Experiencing issues with your S&S carburetor? Don’t worry, you’re not alone.

Many motorcycle enthusiasts face similar problems. S&S carburetors are known for their reliability and performance. Yet, like any mechanical part, they can develop issues over time. Whether your bike is sputtering, losing power, or just not running smoothly, understanding and troubleshooting your S&S carburetor can save you time and money.

This guide will help you identify common problems and offer practical solutions. With a bit of patience and some basic tools, you can get your carburetor back to peak performance. Ready to dive in and keep your ride smooth? Let’s get started!

Common S&S Carburetor Problems

Carburetors play a crucial role in your engine’s performance. They mix air and fuel for internal combustion. Without a properly working carburetor, your engine may face various issues. Understanding common carburetor problems can help you keep your engine running smoothly.

Engine Misfires

Engine misfires can indicate carburetor trouble. If your engine misfires, it might be due to a lean or rich fuel mixture. A lean mixture has too much air and not enough fuel. A rich mixture has too much fuel and not enough air. Both conditions can cause the engine to misfire. Check for clogged jets or air leaks in the carburetor. Cleaning the carburetor jets can often solve the problem.

Poor Fuel Efficiency

Poor fuel efficiency is another sign of carburetor issues. If your vehicle consumes more fuel than usual, it could be a carburetor problem. A rich fuel mixture wastes fuel and reduces efficiency. Check for a stuck choke or a float level that is too high. Adjusting the float level or fixing the choke can improve fuel efficiency. Regular maintenance helps in avoiding these problems.

S&S Carburetor Diagnosing Problems

Diagnosing issues with your S&S Carburetor can be challenging. Recognizing symptoms early helps prevent major problems. Proper diagnosis saves time and money. Below are key steps for identifying and solving carburetor issues.

Identifying Symptoms

Common symptoms include rough idling, backfiring, and poor fuel economy. Notice if the engine hesitates or stalls. Difficulty starting is another sign. Pay attention to unusual sounds or smells. These can point to underlying problems.

Using Diagnostic Tools

Using a vacuum gauge helps check the carburetor’s performance. A multimeter can test electrical components. A fuel pressure gauge ensures the fuel pump is working. A carburetor cleaner can help identify leaks. Proper tools make diagnostics easier and more accurate.

How To Clean S&S Carburetor

Keeping your S&S carburetor clean ensures smooth engine performance. It helps maintain fuel efficiency and prevents engine problems. Cleaning the carburetor is a task you can handle with the right tools and steps.

Tools Needed

Before you start, gather the necessary tools. You will need a set of screwdrivers, carburetor cleaner spray, a small brush, a wrench set, and a clean cloth. These tools will help you disassemble and clean the carburetor parts.

Step-by-step Guide

First, remove the carburetor from the engine. Use a wrench to disconnect any attached parts. Be gentle to avoid damaging any components.

Next, disassemble the carburetor. Remove the float bowl and other removable parts. Keep track of each part and where it belongs.

Spray carburetor cleaner on all parts. Use a small brush to scrub away dirt and deposits. Pay special attention to small passages and jets.

Rinse all parts with clean water and dry them with a cloth. Make sure all parts are completely dry before reassembling.

Reassemble the carburetor. Reattach all parts in the correct order. Double-check to ensure everything is secure.

Finally, reinstall the carburetor on the engine. Reconnect any parts you removed. Start the engine to ensure it runs smoothly.

Regular cleaning of your S&S carburetor will extend its life. It will also keep your engine running efficiently. Follow these steps to keep your carburetor in top shape.

Adjusting Air-fuel Mixture

Adjusting the air-fuel mixture in your S&S carburetor is crucial. It ensures your engine runs smoothly and efficiently. An improper air-fuel ratio can lead to various issues. These include rough idling, poor performance, and even engine damage. Understanding how to adjust this mixture can help you maintain your engine’s health.

Optimal Settings

Finding the optimal settings is key. Start with the manufacturer’s recommended settings. These are usually a good baseline. Every engine is different, so adjustments might be necessary. Keep in mind, the ideal air-fuel ratio is about 14.7:1. This means 14.7 parts air to 1 part fuel.

For performance, slightly richer mixtures are often better. This means more fuel compared to air. Slight adjustments can make a big difference. Always adjust in small increments. Test your engine after each change. Listen and feel for improvements.

Adjustment Techniques

Begin by locating the air-fuel mixture screw. It’s usually near the carburetor base. Turn the screw clockwise to lean the mixture. This reduces the fuel amount. Turn it counterclockwise to richen the mixture. This increases the fuel amount.

Warm up your engine first. Adjust the screw slowly. Listen to the engine’s response. If the engine stumbles, it’s too lean. If it bogs down, it’s too rich. Aim for a smooth and steady idle. Make small adjustments and test. Patience is key.

Check your spark plugs too. They can tell you a lot about your mixture. A light tan color indicates a good mix. Black, sooty plugs mean it’s too rich. White, blistered plugs mean it’s too lean. Adjust accordingly.

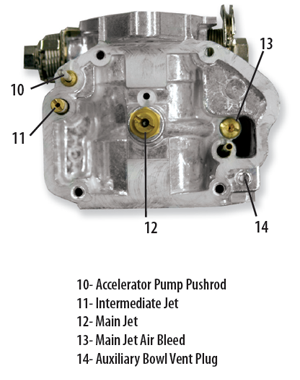

Inspecting S&S Carburetor Parts

The carburetor is a critical component of your engine. If your engine is having trouble, inspecting the carburetor parts is a good place to start. Ensuring each part is in good condition can make a significant difference. Here, we will discuss inspecting the throttle valve and the float chamber.

Throttle Valve

The throttle valve controls the amount of air entering the engine. If it is dirty or damaged, the engine may not perform well. Start by removing the carburetor from the engine. Then, locate the throttle valve. Inspect it closely for any signs of wear or damage. Clean it with a carburetor cleaner. Make sure it moves smoothly when you operate it.

Float Chamber

The float chamber regulates the fuel level inside the carburetor. If it is not working properly, the engine might flood or run lean. To inspect the float chamber, first, remove the carburetor bowl. Check the float for any signs of damage or wear. Ensure it moves freely and is not stuck. Verify the float height is within the manufacturer’s specifications. Adjust if necessary.

Replacing Worn Components

Replacing worn components in your S&S carburetor can improve performance. This process involves inspecting and changing various parts. Each component plays a vital role in the carburetor’s function. Here, we will discuss two key components: gaskets and seals, and jets and needles.

Gaskets And Seals

Gaskets and seals prevent air and fuel leaks. Over time, they can wear out. Worn gaskets and seals affect the carburetor’s efficiency. Inspect them regularly for cracks or damage. Replace any that show signs of wear. Use high-quality materials for better performance. Proper sealing ensures the carburetor operates smoothly.

Jets And Needles

Jets and needles control the fuel flow. They wear out with regular use. Worn jets and needles cause poor fuel mixture. This affects engine performance. Check them for wear and tear. Replace them if they are damaged. Correct fuel flow improves engine efficiency. Always use the recommended size for your carburetor.

Preventive Maintenance

Preventive maintenance is vital for your S&S carburetor. Regular checks keep it running smoothly. This helps avoid sudden breakdowns and costly repairs. Let’s explore some essential preventive maintenance steps.

Regular Inspections

Regular inspections are crucial. Check your carburetor weekly. Look for dirt and grime buildup. Clean it using a soft brush. Inspect the fuel lines for cracks or leaks. Tighten any loose connections.

Here’s a simple checklist:

- Inspect fuel lines

- Clean air filters

- Check for leaks

- Tighten loose connections

- Ensure proper fuel flow

Keeping a routine inspection schedule prevents major issues. It also ensures optimal performance.

Fuel Additives

Fuel additives play a key role in carburetor maintenance. They help keep the fuel clean. They also prevent buildup in the carburetor.

Use high-quality fuel additives. Add them to your fuel tank as per instructions. This helps dissolve deposits. It also ensures a smoother fuel flow.

Some benefits of fuel additives include:

| Benefit | Description |

|---|---|

| Cleaner Fuel | Removes impurities from the fuel |

| Prevent Buildup | Reduces deposits in the carburetor |

| Enhanced Performance | Ensures smooth fuel flow |

Using fuel additives regularly keeps your carburetor in top condition.

Experts S&S Carburetor Troubleshooting Guide

Having trouble with your S&S carburetor? You are not alone. Many motorcycle enthusiasts face similar issues. Here are some expert tips to help you troubleshoot and maintain your carburetor.

Prolonging Carburetor Life

Regular cleaning is crucial. Dirt and debris can clog the jets. Clean the carburetor every few months. Use a carburetor cleaner spray. This will help remove any buildup.

Check fuel quality. Bad fuel can cause problems. Use high-quality fuel to prevent damage. This will keep your carburetor running smoothly.

Enhancing Performance

Adjust the air-fuel mixture. A well-tuned mixture improves performance. Use the adjustment screw to find the right balance. This will ensure optimal engine power.

Inspect the throttle cable. A loose cable can affect performance. Tighten or replace the cable if needed. This will help maintain consistent throttle response.

Replace worn-out parts. Old parts can reduce efficiency. Check for wear and tear regularly. Replacing them on time will boost your carburetor’s performance.

Frequently Asked Questions

Why Is My S&s Carburetor Not Starting?

Your carburetor might be clogged or have a fuel delivery issue. Check the fuel lines and clean the carburetor.

How Do I Adjust My S&s Carburetor?

Turn the idle mixture screw and idle speed screw. Adjust until the engine runs smoothly.

What Causes S&s Carburetor Backfiring?

Backfiring can be caused by a lean fuel mixture or an air leak. Check for air leaks and adjust the mixture.

Why Is My S&s Carburetor Flooding?

Flooding is often due to a stuck float or needle valve. Inspect and clean the float and needle valve.

How Can I Clean My S&s Carburetor?

Disassemble the carburetor and use a carburetor cleaner. Make sure to clean all jets and passages.

Conclusion

Regular maintenance keeps your S&S carburetor running smoothly. Address issues quickly to avoid bigger problems. Use the tips in this guide to troubleshoot common problems. This ensures better engine performance and longevity. Remember, a well-maintained carburetor makes your rides more enjoyable.

Stay proactive, and your bike will thank you! Happy riding!