If you rely on a well for your water supply, you know how frustrating it can be when your water pressure suddenly drops or your pump behaves oddly. Your well pressure switch plays a crucial role in controlling the pump’s operation, keeping your water flowing smoothly.

But what happens when that switch starts acting up? You might notice your pump running non-stop, short cycling on and off, or your water pressure fluctuating without warning. These issues not only disrupt your daily routine but can also lead to costly repairs if left unchecked.

In this guide, you’ll learn how to spot the common signs of a faulty well pressure switch and simple troubleshooting steps you can take to get your system back to normal. Read on to save time, avoid unnecessary expenses, and keep your water running just the way it should.

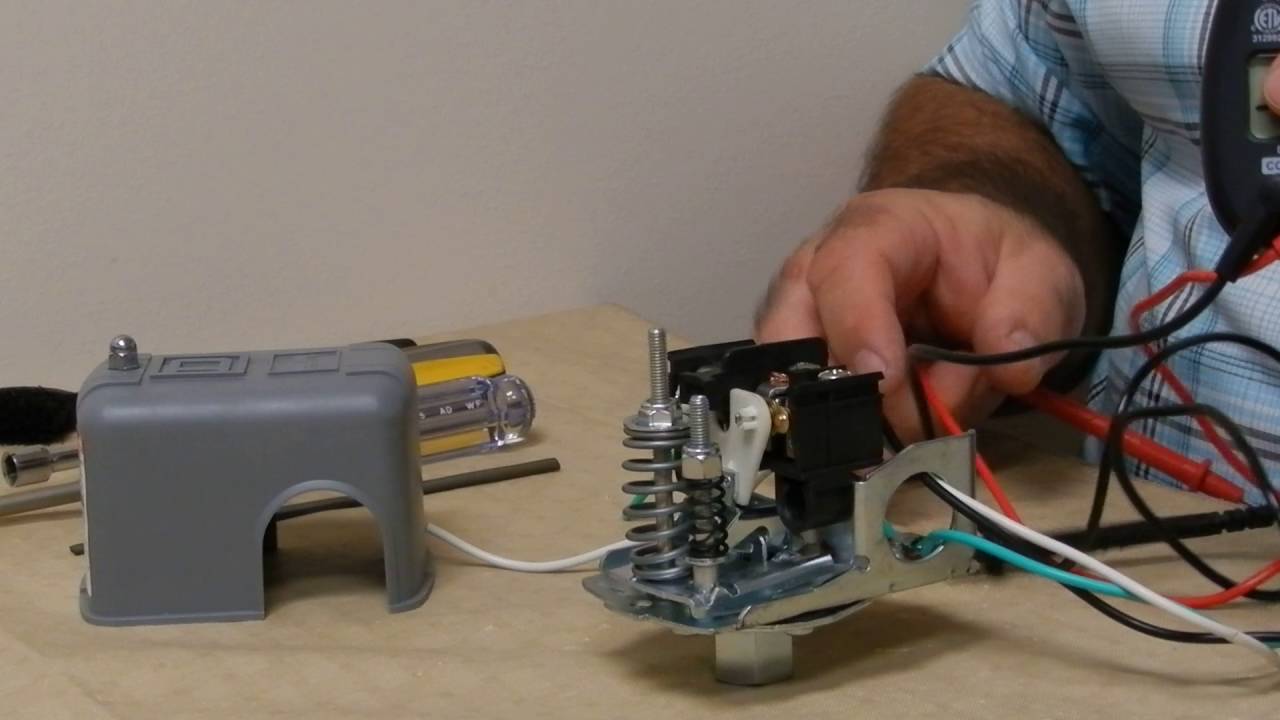

Credit: www.youtube.com

Common Symptoms

Identifying common symptoms helps in troubleshooting a well pressure switch. These signs show how the switch affects your water system. Understanding them prevents bigger problems. Watch for changes in pump behavior, water pressure, sounds, system indicators, and visible damage.

Pump Behavior

Short cycling means the pump turns on and off rapidly. Constant running happens when the pump never stops. No water flow occurs if the pump does not start at all. These behaviors signal a pressure switch issue. They can damage the pump if left unchecked.

Water Pressure Issues

Low water pressure shows weak flow from faucets and showers. Fluctuating pressure causes water to surge or drop suddenly. Both problems point to a faulty pressure switch. The switch may fail to control pressure properly in the system.

Audible Clues

Grinding, humming, or buzzing noises come from the pump area. These sounds suggest the pressure switch or pump is struggling. Strange noises often mean the switch contacts are worn or stuck. Ignoring these sounds can lead to pump failure.

System And Utility Signs

High electricity bills may occur due to the pump running too long. The pressure tank may also feel hot or over-pressurized. Frequent breaker trips or fuse blows can indicate switch problems. These signs warn of an overworked or malfunctioning system.

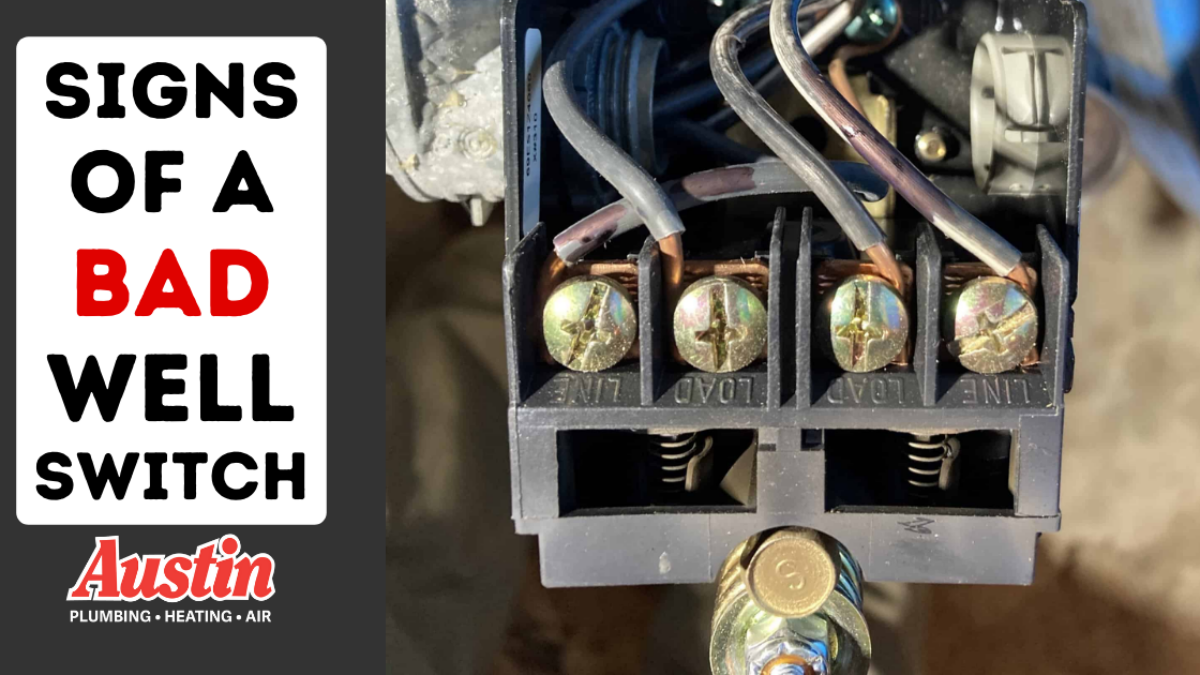

Visible Damage

Corrosion, rust, or dirt on the pressure switch affect its function. Loose or broken wires cause intermittent pump operation. Cracks or water leaks near the switch also show damage. Visual inspection helps catch issues early before system failure.

Credit: teamaustin.com

Typical Problems

Typical problems with well pressure switches often cause water supply issues. These problems affect the pump’s ability to maintain steady water pressure. Understanding common issues helps to troubleshoot and fix them quickly. Below are some frequent causes of well pressure switch failures.

Faulty Contacts

Faulty contacts inside the pressure switch can prevent it from working properly. Dirt, corrosion, or wear may cause the contacts to stick or fail to close. This results in the pump not turning on or off at the right times. Testing the contacts with a multimeter can identify this issue. Cleaning or replacing the contacts often restores normal function.

Clogged Pressure Tubes

Pressure tubes connect the pressure switch to the water system. These tubes can become clogged with dirt or minerals. A blocked tube gives false pressure readings to the switch. This causes the pump to run erratically or stop working. Flushing or replacing the clogged tube clears the problem and improves switch accuracy.

Pressure Tank Issues

The pressure tank works closely with the pressure switch. Problems like a waterlogged tank or broken bladder affect system pressure. This causes the switch to cycle the pump too often or fail to start it. Checking tank pressure and condition helps spot these issues. Repairing or replacing the tank fixes pressure-related switch problems.

Safety Precautions

Safety is the top priority when troubleshooting a well pressure switch. Handling electrical components and pressurized tanks carries risks. Taking proper safety steps protects you from injury and prevents damage. Never skip these basic precautions before starting work on your well system.

Power Shutoff

Always turn off the power before inspecting the pressure switch. Locate the main breaker or switch for your well pump. Switch it off to cut all electricity to the system. This step stops accidental electric shocks and protects the pump from damage. Use a voltage tester to confirm no power is running to the switch.

Check Tank Air Pressure

Release pressure from the tank before working on the switch. Use an air pressure gauge to check the tank’s air level. The proper pressure usually matches the pump cut-in pressure minus 2 psi. If air pressure is too high or low, it can cause switch problems. Adjust the air pressure carefully with an air compressor or by releasing air. Always wear safety glasses and gloves during this process.

Resetting The Pressure Switch

Resetting the pressure switch is a simple step to fix common well pump problems. The pressure switch controls when the pump turns on and off. Sometimes, it needs a reset to work properly again. This can solve issues like no water or the pump running too much.

Knowing how to reset the pressure switch can save time and money. It also helps keep your water system running smoothly. Follow the steps below carefully to reset your pressure switch safely.

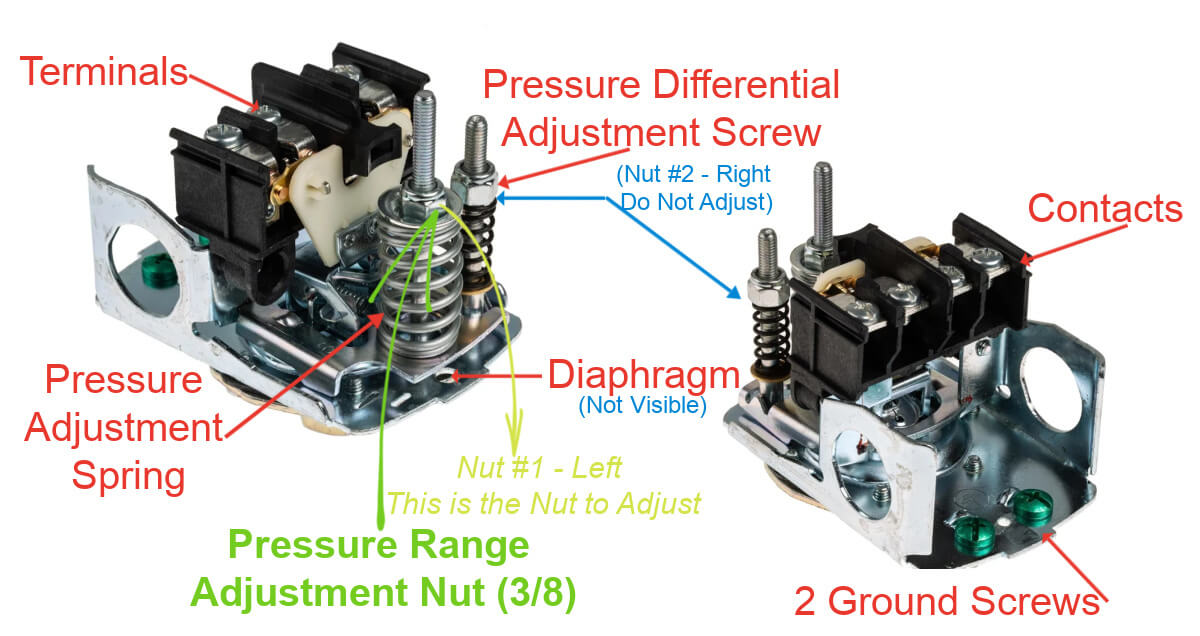

Locating The Switch

The pressure switch is usually near the well pump or pressure tank. Look for a small box with a cover on it. It connects to the water pipes and electrical wires. The cover may have screws or clips to open it. Always turn off the power before touching the switch.

Step-by-step Reset

First, switch off the power to the pump at the breaker box. Next, open the pressure switch cover carefully. Inside, you will see small metal contacts and a spring.

Press the contacts gently to reset the switch. Make sure they are clean and not stuck. Close the cover and turn the power back on. Listen for the pump starting and check if water pressure returns.

When To Call A Professional

Resetting the pressure switch works for simple problems only. Call a professional if the pump still does not work. Also seek help if the switch looks damaged or corroded. Do not try to fix electrical parts if unsure. A licensed technician can safely diagnose and repair the issue.

Inspection And Maintenance

Regular inspection and maintenance keep your well pressure switch working well. Small problems can stop big issues later. Checking parts and cleaning contacts help the system last longer. It also ensures steady water pressure and pump efficiency.

Checking For Corrosion

Corrosion can block the switch and cause failure. Look at metal parts for rust or green buildup. Clean off light corrosion with a wire brush. Replace parts if corrosion is heavy or damages connections. Keep the switch dry to slow corrosion growth.

Testing Electrical Contacts

Electrical contacts control the pump’s on and off signals. Dirty or worn contacts cause poor connection and pump issues. Use a multimeter to check for continuity. Clean contacts gently with fine sandpaper or a contact cleaner. Replace contacts if they are pitted or broken.

Pressure Tank Air Charge

The pressure tank air charge affects pump cycling and water pressure. Use a tire gauge to check the air pressure in the tank’s air valve. It should be 2 psi below the pump cut-in pressure. Add air with a compressor or remove excess air as needed. Proper air charge helps prevent short cycling and extends pump life.

Quick Fixes

Quick fixes for a well pressure switch can save time and money. Many problems come from simple issues that anyone can handle. These fixes improve pump function and water flow fast. Try these easy steps before calling a professional.

Cleaning Contacts

Dirty or corroded contacts often cause switch failure. Turn off power to the pump before starting. Open the switch cover carefully. Use fine sandpaper or a small wire brush to clean the metal contacts. Remove any rust or debris. Close the cover and restore power. Test the pump to see if it runs smoothly.

Clearing Tubes

Clogged tubes can block pressure signals to the switch. Locate the small tube connected to the pressure switch. Detach it gently and check for blockages. Flush it with water or compressed air to clear dirt and sediment. Reattach the tube securely. This quick step helps the switch sense pressure changes correctly.

Adjusting Switch Settings

Pressure switches sometimes need setting adjustments. Locate the adjustment nuts on the switch. Turn the larger nut to change the cut-in pressure (pump start). Turn the smaller nut to change the cut-out pressure (pump stop). Adjust slowly in small steps. Check the pressure gauge after each change. Stop when the water pressure feels steady and normal.

Expert Tips

Understanding how to troubleshoot your well pressure switch can save time and money. Expert tips help you avoid common issues and keep your system running smoothly. These simple steps improve performance and reduce wear on your pump. Follow these guidelines for better water pressure and longer pump life.

Avoiding Short Cycling

Short cycling causes your pump to turn on and off too quickly. This wastes energy and wears out the pump. Check the pressure switch settings to keep proper cut-in and cut-out pressures. Make sure the pressure tank has enough air. Replace worn or damaged parts immediately. A well-maintained switch prevents frequent cycling and pump damage.

Extending Pump Life

Regular maintenance extends your pump’s lifespan. Clean the pressure switch contacts to avoid poor connections. Inspect the electrical wiring for corrosion or damage. Keep the pressure tank in good condition to reduce pump strain. Use a pressure gauge to verify system accuracy. These steps help your pump work efficiently and last longer.

Monitoring Water Pressure

Consistent water pressure ensures a steady water supply. Use a pressure gauge to check for fluctuations. Low pressure might signal a failing pressure switch or a leak. High pressure can damage pipes and fixtures. Adjust the switch settings as needed for stable pressure. Monitoring regularly catches problems early and prevents costly repairs.

Credit: localwaterwellpros.com

Frequently Asked Questions

How To Tell If A Well Pump Pressure Switch Is Bad?

A bad well pump pressure switch causes constant pump running, short cycling, no pump activation, low or fluctuating water pressure, unusual noises, or high electric bills. Check for burnt contacts or corrosion. These symptoms indicate the switch fails to control pump operation properly.

What Are The Common Problems With Pressure Switches?

Common problems with pressure switches include faulty contacts, short cycling, constant pump running, low or fluctuating water pressure, and unusual noises. Corrosion, burnt contacts, and waterlogged pressure tanks also cause failures, leading to pump damage and high electricity bills.

How Do I Reset A Well Pressure Switch?

To reset a well pressure switch, first turn off the pump’s power. Remove the switch cover, inspect and clean contacts. Adjust the pressure settings if needed, then replace the cover and restore power. Test the pump to ensure proper operation and pressure levels.

How To Clean The Contacts On A Pressure Switch?

Turn off power to the pressure switch. Open the cover and inspect contacts for dirt or corrosion. Use fine sandpaper or a contact cleaner to gently clean the contacts. Ensure they are dry before reassembling. Restore power and test the switch for proper operation.

What Are Common Signs Of A Faulty Well Pressure Switch?

A faulty switch causes the pump to run constantly or not at all. You may hear grinding noises or notice low water pressure. Rapid on/off cycling of the pump is also a key sign.

Conclusion

Troubleshooting a well pressure switch helps keep water flow steady. Watch for signs like short cycling or no water. Fixing issues early prevents damage to the pump and tank. Regular checks save money on repairs and electricity bills. Simple tests can identify common switch problems quickly.

Understanding these basics ensures your well system works smoothly. Stay alert to noises or pressure changes in your water system. A working pressure switch means reliable water whenever you need it.