Troubleshooting a Tommy Gate can seem daunting at first. Issues can arise with any liftgate, but you can often fix them with some guidance.

Tommy Gate liftgates are reliable tools for many industries. But, like all machinery, they sometimes face problems. Knowing how to troubleshoot these issues can save you time and money. Whether it’s a motor problem or a hydraulic issue, understanding the basics helps.

This blog will guide you through common Tommy Gate issues and their solutions. With this knowledge, you’ll handle most problems confidently. Read on to learn practical tips and get your liftgate working again. Let’s dive into the world of Tommy Gate troubleshooting!

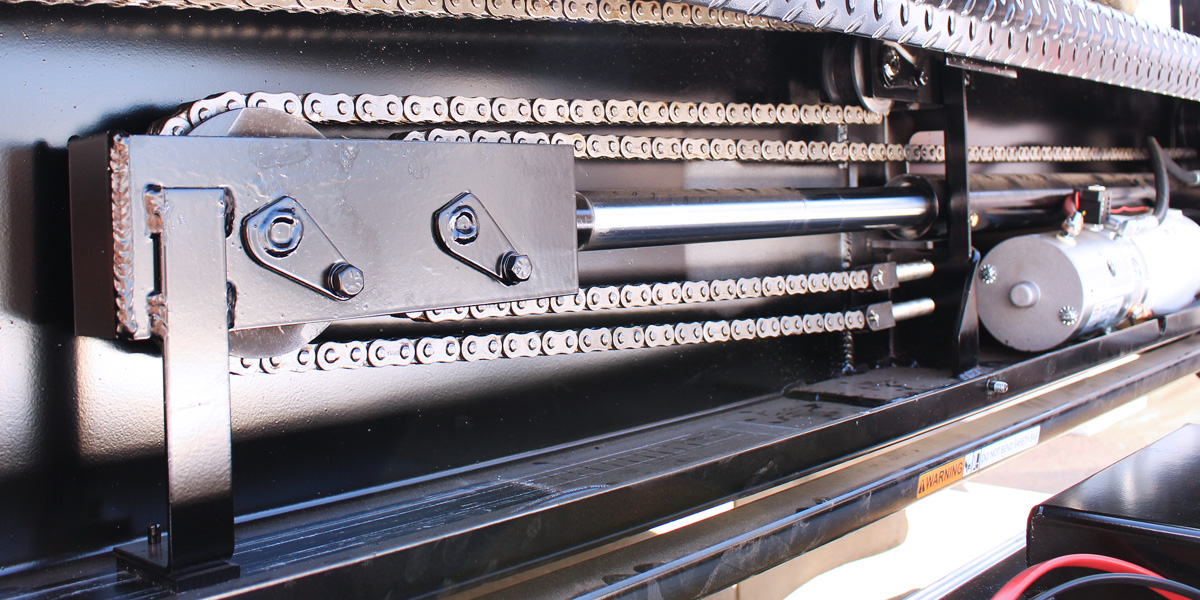

Credit: www.douglasstruckbodies.com

Introduction To Tommy Gate Troubleshooting

Tommy Gate liftgates are essential tools for many businesses. They help in lifting and loading heavy items onto trucks. Over time, these liftgates may face issues that need troubleshooting. This section will guide you through the basics of Tommy Gate troubleshooting.

Purpose And Importance

The primary purpose of troubleshooting is to identify and fix issues quickly. This ensures that your liftgate remains operational. Regular troubleshooting helps in maintaining the efficiency of your equipment. It also extends the lifespan of your Tommy Gate liftgate.

Understanding the importance of troubleshooting can save you money. It prevents costly repairs and replacements. It also reduces downtime, keeping your business running smoothly.

Overview Of Common Issues

There are several common issues that users may encounter with Tommy Gates. Understanding these can help you troubleshoot effectively.

| Issue | Description |

|---|---|

| Power Failure | The liftgate does not operate due to a lack of power. |

| Hydraulic Problems | Issues with the hydraulic system can affect liftgate movement. |

| Mechanical Wear and Tear | Over time, parts may wear out and need replacement. |

| Control Issues | Problems with the control switch or wiring can cause malfunction. |

- Check the battery connections.

- Ensure the battery is fully charged.

- Inspect the wiring for any damage.

- Check for leaks in the hydraulic system.

- Ensure fluid levels are adequate.

- Inspect hoses and fittings for wear.

- Regularly lubricate moving parts.

- Replace worn-out components promptly.

- Inspect the liftgate for signs of rust or damage.

- Check the control switch for proper operation.

- Inspect the wiring for loose connections.

- Replace faulty switches or wiring as needed.

Safety Precautions

Ensuring safety during Tommy Gate troubleshooting is crucial. Following safety precautions can prevent injuries. It’s vital to adhere to these guidelines for a safe working experience.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). Use gloves to protect your hands from sharp edges. Safety glasses shield your eyes from debris. Sturdy boots safeguard your feet. Wearing PPE reduces the risk of accidents significantly.

Safe Work Environment

Maintain a clean and organized work area. Remove any clutter that can cause trips or falls. Ensure the floor is dry to avoid slipping. Proper lighting is essential for visibility. A safe work environment minimizes hazards and promotes efficiency.

Hydraulic System Problems

The hydraulic system is crucial for the proper functioning of your Tommy Gate. Without it, the gate cannot lift or lower loads efficiently. Problems within the hydraulic system can lead to significant downtime and costly repairs. Understanding these issues helps in maintaining the gate’s performance.

Identifying Leaks

Leaks are common in hydraulic systems. They can occur in hoses, fittings, or seals. Inspect the hydraulic fluid reservoir first. Low fluid levels often indicate a leak. Look for wet spots or puddles around the hydraulic components. Check hose connections for tightness. Loose connections often cause leaks.

Examine the seals on the hydraulic cylinders. Worn or damaged seals can also leak fluid. Replace any faulty seals immediately. Regularly check for leaks to prevent further damage.

Fixing Low Pressure

Low pressure in the hydraulic system affects the gate’s lifting power. Check the fluid level in the reservoir first. Low fluid levels can cause low pressure. Fill the reservoir to the recommended level.

Inspect the hydraulic pump. A malfunctioning pump may not generate enough pressure. Ensure the pump is clean and free of debris. Replace the pump if it shows signs of wear or damage.

Check the hydraulic hoses for blockages. Debris or kinks in the hoses can restrict fluid flow. Clear any obstructions to restore proper pressure.

Regular maintenance of the hydraulic system is essential. It helps in avoiding low pressure issues. Keep the system clean and well-lubricated.

Electrical Issues

Addressing electrical issues is crucial for maintaining the functionality of your Tommy Gate. Regular inspections and maintenance can prevent unexpected breakdowns and costly repairs. Understanding the key areas to focus on can make troubleshooting more efficient.

Battery Maintenance

Batteries are the lifeblood of your Tommy Gate. Proper maintenance ensures they deliver consistent power. Follow these simple steps:

- Check the battery terminals for corrosion. Clean them with a wire brush.

- Ensure the battery is fully charged. A multimeter can help check the voltage.

- Inspect the battery case for any signs of damage or leaks.

Use a battery tester to ensure the battery holds a charge. Replace the battery if it fails the test. A well-maintained battery extends the life of your equipment.

Wiring Inspections

Wiring issues can cause intermittent or complete failure of your Tommy Gate. Regular inspections can catch problems early:

| Inspection Point | What to Look For |

|---|---|

| Connections | Loose or corroded connectors |

| Wires | Frayed or damaged insulation |

| Fuses | Blown or discolored fuses |

Use a continuity tester to check for broken wires. Secure all connections and replace any damaged wires. This will ensure a stable electrical system.

Mechanical Failures

Mechanical failures in Tommy Gate systems can cause significant downtime. Understanding the common mechanical issues helps in quick troubleshooting. This guide covers the basics of checking hinges, joints, and proper lubrication. These steps ensure your Tommy Gate operates smoothly.

Checking Hinges And Joints

The hinges and joints are crucial components. Worn-out hinges can lead to misalignment. Regular inspection is necessary.

- Inspect the hinges for visible wear.

- Check for any loose bolts or screws.

- Ensure the joints move freely without resistance.

If you find any issues, tighten the loose parts. Replace any worn-out components promptly. This prevents further damage.

Lubrication Tips

Proper lubrication keeps your Tommy Gate running smoothly. Lack of lubrication can cause friction and wear.

- Use a high-quality lubricant.

- Apply the lubricant to all moving parts.

- Wipe off any excess to avoid dirt accumulation.

Lubricate the hinges and joints regularly. This reduces wear and tear. It also extends the life of your Tommy Gate.

Remember, regular maintenance is key. Keeping an eye on mechanical parts ensures long-term functionality. Follow these tips to avoid mechanical failures.

Credit: nationalliftgate.com

Control Switch Malfunctions

Control switch malfunctions can cause significant problems with your Tommy Gate lift. A faulty switch can hinder the lift’s operation, leading to frustration. Knowing how to troubleshoot and fix these issues is essential. This section will guide you through testing and replacing faulty switches.

Testing The Switch

First, ensure the power is off to avoid any accidents. Use a multimeter to test the switch. Set the multimeter to the continuity setting. Touch the probes to the switch terminals. If there is no continuity, the switch is faulty. If the continuity is present, the issue may lie elsewhere.

Replacing Faulty Switches

If the switch is faulty, you need to replace it. Start by removing the cover to access the switch. Carefully disconnect the wires from the old switch. Connect the wires to the new switch, matching the same terminals. Secure the new switch in place and replace the cover. Turn the power back on and test the lift.

Liftgate Alignment

Ensuring proper liftgate alignment is essential for the smooth operation of your Tommy Gate. Misalignment can lead to uneven lifting, increased wear on components, and potential safety hazards. By regularly checking and adjusting the liftgate alignment, you can extend the life of your equipment and ensure it operates safely and efficiently.

Assessing Alignment

To begin assessing the alignment of your liftgate, follow these steps:

- Park the vehicle on a flat surface.

- Lower the liftgate to the ground.

- Observe the liftgate from different angles.

Check if the liftgate sits evenly on the ground. Look for any gaps or uneven spaces. Use a level tool to measure the horizontal and vertical alignment. Record any discrepancies for reference.

Adjusting Liftgate

If you find the liftgate is misaligned, you can make adjustments. Follow these steps:

- Locate the adjustment bolts on the liftgate hinges.

- Loosen the bolts using the appropriate tools.

- Adjust the liftgate to the correct position.

- Tighten the bolts securely.

Recheck the alignment after making adjustments. Repeat the process if necessary until the liftgate is properly aligned. Ensure all bolts and fasteners are tight to prevent future misalignment.

Regular maintenance and timely adjustments can prevent costly repairs. A well-aligned liftgate contributes to safe and efficient operation. Keep an eye on alignment during routine inspections.

Routine Maintenance Tips

Regularly check the hydraulic fluid levels and inspect for leaks. Ensure all bolts are tightened to prevent malfunctions. Lubricate moving parts to keep your Tommy Gate operating smoothly.

Maintaining your Tommy Gate ensures it runs smoothly and lasts longer. Regular care prevents unexpected breakdowns. Simple steps can keep your liftgate in top shape.Regular Inspections

Check your Tommy Gate often. Look for rust, wear, and tear. Inspect hydraulic hoses for leaks. Check the battery connections. Ensure no debris is stuck in the moving parts. Clean any dirt or grime.Preventative Measures

Lubricate moving parts regularly. Use the recommended oil. Tighten loose bolts and screws. Replace worn-out parts immediately. Keep the battery charged. Store the gate properly when not in use. Follow the manufacturer’s guidelines for maintenance. “`When To Seek Professional Help

Experiencing issues with your Tommy Gate? Seek professional help if you notice unusual noises, slow operation, or malfunctioning controls. Quick expert assistance can prevent further damage and ensure safe and efficient usage.

Sometimes, troubleshooting your Tommy Gate lift can be challenging. It’s important to know when it’s best to call in an expert. Not every issue can be fixed at home. Knowing the limits of your skills can save you time and money.Identifying Severe Issues

Some problems are too complex for DIY fixes. If the lift stops working suddenly, it may indicate a serious issue. Strange noises or jerky movements are also red flags. These could mean internal damage or mechanical failure. Electrical problems can be dangerous to fix alone. Always consider your safety first.Finding A Qualified Technician

Finding the right technician is crucial. Look for someone with experience in Tommy Gate repairs. Check their credentials and read reviews. A good technician will diagnose the problem quickly. They will also offer a reliable solution. Investing in professional help ensures your lift’s longevity. “`

Credit: www.tommygate.com

Frequently Asked Questions

How To Reset A Tommy Gate Lift?

Resetting involves turning the power off, waiting 30 seconds, then turning it back on.

What Causes A Tommy Gate To Stop Working?

Common issues include low battery, loose connections, or damaged wires. Check these first.

Why Is My Tommy Gate Beeping?

Beeping usually means a low battery or a fault in the system. Inspect both.

How To Fix A Slow Tommy Gate?

Lubricate moving parts, check hydraulic fluid levels, and ensure no obstructions.

Can I Troubleshoot Tommy Gate Myself?

Yes, basic checks include inspecting connections, battery charge, and hydraulic fluid levels.

Conclusion

Fixing a Tommy Gate can be straightforward with the right steps. Regular maintenance helps avoid common issues. Always check connections and ensure proper lubrication. Simple adjustments often resolve problems. Consult the manual for specific solutions. Professional help might be necessary for complex issues.

Keep your Tommy Gate in top shape for reliable performance. With these tips, troubleshooting becomes less daunting. Stay proactive and your gate will last longer. Happy lifting!