Waltco liftgates are essential tools for many businesses. They ensure smooth loading and unloading of goods.

But, what happens when these liftgates malfunction? A reliable troubleshooting manual becomes crucial. Understanding the Waltco liftgate troubleshooting manual can save you time and money. It helps you identify common issues and provides step-by-step solutions. This guide is designed to make troubleshooting straightforward, even for those with limited technical skills.

Whether you face hydraulic problems or electrical faults, a well-structured manual can be a lifesaver. Keep reading to discover how this manual can assist you in maintaining your Waltco liftgate, ensuring it works efficiently for your business needs.

Waltco Liftgate Safety Precautions

Safety is crucial when dealing with Waltco liftgates. A thorough understanding of safety measures ensures the well-being of operators and the proper functioning of equipment. This section covers essential precautions to consider.

Personal Safety

Always wear appropriate safety gear. Gloves, safety glasses, and steel-toed boots are essential. Inspect your gear before use. Ensure it’s in good condition. Avoid loose clothing. It can get caught in machinery. Stay alert and focused. Distractions can lead to accidents. Always follow safety protocols.

Equipment Safety

Regularly inspect the liftgate. Check for any signs of wear or damage. Ensure all parts are functioning correctly. Lubricate moving parts as needed. Use the liftgate within its load limits. Overloading can cause failures. Keep the area around the liftgate clean. Debris can interfere with operation. Follow the manufacturer’s guidelines for maintenance. Proper care extends the life of the liftgate.

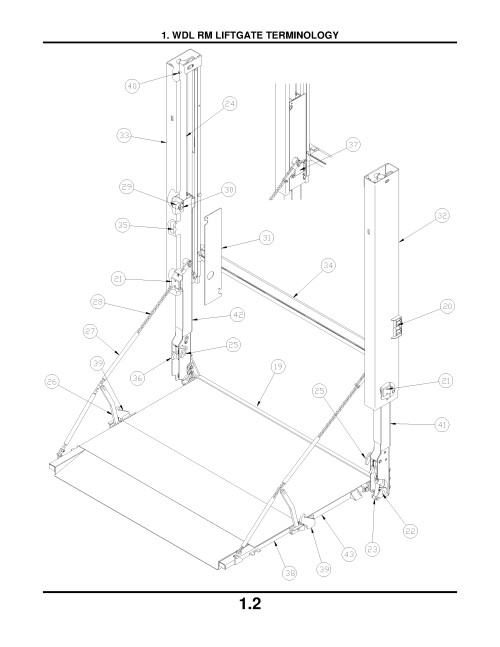

Basic Waltco Liftgate Components

Understanding the basic components of a Waltco liftgate can make troubleshooting easier. Knowing the main parts and their functions helps diagnose issues. Let’s explore the essential components of a Waltco liftgate.

Main Parts

The main parts of a Waltco liftgate include the hydraulic pump, cylinder, platform, control switch, and power source. Each part plays a crucial role in the liftgate’s operation.

Function Of Each Part

The hydraulic pump moves the fluid needed for the liftgate to function. It generates the pressure that powers the liftgate’s movements.

The cylinder converts hydraulic pressure into mechanical force. It raises and lowers the liftgate platform.

The platform is the surface where cargo is loaded and unloaded. It must be strong and sturdy to handle heavy loads.

The control switch allows the operator to control the liftgate’s movements. It is usually located near the rear of the vehicle for easy access.

The power source supplies the necessary energy to the hydraulic pump. It is often the vehicle’s battery or a separate power unit.

Common Waltco Liftgate Problems

Understanding common liftgate issues can save time and frustration. Whether you use your Waltco liftgate daily or occasionally, knowing the common problems and how to troubleshoot them can be a lifesaver.

Hydraulic Problems

Hydraulic issues are frequent with liftgates. These problems can hinder the liftgate’s performance. Here are some common hydraulic issues:

- Fluid Leaks: Check for any visible leaks in the hydraulic lines. Leaks can reduce fluid levels and affect operation.

- Low Fluid Levels: Ensure the hydraulic fluid is at the correct level. Low fluid can cause the liftgate to move slowly or not at all.

- Contaminated Fluid: Dirty or contaminated fluid can clog the hydraulic system. Regularly check and replace the fluid if necessary.

- Hydraulic Cylinder Failure: If the cylinder is damaged, the liftgate will not function properly. Inspect the cylinder for any signs of wear or damage.

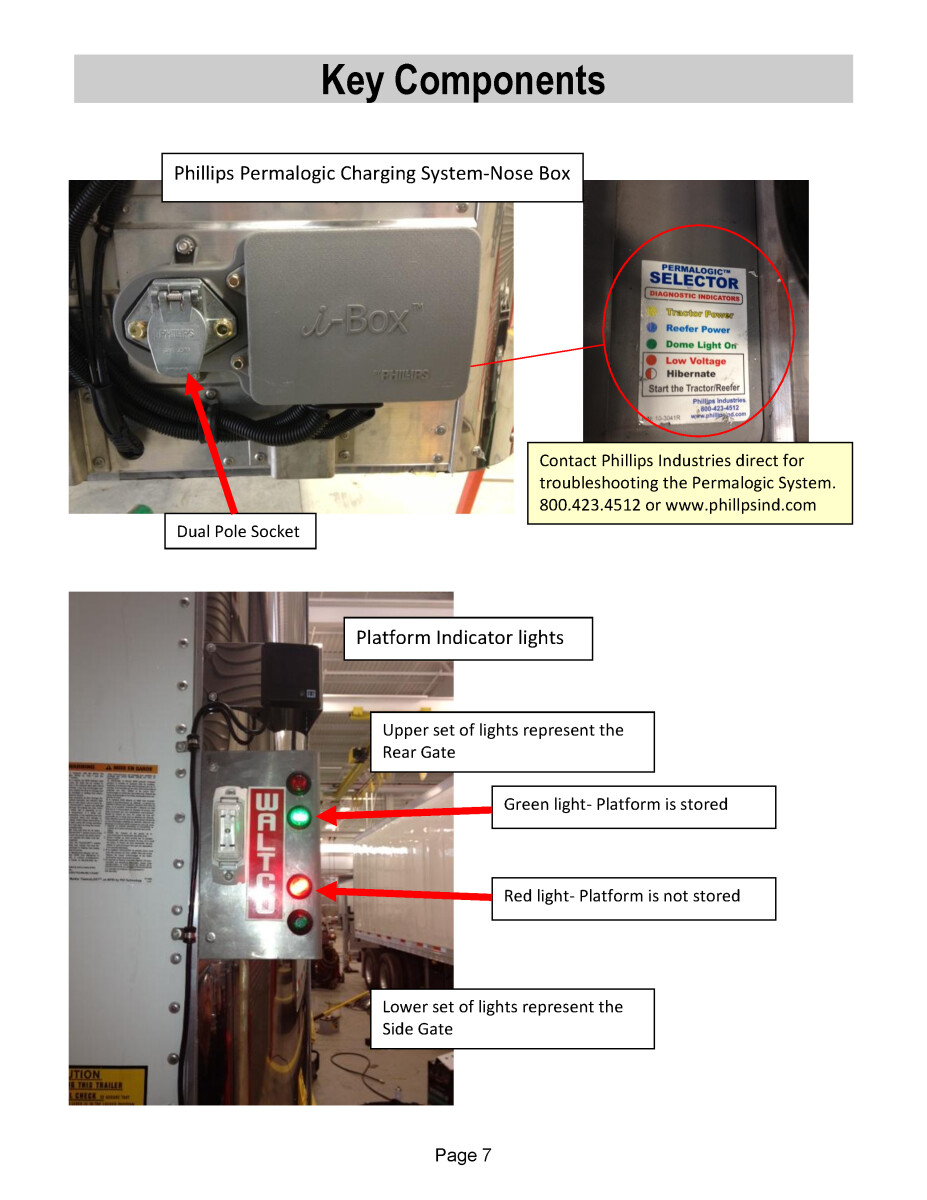

Electrical Problems

Electrical problems can also affect liftgate performance. Identifying and fixing these issues can ensure smooth operation. Common electrical issues include:

- Dead Battery: A dead or weak battery can cause the liftgate to malfunction. Check the battery voltage and connections.

- Faulty Wiring: Inspect the wiring for any signs of damage. Loose or frayed wires can cause intermittent issues.

- Blown Fuses: Check the liftgate fuses. Replace any blown fuses to restore functionality.

- Bad Connections: Ensure all electrical connections are secure. Loose connections can lead to power failures.

Waltco Liftgate Initial Inspections

The initial inspections of your Waltco Liftgate are crucial. They help identify potential issues early and ensure optimal performance. By conducting these checks, you can prevent more serious problems down the line. This section will guide you through two main steps: Visual Inspection and Operational Testing.

Visual Inspection

Begin with a thorough visual inspection of the liftgate. Look for any visible damage or wear. Check the hydraulic lines for leaks. Examine the electrical connections for corrosion or looseness. Ensure that all bolts and fasteners are secure. A detailed visual inspection can reveal issues that need immediate attention.

Operational Testing

Next, perform operational testing. Start by engaging the liftgate and observing its movement. Ensure it operates smoothly without jerks or delays. Listen for any unusual noises. Check the liftgate’s response to controls. Test the safety features to confirm they are functioning correctly. Operational testing helps verify that the liftgate works as intended.

Waltco Liftgate Troubleshooting of Hydraulic Problems

Hydraulic issues can disrupt the operation of your Waltco liftgate. Understanding common problems helps to keep your liftgate running smoothly. Below, we discuss two frequent hydraulic issues and how to address them.

Low Fluid Levels

Low hydraulic fluid levels can cause liftgate malfunctions. First, check the fluid reservoir. Ensure it has the correct amount of fluid. If the fluid is low, add the recommended type. Look for leaks around the hydraulic system. Even a small leak can lead to low fluid levels.

Regularly inspect the hydraulic lines for wear and damage. Replace any damaged lines immediately. Clean the area around the fluid cap before opening. This prevents dirt from entering the system.

Pump Malfunctions

The hydraulic pump is crucial for liftgate operation. If the liftgate moves slowly or not at all, the pump might be the issue. Listen for unusual noises from the pump. A whining noise often indicates a problem.

Check the pump’s power source. Ensure all connections are secure. Inspect the pump for signs of wear or damage. Replacing a faulty pump can restore liftgate function. Keeping the pump clean and well-maintained extends its life.

Waltco Liftgate Troubleshooting of Electrical Problems

Waltco liftgates are vital for efficient loading and unloading. Electrical problems can hinder operations. Understanding common issues helps keep your liftgate functional. This section covers battery issues and wiring problems. Follow these steps to troubleshoot effectively.

Battery Issues

Battery problems often cause liftgate malfunctions. Check the battery terminals first. Ensure they are clean and free of corrosion. Loose connections can disrupt power flow. Tighten the connections if needed.

Next, test the battery voltage. Use a multimeter for accurate readings. A fully charged battery should read around 12.6 volts. If the voltage is low, charge or replace the battery. Regular maintenance extends battery life.

Wiring Problems

Wiring issues can cause liftgate failures. Inspect all wires for damage. Look for frayed or broken wires. Replace damaged wires immediately. Ensure all connections are secure.

Check the fuse box as well. Blown fuses can interrupt power. Replace any blown fuses with the correct type. Use the Waltco Liftgate Troubleshooting Manual for guidance. Proper wiring ensures smooth operation.

Maintenance Tips For Waltco Liftgate

Maintaining your Waltco Liftgate ensures it works smoothly and safely. Regular maintenance can prevent costly repairs and downtime. Here are some essential maintenance tips to keep your liftgate in top condition.

Regular Checks

Regular checks are crucial for liftgate performance. Inspect the hydraulic fluid level weekly. Low fluid can affect liftgate operation. Check for leaks in the hydraulic system. Replace any worn or damaged hoses immediately. Examine the cables and chains for signs of wear. Lubricate them regularly to prevent rust and corrosion. Ensure all bolts and fasteners are tight. Loose parts can cause malfunction.

Preventive Measures

Preventive measures extend the life of your liftgate. Clean the liftgate regularly to remove dirt and debris. Dirt can cause components to wear out faster. Apply a rust inhibitor to exposed metal parts. This prevents rust formation. Test the liftgate’s electrical system monthly. Check the battery and connections for corrosion. Replace the battery if it shows signs of weakness. Train operators on proper liftgate use. Misuse can lead to damage and unsafe conditions.

When To Seek Professional Help

Troubleshooting a Waltco liftgate can sometimes be tricky. Basic issues might be easy to handle. But some situations require professional help. This guide will help you identify when to seek a pro.

Identifying Complex Issues

Some liftgate problems are too complex for a DIY fix. Strange noises, electrical issues, or hydraulic failures need expert eyes. If you notice unusual sounds or movements, it’s time to call a professional. These signs may point to deeper issues.

Electrical problems can be dangerous. If your liftgate doesn’t respond, it could be an electrical fault. This requires special tools and knowledge. Hydraulic failures are another sign. Leaks or slow movements suggest hydraulic problems. Experts can diagnose and fix these safely.

Choosing A Service Provider

Finding the right service provider is crucial. Look for certified technicians. They have the training and tools needed. Check reviews and ask for recommendations. Good feedback often means reliable service. Ensure they have experience with Waltco liftgates.

Cost is another factor. Get quotes from a few providers. Compare their prices and services. Don’t always go for the cheapest option. Quality service might cost more but saves money in the long run. Your liftgate is an investment. Treat it with care.

Frequently Asked Questions

Why Is My Waltco Liftgate Not Working?

Check the power supply, fuses, and wiring. Ensure the battery is charged.

How Do I Reset My Waltco Liftgate?

Locate the reset button on the control box. Press and hold for 10 seconds.

What Causes A Waltco Liftgate To Stop Mid-operation?

Inspect for hydraulic fluid leaks, electrical issues, or a faulty control switch.

How Often Should I Service My Waltco Liftgate?

Service every 6 months or after 1500 cycles to ensure optimal performance.

What Type Of Hydraulic Fluid Does A Waltco Liftgate Use?

Use ISO 32 hydraulic oil. Check the manual for specific recommendations.

Conclusion

Troubleshooting your Waltco liftgate doesn’t have to be complicated. This guide offers clear steps for common issues. Follow these tips to keep your liftgate working smoothly. Regular maintenance ensures a longer lifespan. Address problems early to avoid costly repairs. Remember, safety is key when handling equipment.

Always consult the manual for detailed instructions. With these insights, maintaining your liftgate becomes easier. Stay proactive and keep your operations running efficiently.