Western plows are essential for snow removal. They help keep roads clear and safe.

But sometimes, these plows face issues. Knowing how to troubleshoot common problems is crucial. In this guide, we will cover common issues with Western plows. We aim to help you understand the problems and their solutions. Whether it’s electrical faults or mechanical failures, we’ve got you covered.

This guide will assist you in maintaining your plow for smooth and efficient operation. Stay with us to learn simple fixes that can save you time and money. Your plow will be back to work in no time.

Common Issues

Western plows are reliable, but issues can arise. Understanding common problems helps keep your plow in top shape. This troubleshooting guide covers hydraulic problems, electrical faults, and mechanical failures.

Hydraulic Problems

Hydraulic systems are vital for plow operation. Common issues include:

- Fluid Leaks: Check hoses and seals for cracks or damage.

- Slow Response: Low fluid levels or dirty fluid can cause delays.

- Overheating: Ensure the hydraulic fluid is at the correct level and not contaminated.

Regular maintenance can prevent these issues. Always check fluid levels and replace worn parts.

Electrical Faults

Electrical problems can halt your plow’s operation. Key issues include:

- Dead Battery: Verify the battery is charged and terminals are clean.

- Blown Fuses: Inspect and replace any blown fuses.

- Wiring Issues: Look for frayed wires or loose connections.

Regular checks of the electrical system can save you from unexpected downtime.

Mechanical Failures

Mechanical parts wear out over time. Common failures include:

- Worn Blades: Check blades for wear and replace if needed.

- Broken Springs: Inspect the springs and replace broken ones.

- Loose Bolts: Tighten any loose bolts to ensure stability.

Regular inspections and timely replacements can keep your plow running smoothly.

Credit: www.plowsite.com

Tools And Equipment

Maintaining your Western plow is critical for optimal performance. To ensure your plow functions well, you need the right tools and equipment. These help in diagnosing and fixing issues effectively. Let’s explore the essential tools and specialized equipment needed for troubleshooting.

Essential Tools

Basic tools are necessary for any troubleshooting task. You will need a set of screwdrivers. Both flathead and Phillips screwdrivers are essential. A wrench set is also crucial. It helps in tightening and loosening bolts. Pliers come in handy for gripping and pulling components. A multimeter is useful for checking electrical connections. It helps in identifying electrical faults quickly.

Specialized Equipment

Specialized equipment makes troubleshooting easier. A hydraulic pressure tester is important. It measures the pressure in the hydraulic system. This helps in pinpointing hydraulic issues. A diagnostic scanner is another valuable tool. It reads error codes from the plow’s control system. This provides insights into specific problems. A heat gun is useful for checking the plow’s electrical components. It helps in identifying overheating issues.

Hydraulic System Troubleshooting

The hydraulic system is the heart of your Western plow. It powers the blade movement and ensures smooth operation. But like any system, it can face issues. This guide will help you troubleshoot common hydraulic problems. Let’s dive into the most frequent issues you might encounter.

Low Fluid Levels

Check the hydraulic fluid regularly. Low fluid levels can cause slow or erratic blade movement. Use the recommended fluid for your Western plow. Topping up the fluid might solve the problem. If the fluid keeps dropping, inspect for leaks.

Leaking Hoses

Inspect hoses for any signs of damage. Leaking hoses reduce pressure and affect performance. Replace damaged hoses immediately. Secure all connections tightly to prevent leaks. Regular maintenance can prevent hose issues.

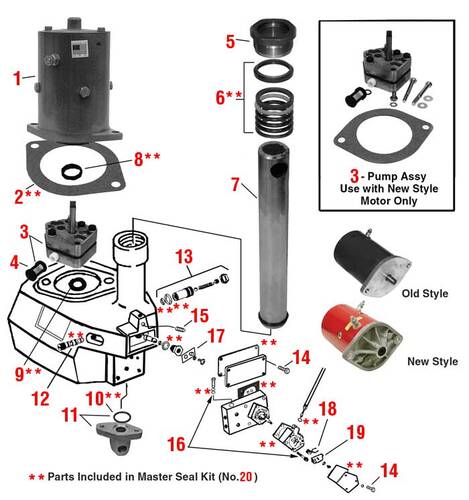

Pump Malfunctions

The pump is crucial for hydraulic operations. Listen for unusual noises from the pump. Strange sounds might indicate a malfunction. Check for any visible damage. Ensure the pump is receiving power. If the pump fails, consider a professional repair.

Electrical System Checks

Checking the electrical system of your Western Plow can prevent many issues. It ensures that the plow functions correctly and avoids downtime. Here are some common areas to inspect.

Blown Fuses

Blown fuses can disrupt the electrical flow in your plow’s system. To check for blown fuses:

- Locate the fuse box using your plow’s manual.

- Inspect each fuse carefully.

- Replace any blown fuses with the correct type.

Using the correct fuse type is crucial. Incorrect fuses can cause further damage.

Corroded Connections

Corrosion on electrical connections can cause poor performance. To check for corroded connections:

- Inspect all wiring and connections for signs of corrosion.

- Clean any corroded areas with a wire brush.

- Apply a protective spray to prevent future corrosion.

Keeping connections clean ensures a strong electrical flow.

Battery Issues

A weak or dead battery can cause many problems. To check for battery issues:

- Test the battery voltage with a multimeter.

- Ensure the battery terminals are clean and tight.

- Charge or replace the battery if needed.

A healthy battery is key to your plow’s performance.

Mechanical Components

Understanding the mechanical components of your Western Plow is vital. Proper maintenance ensures efficient snow removal and extends the equipment’s life. This guide will help you troubleshoot common issues related to the mechanical parts.

Worn Blades

Worn blades can affect the plow’s performance. Check the blade edges regularly. If the edges are rounded or uneven, it’s time for a replacement. Using worn blades can damage the surface you are plowing. Always keep spare blades handy.

Bent Frames

Bent frames can cause serious issues with alignment. Inspect the frame for any signs of bending. A bent frame can lead to uneven plowing. It can also put additional stress on other components. If you find a bent frame, it may need professional repair.

Broken Springs

Springs are crucial for the plow’s movement. Check for any broken or stretched springs. Broken springs can make the plow less responsive. They may also cause unusual noises during operation. Replace any damaged springs immediately. Regular inspections can prevent long-term damage.

Routine Maintenance

Routine maintenance is essential for keeping your Western plow in top condition. Regular care extends the life of your equipment and ensures optimal performance. This section provides a guide on how to maintain your plow effectively.

Lubrication

Lubricating your Western plow is crucial for smooth operation. Apply grease to all pivot points. Ensure the hydraulic system has enough fluid. Check for leaks in hoses and fittings. Use manufacturer-recommended lubricants for best results.

Inspection

Regularly inspect your plow for signs of wear and damage. Look at the cutting edges and bolts. Ensure all connections are tight. Examine the hydraulic hoses and cylinders. Replace any worn or damaged parts immediately.

Cleaning

Cleaning your plow prevents rust and corrosion. Remove dirt, salt, and debris after each use. Use a pressure washer for thorough cleaning. Dry the plow completely before storage. Store in a dry, covered area to protect from elements.

Safety Tips

Ensuring safety is crucial while troubleshooting your Western Plow. This section will guide you through essential safety tips to follow. These tips help you avoid accidents and injuries during the process.

Protective Gear

Always wear the right protective gear before starting any troubleshooting. This includes:

- Gloves – Protect your hands from sharp edges and cold weather.

- Safety Glasses – Shield your eyes from debris and chemicals.

- Steel-toed Boots – Prevent foot injuries from heavy equipment.

- Ear Protection – Guard against loud noises from machinery.

Safe Handling

Proper handling of tools and equipment is vital. Follow these tips:

- Read the user manual before using any tools.

- Use tools for their intended purpose only.

- Inspect tools for damage before use.

- Keep your work area clean and organized.

Emergency Procedures

Be prepared for emergencies. Here are essential procedures:

- Know the location of the first aid kit.

- Keep a fire extinguisher nearby.

- Have an emergency contact list accessible.

- Familiarize yourself with emergency exits.

By following these safety tips, you ensure a safer troubleshooting experience with your Western Plow.

Credit: www.millsupply.com

When To Seek Professional Help

Troubleshooting a Western Plow can sometimes become complicated. While many issues can be fixed with basic tools and knowledge, certain problems require a professional’s expertise. Knowing when to seek professional help can save time, money, and prevent further damage.

Complex Repairs

Some repairs involve intricate systems or hard-to-reach components. For example, issues with the hydraulic system or electrical wiring can be challenging. If you attempt these repairs without proper skills, you might worsen the problem.

| Issue | Professional Needed |

|---|---|

| Hydraulic Leaks | Yes |

| Electrical Failures | Yes |

| Control Module Problems | Yes |

Warranty Considerations

Attempting to fix certain problems yourself might void your warranty. Many manufacturers specify that only certified technicians should handle specific repairs. Always check your warranty terms before starting any repairs.

- Certified Technicians: Ensure the repair is covered under warranty.

- Warranty Terms: Read and understand them thoroughly.

- Authorized Service: Use approved service centers to maintain warranty.

Finding A Technician

Locating a reliable technician is crucial. Start by checking the manufacturer’s website for a list of authorized service centers. You can also ask for recommendations from other Western Plow users or local hardware stores.

- Manufacturer’s Website: Look for authorized service centers.

- Recommendations: Consult other users and local stores.

- Reviews: Read online reviews to find trusted technicians.

Remember, professional help is often the best choice for complex repairs. It ensures your plow remains in good working condition and prolongs its lifespan.

Credit: www.plowsite.com

Frequently Asked Questions

Why Won’t My Western Plow Move?

Check hydraulic fluid levels. Low fluid can cause the plow to stop moving. Also, inspect for leaks.

How Do I Fix A Western Plow Not Lifting?

First, inspect the lift cylinder and connections. Ensure there is no air in the hydraulic system.

Why Does My Western Plow Make Noise?

Noises often mean something is loose or misaligned. Check bolts, connections, and the pump.

What Causes A Western Plow To Overheat?

Overheating can happen from overuse or blocked cooling vents. Ensure proper ventilation and take breaks.

How Do I Troubleshoot A Western Plow Controller?

Verify power connections. Check fuses and wiring for any damage or loose connections.

Conclusion

Troubleshooting your Western plow doesn’t have to be hard. Follow the steps above to identify and fix common issues. Regular maintenance also helps prevent problems. Keep your plow in top shape for reliable performance. Remember, a well-maintained plow saves time and effort.

Use this guide to ensure smooth operations during the winter season. Stay prepared and keep your plow ready for action. Happy plowing!