Is your air conditioning system acting up, leaving you frustrated and uncomfortable? One common culprit behind cooling problems is a faulty thermal expansion valve (TXV).

This small yet crucial component plays a big role in regulating refrigerant flow and ensuring your AC runs smoothly. When it malfunctions, it can disrupt your system’s performance, drive up energy costs, and leave you sweating—literally. But don’t worry! With the right troubleshooting steps, you can pinpoint the issue and get your cooling system back on track.

In this guide, you’ll discover practical tips to identify and fix TXV problems, saving you time, money, and unnecessary stress. Ready to take control of your AC’s performance? Let’s dive in!

Common Issues With Thermal Expansion Valves

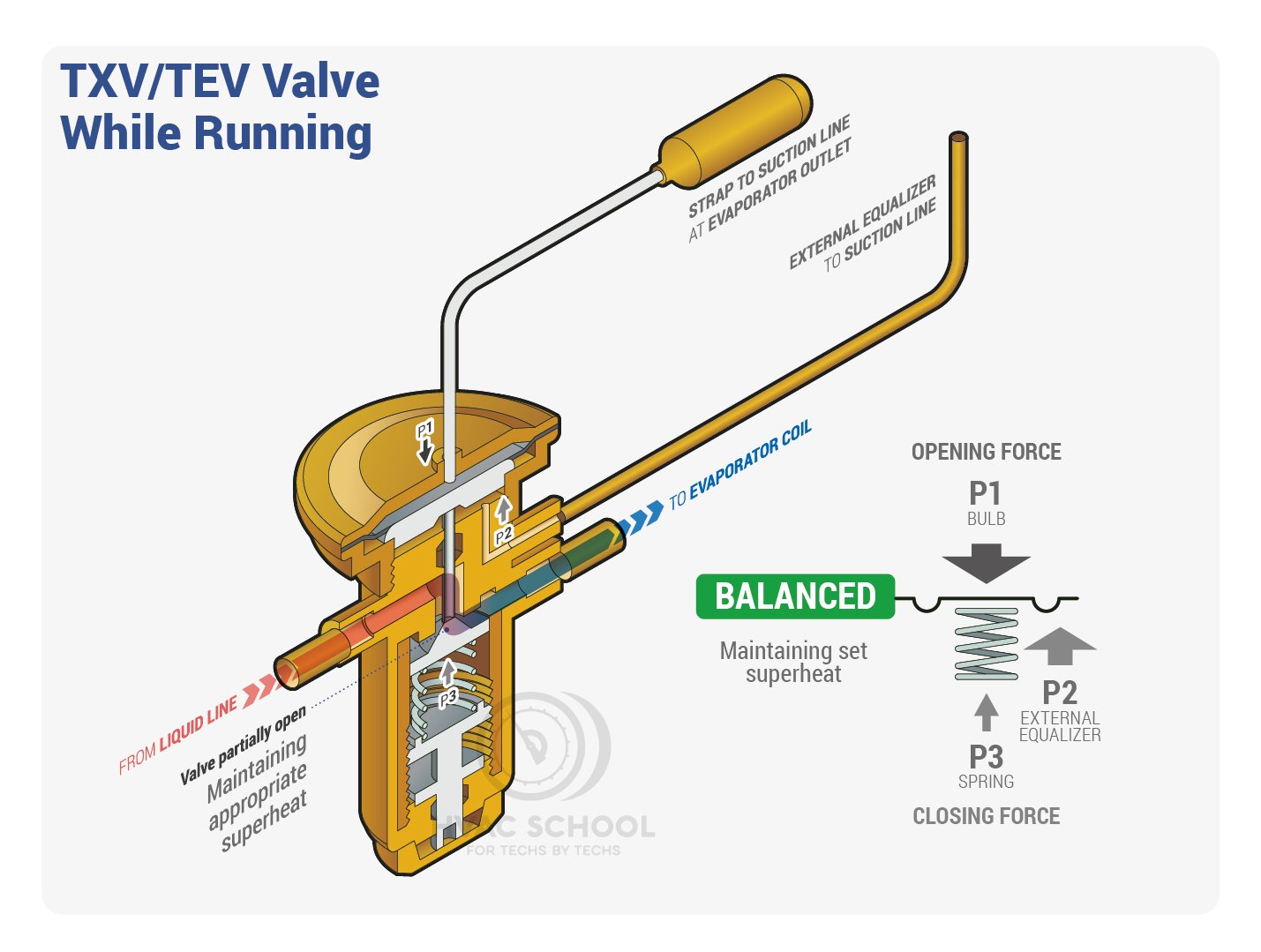

Thermal expansion valves (TXVs) play a critical role in HVAC systems. They regulate refrigerant flow to ensure optimal cooling and system efficiency. Yet, like any mechanical component, they can develop issues over time. These problems can disrupt system performance and lead to energy inefficiency. Below are some common issues you might face with thermal expansion valves, along with their possible causes and effects.

Valve Stuck Open Or Closed

A valve stuck open lets too much refrigerant into the evaporator. This can cause the evaporator coil to freeze and reduce cooling efficiency. On the other hand, a valve stuck closed restricts refrigerant flow entirely. This can lead to higher system pressures and poor cooling. Dirt, debris, or mechanical wear often causes this issue. Regular maintenance can help prevent such problems.

Insufficient Refrigerant Flow

Low refrigerant flow can result from a partially clogged thermal expansion valve. Dirt, oil, or moisture in the system can block the valve. This issue limits the refrigerant entering the evaporator coil. As a result, the system may struggle to cool properly. Cleaning the valve and ensuring a clean refrigerant line can resolve this problem.

Erratic Superheat Levels

Erratic superheat levels signal an unstable thermal expansion valve. The valve may open and close unpredictably, causing temperature fluctuations. This can lead to poor cooling performance and potential compressor damage. Contaminants in the system or improper valve adjustment are common culprits. Inspecting and cleaning the valve can restore stable operation.

Symptoms Of A Faulty Thermal Expansion Valve

A thermal expansion valve is crucial for regulating refrigerant flow in HVAC systems. When it malfunctions, the system’s efficiency and performance suffer. Detecting symptoms of a faulty valve early can prevent costly repairs. Below are the most common signs to watch for.

Frost Or Ice On The Valve

Frost or ice buildup on the valve often indicates a malfunction. This happens due to improper refrigerant flow or pressure issues. Restricted refrigerant can cause freezing and disrupt cooling performance. Regular inspections can help spot this issue early.

Poor Cooling Performance

A faulty thermal expansion valve can impair cooling efficiency. Inconsistent refrigerant flow reduces the system’s ability to cool spaces effectively. You may notice uneven temperatures or extended cooling cycles. These signs point to valve-related problems.

Unusual System Noises

Strange noises like hissing or knocking could signal valve trouble. Noise often results from pressure imbalances or improper refrigerant regulation. These sounds can disrupt the operation and lead to further damage. Pay attention to unusual noises for timely intervention.

Tools Needed For Troubleshooting

Thermal expansion valve (TXV) troubleshooting requires specific tools for accurate results. Using the right tools helps identify issues and ensures proper system performance. Below, we detail the essential tools needed for effective troubleshooting.

Pressure Gauges And Thermometers

Pressure gauges are vital for measuring refrigerant pressures in the system. They help determine if the TXV is regulating the flow properly. Attach the gauges to the system’s service ports for accurate readings.

Thermometers are essential for measuring line temperatures. Compare these readings with pressure gauge results to evaluate system performance. Choose thermometers designed for HVAC systems to ensure reliability.

Multimeter For Electrical Checks

A multimeter is necessary to test the electrical components of the TXV. Use it to measure voltage, resistance, and continuity in the system. This helps identify issues such as faulty solenoids or wiring problems.

Ensure the multimeter settings match the type of test being performed. Always follow safety guidelines while testing electrical components.

Refrigerant Recovery Equipment

Refrigerant recovery equipment is crucial when servicing or replacing a TXV. It safely removes refrigerant from the system to prevent environmental harm. This step is mandatory to comply with regulations.

Choose recovery equipment compatible with the refrigerant type used in your system. Proper recovery ensures no refrigerant is lost during repairs.

Step-by-step Troubleshooting Guide

Thermal expansion valves (TEVs) are critical for regulating the flow of refrigerant in HVAC systems. When something goes wrong, it can disrupt the entire cooling process. This step-by-step troubleshooting guide will help you identify and fix common TEV problems, ensuring your system operates efficiently and reliably. Let’s dive into the process.

Inspecting The Valve For Physical Damage

Begin by visually inspecting the thermal expansion valve. Look for obvious signs of damage, such as dents, cracks, or corrosion on the valve body. A damaged valve can restrict refrigerant flow or cause leaks.

Check the sensing bulb to ensure it’s securely mounted and properly insulated. If the bulb is loose or misplaced, the valve may not respond correctly to temperature changes. Tighten or reposition it as needed.

If you notice excessive dirt, debris, or oil on the valve, clean it thoroughly. Contaminants can clog the valve and interfere with its function. A simple cleaning might save you from unnecessary replacements.

Checking For Refrigerant Leaks

Refrigerant leaks are a common cause of TEV issues. Use a leak detector or soap bubble test to check for leaks around the valve and connecting joints. Bubbles indicate a leak that needs to be addressed.

Ensure all connections are tight and secure. Loose fittings can cause small leaks that disrupt the refrigerant flow. Tighten any loose connections, but be careful not to overtighten and damage the threads.

Don’t forget to check the system pressure. A low refrigerant charge may mimic TEV problems. If the refrigerant level is low, recharge the system after fixing the leak.

Testing Superheat And Subcooling Levels

Measuring superheat and subcooling levels is essential for diagnosing TEV performance. Use a manifold gauge set and a thermometer to take accurate readings. Record the evaporator outlet temperature and compare it with the suction pressure converted to temperature.

If the superheat is too high, the TEV may be restricting refrigerant flow. This could be due to a stuck valve or a sensing bulb issue. Adjust the valve or fix the bulb placement to correct the superheat.

Low superheat can indicate an overfeeding valve. This might lead to liquid refrigerant entering the compressor, which can cause severe damage. Adjust the valve to reduce refrigerant flow and monitor the system closely.

For subcooling, measure the liquid line temperature and compare it with the high-side pressure converted to temperature. Incorrect subcooling levels often point to refrigerant charge issues or a faulty TEV. Make necessary adjustments and recheck your readings.

Troubleshooting a thermal expansion valve may seem daunting, but breaking it into simple steps makes the process manageable. What’s the most challenging TEV issue you’ve encountered? Share your thoughts below!

Causes Of Valve Malfunctions

Thermal expansion valves are key components in refrigeration and air conditioning systems. Malfunctions in these valves can disrupt the cooling process and reduce efficiency. Understanding the causes of these issues is crucial for proper troubleshooting and maintenance. Below are some common causes of valve malfunctions explained in detail.

Dirt Or Debris In The Valve

Contaminants like dirt or debris can block the valve’s internal components. This blockage restricts refrigerant flow, leading to inconsistent cooling performance. Dirty systems or improper installation often introduce debris into the valve. Regular cleaning and maintenance help prevent such issues.

Incorrect Refrigerant Charge

An incorrect refrigerant charge can cause the valve to malfunction. Low refrigerant levels may reduce pressure, affecting the valve’s operation. Overcharging can lead to excessive pressure, which strains the valve. Always ensure proper refrigerant levels during installation or servicing.

Electrical Component Failures

Electrical failures are another common cause of valve problems. Faulty sensors or damaged wiring can disrupt the valve’s control signals. These issues may cause improper refrigerant regulation or complete valve failure. Inspect electrical connections and components during troubleshooting.

Preventive Maintenance Tips

Keeping your thermal expansion valve (TXV) in top shape is essential for maintaining a well-functioning HVAC system. Neglecting preventive maintenance can lead to inefficiencies, costly repairs, or even system failure. Let’s look at some actionable maintenance tips to ensure your TXV performs at its best.

Regular System Inspections

Start with consistent inspections of your HVAC system. Check the TXV and surrounding components for visible signs of wear, corrosion, or leaks. Spotting issues early can save you from expensive repairs down the road.

Schedule these inspections every three to six months, depending on your system’s usage. If your system is in a high-demand environment, like a hot climate or a commercial building, you might need more frequent checks. Remember, it’s always easier to address a small issue before it becomes a big problem.

Cleaning The Valve And System

Dirt and debris can clog the TXV, reducing its efficiency. Turn off the system and carefully clean the valve using a soft cloth or a mild cleaning solution. Avoid using harsh chemicals that might damage the valve components.

Don’t stop at the valve—clean the surrounding system components too. Dust and grime buildup in other areas can indirectly affect the valve’s performance. A clean system works more efficiently and lasts longer.

Monitoring Refrigerant Levels

Refrigerant levels play a critical role in how well your TXV performs. Low or high refrigerant levels can disrupt the valve’s ability to regulate pressure and temperature. Use a refrigerant gauge to check the levels periodically.

If the refrigerant level is off, it could indicate a leak or improper charging. Address this quickly to prevent further damage. When in doubt, consult a professional HVAC technician to ensure the refrigerant is charged correctly.

Have you ever experienced uneven cooling or heating in your space? That could be a sign your refrigerant levels are off. Don’t ignore it—small adjustments can make a big difference.

By following these preventive maintenance tips, you can extend the life of your TXV and keep your HVAC system running smoothly. Which of these steps will you start with today?

When To Replace The Valve

A thermal expansion valve (TXV) plays a crucial role in refrigeration systems. It regulates the flow of refrigerant to maintain efficiency and performance. Over time, the valve may wear out or become faulty, impacting system operation. Knowing when to replace the TXV can prevent costly repairs and downtime. Below are key factors that signal the need for replacement.

Signs Of Irreparable Damage

Visible cracks or leaks on the valve body indicate severe damage. Refrigerant leaks can disrupt cooling and harm system components. Bent or broken internal parts often make repairs impossible. If the valve fails to regulate refrigerant flow, replacement might be necessary.

Frequent System Breakdowns

Recurring issues like inconsistent cooling or compressor failure may point to a faulty TXV. Overloaded compressors can result from improper refrigerant flow. System shutdowns or inefficiency often stem from valve malfunctions. Replacing the valve can restore system stability.

Age And Wear Of The Component

Older valves may lose effectiveness due to wear and tear. Long-term exposure to pressure can degrade internal components. If the valve is nearing its expected lifespan, replacement is a proactive step. Regular inspections can help identify aging parts before failure occurs.

Conclusion

Proper care of your thermal expansion valve ensures efficient system performance. Always check for common issues like blockages, leaks, or incorrect settings. Regular maintenance can prevent costly repairs and keep your system running smoothly. Pay attention to signs like inconsistent cooling or unusual noises.

Addressing problems early saves time and money. Consult a professional if troubleshooting becomes challenging. Understanding these basics helps you maintain a reliable HVAC system. Keep your valve in good condition for optimal comfort and energy efficiency. A little effort goes a long way in avoiding major issues.