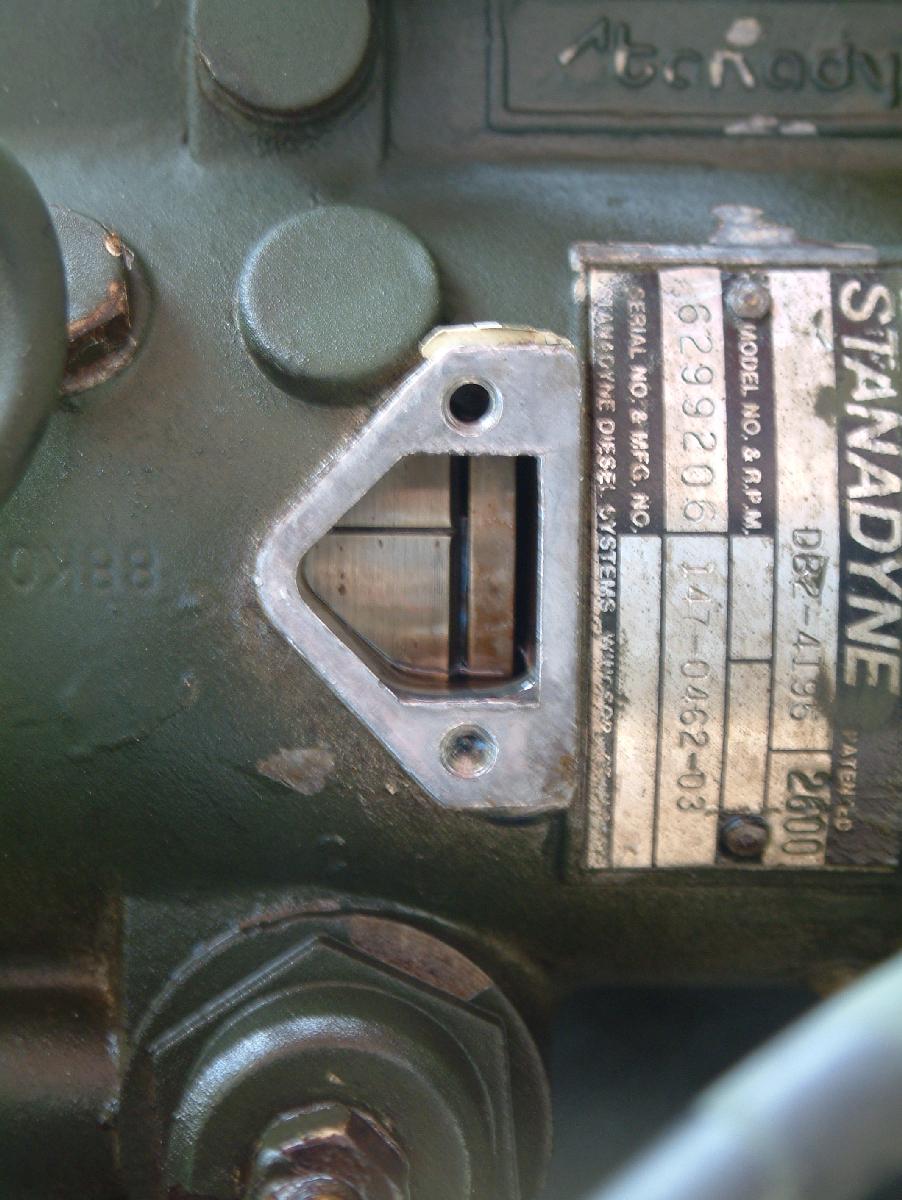

Stanadyne injection pumps are crucial for diesel engines. They ensure fuel is delivered efficiently.

Understanding how to troubleshoot these pumps can save you time and money. Diesel engines rely on the precise function of the Stanadyne injection pump. When issues arise, it can lead to poor engine performance or even failure. Knowing how to identify and fix common problems can extend the life of your pump and improve your engine’s efficiency.

In this guide, we will explore key troubleshooting steps. This knowledge can help you diagnose issues quickly and accurately. Whether you are a mechanic or a DIY enthusiast, understanding Stanadyne injection pump troubleshooting is essential. Let’s dive into the details and keep your diesel engine running smoothly.

Identifying Problems

Identifying problems with your Stanadyne injection pump can save time and money. Knowing the symptoms and using the right diagnostic tools is essential. This section will help you understand the common signs of malfunction and how to diagnose them.

Symptoms Of Malfunction

Common symptoms indicate a problem with the Stanadyne injection pump. One symptom is hard starting or failure to start. Another symptom is rough idling or engine misfiring. You might also notice poor fuel economy or black smoke from the exhaust. Listen for unusual noises from the pump. Pay attention to these signs to catch problems early.

Diagnostic Tools

Using the right diagnostic tools is crucial for troubleshooting. A fuel pressure gauge can help measure fuel pressure. A multimeter can check electrical connections and components. A scan tool can read error codes from the engine control unit. These tools make it easier to pinpoint issues. Keep these tools handy for effective diagnostics.

Fuel Delivery Issues

One common problem with the Stanadyne injection pump is fuel delivery issues. These issues can disrupt the performance of your engine and affect fuel efficiency. Let’s dive into two specific problems that often cause fuel delivery issues: clogged filters and air in the fuel system.

Clogged Filters

Clogged filters can restrict fuel flow, causing poor engine performance. Regularly inspect and replace fuel filters to prevent this. A dirty filter can lead to reduced fuel pressure and injector malfunction.

- Check the fuel filter for debris or dirt.

- Replace the filter if it looks dirty or clogged.

- Ensure proper installation of the new filter.

Ignoring clogged filters can lead to more significant engine issues. Keep an eye on the fuel filter condition to maintain optimal engine performance.

Air In Fuel System

Air in the fuel system can cause starting issues and engine misfires. Bleeding the system to remove air pockets is essential. Air can enter the system through loose fittings or leaks.

- Check for loose fuel lines or fittings.

- Tighten any loose connections to prevent air entry.

- Bleed the fuel system to remove trapped air.

Air in the fuel system can also lead to uneven fuel delivery. Regular maintenance and inspection can help avoid these problems.

| Issue | Solution |

|---|---|

| Clogged Filters | Inspect and replace fuel filters regularly. |

| Air in Fuel System | Check for leaks and bleed the system. |

Taking care of these fuel delivery issues can help your Stanadyne injection pump perform better. Regular maintenance and inspections are key to avoiding these common problems.

Mechanical Failures

Mechanical failures in a Stanadyne injection pump can lead to serious engine problems. Understanding these issues can help you troubleshoot and fix them. This section covers common mechanical failures like worn components and pump timing problems.

Worn Components

Worn components in the Stanadyne injection pump can cause performance issues. Over time, parts like the plungers, delivery valves, and cam plates wear out. Symptoms include poor fuel delivery, reduced engine power, and increased fuel consumption.

To identify worn components, look for these signs:

- Engine misfires

- Starting difficulties

- Unusual noises from the pump

Regular maintenance can extend the life of these components. Check and replace worn parts periodically. A detailed inspection can reveal hidden issues. Use a micrometer to measure wear and tear.

Pump Timing Problems

Pump timing problems can seriously affect engine performance. Incorrect timing causes poor combustion, leading to power loss and increased emissions. Proper timing ensures the pump delivers fuel at the right moment.

To diagnose timing problems, follow these steps:

- Check the timing marks on the pump and engine.

- Use a timing light to verify the pump’s timing.

- Adjust the pump if the timing is off.

A common issue is a worn timing gear or chain. This can slip and disrupt the timing. Regular inspections can help identify and fix timing problems early.

Important: Always consult the manufacturer’s manual for specific timing instructions. Each engine model may have different timing requirements.

Credit: www.youtube.com

Electrical Problems

Electrical problems in Stanadyne injection pumps can cause significant issues. Understanding and troubleshooting these problems can help maintain your pump’s efficiency. Below are common electrical problems you might encounter.

Faulty Wiring

Faulty wiring can disrupt the electrical flow. Check for broken or frayed wires. Look for signs of corrosion on connectors. Ensure all connections are tight and secure. Loose connections can lead to intermittent problems. Use a multimeter to test for continuity in wires. This helps identify broken wires.

Sensor Malfunctions

Sensor malfunctions can cause incorrect readings. Check the sensors for visible damage. Dirt and debris can interfere with sensor function. Clean the sensors regularly. Use a diagnostic tool to check sensor output. Replace any faulty sensors to ensure accurate readings.

Maintenance Tips

Maintaining your Stanadyne injection pump can improve its lifespan and performance. Regular care can prevent major issues and save costs in the long run. Below are some essential maintenance tips to help keep your injection pump in top shape.

Regular Inspections

Conducting regular inspections is crucial for identifying potential problems early. Check for leaks, wear, and tear. Look at the seals and gaskets for any signs of damage. Regularly inspect the fuel lines for cracks or kinks. A simple visual check can reveal many issues that might become serious over time.

| Inspection Area | What to Check |

|---|---|

| Seals and Gaskets | Look for wear or damage. |

| Fuel Lines | Check for cracks or bends. |

| Overall Condition | Inspect for leaks and general wear. |

Proper Lubrication

Proper lubrication is vital for smooth operation. Use the recommended type of lubricant for your Stanadyne injection pump. Check the owner’s manual for specific guidelines. Over-lubrication can cause problems, so follow the instructions carefully. Ensure all moving parts are adequately lubricated to reduce friction and wear.

- Use the recommended lubricant.

- Follow the guidelines in the owner’s manual.

- Lubricate all moving parts to reduce wear.

With proper lubrication, your pump will run smoothly and last longer. Neglecting this simple task can lead to costly repairs down the line.

Credit: www.youtube.com

Diy Fixes

DIY fixes for Stanadyne injection pumps can save you time and money. Many common issues can be resolved without professional help. Understanding how to perform simple repairs and knowing which tools you need can make the process easier.

Simple Repairs

Many Stanadyne injection pump issues stem from minor problems. Often, you can fix these with basic knowledge and tools. Common issues include air leaks, clogged filters, and stuck plungers. Addressing these problems can restore your pump’s performance.

First, check for air leaks in the fuel lines. Tighten any loose connections. Replace damaged hoses. Next, inspect the fuel filter. A clogged filter can restrict fuel flow. Clean or replace the filter to ensure proper fuel delivery. Finally, check the plunger. A stuck plunger can prevent fuel injection. Clean and lubricate the plunger to ensure smooth operation.

Tools Needed

Having the right tools makes DIY repairs simpler. Basic tools for Stanadyne injection pump troubleshooting include wrenches, screwdrivers, and pliers. A fuel pressure gauge can help diagnose fuel delivery issues. A clean workspace is also essential. Keep your tools organized and within reach for quick access.

Wrenches and screwdrivers are needed for tightening and loosening connections. Pliers help with removing and replacing hoses. A fuel pressure gauge can identify low fuel pressure problems. Clean rags and a parts cleaner can help maintain a tidy workspace. Always wear safety gloves and goggles to protect yourself.

When To Seek Professional Help

Troubleshooting a Stanadyne injection pump can be tricky. Not every problem is easy to fix. Sometimes, you need expert help. Knowing when to seek professional assistance can save you time and money. Here are some situations when it’s best to call in the pros.

Complex Issues

Some problems with a Stanadyne injection pump are just too complex. These issues often need special tools and knowledge. Here are a few signs of complex issues:

- Engine won’t start even after basic checks

- Unusual noises from the injection pump

- Fuel leaks that you can’t locate

- Repeated stalling or misfiring

If you notice any of these signs, it’s time to seek professional help. A specialist can diagnose and fix complex problems quickly.

Choosing A Specialist

Not all mechanics are experts in Stanadyne injection pumps. Choose a specialist for the best results. Here are some tips for choosing the right expert:

- Look for certified diesel technicians

- Check reviews and testimonials

- Ask about their experience with Stanadyne pumps

- Get a written estimate before any work begins

By choosing the right specialist, you ensure your injection pump gets the best care. This can extend the life of your pump and improve engine performance.

Preventive Measures

Preventive measures are crucial for maintaining the efficiency of your Stanadyne Injection Pump. Regular maintenance and using quality fuel can help prevent many issues. These steps ensure your pump remains in top condition, promoting longevity and optimal performance.

Routine Maintenance

Regular maintenance is key. Check the pump for wear and tear often. Replace worn parts promptly to avoid bigger problems. Clean the pump regularly to remove any debris. This prevents clogging and ensures smooth operation. Follow the manufacturer’s guidelines for maintenance schedules. These steps help keep the pump functioning well.

Using Quality Fuel

Using quality fuel is essential. Poor quality fuel can damage the injection pump. Always use clean, high-quality diesel fuel. This reduces the risk of contamination. Contaminants can clog the pump and cause failures. Ensure the fuel filter is clean and in good condition. Replace it as needed. Using good fuel and keeping the filter clean helps protect the pump.

Credit: igor.chudov.com

Frequently Asked Questions

What Causes A Stanadyne Injection Pump To Fail?

A Stanadyne injection pump can fail due to wear, contamination, or lack of maintenance.

How Do I Know If My Injection Pump Is Bad?

Symptoms include hard starting, engine misfires, poor fuel efficiency, or unusual noises from the pump.

Can I Repair A Stanadyne Injection Pump Myself?

Repairing a Stanadyne injection pump yourself is possible but requires technical skills and proper tools.

Why Is My Engine Not Starting With A New Injection Pump?

Check for proper installation, correct timing, and ensure there is no air in the fuel lines.

How Often Should I Service My Stanadyne Injection Pump?

Service the Stanadyne injection pump every 2,500 hours or as recommended by the manufacturer for best performance.

Conclusion

Troubleshooting a Stanadyne injection pump can seem daunting. But, with careful steps, it’s manageable. Always start with basic checks. Ensure fuel supply and filters are clean. Listen for unusual noises. Check for leaks. Follow the guide, and you’ll solve most issues.

Regular maintenance prevents many problems. Keep your tools ready and stay patient. Your pump will run smoothly again soon. Thanks for reading our guide. Happy troubleshooting!