Simpson pressure washers are essential for many cleaning tasks. Yet, like any tool, they can face issues.

Knowing how to troubleshoot common problems can save you time and effort. Simpson pressure washers are reliable, but they can develop issues. From low water pressure to engine problems, these hiccups can interrupt your work. Understanding basic troubleshooting can help you fix these issues quickly.

Whether you’re dealing with a clogged nozzle or a machine that won’t start, this guide will help. We’ll explore common problems and offer practical solutions. By the end, you’ll be more confident in handling your pressure washer. Let’s dive into the world of Simpson pressure washer troubleshooting and keep your machine running smoothly.

Common Issues

Simpson pressure washers are reliable tools, but they can have problems. Understanding these issues can save time and money. Below are some common issues and their solutions.

Low Pressure

Low pressure is a frequent problem with pressure washers. Here are some reasons and fixes:

- Clogged Nozzle: A blocked nozzle can cause low pressure. Clean it with a needle or nozzle cleaner.

- Water Supply: Ensure you have an adequate water supply. The hose should be fully open and kink-free.

- Inlet Filter: Check and clean the inlet filter. Dirt can restrict water flow.

- Pump: Inspect the pump for leaks. Replace worn-out seals and valves.

| Issue | Solution |

|---|---|

| Clogged Nozzle | Clean with needle |

| Inadequate Water Supply | Check hose, ensure it is fully open |

| Dirty Inlet Filter | Clean filter |

| Pump Leaks | Inspect and replace seals |

Engine Won’t Start

An engine that won’t start is frustrating. Here are some tips:

- Check Fuel: Ensure there is enough fuel in the tank. Stale fuel can also be an issue.

- Spark Plug: Inspect the spark plug. Clean or replace if it is dirty or worn.

- Air Filter: A clogged air filter can prevent starting. Clean or replace it.

- Oil Level: Ensure the oil level is correct. Some engines have a low oil shut-off feature.

By following these steps, you can resolve many common issues with Simpson pressure washers. Regular maintenance can prevent many of these problems.

Basic Maintenance

Basic maintenance is essential to keep your Simpson Pressure Washer running smoothly. Regular upkeep ensures longevity and peak performance. Neglecting maintenance can lead to costly repairs. Simple tasks can prevent common issues and extend the life of your equipment. Focus on cleaning nozzles and checking oil levels for efficient operation.

Cleaning Nozzles

Clogged nozzles can reduce pressure and cleaning power. Regular cleaning is necessary. Start by turning off the pressure washer. Remove the nozzle from the spray wand. Use a nozzle cleaning tool or a small pin to clear any debris. Rinse the nozzle with water. Reattach the nozzle and test the spray. Repeat this process weekly or after heavy use.

Checking Oil Levels

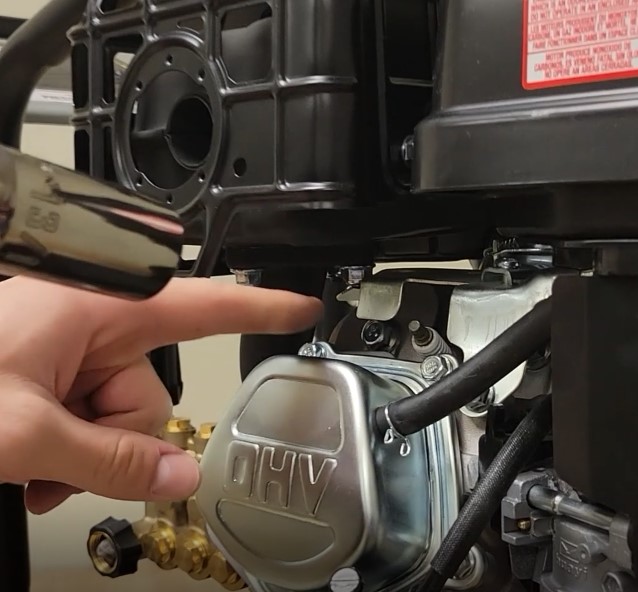

Oil is vital for the engine’s health. Check oil levels before each use. Locate the oil fill cap on the engine. Remove the dipstick and wipe it clean. Insert the dipstick back into the oil fill and remove it again. Ensure the oil level is between the markers. Add oil if needed, using the recommended type. Do not overfill. Replace the dipstick and secure the oil fill cap. Regular oil checks prevent engine damage and maintain performance.

Water Supply Problems

Water supply problems can affect the performance of your Simpson pressure washer. Ensuring a steady water flow is crucial. Let’s discuss common issues related to water supply and how to fix them.

Insufficient Water Flow

Insufficient water flow is a common problem. First, check your water source. Make sure it provides enough water. Your garden hose should deliver at least 2.5 gallons per minute.

Inspect the hose for any leaks. Replace any damaged hoses. Verify that the water tap is fully open. Sometimes, sediment buildup in the hose can restrict water flow. Flush the hose to clear any blockages.

Kinked Hoses

Kinked hoses are another common issue. A kink in the hose can reduce water flow. Inspect your hose for any bends or twists. Straighten the hose to ensure smooth water flow.

Use a hose reel to store your hose properly. This can prevent kinks from forming. If your hose is old and prone to kinking, consider replacing it.

Fuel Troubles

Experiencing fuel troubles with your Simpson pressure washer can be frustrating. Fuel issues are common, but they are fixable. Understanding the root cause can save you time and effort. In this section, we will explore two main fuel-related problems. These are stale fuel and fuel filter blockages. By addressing these issues, you can ensure your pressure washer runs smoothly.

Stale Fuel

Stale fuel can cause your Simpson pressure washer to malfunction. Fuel that sits for too long loses its effectiveness. This can lead to engine problems. Always use fresh fuel for your pressure washer. If you suspect stale fuel, drain the old fuel. Then, refill with fresh gasoline. This simple step can often resolve the issue.

Fuel Filter Blockages

A blocked fuel filter can hinder your pressure washer’s performance. Dirt and debris can clog the filter over time. This prevents fuel from reaching the engine. Regularly check and clean the fuel filter. Replace it if necessary. Keeping the fuel filter clean ensures a steady fuel flow. This helps maintain the efficiency of your pressure washer.

Pump Issues

Experiencing issues with your Simpson pressure washer pump can be frustrating. The pump is crucial for the machine’s performance. Addressing common problems quickly is key to maintaining efficiency. This section will cover two main pump issues: leaking and noisy pumps.

Leaking Pump

A leaking pump can reduce the washer’s efficiency. Check all connections and seals. Loose fittings often cause leaks. Tighten them carefully. Inspect the seals for wear and tear. Replace damaged seals to stop leaks. Sometimes, cracks in the pump casing cause leaks. If you find a crack, consider replacing the pump. Regular maintenance can prevent future leaks.

Noisy Pump

A noisy pump usually indicates a problem. First, check the water supply. Insufficient water can cause noise. Ensure the hose is not kinked. Clean the inlet filter to improve water flow. Another cause can be air trapped in the pump. Run the washer with the trigger pressed to release air. If the noise persists, inspect the pump for wear. Worn parts often cause noise. Replacing these parts can solve the issue. Regular maintenance helps keep the pump quiet.

Electrical Concerns

Dealing with electrical concerns in your Simpson pressure washer can be frustrating. These issues often disrupt your cleaning tasks and can be tricky to diagnose. This section addresses common electrical problems, offering simple troubleshooting tips.

Faulty Power Cord

A faulty power cord is a common issue with pressure washers. The power cord supplies electricity to the machine. If damaged, it can cause the washer to stop working.

- Check the cord for any visible damage.

- Ensure that the plug is not bent or broken.

- If the cord is damaged, replace it immediately.

Using a damaged power cord can be hazardous. Inspect your power cord regularly to ensure safety and functionality.

Tripped Circuit Breaker

A tripped circuit breaker can stop your pressure washer from working. This usually happens when the electrical circuit is overloaded.

- Check your home’s circuit breaker panel.

- Look for any tripped switches.

- If a breaker is tripped, reset it by flipping the switch back on.

Make sure the pressure washer is the only device on that circuit. Overloading the circuit can cause repeated trips.

Both faulty power cords and tripped circuit breakers are common electrical issues. Regular maintenance and checks can prevent these problems. Follow the steps above for a smoother operation of your Simpson pressure washer.

Overheating

Overheating is a common issue with Simpson pressure washers. It can cause the machine to shut down unexpectedly. This can interrupt your work and lead to frustration. Knowing how to troubleshoot overheating can save time and effort.

Cooling System Check

Check the cooling system first. Ensure the cooling fan is working properly. A blocked or damaged fan can cause overheating. Clean any debris around the fan. Look for signs of wear or damage. Replace the fan if necessary.

Proper Ventilation

Ventilation plays a crucial role in keeping the pressure washer cool. Make sure the air vents are not blocked. Clear any obstructions that might prevent airflow. Ensure the unit is placed in a well-ventilated area. Avoid using the pressure washer in confined spaces.

Storage Tips

Proper storage of your Simpson pressure washer ensures its longevity and optimal performance. Whether you’re preparing for winter or storing it for a short period, following specific steps can prevent damage and costly repairs. Below are essential tips for winterizing and safely storing your pressure washer.

Winterizing The Washer

Winter can be harsh on your Simpson pressure washer. To prevent freezing and internal damage, follow these steps:

- Drain the Water: Run the washer until all water is expelled.

- Add Antifreeze: Use a pump saver to circulate antifreeze through the system.

- Disconnect Hoses: Remove all hoses and attachments.

- Store Indoors: Keep the washer in a warm, dry place.

These steps will protect the internal components from freezing temperatures.

Safe Storage Practices

Storing your pressure washer properly involves more than just placing it in the garage. Follow these practices to maintain its condition:

- Clean the Washer: Remove dirt and debris from all surfaces.

- Check for Leaks: Inspect hoses and connections for any leaks.

- Oil the Pump: Lubricate the pump to prevent rust and corrosion.

- Secure the Cords: Wrap the power cord and secure it with ties.

- Cover the Washer: Use a waterproof cover to protect against dust and moisture.

Following these practices will keep your pressure washer in top shape.

Frequently Asked Questions

Why Won’t My Simpson Pressure Washer Start?

Check the fuel level, spark plug, and oil. Ensure the fuel valve is open.

Why Does My Simpson Pressure Washer Lose Pressure?

Check for clogs in the nozzle, unloader valve, and water inlet screen. Clean if necessary.

Why Is My Simpson Pressure Washer Leaking Water?

Inspect hoses and connections for damage or looseness. Tighten connections or replace damaged parts.

How Do I Clean The Simpson Pressure Washer Nozzle?

Remove the nozzle, use a needle to clear debris, and rinse with water. Reattach securely.

Why Does My Simpson Pressure Washer Make Loud Noises?

Check for loose parts, worn bearings, or debris in the pump. Tighten, lubricate, or clean as needed.

Conclusion

Troubleshooting your Simpson pressure washer can be simple with these tips. Regular maintenance prevents many issues. Always check connections and clean filters. Ensure adequate water supply. Follow the user manual for specific guidance. If problems persist, contact professional support. Proper care extends the life of your pressure washer.

Enjoy a powerful and efficient cleaning experience. Keep your equipment in top shape. Happy cleaning!

Can’t remove hoses because of high pressure in the lines.

Starts fine but nothing happens when I pull trigger.

Pressure remains in the line and I can’t remove the tip or any connections

Thanks for the details! Your hose/tip is stuck because pressure is trapped in the system. Try these safe, quick steps before removing any connections.

These steps align with Simpson Pressure Washer Troubleshooting best practices: safely depressurize first, then clear flow restrictions and check the unloader/gun.

Safety: Wear gloves and eye protection. Don’t force couplers under pressure; always bleed lines first.

Let me know if this helps—if pressure still won’t release or the trigger does nothing, I can share a step-by-step unloader and gun check next.