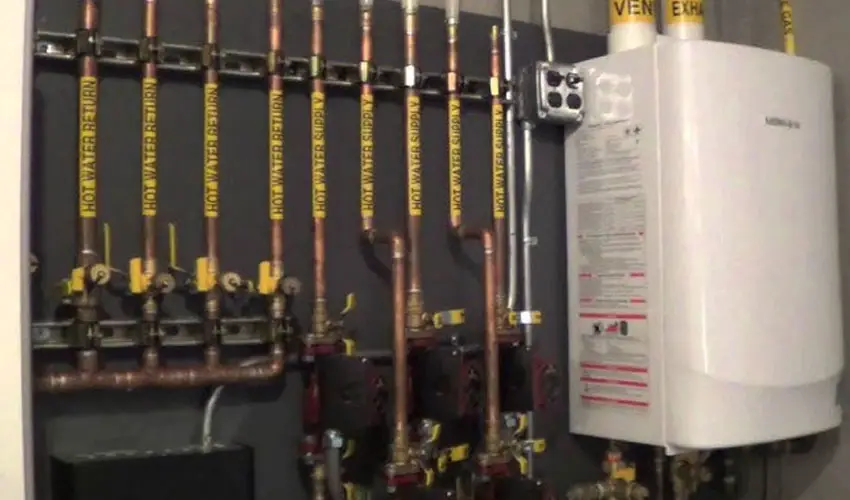

The Triangle Tube Prestige Troubleshooting Guide helps diagnose and fix common boiler issues. It ensures optimal performance and efficiency.The Triangle Tube Prestige boiler is a popular choice for homeowners seeking reliable heating solutions. Like any complex system, it can sometimes experience issues that need troubleshooting. This guide provides step-by-step instructions to identify and resolve common problems. Regular maintenance and timely troubleshooting can extend the boiler’s lifespan and enhance its efficiency.

Clear and concise guidance makes it easy for users to pinpoint issues and find solutions without needing extensive technical knowledge. This troubleshooting guide is an essential resource for maintaining the performance of your Triangle Tube Prestige boiler.

Common Issues

Dealing with a Triangle Tube Prestige boiler can sometimes be challenging. Knowing the common issues helps in troubleshooting effectively. Here, we will discuss three frequent problems and their solutions.

No Heat

If your Triangle Tube Prestige boiler is not producing heat, check the thermostat first. Ensure it is set to the desired temperature. Inspect the power supply to the boiler. Make sure all switches are turned on. Examine the circuit breaker for any tripped switches.

Another aspect to check is the boiler pressure. The ideal pressure range is 1.0 to 2.0 bar. If the pressure is too low, use the filling loop to add water. If you are unsure, consult your user manual for detailed instructions.

Finally, look at the pilot light. If it’s off, follow the manual’s relighting instructions.

Error Codes

Error codes on your Triangle Tube Prestige boiler indicate specific issues. Refer to your user manual for a list of codes and their meanings. Common error codes include:

- E01: Ignition failure

- E02: Flame loss

- E03: Overheat lockout

For E01 and E02, check the gas supply and air vents. Ensure they are clean and unobstructed. For E03, check the thermostat settings and the heat exchanger. Ensure they are not blocked or dirty.

Water Leaks

Water leaks are a common issue with any boiler. Check around the boiler and the pipes for visible signs of leaks. If you find any, tighten the connections.

If the leak persists, inspect the pressure relief valve. A faulty valve often causes leaks. Replacing it might solve the problem. Also, check the expansion tank. If it is full of water, it needs to be drained or replaced.

Regular maintenance can prevent most water leaks. Clean and inspect the boiler periodically.

Diagnostic Tools

Diagnostic tools play a vital role in troubleshooting your Triangle Tube Prestige boiler. These tools help identify issues quickly and accurately. This section covers the essential diagnostic tools: multimeter, pressure gauge, and visual inspection.

Multimeter Usage

A multimeter is an essential tool for checking electrical components. It measures voltage, current, and resistance. Follow these steps to use a multimeter:

- Set the multimeter to the correct setting (voltage, current, resistance).

- Connect the multimeter probes to the component terminals.

- Read the measurement on the display.

Always ensure the boiler is turned off before testing. This ensures safety and prevents damage.

Pressure Gauge

A pressure gauge measures the boiler’s water pressure. Correct pressure is crucial for efficient operation. Follow these steps to use a pressure gauge:

- Locate the pressure gauge on the boiler.

- Read the current pressure level.

- Compare it to the recommended pressure range (usually 1-2 bars).

If the pressure is too low or too high, adjust it accordingly. Use the boiler’s manual for guidance.

Visual Inspection

A visual inspection helps identify obvious issues. Follow these steps for a thorough inspection:

- Check for any visible leaks around the boiler.

- Inspect the pipes and connections for damage.

- Look for any error codes displayed on the boiler’s screen.

Regular visual inspections can prevent minor issues from becoming major problems. They help maintain the boiler’s efficiency and longevity.

Error Code Solutions

Encountering error codes on your Triangle Tube Prestige boiler? Don’t worry. This guide will help you understand and resolve these issues. Let’s dive into the specific errors and their solutions.

Resolving E01 Error

The E01 error indicates an issue with the ignition process. Follow these steps to fix it:

- Check the gas supply. Ensure the gas valve is open.

- Inspect the ignition electrode. Clean it if it’s dirty.

- Reset the boiler. Press the reset button and wait for the boiler to restart.

If these steps don’t work, contact a professional. They can further diagnose and solve the problem.

Fixing E02 Error

The E02 error points to a flame loss. Here’s how to address it:

- Verify the gas pressure. It should match the boiler’s requirements.

- Examine the flame sensor. Clean or replace if necessary.

- Check for obstructions in the vent system. Clear any blockages.

If the error persists, it’s best to get help from a technician.

Addressing E03 Error

The E03 error indicates a fan failure. To resolve it, follow these steps:

- Inspect the fan. Ensure it’s clean and free of debris.

- Check the wiring. Ensure all connections are secure.

- Test the fan motor. Replace it if it’s not working.

If you can’t fix it yourself, seek assistance from a qualified technician.

Heating Problems

Heating problems can be frustrating. They often need quick fixes. This guide helps you troubleshoot your Triangle Tube Prestige boiler.

Thermostat Check

The thermostat must be set correctly. If it’s not, adjust the temperature. Make sure it is in heating mode. Check if the thermostat has power. Replace batteries if needed.

Look at the wiring. Loose wires can cause issues. Tighten any loose connections.

Circulator Pump Issues

The circulator pump moves hot water. If it’s faulty, the heating will fail. Listen for strange noises from the pump. It should run quietly.

Feel the pump. It should be warm, but not hot. If it’s cold, it might be broken.

Check the power supply. Make sure the pump is getting electricity. Replace the pump if it doesn’t work.

Air In System

Air in the system can block hot water. Bleed the radiators to remove air. Use a radiator key to open the valve.

Place a cloth under the valve. Open it slowly. Let the air escape until water flows. Close the valve tightly.

Repeat this for each radiator. Check the pressure gauge on the boiler. It should be within the normal range. Add water if needed.

Water Leak Fixes

Water leaks in your Triangle Tube Prestige boiler can cause serious damage. Addressing these leaks quickly ensures your system runs efficiently. Below, you will find a detailed troubleshooting guide to help you fix water leaks.

Identifying Leak Source

First, you need to find the source of the leak. Look around the boiler for wet spots or drips. Common leak sources include connections, valves, and seals. Use a flashlight to inspect hard-to-see areas. If you find a damp or wet area, you have located your leak source.

Seal Replacement

Worn seals often cause leaks. To replace a seal, you need the correct tools. Follow these steps:

- Turn off the boiler and let it cool.

- Locate the faulty seal.

- Remove the old seal using a wrench.

- Clean the area around the seal.

- Install the new seal and tighten it properly.

Always use seals that match your boiler model. This ensures a perfect fit and prevents future leaks.

Valve Inspection

Valves can also be leak sources. Inspecting valves regularly helps you catch issues early. Follow these steps for valve inspection:

- Turn off the boiler and let it cool.

- Check all valves for signs of wear or damage.

- If a valve is leaking, tighten it with a wrench.

- If tightening does not stop the leak, replace the valve.

Use only high-quality valves designed for your boiler. This ensures durability and reliability.

Maintenance Tips

Keeping your Triangle Tube Prestige boiler in top shape requires regular maintenance. Here are some essential tips to ensure your boiler runs smoothly and efficiently.

Regular Cleaning

Regular cleaning is crucial for your boiler’s efficiency. Dust and debris can accumulate and affect performance. Follow these steps for thorough cleaning:

- Turn off the boiler and let it cool.

- Remove the outer casing carefully.

- Use a soft brush to clean the heat exchanger.

- Wipe the exterior with a damp cloth.

- Check the vents for blockages.

Component Checks

Regularly checking components ensures your boiler works well. Inspect these parts frequently:

| Component | What to Check |

|---|---|

| Heat Exchanger | Look for signs of wear or damage. |

| Burner | Ensure it is clean and free of debris. |

| Pressure Gauge | Check for correct pressure levels. |

| Pumps | Listen for unusual noises. |

Seasonal Maintenance

Seasonal maintenance can prolong your boiler’s life. Prepare your boiler for different seasons with these tips:

- Winter: Increase usage, so inspect more often.

- Spring: Clean thoroughly after heavy use.

- Summer: Perform deep cleaning and checks.

- Autumn: Prepare for increased usage.

Follow these maintenance tips to keep your Triangle Tube Prestige boiler running efficiently. Regular care ensures longevity and reduces repair costs.

When To Call A Professional

Maintaining your Triangle Tube Prestige boiler is vital. Sometimes, troubleshooting becomes too complex. Knowing when to call a professional can save time and money.

Persistent Issues

Some issues keep coming back. If your boiler has persistent issues, it’s time to call a professional. Common persistent issues include:

- Frequent error codes

- Water temperature fluctuations

- Low water pressure

These problems need expert attention. A professional can diagnose and fix the root cause.

Complex Repairs

Some repairs are too complex for DIY. If the repair involves electrical components, you need a professional. Electrical repairs can be dangerous. They require specific knowledge and tools.

Here are some examples of complex repairs:

| Repair Type | Description |

|---|---|

| Control Board Issues | Problems with the main control board |

| Gas Valve Adjustments | Adjusting or replacing the gas valve |

| Heat Exchanger Problems | Leaks or blockages in the heat exchanger |

Safety Concerns

Safety is crucial. If there are any gas leaks, you must call a professional immediately. Leaks can cause explosions or carbon monoxide poisoning. Signs of a gas leak include:

- Smell of gas

- Hissing sounds

- Dead plants near the boiler

Additionally, if your boiler shows signs of electrical issues, such as flickering lights or tripping circuits, get professional help right away. These issues can lead to fires or electrocution.

Frequently Asked Questions

How To Reset Triangle Tube Prestige Boiler?

To reset, press the reset button on the control panel for 3 seconds.

Why Is My Triangle Tube Prestige Not Heating?

Check for error codes, ensure gas supply, and verify thermostat settings.

What Causes Triangle Tube Prestige Error Codes?

Error codes indicate issues like low water pressure, ignition failure, or sensor faults.

How To Fix Triangle Tube Prestige Ignition Issue?

Clean the igniter, check gas supply, and ensure proper venting.

Why Does My Triangle Tube Prestige Keep Shutting Off?

Possible causes include overheating, low water pressure, or a faulty thermostat.

Conclusion

Troubleshooting your Triangle Tube Prestige boiler can be straightforward with the right guidance. Follow these steps to ensure efficiency. Regular maintenance will help prevent issues. Remember, always consult a professional for complex problems. Keep your system running smoothly for years with these tips.

Enjoy a warm, comfortable home all year round.