Janome Sewing Machine Troubleshooting: Quick Fixes

For Janome Sewing Machine troubleshooting, ensure correct threading, needle insertion, and tension settings. Verify needle condition and thread placement.

In Austin, Texas, United States, common issues include needle breakage, skipped stitches, and imbalanced stitching. Follow guides to rethread and check needle placement for optimal performance. Regular maintenance like oiling and cleaning can prevent machine malfunctions. Troubleshooting tips from experts suggest checking for proper needle insertion and tension settings.

By addressing these common issues, you can ensure your Janome Sewing Machine operates smoothly and efficiently. Remember, a well-maintained machine leads to better sewing results and a frustration-free experience.

Initial Checks For Common Issues

Troubleshooting your Janome sewing machine involves initial checks for common issues. Begin by inspecting thread tension, spool caps, and bobbin installation. Ensure correct thread placement, clean the machine inside out, and lubricate moving parts for smooth stitching.

Power And Plug Inspection

Before diving into more complex troubleshooting, it’s always important to check the basics first. Make sure that your Janome sewing machine is properly plugged in and that the power switch is turned on. If you’re using an extension cord, ensure that it’s suitable for your machine’s power requirements. If you’re still experiencing power issues, try plugging your machine into a different outlet to see if that solves the problem.

Needle And Bobbin Basics

Issues with the needle and bobbin are some of the most common problems you’ll encounter when using a sewing machine. Start by checking that the needle is inserted correctly, with the flat side facing the back. Make sure that you’re using the right type of needle for the fabric you’re working with, and that it’s not bent or dull. If you’re experiencing issues with thread tension, try rethreading the machine and ensuring that the bobbin is properly installed and wound.

Other common issues that you may encounter include thread breakage, skipped stitches, and imbalanced or variable stitching. If you’re still having trouble after checking these initial issues, it may be time to consult the manual or reach out to a professional for assistance.

Remember, taking the time to troubleshoot common issues can save you time and frustration down the line, and can help ensure that your Janome sewing machine operates smoothly and efficiently.

Thread Path Troubles

Thread Path Troubles: When troubleshooting issues with your Janome sewing machine, one common area to focus on is the thread path. Proper threading is crucial for smooth stitching.

Threading The Machine Correctly:

1. Ensure the thread follows the correct path as per the machine’s manual.

2. Make sure the thread passes through all necessary guides and tension discs.

3. Check that the thread is securely seated in the needle and bobbin.

Ensuring Smooth Thread Tension:

1. Adjust the tension settings according to the fabric you are using.

2. Regularly check the tension discs for any lint or debris that may affect thread tension.

3. Ensure that the thread flows smoothly without any snags or tangle

Bobbin Woes

When it comes to Janome sewing machine troubleshooting, dealing with bobbin issues can be a common frustration. From inserting the bobbin properly to using the right bobbin type, addressing these problems is crucial for smooth sewing operations.

Inserting The Bobbin Properly

Inserting the bobbin correctly is essential for seamless sewing. Ensure the bobbin is placed in the case with the thread running in the correct direction, following the machine’s manual instructions.

Using The Right Bobbin Type

Using the correct bobbin type is imperative for optimal sewing performance. Always use bobbins specifically designed for your Janome sewing machine to prevent thread tension issues and ensure smooth stitching.

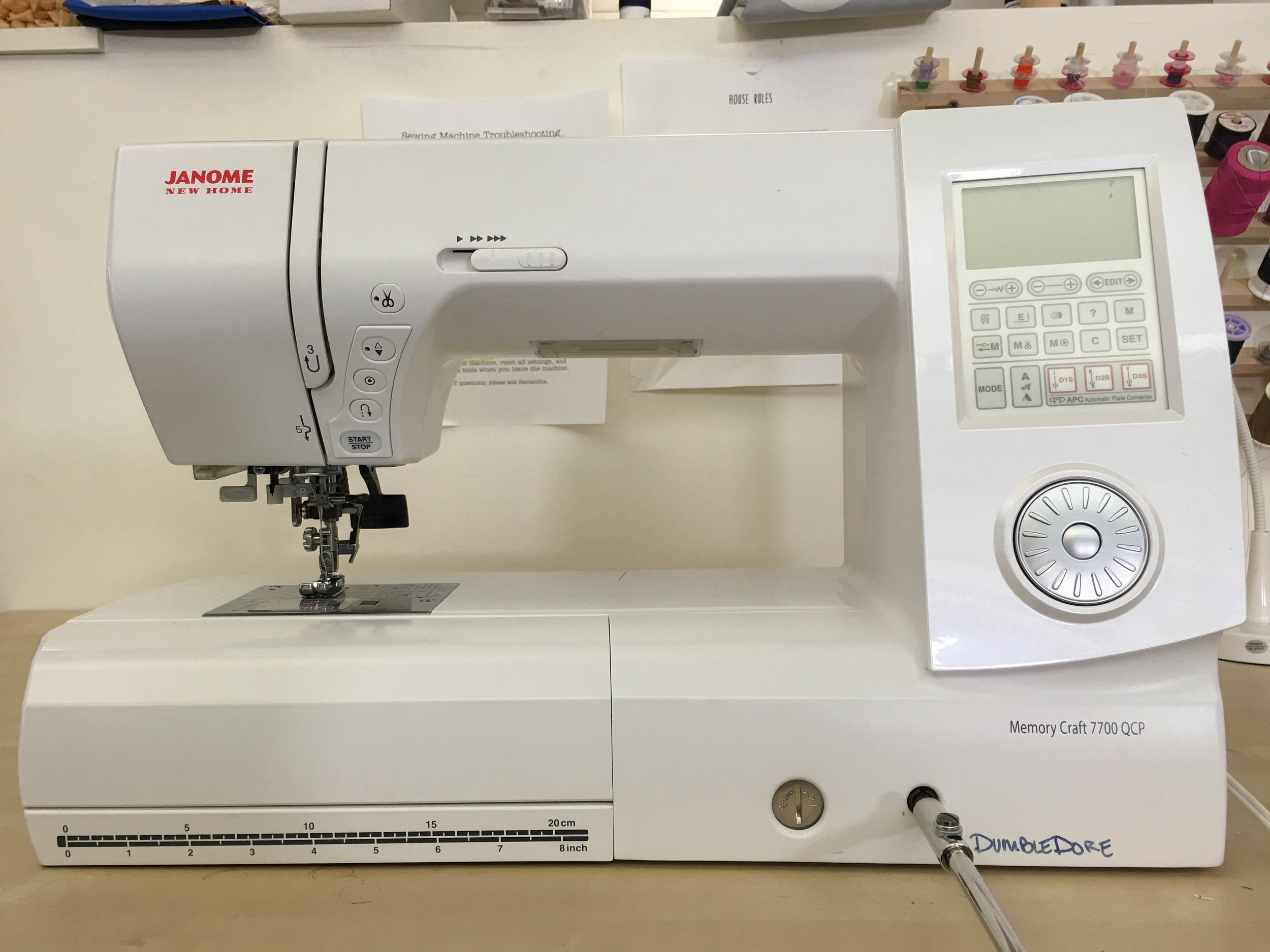

Credit: www.agatheringofstitches.com

Needle Know-how

When it comes to troubleshooting your Janome sewing machine, understanding the intricacies of the needle is essential. From selecting the correct needle for different fabrics to replacing a damaged needle, having needle know-how can help resolve many common sewing machine issues.

Replacing A Damaged Needle

If you notice that your needle is bent, broken, or blunt, it’s crucial to replace it promptly. A damaged needle can cause stitching problems and damage your fabric. Follow these steps to replace a damaged needle:

- Turn off the sewing machine and unplug it for safety.

- Use a screwdriver to loosen the needle clamp screw and remove the old needle.

- Insert the new needle, ensuring that the flat side is facing the back and that it’s pushed up as far as it can go.

- Tighten the needle clamp screw securely.

- Plug in the machine and turn it on to test the new needle.

Choosing The Correct Needle For Fabric

Using the right needle for the fabric you’re sewing is crucial for achieving professional results. Different fabrics require different types and sizes of needles. Here’s a simple guide to help you choose the correct needle:

| Fabric Type | Recommended Needle Type | Needle Size |

|---|---|---|

| Cotton | Universal or sharp needle | 70/10 – 90/14 |

| Denim | Denim or jeans needle | 90/14 – 110/18 |

| Silk or Satin | Microtex needle | 60/8 – 70/10 |

Stitch Quality Struggles

When using a Janome sewing machine, encountering stitch quality issues can be frustrating. Whether you are dealing with skipped stitches or imbalanced stitching, it’s important to troubleshoot and address these problems effectively.

Addressing Skipped Stitches

If you are experiencing skipped stitches with your Janome sewing machine, there are a few potential causes to consider:

- Incorrect needle type or size

- Improper threading

- Tension issues

To address skipped stitches, start by ensuring you are using the correct needle type and size for your fabric. Next, double-check the threading of the machine, making sure the thread is properly seated in the tension discs and the take-up lever. Finally, adjust the tension settings to see if that resolves the issue.

Fixing Imbalanced Stitches

Imbalanced stitches can detract from the quality of your sewing projects. To troubleshoot imbalanced stitches on your Janome sewing machine, consider the following:

- Thread tension adjustments

- Bobbin winding and insertion

- Needle condition and insertion

Begin by checking the tension settings for both the upper and lower threads. Make any necessary adjustments to achieve balanced tension. Additionally, ensure the bobbin is wound and inserted correctly, and inspect the needle for any damage or bending. Proper bobbin winding and needle condition are crucial for achieving balanced stitching.

Tension Adjustments

When it comes to sewing machine troubleshooting, one of the key areas to focus on is tension adjustments. Proper tension ensures neat and balanced stitches, while incorrect tension can lead to a range of stitching issues. Understanding how to adjust and fine-tune the tension on your Janome sewing machine is essential for achieving professional-quality results.

Setting The Tension Dial

Begin by setting the tension dial on your Janome sewing machine to the standard setting recommended for the type of fabric and thread you are using. Refer to your machine’s manual for guidance on the appropriate tension settings for different materials. Ensure the machine is properly threaded before making any adjustments to the tension dial.

Testing And Fine-tuning Tension

After setting the tension dial, test the stitching on a scrap piece of fabric to evaluate the tension. Inspect the stitches carefully for any signs of imbalance or irregularity. If the stitches appear too loose or too tight, make incremental adjustments to the tension dial and continue testing until the stitches are even and well-formed.

Cleaning And Maintenance

When it comes to maintaining your Janome sewing machine, Cleaning and Maintenance are crucial. Regular upkeep ensures optimal performance and longevity of your machine.

Regular Cleaning Steps

Regular cleaning steps are essential to prevent dust and lint buildup, which can affect your machine’s performance. Use a soft brush to gently remove debris from the feed dogs, bobbin case, and needle plate.

Lubrication For Smooth Operation

Lubrication is key to ensuring smooth operation of your Janome sewing machine. Apply a drop of sewing machine oil to the designated points as per the manufacturer’s instructions for optimal performance.

Advanced Fixes

For advanced fixes on Janome sewing machine troubleshooting, address issues like poor stitching by rethreading, checking needle threading, and adjusting tension settings. Ensure correct needle insertion and thread placement for optimal sewing performance. Regular maintenance like oiling and cleaning also aids in preventing common sewing problems.

Advanced Fixes: Resolving Thread Jamming

Thread jamming is a common problem that occurs when the thread gets caught in the machine’s moving parts. It can be frustrating, but there are some advanced fixes you can try to resolve the issue.

1. Check the needle: A bent or damaged needle can cause thread jamming. Make sure the needle is inserted correctly and is not bent or blunt. If the needle is damaged, replace it with a new one.

2. Clean the machine: Dust and lint can accumulate in the machine and cause thread jamming. Clean the machine regularly and make sure to remove any debris from the bobbin area.

3. Check the tension: Incorrect tension can also cause thread jamming. Make sure the tension is set correctly for the fabric you are using.

When to Seek Professional Help

If you have tried all the advanced fixes and the problem persists, it may be time to seek professional help. A trained technician can diagnose the problem and make the necessary repairs to get your machine working properly.

In conclusion, thread jamming can be a frustrating issue to deal with, but with these advanced fixes and knowing when to seek professional help, you can get your Janome sewing machine back up and running smoothly. Remember to always take care of your machine by cleaning it regularly and using the correct needles and thread for your project.

Seam Puckering Prevention

When it comes to achieving flawless seams on your Janome sewing machine, preventing puckering is key. Seam puckering can be a frustrating issue, but with the right techniques, you can troubleshoot and prevent it effectively.

Tension And Fabric Handling

Proper tension and fabric handling are crucial in preventing seam puckering. Ensure that the machine’s tension is adjusted correctly for the fabric being used. Additionally, handle the fabric gently to avoid unnecessary stretching or bunching that can lead to puckered seams.

Troubleshooting Puckered Seams

If you encounter puckered seams while sewing with your Janome machine, there are several troubleshooting steps you can take to address the issue. Start by examining the tension settings and fabric handling techniques. Adjust the tension as needed and handle the fabric with care to minimize puckering.

Reset And Recovery

Troubleshooting your Janome sewing machine for reset and recovery is crucial for optimal performance. Ensure correct thread placement, proper needle insertion, and tension settings. Follow maintenance steps like cleaning and oiling for smooth operation.

How To Reset Your Janome Machine

Resetting your Janome machine can help resolve software glitches and errors. Two common methods to reset your machine are:

- Press the reset key on the function panel.

- Turn off the power switch, unplug the machine, wait a few minutes, then plug it back in and turn it on.

Recovering From Software Glitches

If your Janome sewing machine is experiencing software glitches, follow these steps to recover:

- Check threading guides and ensure the thread is in the take-up lever.

- Verify the needle is inserted correctly with the flat side to the back.

- Inspect the needle for any bends or bluntness.

- Ensure the tension setting is correct for the desired stitch.

Frequently Asked Questions

What Are The 7 Common Sewing Machine Troubles?

The 7 common sewing machine troubles are: 1. Needle thread breakage 2. Bobbin or looper thread breakage 3. Thread fusing when the machine stops 4. Skipped stitches 5. Imbalanced/variable stitching 6. Staggered stitching 7. Variable stitch density

Why Is My Janome Sewing Machine Not Sewing Properly?

Ensure that you follow the threading guide and check that the thread is in the take-up lever. Make sure that the needle is inserted correctly and is not bent or blunt. Check that the tension setting is correct. If the problem persists, try cleaning the machine and changing the needle.

How Do I Reset My Janome Sewing Machine?

To reset your Janome sewing machine, press the reset key on the function panel or power off, unplug for a few minutes, then restart.

Why Is The Sewing Machine Not Moving?

The sewing machine may not move due to lack of lubrication, lint buildup, worn drive belt, or a faulty drive motor. Check for these issues and ensure the needle is inserted correctly with the thread in the take-up lever. Verify the tension setting and try resetting the machine.

Conclusion

Troubleshooting Janome sewing machine issues can be resolved by following simple steps. Regular maintenance and proper threading are key to preventing common problems. Remember to check needle placement, tension settings, and use quality materials for optimal performance. Happy sewing!