Is your Trane unit acting up, and you’re not sure where to start? Don’t worry—you’re not alone.

Troubleshooting a Trane RTRM board can feel overwhelming, especially when your HVAC system isn’t running as it should. But here’s the good news: with the right guidance, you can identify the issue and potentially save yourself time, money, and frustration.

In this post, we’ll walk you through the essential steps to troubleshoot your Trane RTRM board effectively. Whether your system won’t turn on, displays error codes, or simply isn’t performing optimally, we’ve got you covered. By the end, you’ll feel more confident tackling the problem and getting your HVAC system back on track. Let’s dive in and start solving this together!

Common Issues With Trane Rtrm Boards

Trane RTRM boards are the brain of many HVAC systems, ensuring smooth operation and communication between various components. But like any electronic part, they can encounter issues over time. Knowing the common problems can save you time, money, and frustration when troubleshooting your system.

Power Supply Problems

A faulty power supply is one of the most frequent issues with Trane RTRM boards. If the board doesn’t get consistent power, the entire system can fail to operate. Start by checking the power connections and ensuring the voltage matches the board’s requirements.

Loose wires or a blown fuse can also disrupt power. Inspect the wiring and replace fuses if necessary. A multimeter is your best friend here—use it to confirm proper voltage and continuity.

Have you ever had your HVAC suddenly stop working on the hottest day of the year? Often, it’s just a minor power supply issue. Double-checking connections can sometimes restore functionality in minutes.

Communication Errors

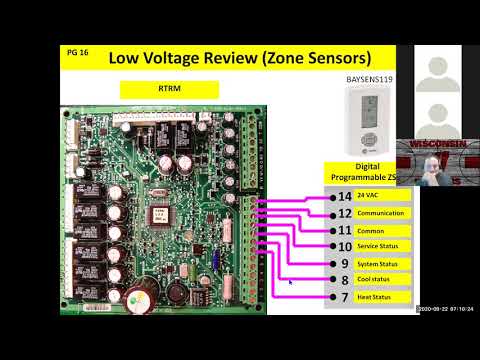

Communication errors between the RTRM board and other system components can cause erratic performance. This issue often shows up as error codes on the thermostat or a complete lack of response.

Check the communication lines for physical damage, like frayed wires or loose connectors. Re-seating the connectors can resolve many issues quickly.

Keep an eye out for interference, too. Nearby electrical equipment can disrupt communication signals. Moving the device or using shielded cables can help maintain proper data transmission.

Sensor Malfunctions

Faulty sensors can mislead the RTRM board, resulting in incorrect system behavior. For example, a temperature sensor reading inaccurately might cause the system to overcool or underheat.

Test sensors using a multimeter to verify their readings. Replace any that show irregular values or fail to respond.

If your HVAC feels “off,” don’t ignore it. Sensor issues can often seem minor but lead to bigger problems if not addressed promptly. A quick check can prevent unnecessary wear and tear on your system.

Tools Needed For Troubleshooting

Having the right tools for troubleshooting a Trane RTRM board can make the entire process smoother and save you time. These tools are essential for pinpointing issues and ensuring your HVAC system runs efficiently. Whether you’re a seasoned technician or a DIY enthusiast, getting familiar with these tools can help you approach the task confidently.

Multimeter Usage

A multimeter is your go-to tool for diagnosing electrical issues in the RTRM board. It helps you check voltage levels, continuity, and resistance. For example, you can use it to measure whether the board is receiving proper power from its source.

Set your multimeter to the appropriate setting—voltage or ohms depending on what you’re testing. Always double-check your readings against the system’s specifications in the manual. If you’re new to multimeters, practice with simpler circuits to get comfortable.

Diagnostic Software

Trane provides diagnostic software tools to simplify troubleshooting. These tools allow you to connect to the RTRM board and view error codes, system status, and real-time data. This software can save you hours of trial-and-error work.

Make sure you have the latest version installed on your laptop or tablet. Connect your device to the board using the recommended interface cable. If a specific error code pops up, refer to the manual for detailed instructions on how to resolve it.

Wiring Diagrams

Wiring diagrams are invaluable when tracing connections and identifying faulty components. They map out how the RTRM board interacts with other parts of the HVAC system. If a wire is disconnected or damaged, the diagram will guide you to its source.

Keep a printed copy or digital version handy while working. Check for any loose or burnt wires that might be causing issues. Match the wiring colors and labels precisely—one wrong connection could lead to further problems.

Do you already have these tools, or are you missing any? Taking inventory before starting can save you from unnecessary trips to the store or delays in your troubleshooting process. The right tools aren’t just helpful—they’re essential for getting the job done efficiently!

Step-by-step Troubleshooting Guide

Trane RTRM boards are essential for controlling HVAC systems effectively. Troubleshooting issues with these boards can save time and money. This step-by-step guide will help you identify and fix common problems. Follow these clear steps to ensure your system runs smoothly.

Checking Power Connections

Start by inspecting the power connections to the RTRM board. Ensure all wires are securely connected to their terminals. Look for loose or damaged wires that may disrupt power flow. Verify that the main power supply is switched on and functioning properly.

Use a multimeter to confirm continuity in the power supply wiring. Proper connections are critical for the board to operate efficiently. Replace any damaged wires or connectors immediately.

Inspecting Fuses And Relays

Fuses and relays protect the RTRM board from electrical overloads. Locate the fuses on the board and check if they are blown. A blown fuse will often appear discolored or broken inside.

If a fuse is blown, replace it with one of the same rating. Next, inspect the relays for proper operation. Listen for a clicking sound when the relay activates. Replace faulty relays to restore normal function.

Testing Voltage Levels

Use a multimeter to test voltage levels at key points on the board. Verify that the board is receiving the correct input voltage from the power source. Incorrect voltage can cause the board to malfunction.

Measure the output voltage to connected components like sensors or motors. Ensure the readings match the manufacturer’s specifications. Abnormal voltage levels may indicate a deeper issue requiring professional attention.

Quick Fixes For Common Problems

When your Trane RTRM board isn’t functioning as it should, it can feel overwhelming. But don’t worry—many common issues can be resolved quickly with a bit of troubleshooting. Here’s a breakdown of actionable fixes that you can try today to get your system back on track.

Resetting The Rtrm Board

Sometimes, a simple reset can solve many issues. To reset the RTRM board, turn off the power to your HVAC unit at the breaker. Wait for about 30 seconds, then turn it back on.

After the system powers up, observe if the issue resolves. If not, check the diagnostic LED lights on the board. These lights can give you a clue about the problem—like a blinking pattern indicating a specific fault code.

Don’t forget to consult the owner’s manual to decode the fault codes. A reset is quick, but if the problem persists, it might point to a deeper issue.

Replacing Faulty Sensors

Faulty sensors can wreak havoc on your system’s performance. Look out for signs like inconsistent cooling or heating, or error codes related to temperature or pressure sensors.

To replace a sensor, first identify the faulty one—temperature sensors, pressure sensors, or humidity sensors are common culprits. Turn off the power before removing the defective sensor and installing the new one.

Once installed, power up the unit and test the system. A faulty sensor replacement can often restore optimal performance in minutes.

Updating Firmware

Outdated firmware might cause communication errors or limit the functionality of your RTRM board. Check your system manual or manufacturer’s website to see if a firmware update is available.

To update, you’ll usually need a USB cable and a computer. Connect the board to your computer, download the update file, and follow the on-screen instructions.

After the update, restart the system and monitor its performance. Firmware updates can fix bugs and improve efficiency, saving you from future headaches.

Have you tried any of these fixes before? If not, why not start with the easiest one today and see the results for yourself?

Preventive Maintenance Tips

Proper maintenance ensures a Trane RTRM board works efficiently. Preventive care reduces unexpected failures and prolongs the system’s lifespan. Regular checks help identify issues early, saving money and effort.

Below are key maintenance tips to keep your board running smoothly.

Regular Inspections

Inspect the board for visible damage or loose components. Look for burnt spots, cracks, or corrosion. Check wiring for frays or disconnections. Regular checks help identify wear and tear before it worsens.

Cleaning Connections

Dust and debris can affect electrical connections. Use a soft brush or compressed air to clean terminals. Ensure all connections are free of dirt for better conductivity. Clean components improve overall system reliability.

Monitoring System Performance

Observe the board’s performance during system operation. Listen for unusual noises or irregular behaviors. Check for error codes displayed on the system. Consistent monitoring helps detect underlying issues quickly.

When To Call A Professional

Complex issues with Trane RTRM boards often require expert attention. Call a professional if troubleshooting doesn’t resolve errors or system failures.

Diagnosing and fixing issues with a Trane RTRM board can be tricky. While some minor problems are manageable, others need professional expertise. Knowing when to call a technician ensures proper repairs. It also prevents further damage to the system.

Signs Of Advanced Issues

Some problems show the need for a professional. If the HVAC system fails to start, it could be a serious issue. Unresponsive components or repeated error codes often require expert evaluation. Flickering or dimming lights on the RTRM board may signal deeper electrical faults. Strange smells or unusual noises coming from the unit are also warning signs. These could indicate wiring problems or internal damage. Ignoring such issues may lead to costly repairs later.

Warranty Considerations

Repairs handled by unqualified personnel might void the warranty. Many manufacturers require licensed technicians for maintenance and troubleshooting. This ensures the system stays covered under warranty terms. Using a professional also guarantees proper documentation of repairs. This can be valuable for future claims or maintenance needs. Always check warranty details before attempting repairs yourself.

Safety Concerns

Working on an RTRM board can pose safety risks. High-voltage components may cause shocks if handled improperly. Incorrect repairs could also lead to electrical fires or system malfunctions. Technicians have the tools and training to handle these risks safely. They can diagnose and fix the problem without endangering anyone. If safety is a concern, it’s best to leave the job to an expert. `

Conclusion

Proper troubleshooting ensures your Trane RTRM board works efficiently. Start by checking connections and power supply. Address error codes promptly to prevent further issues. Regular maintenance can help avoid unexpected breakdowns. Use the manual as a reliable guide for repairs.

Consult a professional if problems persist or seem complex. Understanding the basics saves time and reduces stress. Keep your system running smoothly with consistent care and attention. A well-maintained system enhances performance and longevity. Stay proactive to minimize disruptions and costly repairs.