobacco Jam

Tobacco jams are a common problem with the Poweroll 2. First, make sure you are using the right type of tobacco. Coarse or overly moist tobacco can cause jams. If a jam occurs, turn off the machine and unplug it. Carefully remove any visible tobacco from the machine.

Use a small brush to clean the feeding tube and hopper. Regular cleaning can prevent future jams. If the jam persists, disassemble the machine as per the manual. Check for any hidden blockages and clean them out. Always ensure the machine is dry before reassembling.

Power Supply Problems

Experiencing power supply problems with your Poweroll 2 by Top-O-Matic can be frustrating. This section will guide you through simple checks and fixes. These steps can help you diagnose and solve common power supply issues.

Checking The Power Cord

The power cord is the first thing to check. Make sure it is securely connected to both the machine and the wall socket. A loose connection can prevent the machine from working.

Inspect the cord for any visible damage. Look for cuts, frays, or exposed wires. These can cause power issues. If the cord is damaged, replace it immediately.

Inspecting The Fuse

If the power cord appears fine, the next step is to inspect the fuse. The fuse protects the machine from electrical surges. Locate the fuse holder, usually near the power switch.

Remove the fuse and check if it is blown. A blown fuse often has a broken wire inside or looks blackened. If the fuse is blown, replace it with a new one of the same type and rating.

After replacing the fuse, try turning on the machine again. If it still does not power on, there may be a deeper issue. You might need professional help.

Motor Malfunctions

The Poweroll 2 by Top-O-Matic is a reliable machine. Yet, users sometimes face motor malfunctions. These issues can disrupt your rolling experience. This section will help you troubleshoot common motor problems. Follow these tips to keep your Poweroll 2 running smoothly.

Overheating Issues

Overheating can cause your Poweroll 2 to shut down. Place the machine in a well-ventilated area. Avoid using it for extended periods. Let it cool down after each use. Check for dust and debris. Clean the motor vents regularly. This ensures proper airflow and prevents overheating.

Strange Noises

Strange noises often indicate a problem. Listen for grinding or buzzing sounds. These may signal a motor issue. First, check for any obstructions. Remove any visible debris. Next, ensure all parts are secure. Loose components can cause noise. If the noise persists, contact customer service. They can provide further assistance.

Credit: www.ebay.com

Tobacco Feeding Issues

Tobacco feeding issues can be frustrating for users of the Poweroll 2 by Top-O-Matic. If the machine isn’t feeding tobacco correctly, it can lead to uneven cigarettes or jams. Understanding the common problems and their solutions can help ensure smooth operation and satisfaction.

Tobacco Consistency

The consistency of your tobacco plays a crucial role in the feeding process. Tobacco that is too moist or too dry can cause problems. Wet tobacco tends to clump together, making it hard for the machine to feed it evenly. On the other hand, overly dry tobacco can crumble, leading to uneven distribution and potential jams. Aim for a balanced moisture level for optimal performance.

Correct Loading Techniques

Proper loading techniques are essential for smooth tobacco feeding. Start by ensuring the tobacco hopper is clean and free of debris. Place the tobacco evenly in the hopper, avoiding overfilling. Use gentle, even pressure to pack the tobacco, ensuring it sits uniformly. If you apply too much force, it can compact the tobacco too tightly, causing feeding issues.

Regular maintenance and cleaning can also help prevent feeding problems. Check the machine’s components for any signs of wear or damage. Replace parts as needed to maintain efficiency. By following these steps, you can reduce tobacco feeding issues and enjoy a better cigarette-making experience.

Cigarette Tube Problems

Cigarette tube problems can be frustrating for those using the Poweroll 2 by Top-O-Matic. These issues can disrupt your cigarette-making process. This section will help you troubleshoot common tube problems.

Tube Not Filling Evenly

One common issue is the tube not filling evenly. This can result in cigarettes that burn poorly. Make sure the tobacco is evenly distributed in the chamber. If the tobacco is packed too tightly, the tube may not fill correctly. Also, check the tube for any defects. Even a small tear can cause uneven filling.

Tube Getting Stuck

Another issue is the tube getting stuck. This can happen during the filling process. Check if the tube is the right size for the machine. Using the wrong size can cause it to get stuck. Also, ensure the machine is clean. Residue can build up and cause the tube to stick. Regular cleaning can prevent this problem.

Credit: www.youtube.com

Cleaning And Maintenance

Proper cleaning and maintenance of your Poweroll 2 by Top-O-Matic is key. It ensures the machine works efficiently. It also helps in extending its lifespan. Below are some simple yet effective tips for keeping your Poweroll 2 in top condition.

Regular Cleaning Tips

Cleaning your Poweroll 2 regularly prevents tobacco buildup. Here’s how you can do it:

- Unplug the machine before cleaning.

- Use a small brush to remove loose tobacco.

- Wipe surfaces with a soft, damp cloth.

- Check for any jammed tobacco pieces.

Performing these steps weekly can keep your machine running smoothly.

Lubrication Advice

Lubrication is important for the moving parts of the Poweroll 2. Follow these simple steps:

- Identify the moving parts that need lubrication.

- Use a small amount of machine oil.

- Apply the oil to the parts with a cotton swab.

- Rotate the parts to distribute the oil evenly.

Lubricate your machine every three months. This reduces friction and prevents wear and tear.

Replacement Parts

Maintaining your Poweroll 2 by Top-O-Matic is essential for smooth operation. Replacing parts on time can extend the life of your machine. Let’s explore how to find genuine parts and replace worn components.

Finding Genuine Parts

Using genuine parts is crucial for the best performance of your Poweroll 2. Authentic parts ensure compatibility and durability. Finding genuine parts may seem challenging, but it’s easier with the right resources.

Here are some tips to help you find genuine parts:

- Visit the official Top-O-Matic website.

- Check authorized dealers and retailers.

- Look for certified logos and trademarks.

- Read customer reviews and feedback.

- Contact customer support for guidance.

Replacing Worn Components

Regular maintenance of your Poweroll 2 includes replacing worn components. This process ensures the machine functions efficiently. Follow these steps to replace common parts:

- Identify the worn part: Inspect your machine for signs of wear. Common parts include the spoon injector, nozzle, and screws.

- Gather tools: You may need a screwdriver, pliers, and replacement part.

- Disassemble the machine: Carefully remove screws and parts to access the worn component.

- Replace the worn part: Install the new part in place of the old one. Ensure it fits properly.

- Reassemble the machine: Put all parts back together. Tighten screws securely.

- Test the machine: Run the machine to ensure it works smoothly.

Replacing worn components on time keeps your Poweroll 2 running like new. Proper maintenance saves you money and extends the machine’s lifespan.

Credit: hardworkingproducts.com

Customer Support

Poweroll 2 by Top-O-Matic is a reliable machine. Yet, sometimes things go wrong. This is where customer support comes in. Knowing how to get help can save you time and stress. Let’s explore the key support areas.

Contacting Top-o-matic

If you have issues, reach out to Top-O-Matic. They have a dedicated support team. The team is ready to help you. You can contact them via phone or email. Check their website for contact details. They also have a help section. This includes FAQs and troubleshooting tips. Use these resources for quick answers. Sometimes, the solution might be simpler than you think.

Warranty Information

Top-O-Matic offers a warranty on their products. This warranty covers defects in materials and workmanship. It is important to register your product. Registration ensures your warranty is valid. Keep your purchase receipt safe. You will need it for warranty claims. The warranty lasts for a specific period. Check your user manual for details. If your machine breaks within this time, contact support. They will guide you through the warranty claim process.

Frequently Asked Questions

Why Won’t My Poweroll 2 Turn On?

Check the power cord and ensure it’s plugged in properly. Verify the outlet works.

How Do I Clean My Poweroll 2?

Unplug it first. Use a soft brush to remove tobacco residue. Wipe with a dry cloth.

Why Is My Poweroll 2 Jamming?

Check for overfilled or unevenly packed tobacco. Clean the machine regularly to prevent clogs.

Can I Use Different Tobacco Types In Poweroll 2?

Yes, but make sure the tobacco is dry and cut finely. This helps avoid jams.

How Do I Fix Unevenly Packed Cigarettes?

Ensure consistent tobacco amounts. Avoid overfilling. Clean the machine to ensure smooth operation.

Conclusion

Maintaining your Poweroll 2 by Top-O-Matic ensures smooth operation. Troubleshooting common issues can save time and frustration. Follow the steps discussed to resolve problems quickly. Regular cleaning and proper use extend the machine’s life. If problems persist, consider contacting customer support.

This guide helps you enjoy a hassle-free experience with your Poweroll 2. Thank you for reading, and happy rolling!