Struggling with your Roosa Master Injection Pump? You are not alone.

These pumps are vital for engine performance, but they can sometimes fail. Understanding the common issues and their fixes can save you time and money. Roosa Master Injection Pumps are crucial in diesel engines. They ensure proper fuel delivery and engine efficiency.

When they malfunction, it can lead to poor engine performance or complete failure. This guide will help you identify and troubleshoot common problems. You will learn simple, practical steps to get your pump working again. Fixing these issues can improve engine performance and extend its life. Ready to get started? Let’s dive into the world of Roosa Master Injection Pump troubleshooting.

Introduction To Roosa Master Injection Pump

The Roosa Master Injection Pump is a vital component in many diesel engines. It plays a crucial role in delivering fuel to the engine with precision. Understanding its function and troubleshooting issues can improve engine performance.

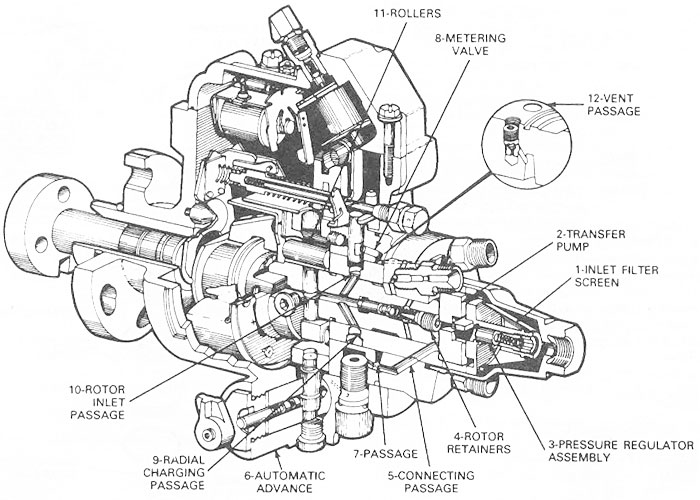

History And Development

Stanadyne Corporation developed the Roosa Master Injection Pump in the early 1950s. The pump was designed to provide a more reliable and efficient fuel injection system. Over the years, it has undergone several improvements. These advancements have made it a popular choice for diesel engines worldwide.

Importance In Diesel Engines

The Roosa Master Injection Pump is essential for diesel engine operation. It ensures accurate fuel delivery under various engine conditions. Proper functioning of this pump leads to better fuel efficiency and reduced emissions. Troubleshooting and maintaining the pump can prevent engine problems and extend its lifespan.

Common Roosa Master Injection Pump Problems

Roosa Master injection pumps are critical in diesel engines. They ensure efficient fuel delivery. However, they can face some common issues. Troubleshooting can help maintain engine performance.

Fuel Leaks

Fuel leaks are a frequent problem. They can occur at various points. Check the fuel lines first. Loose connections often cause leaks. Tighten any loose fittings. Inspect the pump housing too. Cracks or damage may lead to leaks. Replace damaged parts immediately. Look at the seals and gaskets. Worn-out seals often cause leaks. Replace them to stop the problem.

Engine Misfires

Engine misfires can be alarming. They are often due to fuel issues. Check the fuel filter first. A clogged filter restricts fuel flow. Replace the filter if needed. Inspect the fuel injectors next. Dirty or faulty injectors cause misfires. Clean or replace them as necessary. Examine the pump timing. Incorrect timing disrupts fuel delivery. Adjust the timing to the correct setting.

Roosa Master Injection Pump Pre-troubleshooting Checks

Pre-troubleshooting checks are essential for diagnosing issues with your Roosa Master Injection Pump. These checks help pinpoint problems before diving into more complex diagnostics. This section covers two critical pre-troubleshooting steps: Visual Inspection and Checking Fuel Quality.

Visual Inspection

Start by performing a thorough visual inspection of the injection pump. Look for obvious signs of wear or damage. Pay attention to the following:

- Loose or damaged connections

- Leaking fuel

- Corrosion or rust

- Cracked or broken parts

If you notice any of these issues, address them immediately. A visual inspection can often reveal simple problems that are easy to fix.

Checking Fuel Quality

The quality of the fuel is crucial for the proper functioning of your injection pump. Poor fuel quality can cause various issues. Follow these steps to check the fuel quality:

- Drain a small sample of fuel from the tank.

- Inspect the sample for contaminants such as water, dirt, or debris.

- Check the fuel’s color. It should be clear and bright.

- Smell the fuel. It should have a fresh diesel scent.

If the fuel is contaminated, replace it with fresh, clean fuel. Always use high-quality fuel from a reliable source to prevent issues.

These pre-troubleshooting checks can save you time and effort. They help you identify and address simple issues before moving on to more complex diagnostics.

Diagnosing Roosa Master Injection Pump Fuel Leaks

Fuel leaks in your Roosa Master injection pump can cause many problems. They can lead to poor engine performance and increased fuel consumption. Diagnosing fuel leaks early can save you time and money. This section will help you identify leak points and the tools needed for the job.

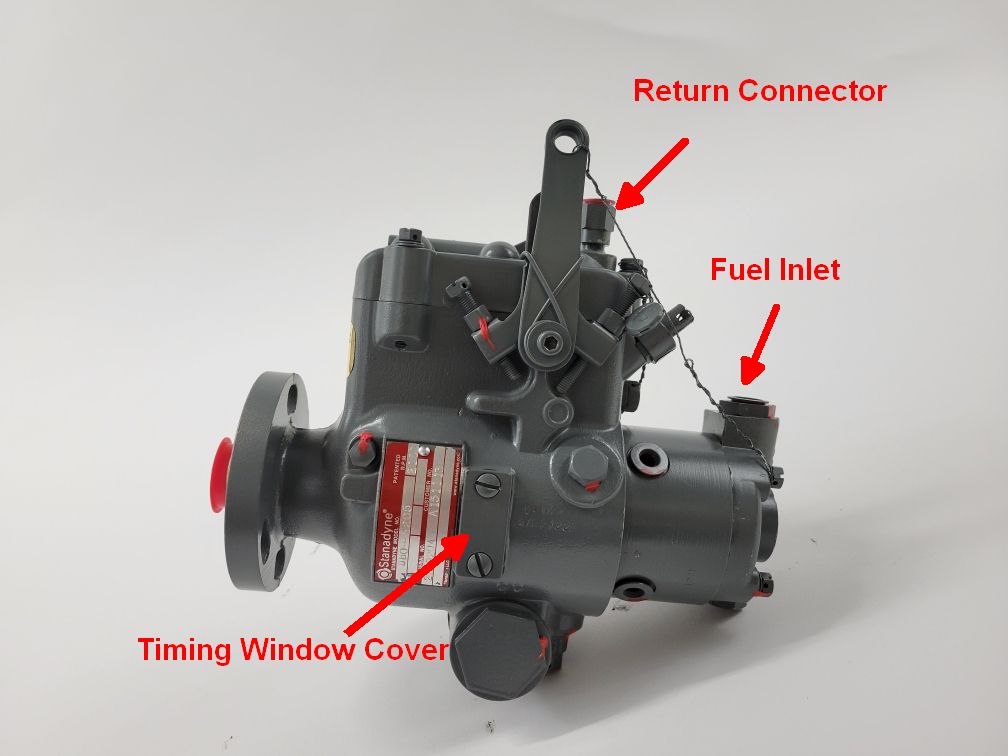

Identifying Leak Points

First, inspect the injection pump and surrounding areas. Check for wet spots or fuel stains. Common leak points include the fuel inlet and outlet connections. Seals and gaskets can also leak. Look for cracks or wear. The pump body itself can develop leaks over time. Pay attention to any unusual smells or drips.

Tools Needed

You will need a few essential tools. A flashlight helps you see in tight spaces. Use a clean rag to wipe away dirt and reveal leaks. A set of wrenches will help tighten loose connections. Have replacement seals and gaskets on hand. Fuel-resistant thread sealant can help with minor leaks.

Safety is crucial. Wear gloves to protect your hands from fuel. Work in a well-ventilated area. Keep a fire extinguisher nearby. Fuel is flammable and can be dangerous.

Roosa Master Injection Pump Engine Misfires Troubleshooting

Engine misfires can be frustrating and may cause serious damage if left unchecked. A Roosa Master Injection Pump plays a crucial role in the proper functioning of your engine. Understanding the symptoms and knowing how to troubleshoot can save time and money.

Symptoms Of Misfires

Recognizing the symptoms of engine misfires is the first step. Here are some common signs:

- Rough idling

- Poor fuel economy

- Loss of power

- Black smoke from the exhaust

- Difficulty starting the engine

Step-by-step Solutions

Follow these steps to troubleshoot and fix engine misfires:

- Check the Fuel Supply: Ensure the fuel tank is full and the fuel lines are clear.

- Inspect the Injection Pump: Look for leaks or damages. Replace any worn-out parts.

- Test the Injectors: Remove and clean the injectors. Replace if necessary.

- Check the Timing: Ensure the injection pump timing is correct. Adjust as needed.

- Examine the Glow Plugs: Glow plugs help in cold starts. Replace faulty plugs.

By following these steps, most engine misfires can be fixed. Regular maintenance of the Roosa Master Injection Pump will ensure smooth engine performance.

Maintaining Your Roosa Master Injection Pump

Maintaining your Roosa Master injection pump is crucial for optimal performance. Regular care helps extend its lifespan and ensure your engine runs smoothly. Follow these tips to keep your injection pump in top condition.

Routine Maintenance Tips

Check your fuel filters regularly. Replace them if they are dirty. Clean the exterior of the pump to prevent dirt buildup. Use a clean cloth for wiping. Inspect the fuel lines for leaks or cracks. Tighten or replace them if needed.

Ensure the pump is properly lubricated. Use the recommended oil. Monitor the engine’s performance. Any drop could indicate pump issues. Schedule a professional inspection annually. This helps catch problems early.

Recommended Products

Use high-quality diesel fuel additives. They help keep the pump clean. Choose reputable brands for fuel filters. This ensures durability and efficiency. Consider synthetic lubricants. They offer better protection and longer intervals between changes.

Opt for OEM parts when replacements are needed. They fit better and last longer. Keep a spare set of fuel filters handy. Quick replacements reduce downtime and protect the pump.

Expert Tips For Longevity

The Roosa Master Injection Pump is a crucial component of many diesel engines. Ensuring its longevity is vital for the engine’s performance and efficiency. Follow these expert tips to help extend the life of your injection pump.

Avoiding Common Mistakes

Many users make mistakes that can damage the Roosa Master Injection Pump. Avoiding these can save time and money.

- Incorrect Fuel: Always use the recommended fuel type. Using the wrong fuel can clog the pump.

- Poor Maintenance: Regularly check and replace filters. Dirt and debris can cause wear and tear.

- Ignoring Leaks: Address any fuel leaks immediately. Leaks can lead to pressure drops and inefficient fuel delivery.

Best Practices

Adopting best practices ensures the Roosa Master Injection Pump runs smoothly.

- Regular Inspections: Schedule routine checks. Look for signs of wear or damage.

- Clean Fuel System: Keep the fuel system clean. A clean system prevents contaminants from entering the pump.

- Proper Storage: Store the pump in a dry place. Moisture can cause rust and corrosion.

| Task | Frequency |

|---|---|

| Check Filters | Monthly |

| Inspect for Leaks | Every 3 months |

| Fuel System Cleaning | Every 6 months |

Following these tips can help maintain the Roosa Master Injection Pump. This ensures your engine runs efficiently and lasts longer.

When To Seek Professional Help

Experiencing persistent issues with your Roosa Master injection pump? Seek professional help if troubleshooting steps do not resolve the problem. Timely intervention can prevent further damage and ensure optimal performance.

When dealing with the Roosa Master Injection Pump, there are times when DIY troubleshooting is not enough. Some issues require the expertise of a professional mechanic. Knowing when to seek professional help can save you time and money.

Signs Of Severe Issues

Certain signs indicate severe issues with your Roosa Master Injection Pump. Here are the critical signs to watch for:

- Unusual noises: Grinding or knocking sounds.

- Engine stalling: Frequent stalling even after minor repairs.

- Excessive smoke: Black or white smoke from the exhaust.

- Fuel leaks: Visible leaks around the pump.

- Performance drop: Significant loss in power and efficiency.

If you notice any of these signs, it is time to get professional help.

Choosing A Reliable Mechanic

Selecting a trustworthy mechanic is crucial. Here are some tips:

- Check reviews: Look for online reviews and ratings.

- Certifications: Ensure the mechanic has the necessary certifications.

- Experience: Choose a mechanic with experience in diesel engines.

- Ask for referrals: Get recommendations from friends and family.

- Compare prices: Get quotes from multiple mechanics to find a fair price.

A reliable mechanic will diagnose and repair your Roosa Master Injection Pump effectively.

| Criteria | Importance |

|---|---|

| Reviews and Ratings | High |

| Certifications | High |

| Experience | Medium |

| Referrals | Medium |

| Price Comparison | Low |

Frequently Asked Questions

What Are Common Problems With Roosa Master Injection Pump?

Clogged filters, worn-out seals, and air leaks are common issues.

How Do You Diagnose A Failing Roosa Master Pump?

Look for hard starting, engine misfire, and fuel leaks.

Why Is My Roosa Master Injection Pump Leaking?

It may leak due to worn seals or damaged gaskets.

How Often Should I Service My Roosa Master Injection Pump?

Service it every 600 to 1,000 hours of operation.

What Tools Are Needed For Roosa Master Pump Troubleshooting?

Basic tools include wrenches, screwdrivers, and a fuel pressure gauge.

Conclusion

Troubleshooting a Roosa Master Injection Pump can seem daunting. But with basic knowledge, it becomes manageable. Remember to check for common issues like fuel leaks or air locks. Regular maintenance helps prevent major problems. Always follow safety guidelines during repairs.

This ensures both effective and safe troubleshooting. Feel confident in your ability to address these issues. A well-maintained pump leads to better engine performance. Happy troubleshooting!

My tractor has set for a year or more and now I get no fuel to the injectors. What do you think?

It sounds like your tractor has been sitting for quite some time, and now you’re having trouble getting fuel to the injectors. There are a few possible causes for this issue:

I recommend checking the fuel system thoroughly—starting with the fuel filter and fuel lines—and then moving on to the injection pump if needed. If you’re not sure, it might be best to seek the help of a professional mechanic to avoid causing any further damage.

Good luck, and let me know if you need more help!