Are you feeling frustrated with your Unimac commercial washer acting up again? You’re not alone.

Many people experience hiccups with their laundry equipment, but don’t worry—help is at hand. Imagine the satisfaction you’ll feel when you solve those pesky issues yourself, saving time and money. In this guide, we’ll walk you through straightforward troubleshooting steps for your Unimac washer.

You’ll gain insights that will empower you to tackle common problems head-on, ensuring your laundry business runs smoothly. Ready to dive into solutions that work? Let’s get started!

Common Washer Issues

Unimac commercial washers are reliable and efficient. Yet, like all machines, they sometimes face issues. Recognizing common problems helps in troubleshooting. This knowledge ensures your washer runs smoothly, reducing downtime and maintenance costs.

Machine Not Starting

Does your Unimac washer refuse to start? First, check the power connection. Ensure the plug is secure in the outlet. Next, inspect the circuit breaker. A tripped breaker can prevent the machine from starting. Also, examine the washer’s door. The machine won’t start if the door isn’t closed properly. Lastly, ensure the control settings are correct. Incorrect settings can halt the starting process.

Water Drainage Problems

Water not draining? This issue can cause delays. Check the drain hose for clogs. A blocked hose can prevent water from exiting. Also, inspect the pump filter. A dirty filter can restrict water flow. Finally, examine the drain valve. A malfunctioning valve can lead to drainage issues. Address these areas to solve water drainage problems.

Excessive Vibration Or Noise

Vibration and noise can disrupt your laundry process. Check if the washer is level. An uneven surface can cause excessive shaking. Examine the load inside the drum. An unbalanced load can lead to noise and vibration. Finally, inspect the shock absorbers. Worn-out absorbers can increase vibration. Regular checks help maintain a quiet and smooth operation.

Diagnosing Electrical Problems

Electrical issues in Unimac commercial washers can be perplexing, especially if you’re in the middle of a busy laundry day. Understanding how to diagnose these problems efficiently can save you time and prevent prolonged downtime. Whether you’re a seasoned technician or a business owner trying to troubleshoot your equipment, pinpointing the exact cause of electrical problems is crucial. Let’s dive into some key areas you should examine when diagnosing electrical issues.

Checking Power Supply

Start with the simplest step: ensuring your washer is receiving power. Check the power cord for any visible damage. A frayed or broken cord can interrupt the electricity flow. Ensure the plug is securely inserted into the outlet. Sometimes, a loose connection is all it takes to cause a malfunction.

If everything looks intact, test the outlet with another device to confirm it’s working. A faulty outlet can be the root of your washer’s woes. Consider using a multimeter to check voltage levels for precision. Does your outlet supply the correct voltage?

Inspecting Fuses And Breakers

Fuses and breakers act as the washer’s safety guards, preventing electrical overloads. If your washer suddenly stops working, a tripped breaker or a blown fuse might be the culprit. Head to your electrical panel and check if the breaker for your washer has tripped.

Reset the breaker if necessary, but if it trips again, this indicates a deeper issue. Examine any fuses associated with the washer. A blown fuse is a clear sign of an electrical problem. Replacing a fuse is straightforward—just ensure you use the correct type and rating.

Testing Control Panel

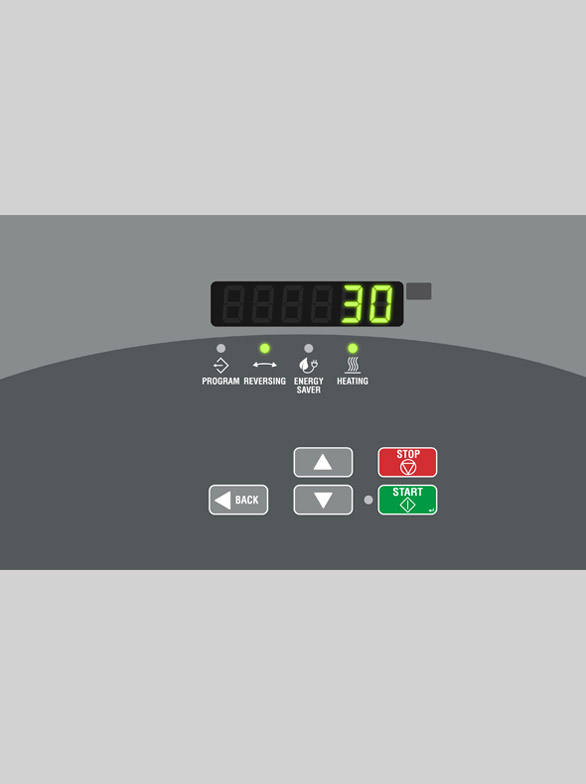

The control panel is your washer’s brain, and electrical problems here can halt operations. First, ensure the control panel lights are functioning. If they’re not, you might be dealing with an internal electrical fault.

Use a multimeter to test the control panel’s circuits. This can reveal if electricity is flowing properly. If the panel shows no signs of life despite a working power supply, it might need repairs or replacement. When was the last time your control panel was serviced?

Diagnosing electrical problems requires patience and a methodical approach. By systematically checking these areas, you can identify issues before they escalate. Have you encountered a unique electrical issue with your Unimac washer? Share your experiences and solutions below!

Addressing Mechanical Failures

Addressing mechanical failures in Unimac commercial washers can be a daunting task, especially when your business relies on these machines running smoothly. However, understanding and identifying the root cause of issues can save you time and money. Let’s dive into some common mechanical problems and how you can troubleshoot them effectively.

Belt And Pulley Inspection

One of the most common issues with commercial washers is a worn or broken belt. A loose belt can cause the drum to spin inefficiently, affecting wash quality. Check the belt for any signs of wear or cracks. If you notice any damage, it’s time for a replacement.

Inspect the pulleys for misalignment or damage. Misaligned pulleys can cause excessive wear on the belt, leading to premature failure. Ensure they are aligned properly to prevent future issues. Don’t overlook this small but crucial part of the inspection process.

Motor Malfunction

Is your washer making unusual noises or failing to start? The motor might be the culprit. First, check the motor connections and ensure they are secure. Loose connections can cause intermittent power issues.

If the problem persists, consider whether the motor might be overheating. Overheating can occur due to overloading or insufficient ventilation. To extend the motor’s life, ensure the washer isn’t overloaded and the ventilation is adequate.

Drum Alignment

A misaligned drum can result in noisy operation or even damage to the washer over time. Check if the drum is level and aligned properly. An unbalanced load can also cause the drum to shift, so ensure the washer is on a stable surface.

Are your clothes coming out wetter than expected? Misalignment might be affecting the spin cycle. Adjust the drum alignment if necessary to achieve optimal performance. Ensuring proper drum alignment can prevent long-term damage and costly repairs.

Have you ever experienced any of these issues? Share your insights or tips in the comments below. Your experiences might just help someone else facing the same challenges.

Credit: uni-sourcesupply.com

Resolving Water Supply Issues

Experiencing water supply issues with your Unimac commercial washer can disrupt your laundry operations and lead to costly downtimes. Addressing these problems promptly can save you from a lot of hassle. Let’s dive into some common water supply issues you might face and how to fix them.

Inlet Valve Blockages

One of the first things you should check if your washer isn’t filling with water is the inlet valve. Blockages in the valve can prevent water from entering the machine. Imagine dealing with a backlog of laundry, only to find out a simple blockage was the culprit.

To resolve this, disconnect the washer from power and water sources. Remove the inlet hoses and inspect the valve for debris or mineral build-up. Cleaning it thoroughly can often restore normal water flow. Have you checked your inlet valve lately?

Hose Leaks

Leaks in the water hoses can cause inadequate water supply to your washer. This issue is not only wasteful but can also lead to higher water bills. If your washer is not filling up as expected, it might be time to examine those hoses.

Look for visible signs of wear, such as cracks or bulges, in the hoses. You can also run your fingers along them to feel for moisture. Replacing damaged hoses is a straightforward task and ensures your washer operates efficiently. When was the last time you inspected your hoses?

Water Pressure Concerns

Insufficient water pressure can severely impact your washer’s performance. This can happen if there’s a problem with your building’s water supply or if the pressure regulator is malfunctioning. Have you considered this factor when diagnosing your washer issues?

To test the water pressure, use a pressure gauge connected to the nearest faucet. Ideally, the pressure should be between 20 and 116 psi for optimal performance. If the pressure is too low, contacting a plumber might be necessary. How confident are you in your water pressure levels?

Tackling these issues head-on can keep your Unimac commercial washer running smoothly. Regular maintenance and timely checks can prevent small problems from becoming major headaches. Are you ready to take control of your washer’s water supply issues?

Dealing With Drainage Challenges

Dealing with drainage challenges in your Unimac commercial washer can be frustrating. Imagine standing in front of your machine, ready to tackle a mountain of laundry, only to find it stubbornly refusing to drain. It’s a moment that can halt your operation and leave you puzzled. But fear not, tackling drainage issues often boils down to a few key areas that, with a bit of know-how, can be resolved quickly and efficiently.

Pump Obstructions

The pump is crucial for moving water out of the washer. If water isn’t draining, check for obstructions. Small items like coins or fabric can block the pump. Remove the access panel and inspect the pump for debris. You might be surprised at what you find! Once cleared, test the machine to see if the issue persists.

Clogged Filters

Filters catch debris before it reaches the pump. If these filters become clogged, water drainage can slow to a crawl. Regularly clean the filters to ensure smooth operation. Simply remove the filter cover and rinse it under warm water. A clean filter can make a world of difference in your washer’s performance.

Drain Hose Inspection

The drain hose carries water away from the washer. Inspect it for kinks or clogs. Sometimes, the hose can be inadvertently pinched or blocked. Straighten any kinks and use a flexible brush to clear the inside of the hose. A well-maintained hose ensures effective water drainage.

Have you ever faced these drainage challenges? Share your experiences and insights. Your story might help someone else get their Unimac washer back on track!

Handling Unusual Noises

Unusual noises in Unimac commercial washers can signal a problem. These sounds might indicate minor or serious issues. Identifying the source quickly prevents further damage.

Listen closely to understand the noise type. Rattling, grinding, or banging sounds provide clues. Each type of noise has a specific cause.

Loose Components

Loose components often cause rattling noises. Check the washer’s exterior panels and fasteners. Tighten any that are loose. Inspect the drum and motor mountings as well. Secure these components to eliminate the noise.

Bearing Wear

Grinding sounds may suggest bearing wear. Bearings support the drum’s rotation. Worn bearings create friction and noise. Inspect the bearings if the noise persists. Replacing worn bearings improves performance and reduces noise.

Foreign Objects In Drum

Foreign objects in the drum can cause unusual noises. Items like coins or buttons create loud banging sounds. Inspect the drum for foreign objects. Remove any found to stop the noise and protect the washer.

Regular maintenance helps avoid these issues. Listen carefully and act quickly to fix problems. Maintaining your Unimac washer ensures efficient operation.

Expert Maintenance Tips

Unimac commercial washers are reliable machines. Regular maintenance keeps them running smoothly. Expert maintenance tips can prevent breakdowns and extend lifespan. Careful attention to cleaning, professional checks, and timely parts replacement is key.

Regular Cleaning Routine

Clean the washer exterior daily. Wipe surfaces with a damp cloth. Remove lint and debris from the lint trap. Check hoses for any clogs or leaks. Monthly, clean the drum with mild detergent. This prevents residue build-up and keeps the washer fresh.

Scheduled Professional Checks

Regular inspections by a technician are essential. Schedule checks every six months. Professional checks ensure all parts work correctly. They can detect issues early and prevent costly repairs. This keeps your washer running efficiently.

Parts Replacement Guidelines

Replace worn parts promptly. Check the belt and motor regularly. If you hear unusual sounds, inspect them immediately. Use original parts for replacements. This ensures compatibility and longevity. Follow the manufacturer’s guidelines for part replacement.

Credit: unimac.com

Credit: www.scribd.com

Frequently Asked Questions

How Do I Fix A Leaking Unimac Washer?

Check the hoses and connections for damage. Tighten any loose fittings. Replace damaged parts to stop leaks.

Why Is My Unimac Washer Not Starting?

Ensure the door is fully closed. Check the power supply and reset the circuit breaker. Inspect the control panel.

What Causes Unimac Washers To Vibrate Excessively?

Uneven loads and unbalanced leveling can cause vibrations. Adjust the load and check the leveling feet.

How Do I Resolve Unimac Washer Error Codes?

Consult the user manual for error code meanings. Follow troubleshooting steps or contact support for help.

Why Won’t My Unimac Washer Drain Water?

Inspect the drain hose for clogs. Check the pump filter. Ensure proper installation and maintenance.

Conclusion

Troubleshooting Unimac washers doesn’t have to be difficult. Start by identifying the problem. Check power sources and connections. Clean filters regularly to prevent blockages. Inspect belts and hoses for wear. Use manufacturer’s manual for guidance. Contact customer support for unresolved issues.

Regular maintenance can prevent many problems. Keep your washer running smoothly for years. A well-maintained washer saves time and money. Happy washing!