Are you facing issues with your grain dryer and feeling frustrated? You’re not alone.

Many people encounter problems with their dryers, but the good news is most of these issues can be solved with some straightforward troubleshooting. Imagine the relief of knowing exactly what to do to ensure your equipment runs smoothly and efficiently.

Your time and money are valuable, and understanding how to fix common problems can save you both. We’ll guide you through practical steps to tackle these challenges head-on, empowering you to keep your grain dryer in top shape. Ready to transform your drying process from troublesome to superb? Let’s dive in and get your dryer working perfectly again.

Common Issues In Grain Dryers

Grain dryers play a crucial role in agriculture. They help preserve grain quality by reducing moisture. Yet, they often face common issues. These problems can affect efficiency and crop quality. Understanding these issues aids in timely troubleshooting. Let’s explore some frequent challenges.

Uneven Drying

Uneven drying is a common problem in grain dryers. It occurs when moisture is not uniformly removed. This can lead to spoilage and reduced grain quality. Often, clogged ducts or improper airflow cause this issue. Regular maintenance can prevent such blockages. Check and clean ducts to ensure even airflow.

Excessive Energy Consumption

Grain dryers can consume a lot of energy. This increases operational costs significantly. Faulty sensors or poor insulation often lead to high energy use. Ensure sensors are calibrated correctly. Inspect insulation regularly to prevent energy loss. Efficient dryers save money and resources.

Mechanical Failures

Mechanical failures disrupt dryer operations. They can include belt wear, motor issues, or fan problems. Regular inspections can catch early signs of wear. Replace worn parts to avoid breakdowns. Proper lubrication helps maintain machine health. Timely repairs minimize downtime and losses.

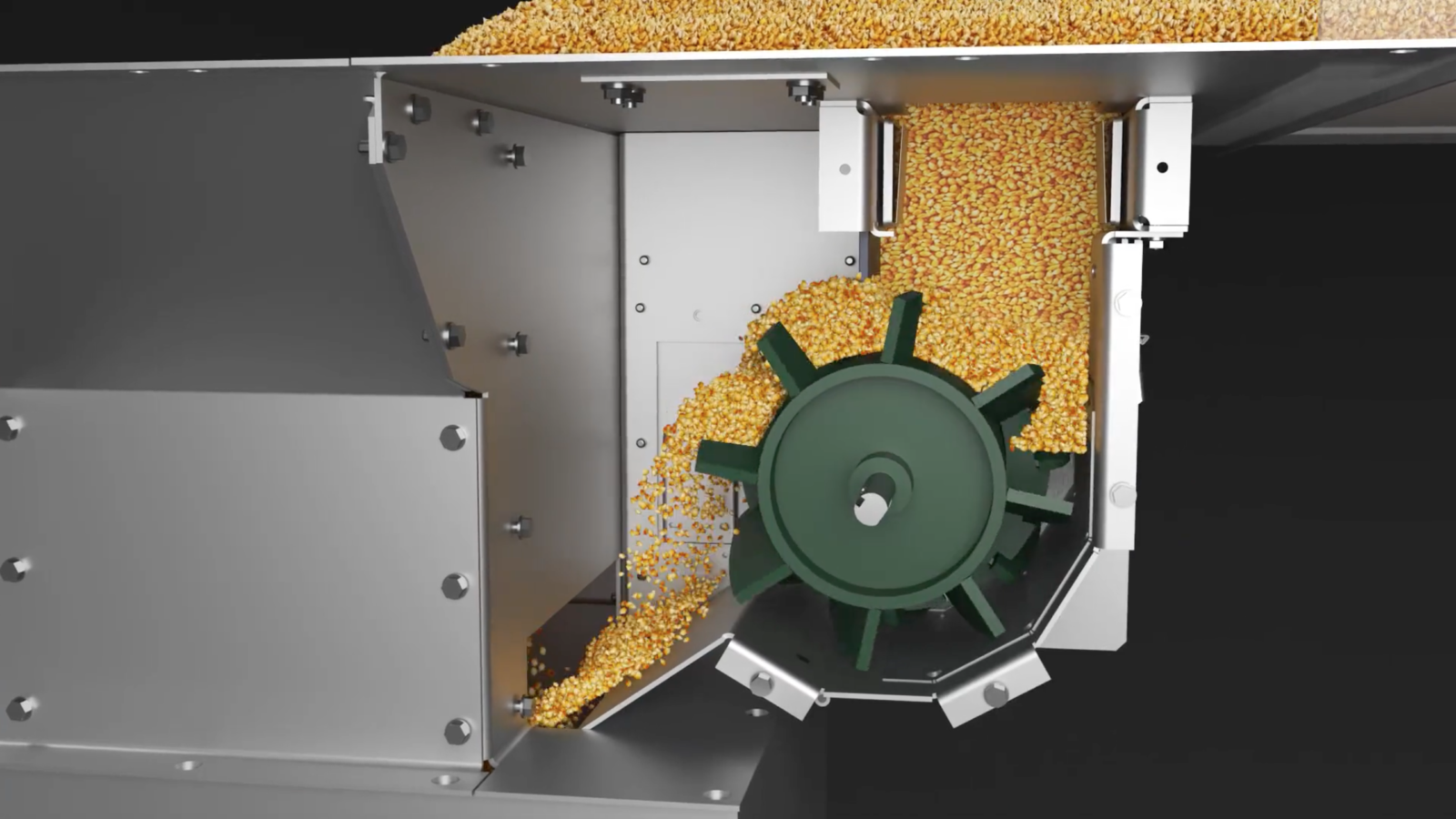

Credit: www.fosterequipmentsales.com

Diagnostic Techniques

Diagnosing issues with your Superb Grain Dryer can save time and money. Knowing the right techniques helps maintain optimal performance. Let’s explore some effective diagnostic techniques.

Visual Inspection

Start with a thorough visual inspection. Look for signs of wear or damage. Check for leaks or obstructions in visible parts. Ensure all components appear intact and functional.

Checking Electrical Connections

Inspect the electrical connections for any loose wires. Ensure all connections are secure and free from corrosion. Verify that the control panel operates correctly. Faulty connections can lead to malfunction.

Assessing Airflow

Assess airflow to ensure the dryer operates efficiently. Check for blockages in ducts or vents. Clean filters regularly to maintain adequate air movement. Proper airflow is crucial for effective drying.

Maintenance Best Practices

Troubleshooting a grain dryer efficiently requires attention to detail and regular checks. Inspect the dryer for blockages and clean filters frequently. Ensure all electrical connections are secure and functioning. Regular maintenance prevents unexpected breakdowns and ensures optimal performance, saving time and resources.

Maintaining your Superb Grain Dryer is crucial to ensure its longevity and efficiency. Adhering to maintenance best practices can prevent unexpected breakdowns and enhance performance. These practices are straightforward and can be integrated into your routine without much hassle.Regular Cleaning

Regular cleaning is a simple yet effective maintenance practice. Dust and debris can accumulate quickly, affecting the dryer’s efficiency. Make it a habit to clean the dryer’s interior and exterior surfaces. Use a soft brush or cloth for delicate components. Keeping the dryer clean will not only improve its function but also extend its lifespan.Routine Component Checks

Checking components routinely can save you from costly repairs. Pay attention to belts, motors, and electrical connections. Inspect these parts for wear and tear. Tighten any loose bolts or screws to prevent mechanical issues. Routine checks can catch potential problems early, keeping your dryer running smoothly.Lubrication Tips

Lubrication is essential to prevent friction and wear on moving parts. Use a quality lubricant to ensure optimal performance. Apply lubricant to bearings and joints regularly. Follow the manufacturer’s guidelines for the correct type of lubricant. Proper lubrication can significantly reduce downtime and keep your dryer in top condition. A well-maintained grain dryer not only boosts efficiency but also contributes to your peace of mind. What maintenance practices have you found most effective? Share your experiences and insights in the comments below.

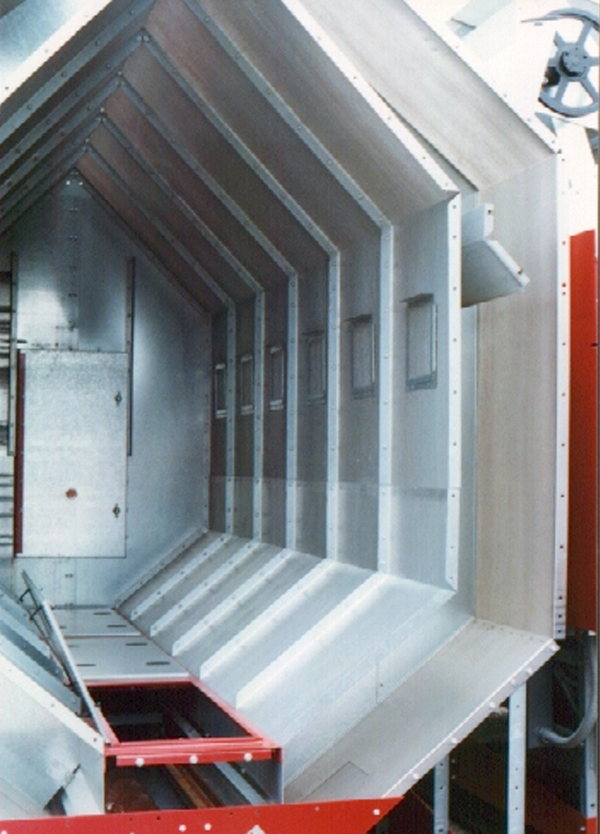

Credit: www.brockgrain.com

Advanced Troubleshooting Methods

Effective troubleshooting of grain dryers involves checking common issues like airflow, temperature settings, and moisture levels. Identifying and fixing these problems ensures efficient drying and prevents crop damage. Regular maintenance helps in keeping the dryer in top condition for reliable performance.

Troubleshooting a superb grain dryer can be challenging, especially when traditional methods fall short. Advanced troubleshooting methods can provide deeper insights into the issues your equipment faces. These techniques can not only save time but also enhance the efficiency and lifespan of your grain dryer. Let’s dive into some advanced strategies that can make a real difference.Thermal Imaging

Thermal imaging is a powerful tool for diagnosing temperature-related issues in your grain dryer. It helps you identify hot spots that could indicate blockages or malfunctioning components. Imagine holding a device that lets you “see” heat. With thermal imaging, you can quickly pinpoint areas of concern without disassembling the machine. By addressing these hot spots, you can prevent potential fires and improve the dryer’s performance. Have you ever wondered why your grain dryer seems to overheat unexpectedly? Thermal imaging might just hold the answer.Using Moisture Sensors

Moisture sensors can provide crucial insights into the drying process. These sensors allow you to monitor the moisture levels in real-time, ensuring optimal drying efficiency. By placing moisture sensors at various points within the grain dryer, you can detect inconsistencies in moisture levels. This helps in adjusting settings and flow rates, ensuring even drying. You can avoid over-drying or under-drying, which can affect grain quality and energy consumption. Have you noticed uneven drying patterns in your grain batches? Moisture sensors could be the solution you need.Software Diagnostics

Modern grain dryers often come equipped with software diagnostics tools. These tools can analyze the machine’s operations and alert you to any irregularities. Software diagnostics allow you to track performance metrics and receive alerts for maintenance needs. This proactive approach can prevent costly breakdowns. Have you utilized all the features of your grain dryer’s software? Understanding these tools can give you a leg up in maintaining your equipment. By integrating these advanced troubleshooting methods, you can enhance the reliability and efficiency of your grain dryer. Each technique offers unique benefits, making it easier to maintain your equipment and ensure high-quality grain processing. Which of these methods will you try next to optimize your grain drying process?Expert Repair Tips

Expert repair tips can enhance the performance of your grain dryer. Fixing issues at home may save time and money. Knowing how to replace parts and adjust settings can prevent breakdowns. Sometimes, professional servicing is necessary for complex problems. Follow these expert tips to maintain your dryer efficiently.

Replacing Faulty Parts

Identify the faulty part that needs replacement. Use the manual to find the part number. Buy a replacement from a trusted supplier. Ensure the part is compatible with your model. Disconnect power before replacing the part. Follow safety guidelines during the replacement process. Test the dryer after replacing the part to ensure it works properly.

Adjusting Settings

Correct settings are crucial for optimal dryer performance. Check the manual for recommended settings. Adjust temperature and airflow according to grain type. Use the control panel to make adjustments. Regularly monitor the settings to avoid overheating. Improper settings can lead to inefficient drying.

Professional Servicing

Some issues require professional servicing. Hire a certified technician for complex repairs. They have the expertise to handle intricate problems. Regular servicing prolongs the life of the dryer. Schedule annual maintenance for thorough checks. Professional servicing ensures safety and efficiency.

Credit: www.brockgrain.com

Preventive Measures

Identifying potential issues early ensures efficient operation of grain dryers. Regular checks prevent unexpected breakdowns, saving time and money. Maintain clean filters and inspect belts frequently for wear.

Effective preventive measures can significantly enhance the performance and longevity of your superb grain dryer. By investing time in regular upkeep, training, and upgrades, you can minimize unexpected breakdowns and optimize efficiency. Let’s dive into some key strategies that can help you keep your grain dryer running smoothly.Scheduled Maintenance

Regular maintenance is crucial for preventing costly repairs. Create a maintenance calendar that outlines specific tasks to be completed weekly, monthly, and annually. Check filters and belts regularly, as these components can wear out quickly. Addressing small issues promptly can prevent more significant problems later. Consider partnering with a professional service to conduct annual inspections. They can identify hidden issues that might not be apparent to untrained eyes.Training For Operators

Proper training for your operators is essential. Ensure they understand the functionality of the grain dryer and how to operate it safely. Organize hands-on training sessions where operators can practice troubleshooting common issues. This not only enhances their skills but also builds their confidence in handling unexpected situations. Encourage a culture of learning. Operators who feel empowered to ask questions and share knowledge can contribute to a more efficient and safer working environment.Upgrading Equipment

Sometimes, upgrading equipment is the best preventive measure. Newer models often come with enhanced safety features and improved efficiency. Assess the performance of your current equipment. If it’s frequently breaking down or consuming too much energy, it might be time for an upgrade. Explore options that offer better technology and reliability. Investing in advanced equipment can reduce downtime and increase productivity in the long run. By focusing on these preventive measures, you can ensure your superb grain dryer remains a reliable asset. What steps will you take today to enhance your equipment’s performance?Optimizing Performance

Optimizing the performance of your Superb Grain Dryer is crucial for ensuring efficient drying and maintaining grain quality. It’s not just about having a machine that works; it’s about making sure it works well. Let’s dive into some practical strategies to keep your dryer running at its best.

Improving Air Circulation

Air circulation is key to effective drying. Ensure that your dryer’s vents are clear of obstructions. Clean out any debris or dust regularly to prevent blockages.

Consider adjusting the fan speed to improve airflow. Faster airflow can enhance drying efficiency but watch for overheating. A balance is necessary for optimal performance.

Have you checked the fan blades recently? Bent or damaged blades can impede circulation. Make it a routine to inspect them and replace as needed.

Calibration Techniques

Calibration can significantly impact dryer performance. Regularly calibrate temperature sensors to ensure accurate readings. This will help prevent under-drying or over-drying.

Set up a schedule for checking calibration. Consistency is key. Even a small error can affect grain quality.

Use a digital thermometer to verify your dryer’s internal temperature against the settings. It’s a simple step that can save a lot of trouble.

Energy Efficiency Strategies

Energy efficiency not only saves money but also improves dryer performance. Check for leaks in the system. Sealing them can prevent energy waste.

Optimize drying times by experimenting with different settings. Sometimes, less time is needed for certain grains. Shorter drying cycles can reduce energy consumption.

Consider insulating your dryer. Proper insulation can maintain heat, reducing the energy required to reach and sustain desired temperatures.

Optimizing your grain dryer isn’t just about technical tweaks; it’s about asking the right questions. How can you refine each element for better results? By focusing on these strategies, you can enhance your grain dryer’s performance, ensuring it operates efficiently and effectively.

Frequently Asked Questions

Why Is My Grain Dryer Not Heating?

Check thermostat settings and burner. Ensure fuel supply is adequate. Inspect for blockages in the air intake.

How Do I Fix Uneven Drying?

Ensure grain is evenly distributed. Check fan operation. Adjust the drying temperature. Inspect the auger for blockages.

What Causes Grain Dryer Alarms?

Alarms often signal overheating, low fuel, or airflow issues. Regular maintenance can prevent these common problems.

Why Is My Dryer Making Loud Noises?

Noises may indicate loose parts or obstructions. Inspect bearings, belts, and fans. Tighten or replace worn components.

How Can I Improve Dryer Efficiency?

Clean filters regularly. Ensure proper airflow. Use recommended settings for your grain type. Regular maintenance improves performance.

Conclusion

Troubleshooting grain dryers need not be complicated. With patience and a basic understanding, many issues can be resolved quickly. Regular checks help prevent bigger problems. Listen for unusual noises or smells. Address them promptly to avoid costly repairs. Remember, a well-maintained dryer boosts efficiency.

It saves time and resources. Always consult the manual for guidance. Seek professional help when needed. This ensures safe and effective operation. Keep your dryer in top condition for better harvest results. Your grains deserve the best care. Happy drying!