Lanair Waste Oil Heater Troubleshooting: Quick Fixes

To troubleshoot a Lanair Waste Oil Heater, check for a clogged filter, faulty thermostat, pump issues, or burner malfunction. Start by inspecting and replacing the filter if dirty.

If the heater still doesn’t fire up, further investigation may be needed to identify the root cause of the problem. Common issues with oil heaters can often be resolved by simple maintenance tasks like filter replacement or checking for obstructions in the system.

Consulting professional HVAC services for thorough inspection and repair is recommended for complex problems. Regular maintenance and prompt troubleshooting can ensure efficient functioning of Lanair Waste Oil Heaters.

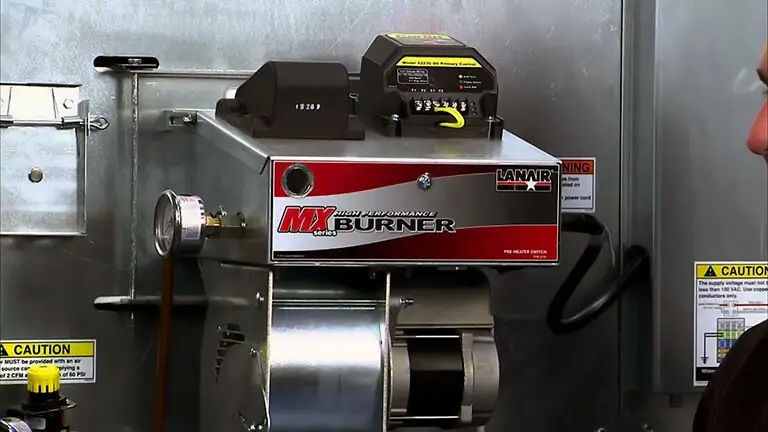

Introduction To Lanair Waste Oil Heaters

Experiencing issues with your Lanair waste oil heater? Troubleshooting can help resolve common problems such as a malfunctioning thermostat, clogged filter, or faulty pump. Check the filter for dirt and consider replacing it to ensure smooth operation of your oil heater.

Lanair waste oil heaters are an excellent solution for businesses looking to reduce their heating bills while also disposing of their waste oil in an eco-friendly manner. Lanair heaters are designed to burn a variety of waste oils, including motor oil, hydraulic oil, and transmission fluid. These heaters are easy to operate, reliable, and can save businesses thousands of dollars in heating costs every year.

Benefits Of Using Lanair Waste Oil Heaters

There are numerous benefits to using Lanair waste oil heaters in your business. Some of the most significant benefits include:

- Cost savings: Lanair heaters can save businesses thousands of dollars in heating costs every year, as they burn waste oil that would otherwise need to be disposed of.

- Eco-friendly: Lanair heaters are an eco-friendly solution for businesses looking to dispose of their waste oil. Rather than sending the oil to a landfill, it is burned for heat.

- Easy to operate: Lanair heaters are designed to be easy to operate, with simple controls and minimal maintenance requirements.

- Reliable: Lanair heaters are built to last, with durable components that can withstand heavy use.

Common Issues Encountered

While Lanair heaters are generally reliable and easy to operate, there are some common issues that businesses may encounter. These issues include:

- Failing to ignite: If your Lanair heater is not igniting, it could be caused by a clogged or blocked filter, a broken thermostat, a bad pump, or an oil burner that needs cleaning.

- Flame adjustment: If your Lanair heater is not producing enough heat, it may be due to improper flame adjustment. This can be fixed by adjusting the air pressure regulator, flame sensor, and air baffle.

- Pump motor issues: If your Lanair heater’s pump motor is not functioning properly, it may be due to a broken coupler or a motor that needs replacement.

In conclusion, Lanair waste oil heaters are an excellent solution for businesses looking to save money on heating costs while also disposing of their waste oil in an eco-friendly manner. While there are some common issues that businesses may encounter, these can usually be resolved with basic troubleshooting and maintenance. By investing in a Lanair waste oil heater, businesses can enjoy reliable, efficient heating for years to come.

Initial Troubleshooting Steps

When troubleshooting your Lanair Waste Oil Heater, it’s essential to start with the initial steps to identify and resolve common issues. By following these steps, you can quickly diagnose and potentially fix the problem without the need for professional assistance.

Checking Power Supply And Connections

- Ensure the heater is plugged in and the power source is functioning.

- Inspect the power cord for any damages or loose connections.

- Check the circuit breaker or fuse box to see if a tripped breaker or blown fuse is the issue.

Verifying Thermostat Settings

- Check the thermostat to ensure it is set to the desired temperature.

- Make sure the thermostat is in the heating mode and not in the cooling mode.

- Replace the thermostat batteries if it is a battery-operated model.

If the Lanair Waste Oil Heater is still not functioning after performing these initial troubleshooting steps, further investigation or professional help may be required.

Fuel System Diagnostics

When troubleshooting Lanair waste oil heater problems, diagnosing issues with the fuel system is crucial to ensuring optimal performance. The fuel system is a critical component of the waste oil heater, and any malfunctions in this system can lead to heating inefficiencies or complete breakdowns. The following fuel system diagnostics will help you identify and address common issues with the fuel pump and filters.

Inspecting The Fuel Pump

Inspecting the fuel pump is essential to ensure that it is functioning properly and delivering the necessary fuel to the burner. Follow these steps to inspect the fuel pump:

- Check for any visible signs of damage or wear on the fuel pump.

- Ensure that the fuel pump is receiving power and that the electrical connections are secure.

- Test the fuel pump’s operation by activating the heater and observing the pump’s performance.

- Listen for any unusual noises or vibrations coming from the fuel pump, which may indicate a potential issue.

Cleaning Or Replacing Filters

The filters in a waste oil heater play a crucial role in ensuring the purity of the fuel and preventing contaminants from reaching the burner. Here’s how you can clean or replace the filters in the fuel system:

- Shut off the waste oil heater and allow it to cool down before attempting to clean or replace the filters.

- Locate the filters in the fuel system and inspect them for any signs of clogging, dirt, or damage.

- If the filters are reusable, carefully clean them using an appropriate solvent or cleaning solution, ensuring that all debris and impurities are removed.

- If the filters are disposable or damaged, replace them with new, compatible filters recommended by the manufacturer.

- After cleaning or replacing the filters, restart the waste oil heater and monitor its performance to ensure that the fuel system is functioning optimally.

Ignition System Issues

An efficient waste oil heater relies on a properly functioning ignition system to ensure reliable and consistent operation. Ignition system issues can disrupt the heating process and lead to downtime, impacting productivity and comfort. Below, we will discuss common ignition system issues and the steps to troubleshoot them effectively.

Checking The Igniter

The igniter plays a crucial role in initiating the combustion process in a waste oil heater. Over time, the igniter may become worn or damaged, resulting in ignition failure. To address this issue, follow these steps:

- Turn off the heater and allow it to cool down completely.

- Locate the igniter and visually inspect it for any signs of damage or wear.

- If the igniter appears damaged, replace it with a new one according to the manufacturer’s guidelines.

- Ensure that the igniter is properly positioned and secured within the heater.

- Turn on the heater and observe the ignition process to verify that the new igniter functions correctly.

Assessing The Spark Transformer

The spark transformer is responsible for generating the high-voltage electrical spark needed to ignite the waste oil in the burner. If the spark transformer malfunctions, it can lead to ignition failures and operational issues. To assess the spark transformer, follow these steps:

- Turn off the heater and disconnect it from the power source.

- Locate the spark transformer and inspect it for any visible damage or signs of electrical failure.

- Check the wiring connections to ensure they are secure and free from corrosion.

- Use a multimeter to test the output voltage of the spark transformer according to the manufacturer’s specifications.

- If the output voltage is below the specified range, replace the spark transformer with a new one that meets the required electrical parameters.

- After replacing the spark transformer, reconnect the power and test the heater to verify proper ignition operation.

Flame And Burner Adjustments

When it comes to troubleshooting Lanair waste oil heaters, one crucial aspect is assessing and adjusting the flame and burner. Proper flame and burner adjustments ensure efficient combustion and optimal heat output. In this guide, we will delve into flame quality evaluation and the process of adjusting the air and fuel mix to achieve the desired flame characteristics.

Flame Quality Evaluation

Before proceeding with any adjustments, it’s essential to evaluate the quality of the flame produced by the waste oil heater. A healthy flame should exhibit steady, blue combustion with minimal smoke or soot formation. The flame’s appearance is indicative of the combustion efficiency and can help identify any underlying issues.

Adjusting Air And Fuel Mix

One of the key factors influencing flame quality is the precise mixture of air and fuel within the combustion chamber. An imbalanced air-fuel ratio can lead to inefficient combustion and the production of undesirable byproducts. By adjusting the air and fuel mix, you can optimize the combustion process to achieve an ideal flame.

Heat Output Concerns

When your Lanair waste oil heater is not producing the expected heat output, it can be a cause for concern. In this section, we will discuss troubleshooting steps to address heat output concerns. Let’s delve into two key areas that can impact the heat output of your waste oil heater: inspecting the heat exchanger and testing the blower motor.

Inspecting The Heat Exchanger

One of the primary components that directly impacts the heat output of your waste oil heater is the heat exchanger. Over time, the heat exchanger can become clogged with soot and debris, hindering its ability to efficiently transfer heat. To inspect the heat exchanger, follow these steps:

- Turn off the waste oil heater and allow it to cool down.

- Remove the access panel to gain access to the heat exchanger.

- Visually inspect the heat exchanger for any signs of soot buildup or blockages.

- Carefully clean the heat exchanger using a soft brush or vacuum to remove any accumulated debris.

- After cleaning, reassemble the access panel and restart the waste oil heater.

Testing The Blower Motor

The blower motor plays a crucial role in circulating heated air throughout the waste oil heater. If the blower motor is not functioning optimally, it can result in reduced heat output. Here’s how you can test the blower motor:

- Turn off the waste oil heater and disconnect the power supply.

- Locate the blower motor and inspect it for any visible signs of damage or obstruction.

- Manually rotate the blower motor to check for smooth operation.

- Use a multimeter to test the electrical continuity of the blower motor.

- If the blower motor fails the continuity test, it may need to be replaced.

Electrical Components Check

To troubleshoot Lanair Waste Oil Heater, start by checking for clogged filters, faulty thermostat, or pump issues. Ensure proper functioning of the oil burner for optimal performance. Regular maintenance can prevent heater malfunction.

Assessing Control Board Functionality

If the Lanair waste oil heater is not functioning properly, start by assessing the control board functionality. Check for any visible signs of damage or loose connections.

Troubleshooting Wiring Issues

Inspect the wiring of the waste oil heater for any frayed or damaged wires. Ensure that all connections are secure and there are no exposed wires that could be causing a short circuit.

Assessing Control Board Functionality

- Check for visible signs of damage or loose connections on the control board.

- Ensure that all components on the control board are properly seated.

- Use a multimeter to test the voltage output of the control board components.

Troubleshooting Wiring Issues

- Inspect all wiring for any signs of wear, fraying, or damage.

- Secure any loose connections and ensure all wires are properly connected.

- Test the continuity of the wiring using a multimeter to identify any potential issues.

Preventive Maintenance Tips

Discover essential preventive maintenance tips for troubleshooting your Lanair waste oil heater. Ensure regular filter checks, thermostat inspections, pump maintenance, and burner efficiency to prevent common issues and ensure optimal performance. Regular upkeep can help avoid malfunctions and keep your heating system running smoothly.

Regular Cleaning Schedule

Regular cleaning of your Lanair waste oil heater is crucial to ensure its efficient and effective operation. A dirty heater can lead to clogging of the burner and filters, which can eventually cause a malfunction. To prevent this, schedule a regular cleaning of your heater at least once every three months. This includes cleaning the burner, fuel pump, and chimney. You should also clean or replace the air filter and oil filter regularly to ensure that the heater runs smoothly.

Critical Component Replacements

Certain components of your Lanair waste oil heater are critical to its operation. These include the fuel pump, burner motor, ignition transformer, and flame sensor. It is important to replace these components as soon as you notice any signs of wear or malfunction. Failure to do so can result in your heater not functioning properly, which can lead to costly repairs.

To ensure that you are replacing these components on time, create a schedule for replacement based on the manufacturer’s recommendations. If you are unsure, consult with a professional HVAC technician who can advise you on the best course of action.

By following these preventive maintenance tips, you can avoid most common issues with your Lanair waste oil heater. Regular cleaning and maintenance can help to extend the life of your heater and save you money in the long run. If you do experience any issues, don’t hesitate to consult with a professional HVAC technician for assistance.

Frequently Asked Questions

Why Is My Oil Heater Not Firing Up?

Potential reasons for your oil heater not firing up include a clogged filter, faulty thermostat, pump issues, or burner malfunction. Start by checking and replacing the filter if dirty. Ensure all registers are open and check the reset button on the furnace control module.

Why Is My Oil Burner Not Working Properly?

Possible reasons for oil burner malfunction include clogged filter, broken thermostat, faulty pump, or burner issues. Start by checking and replacing the filter, ensuring registers are open, and looking for the reset button on the control module. If the furnace still doesn’t run, it could be fuel-related.

How Does A Lanair Waste Oil Heater Work?

A Lanair waste oil heater works by pumping used oil to the burner, where it is preheated.

What Would Cause An Oil Furnace Not To Ignite?

A clogged filter, broken thermostat, bad pump, or malfunctioning oil burner can cause an oil furnace not to ignite. Start by checking and replacing a dirty filter. Ensure all registers are open and not obstructed. Look for the reset button on the furnace control module.

If it is popped, the problem with your furnace not running could be fuel related.

Conclusion

Troubleshooting a Lanair Waste Oil Heater involves checking the thermostat, pump motor, flame adjustment, and ignition. Common issues include dirty filters, faulty thermostats, or pump problems. Regular maintenance and following proper procedures can help ensure your heater functions efficiently. Remember to consult professionals for complex issues.