VMI ramp troubleshooting can be tricky. It’s essential to ensure smooth operation.

VMI ramps help individuals with mobility challenges access vehicles more easily. But like any mechanical device, they can have issues. If your VMI ramp isn’t working properly, you need to know how to diagnose and fix it. This guide will help you identify common problems and provide solutions.

Understanding the basics of VMI ramp troubleshooting can save time and frustration. Let’s explore the steps to keep your ramp functional and reliable.

Common Vmi Ramp Issues

VMI ramps are essential for vehicle accessibility. But they can have issues. Knowing common problems helps with quick fixes. This section covers typical VMI ramp troubles.

Electrical Problems

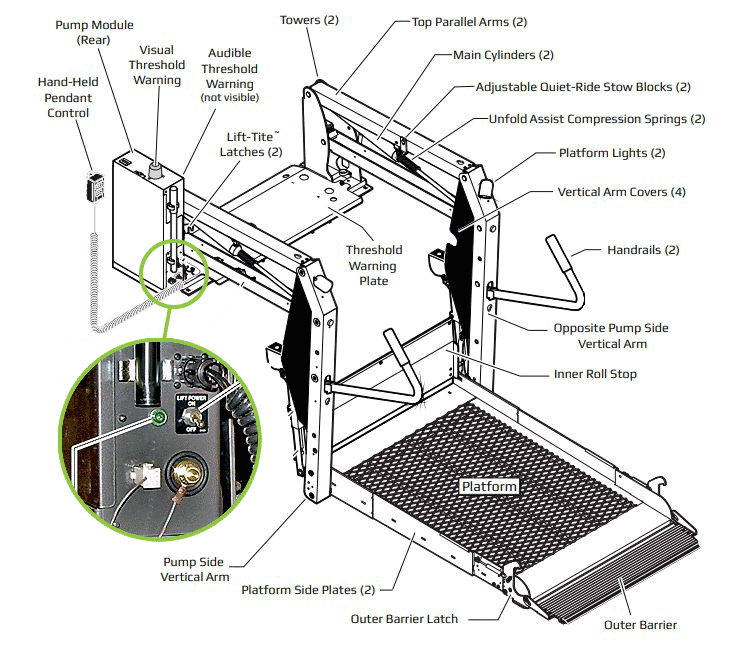

Electrical issues are common in VMI ramps. Faulty wiring can prevent proper operation. Inspect connections for corrosion or damage. Check the battery and fuses. Ensure they are in good condition. A multimeter helps in checking voltage levels. Low voltage can cause malfunction.

Mechanical failures can also disrupt VMI ramps. Regular wear and tear affect performance. Hinges and joints may become loose. Tighten them to ensure smooth operation. Look for any signs of rust. Rust can lead to breakdowns. Lubricate moving parts regularly. This reduces friction and prolongs life.

Diagnosing Electrical Problems

Diagnosing electrical problems in a VMI ramp can be daunting. But breaking it down step-by-step makes it manageable. This guide will walk you through the process. Focus on the essentials like checking connections and testing circuitry.

Checking Connections

Start by inspecting all electrical connections. Loose or corroded connections can cause issues. Use a multimeter to check for continuity. Ensure all connectors are tight and free of corrosion.

- Identify all connection points.

- Check for any visible damage.

- Use a wire brush to clean corroded terminals.

- Reattach and secure all connections.

Another important step is to check the battery terminals. Ensure they are clean and tight. Faulty battery connections can lead to power issues.

Testing Circuitry

Next, you need to test the electrical circuitry. Use a multimeter to check voltage levels. Ensure the circuit is receiving the correct voltage.

- Turn off the ramp’s power.

- Set the multimeter to the correct voltage range.

- Connect the multimeter probes to the circuit.

- Check the readings against the manufacturer’s specifications.

If the voltage readings are off, there may be a problem with the circuit. Look for signs of wear or damage in the wires. Replace any damaged components immediately.

Lastly, ensure all fuses are intact. Blown fuses can disrupt the electrical flow. Replace any blown fuses with the correct type.

Following these steps will help you diagnose electrical issues in your VMI ramp effectively.

Mechanical Failures

Mechanical failures in VMI ramps can halt operations. Diagnosing issues quickly helps ensure smooth functioning. Understanding common mechanical failures and their fixes can save time and resources.

Inspecting Components

Begin by inspecting components regularly. Check for loose bolts, worn-out parts, and any signs of damage. Use a checklist to ensure nothing is overlooked.

- Check the ramp’s hydraulic system for leaks.

- Examine the wiring for wear or damage.

- Ensure the motor is functioning properly.

Regular inspections can catch issues early. This prevents bigger problems down the line.

Addressing Wear And Tear

Wear and tear is inevitable with frequent use. Addressing it promptly is crucial.

| Component | Common Issues | Maintenance Tips |

|---|---|---|

| Hydraulic Cylinder | Leaking fluid | Check seals and replace if needed |

| Wiring | Frayed wires | Replace damaged wires |

| Motor | Overheating | Ensure proper ventilation |

By following these tips, you can extend the life of your VMI ramp. Regular maintenance is key to preventing mechanical failures.

Credit: movemobility.ca

Hydraulic System Troubles

Hydraulic system troubles can disrupt the smooth operation of your Vmi ramp. Understanding and addressing these issues is crucial. This section will guide you through common hydraulic system problems.

Fluid Levels

Check the hydraulic fluid levels regularly. Low fluid levels can affect ramp performance. This can cause slow or erratic movements. Ensure the fluid reservoir is filled to the recommended level. Use the correct hydraulic fluid type.

Pump Performance

The pump is vital for hydraulic system efficiency. Monitor the pump’s performance closely. Listen for unusual noises. These may indicate wear or damage. Inspect for leaks around the pump area. Replace the pump if necessary. Regular maintenance can prevent serious issues.

Software Glitches

Software glitches can be a common issue in Vmi ramp systems. These glitches can disrupt the smooth operation of the ramp. Understanding and addressing these software issues is essential for maintaining functionality. Below are some key areas to consider while troubleshooting software glitches.

Firmware Updates

Firmware updates are crucial for the optimal performance of your Vmi ramp. Regular updates ensure that the system runs smoothly. Outdated firmware can cause various operational issues. To update the firmware, follow the steps provided by the manufacturer.

- Check the current firmware version.

- Visit the official website for any available updates.

- Download the update file.

- Follow the instructions to install the update.

Always ensure your device is connected to a stable power source during the update. Interrupted updates can lead to more significant problems.

System Resets

Sometimes, performing a system reset can resolve software glitches. A system reset reverts the device to its default settings. This process can eliminate any corrupted files causing the issue.

Here’s how you can perform a system reset:

- Turn off the Vmi ramp system.

- Locate the reset button or option in the settings menu.

- Press and hold the reset button for a few seconds.

- Wait for the system to restart.

Ensure to back up any essential data before performing a reset. A system reset will erase all existing configurations.

By keeping your firmware updated and knowing how to perform system resets, you can mitigate many software glitches in your Vmi ramp system.

Credit: www.youtube.com

Preventative Maintenance

Vmi ramp troubleshooting ensures smooth operation and reduces downtime. Regular checks help identify issues early, preventing costly repairs. Keep equipment reliable with consistent maintenance.

Preventative maintenance is key to keeping Vmi ramps in top condition. It helps avoid unexpected issues and extends the lifespan of the equipment. Two main areas to focus on are regular inspections and scheduled servicing.Regular Inspections

Regular inspections help in identifying issues early. Check for any signs of wear and tear. Look at the ramp’s moving parts. Lubricate them if necessary. Ensure all bolts and screws are tight. Check the electrical connections. Make sure they are secure and free from corrosion. Inspect the hydraulic system. Look for leaks or damaged hoses.Scheduled Servicing

Scheduled servicing should be part of your maintenance routine. Follow the manufacturer’s guidelines. Service the ramp at recommended intervals. Replace worn-out parts during servicing. This reduces the risk of breakdowns. Keep a record of all maintenance activities. This helps track the ramp’s health over time. It also helps in diagnosing recurring issues.“`Safety Checks

Performing safety checks on your VMI ramp is crucial. It ensures the ramp operates efficiently and safely. Regular safety checks prevent accidents and costly repairs.

Operational Tests

Operational tests are the first step in safety checks. These tests ensure the ramp functions smoothly under normal conditions. Follow these steps:

- Inspect the ramp for any visible damage.

- Test the ramp’s movement up and down.

- Check for unusual noises during operation.

- Ensure the controls respond accurately.

Keep a record of any issues you find. Address them promptly to maintain safety.

Emergency Protocols

Understanding emergency protocols is vital for safety checks. These protocols help during unexpected situations. Follow these guidelines:

- Locate the emergency stop button.

- Ensure the emergency stop button works correctly.

- Know how to manually operate the ramp if needed.

- Train all users on emergency procedures.

Emergency protocols save lives. Practice them regularly to stay prepared.

Performing these safety checks enhances the longevity and reliability of your VMI ramp. Stay safe and maintain your equipment regularly.

Expert Repair Tips

Maintaining and troubleshooting your Vmi ramp can be challenging. But with the right knowledge, you can keep it functioning smoothly. Here are some expert repair tips to help you.

Using The Right Tools

Having the correct tools is vital for effective repairs. Use a multimeter to check electrical connections. A wrench set helps in tightening loose bolts. Keep a set of screwdrivers for various screws. Here’s a quick list of essential tools:

- Multimeter – For electrical testing

- Wrench set – For bolts and nuts

- Screwdrivers – For different types of screws

- Lubricant – To reduce friction

Consulting Professionals

If you encounter complex issues, consulting professionals is wise. They have the expertise to diagnose and fix problems. Professionals can ensure your ramp meets safety standards. Here’s why you should reach out to them:

- Expert diagnosis – Identify hidden issues

- Proper tools – They have specialized equipment

- Safety standards – Ensure compliance

By following these tips, you can keep your Vmi ramp in top shape.

Credit: www.blvd.com

Frequently Asked Questions

Why Is My Vmi Ramp Not Deploying?

The ramp might be stuck due to a power issue or debris blockage. Check the battery and clear any obstructions.

How Do I Reset My Vmi Ramp?

Turn off the vehicle, then restart it. This often resets the ramp system.

What Should I Do If The Ramp Is Noisy?

A noisy ramp may need lubrication. Use manufacturer-recommended lubricant on moving parts.

Can Weather Affect My Vmi Ramp?

Yes, extreme temperatures can impact ramp functionality. Keep the ramp clean and dry for optimal performance.

How Often Should I Service My Vmi Ramp?

Service your ramp every 6-12 months. Regular maintenance ensures smooth operation and longevity.

Conclusion

Troubleshooting a VMI ramp can seem challenging at first. But with patience and the right steps, it becomes manageable. Regular maintenance helps prevent issues. Always follow the manufacturer’s guidelines. If problems persist, seek professional help. Keep safety a priority. Your ramp should work smoothly, ensuring easy access and mobility.

By addressing issues early, you can extend the life of your VMI ramp. Stay informed and proactive. A well-maintained ramp means peace of mind for everyone.